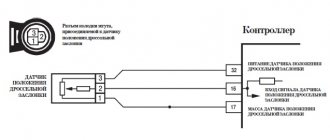

In a system with an EDP (electric throttle pipe), two TPS are used. Each such sensor is a potentiometric-type resistor, one of whose terminals is supplied with a reference voltage (3.3 V) from the controller, and the second is supplied with ground from the controller. From the pin connected to the moving contact of the potentiometer, the TPS output signal is supplied to the controller.

The sensor is located in the throttle body near the air intake pipe. An idle speed regulator is installed next to it.

Throttle valve in pre-start position

The controller's task is to control the position of the throttle valve through an electric drive, which is set by pressing the accelerator pedal. TPS is needed just so that the controller can monitor the current position of the throttle valve.

When the ignition is turned on in the car, the damper is set by the controller to the pre-start position. At this moment, the degree of opening determines what temperature the liquid in the cooling system has. When the throttle valve is in the pre-start position, the output signal on the sensors from the first terminal should be about 0.39-0.52V , and from the second - 2.78-2.91V .

Throttle valve at rest

If within 15 seconds from the moment the ignition is turned on, the engine is not started and the accelerator pedal remains at rest, the controller will stop the supply of power to the electric throttle drive, as a result of which the damper will move to an almost closed position (no more than 7% opening). In this state, the output signal power of the first sensor will be 0.5-0.6V , and the second - 2.7-2.8V .

If the engine and accelerator remain at rest for the next 15 seconds, the throttle will automatically enter test mode. This means that it will move to the zero position until it is completely closed and then moved to the pre-start position, after which the electric throttle drive will be completely de-energized until the next ignition is turned on.

If a problem is detected in the sensor circuit, the controller completely stops supplying voltage to the throttle actuator, while simultaneously storing the error code in memory and displaying it on the dashboard. In this case, the throttle valve is always set to 6-7% opening

.

Regardless of what position the throttle valve is in, the output signals from both sensors should add up to 3.3V . The maximum permissible deviation is 0.1V .

TPS malfunctions

Owners of Kalin and Prior may encounter a large number of TPS faults. In each individual case, the nature of the breakdown affects the operation of the motor differently, so the symptoms may vary. Let's look at the main signs of sensor malfunction:

- floating speed when starting the engine, and then recovery during warm-up;

- jerks during acceleration;

- power reduction;

- uncontrolled increase in speed;

- increased fuel consumption;

- The motor is unstable and stalls.

If you have problems with the engine idling, you should not rush to change the idle speed control; the problem often lies in the throttle position sensor. It needs to be checked first.

Most often there are 3 main causes of malfunction:

- the coating layer on the mechanism wears out;

- the movable core stops working;

- The regulator substrate is partially or completely worn out.

Lada Kalina 2. Throttle position sensor malfunctions

What does the throttle position sensor do?

A part such as a throttle position sensor (TPS) is designed to transmit information to the electronic engine control unit about the exact state of the bypass valve at a given moment in time. Essentially, it is a combination of a fixed and variable resistor, and its maximum total resistance is approximately 8 ohms. The TPS has three contacts in its design, two of them are supplied with voltage (usually its value is about 5 V), and the third is a signal and is connected to the corresponding controller

Symptoms of a malfunctioning throttle position sensor

The throttle position sensor in the fuel system plays a “smoothing” role, and therefore, if it is working properly, then the car drives without jerking, smoothly, and demonstrates “responsiveness” when you press the gas pedal. If the TPS is faulty, then this can be determined by the following signs:

-The engine starts to start poorly; -Fuel consumption increases significantly; -The car drives jerkily; -The number of engine revolutions at idle increases significantly; -When the car accelerates, it happens with some delay; - “Popping” sounds are heard from the intake manifold; -The engine stalls at idle; -The Check Engine light either stays on constantly or lights up intermittently. If at least one of the above symptoms appears, then it is likely that the TPS is faulty. As practice shows, in most cases, the breakdown of this part is associated with its natural wear and tear. The fact is that the variable resistor present in the design of the throttle position sensor has a sprayed base layer, which the metal contact moving over it wears out over time. Accordingly, the TPS begins to produce incorrect data.

