Hi all! I hope the information from this post will be useful and will be useful to someone! Good luck on the roads and a full tank!

The “symptoms” of a faulty throttle position sensor include the following:

1. Increased idle speed. 2. The engine stalls in neutral gear. 3. Idle speed floats. 4. Jerks during acceleration. 5. Deterioration in dynamics. 6. In some cases, the Check Engine light may come on.

Diagnosis of the throttle position sensor is carried out as follows:

1. Turn on the ignition, then check the voltage between the slider contact and the minus with a voltmeter. The voltmeter should show no more than 0.7 V. 2. Next, turn the plastic sector, thereby fully opening the damper, then measure the voltage again. The device should show at least 4 V. 3. Now turn off the ignition completely and pull out the connector. Check the resistance between the slider contact and any terminal. 4. Slowly, turning the sector, monitor the voltmeter readings. Make sure that the needle moves smoothly and slowly; if you notice jumps, the throttle position sensor is faulty and must be replaced.

Replacing the throttle position sensor:

1. Disconnect the wire from the “–” terminal of the battery. 2. Disconnect the block with wires from the throttle position sensor by pressing the plastic latch. 3. Unscrew the two mounting screws and remove the throttle position sensor from the throttle pipe. 4. Install the new sensor in the reverse order, but do not forget about the foam ring. The throttle position sensor does not require any adjustment, since the controller perceives idle speed (i.e. the throttle valve is completely closed) as the zero mark.

The “symptoms” of a faulty idle speed sensor include the following:

1. Spontaneous unregulated change in engine speed (sudden decrease or increase). 2. When turning on a “cold” engine, there is no increase in speed. 3. When using additional vehicle devices (heater, headlights), the idle speed is simultaneously reduced. 4. The engine stalls at idle and when shifting gears. It is necessary to remember that the readings of the VAZ 2110 injector idle speed sensor are not “readable” by the automatic on-board power system, and it is not integrated into the “Check Engine” alarm system.

Diagnostics of the idle speed controller is carried out as follows:

There are several ways to analyze the idle speed sensor, but the main ones - the simplest and most effective - are the methods described below:

1. First you need to “get” to the device, disconnect it from the connecting block of wires 2. Using the most common voltmeter, check for the presence of voltage - the “minus” goes to the engine, and the “plus” to the terminals of the same block of wires A and D. 3. Turns on ignition, and the received data is analyzed - the voltage should be within twelve volts, if less, then most likely there are problems with the battery charge; if there is no voltage, then you will have to check both the electronic control unit and the entire circuit. 4. Then we continue the inspection with the ignition on, and analyze terminals A:B, C:D one by one - the optimal resistance will be about fifty-three ohms; During normal operation of the IAC, the resistance will be infinitely high.

Also, with the sensor removed and the ignition on, if you connect a power supply to it, the conical needle of the sensor should move out; if this does not happen, it means it is faulty.

1. Remove the negative terminal of the battery. 2. Disconnect the IAC from the block harness. 3. Using a multimeter, we measure the resistance of the external and internal windings of the IAC, while the resistance parameters of contacts A and B, and C and D should be 40-80 Ohms. 4. If the instrument scale is zero, it is necessary to replace the IAC with a serviceable one, and if the required parameters are obtained, we check the resistance values in pairs B and C, A and D. 5. The instrument must detect an “open circuit.” 6. With such indicators, the IAC is in good working order, and if they are absent, the regulator must be replaced.

If the problem lies precisely in the operation of the regulator, then you should not rush and immediately go to a car service center, since you can clean the idle speed sensor yourself, as well as replace it.

Cleaning and replacing the idle air control.

The first thing you need to do is purchase a carburetor cleaner, and then get down to business: 1. The wire block is disconnected from the sensor. 2. Afterwards, both of its fastenings are unscrewed, and the sensor is removed. 3. If necessary, the IAC is completely cleaned of possible debris and contaminants on the cone needle and spring. 4. Also, do not forget to clean the mounting hole on the throttle assembly, where the conical needle of the sensor enters. 5. After cleaning, install everything in its original location.

If nothing has changed in the operation of the car - the same problems and inconveniences are present - then the regulator should be replaced.

It is worth noting that when purchasing you need to pay attention to the end mark 04. Sensors are produced with mark 01 02 03 04, so look at the mark of the old sensor and purchase the same one. If you put, for example, a sensor labeled 04 instead of 01, the sensor will not work. The following replacement is allowed: 01 to 03, 02 to 04 and vice versa.

Replacing the idle speed sensor can also be done without any problems:

1. The on-board system of the car is de-energized. 2. The block with wires is disconnected from the XX regulator. 3. The screws are unscrewed and finally the sensor is removed. 4. Attach the new device in the reverse order.