Signs of a bad throttle valve

The throttle assembly regulates the air supply to the intake manifold, which subsequently creates an air-fuel mixture with parameters that are optimal for the engines. Accordingly, if the throttle valve is faulty, the technology for creating this mixture changes, which negatively affects the behavior of the car. Specifically, signs of a bad throttle position include:

- problematic engine starting, especially “cold”, that is, on an unheated engine, as well as its unstable operation; - the engine speed value constantly fluctuates, and in a variety of modes - at idle, under load, in the average range of values; -loss of dynamic characteristics of the car, poor acceleration, loss of power when driving uphill and/or with a load; - “dips” when pressing the accelerator pedal, periodic losses of power; -increased fuel consumption; - a “garland” on the dashboard, that is, the Check Engine indicator light comes on and then goes out, and this repeats periodically; - the engine suddenly stalls, after restarting it works normally, but the situation soon repeats; - frequent occurrence of engine detonation; -a specific gasoline smell appears in the exhaust system, associated with incomplete combustion of fuel; - in some cases, self-ignition of the air-fuel mixture occurs; - in the intake manifold and/or in the muffler, soft popping noises are sometimes heard.

Causes of throttle valve malfunction

There are a number of typical reasons that lead to malfunctions of the throttle assembly and the problems described above. Let us list in order what malfunctions of the throttle valve can occur.

Idle speed control

The idle air control valve (or IAC for short) is designed to supply air to the intake manifold of the engine when it is idling, that is, when the throttle valve is closed. If the regulator fails partially or completely, the engine will experience unstable operation at idle until it stops completely. Since it and the throttle assembly work in tandem.

Throttle sensor malfunctions

Another common cause of throttle failure is problems with the throttle position sensor (TPS). The function of the sensor is to fix the position of the throttle valve in its seat and transmit the corresponding information to the ECU. The control unit, in turn, selects a certain operating mode, the amount of supplied air, fuel and adjusts the ignition timing. If the throttle position sensor malfunctions, this unit transmits incorrect information to the computer or does not transmit it at all. Accordingly, the electronic unit, based on incorrect information, selects incorrect engine operating modes or switches it to operation in emergency mode. Typically, when a sensor fails, the Check Engine light on the dashboard lights up.

Throttle Actuator

There are two types of throttle valve actuator - mechanical (using a cable) and electronic (based on information from a sensor). A mechanical drive was installed on cars of older models, and is now becoming less common. Its operation is based on the use of a steel cable connecting the accelerator pedal and the lever on the throttle rotation axis. The cable can stretch or break, although this is quite rare.

Electronic throttle control is widely used in modern cars. Commands for the throttle position are received by the electronic control unit based on information received from the damper actuator sensor and the throttle sensor. If one or another sensor fails, the control unit is forced into emergency mode. In this case, the damper drive is turned off, an error is generated in the ECU memory, and the Check Engine warning lamp lights up on the dashboard. The problems described above arise in the behavior of the machine:

- the car reacts poorly to pressing the accelerator pedal (or does not react at all); - engine speed does not rise above 1500 rpm; - the dynamic characteristics of the machine are reduced; -unstable idle speed, up to the complete stop of the engine. In rare cases, the damper drive motor fails. In this case, the damper is located in one position, which fixes the control unit, putting the machine in emergency mode.

System depressurization

Often the cause of unstable operation of a car engine is depressurization in the intake tract. In particular, air can be sucked in in the following places: - the place where the damper is pressed against the body, as well as its axis; - cold start jet; - connecting corrugated tube behind the throttle position sensor; -joint (inlet) of the crankcase gas cleaner pipe and corrugation; - injector seals; - conclusions for gasoline fumes; - vacuum brake booster pipe; -throttle body seals.

Air leaks lead to incorrect formation of the air-fuel mixture and errors in the operation of the intake tract. In addition, the air leaking in this way is not cleaned in the air filter, so it may contain a lot of dust or other harmful small elements.

Damper contaminated

The throttle body in a car engine has a direct connection with the crankcase ventilation system. For this reason, tar and oil deposits and other debris accumulate on its body and axle over time. Typical signs of throttle valve contamination occur. This is reflected in the fact that the valve does not move smoothly; it often sticks and jams. As a result, the engine is unstable and corresponding errors are generated in the electronic control unit.

To get rid of such troubles, you need to regularly check the condition of the throttle valve, and if necessary, clean it with special means, for example, carburetor cleaners or their equivalents.

The damper adaptation has failed

In rare cases, throttle adaptation may be reset. This may also lead to the above problems. The reasons for the failed adaptation may be: - disconnection and further connection of the battery in the car; - dismantling (disconnection) and subsequent installation (connection) of the electronic control unit; - the throttle valve has been removed, for example, for cleaning; -the accelerator pedal has been removed and reinstalled. Also, the cause of a failed adaptation may be moisture getting into the chip, a break or damage to the signal and/or power wire. You need to understand that there is an electronic potentiometer inside the throttle valve. Inside it there are tracks coated with graphite. Over time, during the operation of the unit, they wear out and can wear out to such an extent that they will not transmit correct information about the position of the damper.

contents .. 231 232 233 234 ..

How to check throttle sensors

The first signal indicating the need to determine a malfunction of the TPS on Kalina or Priora (as well as other injection cars) is the lighting of the “Check Engine” icon. Using a diagnostic scanner, you can find out the error code, and then use a multimeter to take the necessary measurements of voltage and changes in resistance when moving the damper.

Scanner check

Throttle position data

We connect the autoscanner and look at two values in the OpenDiag application:

- “Throttle position sensor 1”;

- “Throttle position sensor 2”.

The indicators should be 4.3 and 0.7V , respectively.

To check, you need to press the E-gas pedal to the floor. The indicators will change by 0.8 and 4.2V , respectively. Ideally, the sum of these indicators should be 5V. If a malfunction is detected, the program displays error code P2138 or P2135. This means that a breakdown has occurred in one of three components: the TPS, the electronic gas pedal position sensor, or in contacts “A” and “B” of these sensors.

Checking with a multimeter

Sensor testing

First, the current is checked at the two contacts of the sensor. This is done in order to find out the condition of the wires, since they could simply break.

When you turn on the ignition, the multimeter should display a voltage within 5V , with a probability of deviation by 0.5V . You can check the sensor without dismantling it.

We disconnect the terminal from the battery, remove the wires with the chip, place the wire on the pin that transmits the signal to the on-board computer and mount the chip in place.

We attach the multimeter probe to the additional wire on the other side, and connect the second probe to the negative terminal of the battery. After this, the terminals need to be put on the battery, but the engine must not be started.

Sensor readings with the damper closed

We set the device to a mode that measures direct current and smoothly press the gas pedal. When you gradually press the floor, the voltage indicator should change gradually. When the damper is completely closed, the voltage will be from 0 to 0.5V . When it is fully opened, the indicator will reach 5V . If you notice sudden voltage surges, the sensor is faulty.

In addition to measuring voltage, there is a way to test the sensor by measuring resistance. To do this, you need to set the appropriate mode on the multimeter and remove the TPS.

After unscrewing the two screws with a Phillips screwdriver, disconnect the wire and remove the sensor. To connect to the negative contact and the output of the signal wire, we use additional wires.

We smoothly turn the mount on the sensor, thereby simulating the movement of the throttle valve.

When the damper is in the closed position, the resistance will be 1.5 kOhm. When fully open, the resistance changes to 7.5 kOhm.

The resistance value should also change smoothly, like the voltage.