If you are faced with a situation where the engine idles unevenly or the car periodically stalls for unclear reasons , then the fault of the power unit may be a malfunction of the throttle position sensor . You should not immediately go to a service station, because this problem can be eliminated on your own.

TPS design

The throttle position sensor is a device that is designed to accurately distribute the amount of fuel mixture entering the engine combustion chamber. Its use in modern engines allows increasing the efficiency of the car, as well as increasing the efficiency of the power unit. It is located in the fuel supply system on the throttle valve axis.

This is what the TPS design looks like

At the present stage of development of automotive technology, the following types of TPS are presented on the market:

Non-contact throttle position sensor with pin designation

The latter structurally have resistive contacts in the form of tracks along which the voltage is determined, while non-contact ones carry out this measurement based on the magnetic effect. Sensor differences are characterized by their price and service life. Contactless ones are more expensive, but their service life is noticeably longer.

Operating principle

As mentioned above, the sensor is located near the throttle valve . When you press the pedal, it measures the output voltage. In the case when the throttle valve is in the “closed” position, the voltage in the sensor is up to 0.7 Volts . When the driver presses the gas, the throttle axis rotates and accordingly changes the inclination of the slider at a specific angle. The sensor response is manifested in a change in resistance on the contact tracks and, consequently, an increase in the output voltage. When the throttle is fully open, the voltage is up to 4 Volts . The data is for VAZ cars .

These values are read by the vehicle's electronic control unit. Based on the data obtained, he applies changes to the amount of fuel mixture supplied. It is worth noting that this entire procedure occurs almost instantly, which allows you to effectively select the engine operating mode, as well as fuel consumption.

Purpose of the sensor

The sensor is designed to determine the angle at which the throttle valve has opened. The sensor transmits the received data to the engine control unit, which processes this signal.

Resistor TPS

Resistor TPS

The principle of operation of the sensor is based on a conventional electrical resistor, which, when rotated around its axis, changes the resistance. The data sent to the ECU is based on resistance. This operating principle reduces the cost of producing the sensor, but affects its durability. With this design, the working part of the sensor, namely its tracks, frays quite quickly, which leads to loss of conductivity and, consequently, to sensor malfunction.

The advantage of this sensor is its low price, but due to its rapid breakdown it is not justified.

Non-contact TPS

Non-contact TPS

There is another type of sensor - non-contact. As a rule, such a sensor costs much more, but its durability is several times higher than that of a standard sensor.

It is recommended to purchase a non-contact sensor, as it has more advantages and is more durable in comparison with a resistor TPS.

Signs of sensor malfunction

When the TPS is in good working order, your vehicle operates without uncharacteristic jerking or jerking and quickly responds to pressing the gas pedal. If any of these conditions are not met, then there may be a sensor malfunction. This can be determined by the following signs:

- Starting the engine is difficult both hot and cold;

- Fuel consumption increases significantly;

- When driving, the engine jerks;

- At idle, the speed is often higher than normal;

- The car's acceleration is sluggish;

- Sometimes there are extraneous sounds similar to popping noises in the area of the intake manifold;

- The power unit may stall at idle;

- The Check indicator on the instrument panel blinks or stays on.

Most often, the sensor becomes unusable due to exceeding its service life due to wear-out. The contact group has a coating and, accordingly, it is characterized by wear. Those TPS that operate on a non-contact principle do not have this drawback and, accordingly, last much longer.

In order to finally make sure that it is necessary to replace this part, you need to be able to check the sensor .

Video on the topic:

Description and features of replacing sensors

Where are all the sensors on the VAZ 2112 16 valves located and what are they responsible for? The location of the sensors, as well as their purpose, are described below. The entire list of controllers includes many devices, but we will not describe all VAZ sensors, but will pay attention only to the most basic ones.

Throttle Positions

The VAZ throttle position sensor reads readings in accordance with the position of the gas pedal. The TPS is located on the throttle body and is connected to the throttle axis mechanically. This device itself is a resistor device of a potentiometric type - one terminal of the TPS is intended for connection to the on-board network, and the second is connected to ground. The third pin is connected to the controller, which, in turn, determines the position of the damper based on readings from other regulators.

Failure of the regulators can occur either as a result of wear or after washing the engine if it is damaged. To replace them, you only need to disconnect the device from the power supply and unscrew the bolts that secure the VAZ throttle sensor. When installing, you must connect the contacts correctly.

Speeds

The VAZ speed sensor is designed to inform the motorist about how fast the car is moving. The quality of these devices in general is average; their breakdown leads to a deterioration in the dynamics of the vehicle. These devices are mounted in the slot of the gearbox; their operating principle is based on the Hall effect.

Designation of contacts for connecting DS

The regulator receives a 12-volt signal from the controller. The device transmits a signal of a certain frequency to it, which depends on the speed of the car. In addition, the device is also involved in controlling the injection system. To replace the DC, you first need to disconnect it from the power supply and then unscrew it from the installation location using a wrench. As you can see, there is nothing complicated about this.

To understand that the speed controller needs to be replaced, you just need to monitor the operation of the engine - usually the symptoms speak for themselves:

- The speed of the power unit began to fluctuate, especially when driving in neutral gear or while the car was parked. In some cases, the engine may randomly shut down if the driver does not press the gas pedal.

- The main symptom is that the speedometer does not show the speed of the car. The arrow may not rise at all, or it rises and falls; in general, it generally does not work correctly.

- Another sign by which a breakdown can be determined is an increase in gasoline consumption. Of course, such a symptom can indicate various malfunctions in the engine, but if the speed fluctuates and the speed is displayed incorrectly, then you should think about replacing the engine.

- Engine power has generally decreased.

Crankshaft

The VAZ crankshaft position controller consists of a winding as well as a magnetized core. DPKV is an induction type device, its purpose is to monitor the passage of 60 crankshaft teeth past the core, all of these teeth are spaced 6 degrees apart. It should be noted that their number on the shaft is not complete - two teeth are missing, resulting in a slight gap. It is at the moment when the crankshaft position sensor detects the absence of teeth, it generates a special signal that is transmitted to the control unit (the author of the video about starting the engine with a faulty DPKV is the Avtoelektika HF channel).

Checking TPS

Checking the throttle position sensor for VAZ 2110, 2114, Priora, Kalina, Renault Logan , etc. cars is carried out as follows:

- Turn off the car ignition;

- Use a voltmeter to check the sensor voltage, which is about 0.7 Volts when the damper is closed;

- Measure the output voltage with the damper fully open. It should be about 4 Volts;

- Check the uniformity of the voltage change by turning the sensor slider. In this case, there should be no jumps in values.

If there are deviations in the received data, the part must be replaced with a new one. In cases where the values coincide, the sensor is working and the breakdown should be looked for in other sensors.

Replacement

In fact, changing this sensor is insanely easy.

So don't rush to send your car to a service station. Everything can be done with your own hands, the quality will not suffer from this. To remove the throttle position sensor, you first need to find it. As we have already noted, the desired unit is located on the side of the throttle pipe on the throttle valve axis. Having found the element, pick up a shaped screwdriver. Using this simple tool, unscrew a couple of bolts that hold the device. Pay special attention to the gasket that is available under the old regulator. We do not recommend using it again; it is better to immediately buy a new one

Often the gasket is already included with the throttle sensor itself. After removing the old sensor, you can slightly clean the place where it is installed if there is dirt there. Next, a new sensor is installed along with a new foam gasket and the bolts are tightened. Try to tighten the fasteners as far as possible, otherwise the new throttle sensor will quickly lose its effectiveness. The work will have to be done again. There is no need to make any adjustments after replacement. The zero mark on the controller will determine that the throttle is completely closed.

Foam pad

What to choose?

When replacing, many more or less experienced car owners have a question about which regulator is better to install. After all, there are two types.

| Sensor type | Peculiarities |

| Film-resistive | These sensors are usually factory installed. The service life of such a throttle position sensor is stated to be about 55 thousand kilometers, but in practice it has to be changed more often |

| Contactless | The operation of such a device is based on the magnetic-resistive phenomenon; a Hall element is used. The cost is noticeably higher than the first option, but it is unlikely to have to be changed. Huge resource, high reliability |

In pursuit of savings, many forget about the importance of quality. But it should be in the first place when choosing spare parts when repairing a car

TPS is an important, but easy to replace device. The repair operation will take you no more than an hour, even if you are just beginning to learn the joys of repairing your car yourself.

But under no circumstances delay repairing the sensor, otherwise this may negatively affect the operation of the engine, its service life and the cost of fuel, which you will overuse due to incorrect data from the sensor to the ECU.

Loading …

What is TPS in a VAZ-2110 car?

The throttle position sensor is abbreviated as TPS among motorists. This part is used in several types of engines:

- Gasoline injection type.

- Single injection type.

- Diesel engines.

TPS is also known as a throttle valve potentiometer. This is due to the fact that the sensor is designed to function as a variable resistor. The sensor itself is installed in the engine compartment - the place of fixation is the throttle pipe. The mechanism of operation of the sensor is as follows: depending on the position and degree of opening of the throttle valve, the resistance also changes. That is, the level of the value of such resistance depends on the pressing of the gas pedal. If the pedal is not pressed, the throttle valve will be closed and the resistance will be minimal. The opposite is true when the damper is open. Accordingly, the voltage across the TPS, which is directly proportional to the resistance, will also change.