TPS repair

Rheostat and sensor contact groups

If the throttle sensor fails, you can try to repair it, but they are often simply replaced. Repair and restoration of operability are allowed only if the contact groups or rheostat tracks have oxidized.

To do this, it is necessary to dismantle the TPS cover. A rheostat is located under it in an inverted state. It needs to be carefully bent, after which the tracks and 2 contact groups (sliders) that come into contact with the tracks will be visible. Bend the sliders away from the body so that they fit more tightly to the rheostat. You can learn more about TPS repair by watching the video:

Throttle Position Sensor Repair

To clean the contacts and current collector tracks, wipe with alcohol.

After this, the sensor must be checked for resistance by connecting probes to the central and left contacts of the device. If, during operation of the rheostat on the multimeter, the resistance readings do not smoothly increase and decrease, but jump chaotically, then the sensor needs to be replaced.

Operating principle of the sensor

The Kalina throttle sensor is used to transmit a signal to the engine ECU. This part is a potentiometer, the maximum output voltage of which does not exceed 5 Volts. The element consists of a housing, inside of which there is a variable resistor. The positive power wire is connected to one of the contacts of the product, and ground to the second. An output conductor is connected to the third terminal, the voltage of which depends on the angle of the throttle valve. The potential difference is changed by moving the moving part of the third contact along resistive tracks.

How to Replace a Throttle Position Sensor

Since the TPS on Priora and Kalina does not have a long service life, most owners of these cars have to change it. Therefore, we will consider all 3 stages of replacement: dismantling, installing a new one and resetting the error in the ECU memory.

Replacing TPS

Step by step replacement:

- check if the ignition is turned off;

- remove the connector (chip) with wires;

- Use a Phillips screwdriver to unscrew the bolts;

- We take a new TPS and before installation we correctly position the foam rubber gasket;

- install a new damper sensor, turning it until the holes match;

- tighten the screws back;

- install the chip in its place.

The process of replacing a sensor on a Priora

Bolt for adjusting the damper position

To reset the error stored on the ECU, remove the terminal from the battery for 10 minutes or reset it programmatically. After replacement, the new throttle position sensor is not adjustable. You can only set the damper closing level. We unscrew or tighten a special bolt that limits the degree of closure.

Frequent injection system malfunctions

Symptoms such as jerking, dips, and jerking during acceleration often appear. In this case, the treasured indicator indicating an engine error does not light up. The first thought is that the spark plugs are faulty. And then the driver remembers that his Kalina has been driving for a year or more, and these important elements of the ignition system have not even been unscrewed. If after replacement no positive effect is observed, you should immediately pay attention to what kind of gasoline you are pouring into the tank. This is the most common cause of car breakdowns.

Ignition coils are Kalina’s sore spot

Pay attention to the ignition module. It is quite possible that the malfunction lies there. But the module can only be checked using modern motor testers. Therefore, you need to contact an experienced auto electrician who will quickly identify the fault and replace or repair the module. If it is possible to install and test a working element, take advantage of it. The engine started working perfectly - run to the store for a new module. Repairing this unit is possible, but finding a professional technician is quite difficult.

No less often, on VAZ-2110, Priora and Kalina cars, the problem of floating speed occurs. The tachometer doesn't know where to go. The needle gradually moves from the minimum 850 rpm. up to maximum 1200 rpm. The malfunction is obvious, but the treasured lamp, which should indicate an error, does not light up! In this case, the throttle position sensor is clearly broken, which is especially common in old models of VAZ cars of the 2110 family, as well as in modifications of the Lada Kalina. In recent years, fairly high-quality TPS systems have begun to be installed, so problems with them rarely arise.

A malfunction of the idle speed control can be determined by the following symptom: it is impossible to start the engine without pressing the gas. The sensor is located next to the TPS, directly on the pipe. But you shouldn’t change it right away; try rinsing and cleaning it first. Very often the regulator simply becomes dirty, so it feels like it has failed. The price of such items has now dropped, and the choice of them in stores is very large.