The control of such changes is carried out by the electronic control system; it is the one that receives all signals from the TPS and supplies fuel using the fuel system.

So, at the maximum voltage of the signal contact of the throttle position sensor, the fuel system of the VAZ-2110 car will supply the largest portion of fuel.

Thus, the more accurate the TPS indicators, the better the VAZ-2110 electronic system adjusts the engine to the correct operating mode.

The main symptoms of a malfunction of the VAZ-2110 TPS: how to check them

Owners of VAZ-2110 cars often have to repair their vehicle. And the consequence of repair work can be both significant breakdowns and minor malfunctions. What type of failure is a malfunction of the throttle position sensor? What is this part responsible for in a car? How can we determine that this particular part is no longer functioning correctly? Read about it in our article.

What is TPS in a VAZ-2110 car?

The throttle position sensor is abbreviated as TPS among motorists. This part is used in several types of engines:

- Gasoline injection type.

- Single injection type.

- Diesel engines.

TPS is also known as a throttle valve potentiometer. This is due to the fact that the sensor is designed to function as a variable resistor. The sensor itself is installed in the engine compartment - the place of fixation is the throttle pipe. The mechanism of operation of the sensor is as follows: depending on the position and degree of opening of the throttle valve, the resistance also changes. That is, the level of the value of such resistance depends on the pressing of the gas pedal. If the pedal is not pressed, the throttle valve will be closed and the resistance will be minimal. The opposite is true when the damper is open. Accordingly, the voltage across the TPS, which is directly proportional to the resistance, will also change.

The control of such changes is carried out by the electronic control system; it is the one that receives all signals from the TPS and supplies fuel using the fuel system.

So, at the maximum voltage of the signal contact of the throttle position sensor, the fuel system of the VAZ-2110 car will supply the largest portion of fuel.

Thus, the more accurate the TPS indicators, the better the VAZ-2110 electronic system adjusts the engine to the correct operating mode.

Communication of the throttle valve with other automotive systems of the VAZ-2110

The throttle valve of a VAZ-2110 car is a component of the engine intake system and is directly connected to a large number of other vehicle systems. These include the following systems:

- directional stability;

- anti-blocking;

- anti-slip;

- anti-slip;

- cruise control.

In addition, there are those systems that are controlled by the electronics of the gearbox. After all, it is this throttle valve that regulates the flow of air into the car system and is responsible for the quality composition of the fuel-air mixture.

TPS design

The throttle position sensor can be of two types:

- film;

- magnetic or contactless.

In its design, it resembles an air valve - in the open position the pressure corresponds to atmospheric pressure, in the closed position it drops to a vacuum state. The TPS includes DC and AC resistors (each resistance is 8 ohms). The process of opening and closing the damper is monitored by the controller, with subsequent adjustment of the fuel supply.

If at least one symptom of a malfunction occurs in the functioning system of this sensor, then fuel may be supplied to the engine either in excess or in deficiency. Such malfunctions in engine operation are reflected in the engine of the VAZ-2110 car and on its gearbox.

Characteristic symptoms of a malfunctioning TPS condition

Thanks to the correct functioning of the throttle position sensor, the fuel system of the VAZ-2110 car engine works with a smoothing effect. That is, the vehicle moves smoothly, and the gas pedal responds well to pressure. Therefore, a malfunction of the TPS can be noticed almost immediately by the following signs:

- Poor engine starting.

- Noticeable increase in fuel consumption.

- The car's movements are intermittent.

- The idle speed of the engine is noticeable when running.

- The Check e light comes on on the dashboard

- The car accelerates poorly due to delays in acceleration.

- Popping sounds are heard in the intake manifold.

Of course, these signs of a faulty sensor may not all be observed at once. But even if you notice only one of the above symptoms, it is worth carrying out computer diagnostics of the vehicle at a service center.

TPS problems and their diagnosis

As you know, eternal parts for cars have not yet been invented. And the breakdown of the TPS can be foreseen; for this you need to inquire about the possible reasons for the failure of this part. Here are the main ones:

- Abrasion of the sprayed base layer, which serves to move the slider (the result is incorrect TPS readings).

- Failure of the movable type core (the result is deterioration of the contacts between the slider and the resistive layer).

How can you figure out problems with this sensor yourself? To do this, you can independently diagnose the operation of your diagnostics:

- Listen to the VAZ-2110 engine idling:

- the breakdown is obvious if you notice that its speed is in a “floating” state;

- Quickly release the gas pedal:

- a malfunction is present if the engine stops after this action.

- Pick up speed:

- There is a problem with the TPS if the car starts to move jerkily, which indicates an incorrect supply of fuel to the system.

Experts say that most often the sensor fails when the resistive track is heavily contaminated or is completely broken. To verify the opposite, you need to check the working condition of the TPS.

Checking the operation of the throttle position sensor

To check the TPS yourself, it is not necessary to call an auto electrician for consultation. To do this you need a multimeter or voltmeter. Next, experts offer step-by-step instructions for checking the sensor.

The first step is to turn the key in the ignition switch, take the voltage readings between the sensor slider contact and the minus. In normal condition, the indicator will be up to 0.7 V.

The second step is to turn the plastic sector and open the damper, and then take measurements again. In the normal state of the sensor, the device will show a result of 4 V.

The third step is to turn on the ignition completely (as a result of this the connector will stretch out), measure the resistance between the slider and any terminal. When rotating the sector, you must monitor the measuring device:

- when the multimeter or voltmeter needle moves smoothly, the sensor is working;

- when the needle on the meter shows sudden changes, the DPPZ is faulty.

Once the sensor is faulty, it can be adjusted or replaced. The VAZ-2110 car repair service center will tell you how to do the right thing.

Communication of the throttle valve with other automotive systems of the VAZ-2110

The throttle valve of a VAZ-2110 car is a component of the engine intake system and is directly connected to a large number of other vehicle systems. These include the following systems:

- directional stability;

- anti-blocking;

- anti-slip;

- anti-slip;

- cruise control.

In addition, there are those systems that are controlled by the electronics of the gearbox. After all, it is this throttle valve that regulates the flow of air into the car system and is responsible for the quality composition of the fuel-air mixture.

Characteristic symptoms of a malfunctioning TPS condition

Thanks to the correct functioning of the throttle position sensor, the fuel system of the VAZ-2110 car engine works with a smoothing effect. That is, the vehicle moves smoothly, and the gas pedal responds well to pressure. Therefore, a malfunction of the TPS can be noticed almost immediately by the following signs:

- Poor engine starting.

- Noticeable increase in fuel consumption.

- The car's movements are intermittent.

- The idle speed of the engine is noticeable when running.

- The Check e light comes on on the dashboard

- The car accelerates poorly due to delays in acceleration.

- Popping sounds are heard in the intake manifold.

Of course, these signs of a faulty sensor may not all be observed at once. But even if you notice only one of the above symptoms, it is worth carrying out computer diagnostics of the vehicle at a service center.

TPS on VAZ 2114: signs of malfunction, checking operation and procedure for replacing the sensor

The VAZ 2114 “nines” that appeared after modernization are equipped with an injection engine. To ensure stable operation of such a motor, a large number of automatic devices are installed; they independently control and regulate the uninterrupted operation of absolutely all systems of the power unit.

Disassembled throttle position sensor

The principle of regulating the supply of gasoline to the engine has been radically changed. Previously, it was mechanical, but now the fuel supply is controlled electronically. The mechanical connection of the gas pedal with the throttle valve is eliminated. To adjust the idle speed, the damper itself moves.

Fuel supply and consumption are controlled by a control unit, which receives signals from sensors from different engine systems. One of them is the throttle position sensor, or TPS, as mechanics call it for short.

TPS problems and their diagnosis

As you know, eternal parts for cars have not yet been invented. And the breakdown of the TPS can be foreseen; for this you need to inquire about the possible reasons for the failure of this part. Here are the main ones:

- Abrasion of the sprayed base layer, which serves to move the slider (the result is incorrect TPS readings).

- Failure of the movable type core (the result is deterioration of the contacts between the slider and the resistive layer).

How can you figure out problems with this sensor yourself? To do this, you can independently diagnose the operation of your diagnostics:

- Listen to the VAZ-2110 engine idling:

- the breakdown is obvious if you notice that its speed is in a “floating” state;

- Quickly release the gas pedal:

- a malfunction is present if the engine stops after this action.

- Pick up speed:

- There is a problem with the TPS if the car starts to move jerkily, which indicates an incorrect supply of fuel to the system.

Experts say that most often the sensor fails when the resistive track is heavily contaminated or is completely broken. To verify the opposite, you need to check the working condition of the TPS.

TPS: malfunctions

Like any other part, the throttle position sensor tends to fail. In this case, you need to know the main symptoms of its breakdown. So, what are the signs of a malfunction in the TPS?

First of all, you should pay attention to the engine's idle speed. If its speed “floats”, this may indicate that the sensor is not working properly. Also, a symptom of its malfunction may be the engine stopping when the gas pedal is suddenly released. The malfunction of the sensor is very noticeable when accelerating the car. In this case, there may be failures when accelerating (it seems as if no fuel is entering the engine at all). Sometimes when driving, the car may not respond to the gas pedal. In addition, the engine speed may freeze at 1.5-3 thousand and not drop even when the gear is off and idling. That is, signs of malfunction of this element are directly related to the operation of the engine, and any incorrect operation may indicate a malfunction of the sensor or damper. If you notice at least one similar symptom, then you need to check the performance of the TPS. VAZ-2114 “Samara” and its successors are diagnosed almost identically. Therefore, the instructions outlined below can be used on all domestic (and even foreign) cars.

Checking the operation of the throttle position sensor

To check the TPS yourself, it is not necessary to call an auto electrician for consultation. To do this you need a multimeter or voltmeter. Next, experts offer step-by-step instructions for checking the sensor.

The first step is to turn the key in the ignition switch, take the voltage readings between the sensor slider contact and the minus. In normal condition, the indicator will be up to 0.7 V.

The second step is to turn the plastic sector and open the damper, and then take measurements again. In the normal state of the sensor, the device will show a result of 4 V.

The third step is to turn on the ignition completely (as a result of this the connector will stretch out), measure the resistance between the slider and any terminal. When rotating the sector, you must monitor the measuring device:

- when the multimeter or voltmeter needle moves smoothly, the sensor is working;

- when the needle on the meter shows sudden changes, the DPPZ is faulty.

Once the sensor is faulty, it can be adjusted or replaced. The VAZ-2110 car repair service center will tell you how to do the right thing.

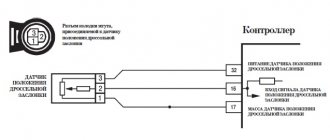

Features of checking contact and non-contact TPS on Priora: pinout

If the corresponding signs of a malfunction of the TPS on the Priora appear, it would not hurt to check the product to make sure that the sensor has actually failed and that the wire has not been damaged or the contacts in the power supply have oxidized. To do this, you will need to know the TPS pinout, which is presented in the diagram below.

The easiest way to check is to use a multimeter. The detailed process for checking the Priora TPS is described below:

- Checking the serviceability of the supply wires. Disconnect the power supply from the sensor. Connect the multimeter probes to pins A and B, then turn on the ignition and check the voltage. The supply voltage should be 4.8-5.2V. If the value differs from the specified value (usually it is lower), then you should look for the cause in a wire that has a short to ground.

- Next, we proceed to check the contact sensor. The best way to check it is to measure the resistance between contacts A and C, that is, the signal and positive contacts. It is recommended to perform the test on a removed sensor. We connect the probes to the corresponding terminals and measure the resistance in kOhms. It should be in the range from 1 to 3 kOhm. When changing the position of the slider, the resistance should increase, and very smoothly without sudden jumps. If a different picture is observed, then the TPS needs to be replaced.

- Another test method (suitable for both contact and non-contact devices), which does not require removing the sensor, is to measure the voltage at the signal contact. However, it is recommended to implement it in exceptional cases, since it involves violating the integrity of the contacts of the sensor chip. It is carried out as follows: using pins, you need to attach the probes of the multimeter to the back side of the chip. You need to connect to terminals B and C, that is, signal and ground. After connecting, you need to turn on the ignition and, without starting the engine, change the position of the damper. If the voltage smoothly increases to 5V when the damper is opened to maximum, it means the part is working properly. If sudden changes (jumps) occur in the contact-type TPS, the product must be replaced. If the non-contact TPS is faulty, then its voltage will not change or will change, but in a low range.

Below is a video that shows in detail the process of checking the mechanical TPS.

Having confirmed that the throttle position sensor on the Priora is faulty, it should be replaced. Do not attempt to disassemble or repair it, as it is not repairable.

This is interesting! You can check the health of the sensor using a Bluetooth scanner connected to the OBD2 connector, as well as a special application on your smartphone.

If the BC displays a low signal error from the sensor, you need to check the power wires, since most likely the insulation has been damaged. If the signal level is high, then the fault is probably in the sensor itself.

Replacing the throttle position sensor on a VAZ 2110, VAZ 2111, VAZ 2112

Welcome! Throttle position sensor - it transmits readings to the controller (ECU) about what position the throttle valve is currently in; when you press the gas, the valve opens to a larger angle (Accordingly, you need to increase the fuel supply) and therefore the controller reads this (The sensor transmits readings to it) and increases the fuel supply to the cylinders, thanks to which the engine runs normally and without interruptions, unlike if the sensor fails (There will be serious problems with the operation of the engine, one of them is that it will not run The second one won’t really work either, the car will twitch when accelerating).

Note! To replace the throttle position sensor (abbreviated TPS), stock up on: A screwdriver, as well as a special one. a device with which you can check resistance (Ohm) and Voltage (Volt), such a device can be a multi-meter or an Ohmmeter with a Voltmeter separately, in addition to this, you will also need wires with bare ends (Or so that there are alligators at the ends) and that’s all, essentially, the latest devices and the wires are only needed to check the TPS for serviceability, if you don’t need this, then you don’t even have to buy anything like that, but just a sensor and a screwdriver so you can remove it!

Where is the throttle position sensor located? It is very easy to find, just open the hood and look for the throttle assembly, when you find it, look for two sensors on the side of it, one will be installed a little lower, and the other a little higher, and this is the one above (Indicated by a red arrow in the photo below ) is located and will be the TPS, but that’s not all, there is a foam ring under the sensor (see small photo), it must be replaced with a new one and therefore when you come to the auto store, don’t forget to buy it if it’s included with the TPS didn't work for you.

When should I replace my throttle position sensor? First, let's talk about the symptoms, they are as follows: The car's fuel consumption increases, Idle Speed (Idle) starts to work, I don't understand how (As a rule, it rises or just floats and the car does not work stably on it), and jerks may also appear during acceleration , the car may periodically stall while driving and, of course, “CHECK ENGINE” may light up for you (But this may not happen at all).

We’ve sorted out the symptoms, but let’s say right away that they are inherent not only to this sensor, but can also be attributed to the DPKV (They are identical there), so if your car has them, it’s simply stupid to go and buy a new DPZ right away, because the engine didn’t work as it should. it can continue to work steadily in the same way, in this case the sensor is checked for serviceability (The easiest way, in order not to bother, is to check the sensor by replacing it with an identical one, and the identical one can be removed from the same injection system of a friend, for example, or from the seller will agree to install a sensor, see if the engine’s performance will change and if it changes, then buy it), if you don’t have such a chance (Find an identical sensor), then special. the device will be needed, we don’t see the point in explaining in words how to check the sensor using a multi-meter, because it’s long, it’s better to watch the detailed video that is posted below, it shows the whole test, if something is not clear, then ask your questions using the comment form below and we will answer you as soon as we can.

Changing the sensor

- The car's service manual contains instructions that will help you determine the location of the sensor; you can watch a video on this topic.

- Replacing the VAZ 2112 throttle position sensor is a fairly simple procedure that any beginner can understand. So: turn off the ignition and disconnect the wire from the negative terminal of the battery.

- Then, by squeezing the plastic latch, we disconnect the entire block with wires from the sensor. To remove the TPS from the pipe, you just need to unscrew two bolts with a Phillips screwdriver. They are shown by arrows in the photo.

Sensor without pipe

- A foam rubber ring is used as a seal between the throttle pipe and the sensor itself, which is included in the kit of the device and must be replaced. When reinstalling the new TPS, the fastening screws are tightened as much as possible until the ring is completely compressed.

Sealing foam ring

Having installed the sensor in its rightful place, connect the block of wires. The device does not require any adjustment, so the replacement of the VAZ 2110 throttle position sensor is complete. The whole job took you no more than ten minutes.

How to replace the throttle position sensor on a VAZ 2110-VAZ 2112?

Removal: 1. First, simply press out the latch that holds the wire block and then disconnect the block (see photo 1), insert the key into the ignition and turn it until all the devices light up, then turn on the device, namely the Voltmeter function and from device, place the minus probe (it usually comes in black) to ground (the ground can be the car body or engine), and connect the plus probe to terminal A of the wire block (All terminals on the block are marked, look carefully) and the device should give a reading of approximately 5 Volts, but in no case less, if this is the case, then everything is in order with the wiring and most likely the sensor itself is to blame, if the voltage is less, then either the controller is faulty or there is a problem with the wiring, after the operation, turn off the ignition don’t forget, and when the wiring is checked, you can start replacing the sensor with a new one, for which unscrew the two screws that secure it to the throttle body body and then remove the sensor, under it there will be a foam ring that must be replaced.

Note! If you are going to change the sensor, do not forget to remove the minus terminal from the battery, how to do this, read the article: “Replacing the battery on VAZ cars”, point 1!

Installation: The sensor is installed in the reverse order of removal; when installing, its leads should be directed towards the engine shield. To make sure that the sensor will be installed correctly, lean it against the throttle assembly and make sure that the holes for the screws in the sensor coincide with the threaded holes in body and then fully open the throttle valve using the sector (or the gas pedal, let an assistant gently and slowly press it all the way), if everything goes well, the throttle valve will open completely and you can then tighten the sensor mounting screws until they stop.

Additional video: Visually watch the process of replacing the TPS in the video below:

Main set of sensors for 16-valve VAZ-2112 engines

The ECU must control many parameters at once. The most important information will be the position of the crankshaft. You can turn off all sensors except the DPKV, and this will not lead to the engine stopping.

Sensors connected to the ECU

Let's list all the elements one by one:

- 15 – DTOZH. A resistor screwed into the thermostat housing. The temperature of the antifreeze is determined;

- 17 – DPRV, also known as DF (phase sensor). The operating principle is the Hall effect. The position of the camshaft is controlled. Check it out here.;

- 20 – TPS. Resistor fixed to the throttle assembly 19. The angle of deflection of the throttle valve is measured;

- 21 – Mass air flow sensor. Sensor connected to the filter housing. Controls air flow; the main signs of its malfunction are discussed here;

- 22 – IAC. Not a sensor, but a regulator (electromagnet). Used in idle mode. About its testing and diagnostics here. About replacing the IAC here.;

- 24 – lambda probe or oxygen sensor (see above);

- 25 – speed sensor. Fixed in the gearbox slot. Operating principle – Hall effect;

- 26 – DPKV. Electromagnetic sensor. The position of the crankshaft is controlled;

- 27 – DD (knock sensor). A piezoelectric element mounted on the outer wall of the cylinder block.

Let's take a look at how all the elements look in real life. Shown are pictures of VAZ-2112 sensors (16-valve internal combustion engine).

Each element will be easy to find under the hood

Everything said above is true for two engines at once - for units 21124 and 21120 (1.6 and 1.5 l).

You cannot unscrew the DTOZH sensor without draining the coolant. And to disconnect the sensor means to disconnect the connector, but not to dismantle the sensor itself.

Where is which sensor located - engine compartment diagram

Let's look at another picture.

Throttle position sensor VAZ 2112

The sensor itself is a potentiometer (+5V is supplied to one end, and the other goes to ground. The third pin (from the slider) goes the output signal to the controller). When there is an impact on the accelerator pedal, the throttle valve rotates and the voltage at the TPS output changes (it is 4V when the throttle is closed). Thus, the controller monitors the TPS output voltage and adjusts the fuel supply depending on the throttle opening angle.

How to check

To check the throttle position sensor, we will need the following tools: a multimeter (ohmmeter, voltmeter), pieces of wire.

Having opened the hood, we find the sensor we need (we look for it on the throttle assembly next to the IAC).

Disconnect the wire block from the sensor

Take a multimeter and set it to voltmeter mode. Volts negative terminal (on the engine). We connect the positive terminal of the voltmeter to the sensor wire block to terminal “A” (the pin numbering is indicated on this wire block)

Turn on the ignition and check the voltage: the voltmeter should show a voltage of around 5 volts. If the voltage is not supplied, or it is much lower than 5 volts, then the problem is either an open circuit or a malfunction in the electronic engine control system (in the brains). But if the voltage is normal, then, accordingly, the TPS is faulty.

Conclusion: If the sensor is faulty, then there are two options to solve the problem:

1) Repair the sensor (How to repair the TPS?). Most often it is easier to replace the sensor with a new one, because The cause of failure is most often normal wear of the part.

2) Replace the sensor with a new one

The speed sensor on the link does not work.

Location and principle of operation of the meter

The sensor is installed on the throttle valve block and is mechanically connected to its axis. Thanks to this, the device is able to solve 3 problems:

- inform the controller at what angle the throttle is currently open;

- signal that the air supply is completely closed (the driver has released the accelerator pedal);

- monitor the speed at which the damper opens.

Based on this information, the electronic powertrain control unit (ECU) makes a decision to increase or decrease the fuel supply and fuel injection for intense acceleration when the gas pedal is sharply pressed.

Reference. Two types of TPS are installed on cars: resistive and non-contact. The first ones are cheaper and therefore are found on all budget cars. The latter are more reliable and more expensive, and are installed on cars of medium and high price categories.

The operating algorithm of the resistive sensor is as follows:

- At idle, the damper is closed and air flows into the engine through a separate channel. The voltage at the output of the device does not exceed 0.5 volts; the controller supplies fuel to maintain engine idle speed.

- When the driver presses the gas pedal, the sensor slider moves along the resistive film. The resistance of the electrical circuit into which the device is connected in series decreases.

- The ECU “sees” the increase in voltage in the meter circuit, makes a calculation, prepares the air-fuel mixture in the required quantity and supplies it to the cylinders. The maximum voltage at wide open throttle is about 4.5 V.

- When the driver sharply presses the accelerator pedal, the controller notes a similar voltage surge and delivers a portion of the enriched mixture for dynamic acceleration.

Note. The operating voltage values are indicated for a common Russian car - VAZ 2110.

The non-contact throttle position sensor functions identically. The difference lies in the method of influencing the electrical circuit. A resistive device changes resistance using a slider moving across the film, while a non-contact device changes resistance due to the magnetic-resistive effect. Thanks to this principle of operation, the TPS lasts much longer and does not create problems for the owner of the car.

We recommend: How to install bi-xenon H4 with your own hands: diagrams and connection sequence