The Nine managed to make a lot of noise among the people, in the 90s “bandits” drove it, and in the 2000s it was used by young people, but even today there are more than enough of these cars. Initially, in 1993, the VAZ 2109 was equipped with a carburetor engine, but progress did not stand still and in the late 90s the nine received an injection engine, which had a positive effect on its technical characteristics.

As you know, for proper and reliable operation, an injection engine requires a large number of sensors and a “brain” that will manage it all. There are a lot of sensors on the VAZ 2109 and they are all interconnected in their own way.

This article will focus specifically on the sensors of the injector system on the VAZ 2109, namely, their purpose, location and signs of malfunction.

Electronic engine control unit

The engine control unit is responsible for the operation of almost the entire car. In this part, hundreds of processes are calculated, all readings from sensors installed on the car are processed. Many people call the ECU a “computer” and it’s impossible to disagree with this. The unit, receiving readings from the sensors, processes them and controls the engine, adjusting the supply of fuel and air to the combustion chamber.

Location

The engine control unit on the VAZ 2109 is located under the glove compartment at the feet of the front passenger. You can see it by looking under the panel; the block is closed with a special plastic cover.

Signs of malfunction:

Problems with the operation of the sensor are most often associated with damage to the microcircuit, for example, burnout of a track or damage to one of the radio components, due to which one of the cylinders may fail, etc. It is quite difficult to judge the failure of the ECU based on its symptoms, since they are all similar to the failure of one of the sensors, so the malfunction of the unit can only be determined by diagnosing, disassembling, or replacing it with a known good one.

Causes of TPS malfunction

There are two types of throttle position sensors - contact (film-resistive) and non-contact (magnetoresistive). Most often, it is the contact sensors that fail. Their work is based on the movement of a special slider along resistive tracks. Over time, they wear out, which is why the sensor begins to provide incorrect information to the ECU. So, the reasons for the failure of a film-resistive sensor may be:

- Loss of contact on the slider. This can be caused either simply by physical wear or by a broken tip. The resistive layer may simply wear out, causing the electrical contact to also disappear.

- The linear voltage at the sensor output does not increase. This situation may be caused by the fact that the base coating has worn off almost to the base in the place where the slider begins to move.

- Wear of the slider drive gears.

- Broken sensor wires. These can be both power and signal wires.

- A short circuit has occurred in the electrical and/or signal circuit of the throttle position sensor.

Speed sensor

With the transition of the nine to an injector, the measurement of vehicle speed began to be carried out not mechanically, using a special sensor that reads readings from the rotation of the gearbox gears, transmitting the readings to the computer. The block processes the readings from the sensor and sends signals to the speedometer.

Location

The VAZ 2109 speed sensor is located on the gearbox housing, you can see it by looking under the thermostat and you can find this sensor next to the gearbox dipstick.

Signs of malfunction:

- The speedometer does not work;

- The speedometer does not show the speed correctly;

- The odometer does not work;

Installation features of some sensors

If you purchased temperature, oil pressure and coolant temperature sensors, then a special sensor should be included in the kit. It performs the function of reading data from the engine and transmitting it to a device installed in the cabin. Let's take a closer look at how car sensors are installed . Let's start with the coolant sensor. To install it, you need a spacer in the pipe. Since they can be different diameters, you should measure the diameter of the top pipe of your machine.

The work is performed in this order:

- installing a spacer in the gap in the radiator pipe;

- tightening clamps;

- screwing in the sensor;

- wiring;

- setting up the device.

A spacer is required to install pressure and temperature sensors. It is intended for two sensors at once. Therefore, there is no need to purchase this part separately for each sensor. A spacer is installed between the engine block and the oil filter. At the final stage, you need to run the wires and configure the device. If you decide to install car sensors , you can buy them in the Dvizhkom store at an affordable price.

Found an inaccuracy in the description? Select it and press Shift+Enter or write to us

The quantity to order an item must be a multiple of

You might be interested in our special offer!

In order to send a VIN request you need to register or

log in

.

You have successfully registered!

We have sent you a password to the specified email address. You can change your password or other registration data in your personal account settings

Consent to the processing of personal data

Hereby, in accordance with Federal Law No. 152-FZ “On Personal Data” dated July 27, 2006, you confirm your consent to the processing of personal data by RAT LLC: collection, systematization, accumulation, storage, clarification (updating, changing), use, transfer solely for the purpose of fulfilling your order and informing about it, as well as promotions and campaigns of RAT LLC, including blocking, depersonalization, destruction. We, RAT LLC, guarantee the confidentiality of the information we receive. The processing of personal data is carried out for the purpose of effective execution of orders, contracts and other obligations accepted by RAT LLC as binding on you.

This consent applies to the following personal data: last name, first name and patronymic, email address, postal address for delivery of orders, contact phone number, payment details.

The validity period of your consent is unlimited, however, you have the right to revoke this consent at any time by sending a written notice to the address: 192171, Russian Federation, St. Petersburg, st. Sedova, 61, lit. A., room 7N, at RAT LLC, with the note “revocation of consent to the processing of personal data.” Please note that withdrawal of your consent to the processing of personal data entails the deletion of your account from the Internet site (https://dvizhсom.ru), as well as the destruction of records containing your personal data in the personal data processing systems of LLC " RAT", which may make it impossible to use the Internet services of RAT LLC.

Knock sensor

The knock sensor on the nine is used to detect detonations in the engine that occur due to low-quality fuel. These detonations can cause serious damage to the engine if they are not corrected in time, which is exactly what the knock sensor does. It detects detonation, then sends a signal to the ECU, which adjusts the ignition timing, thereby reducing detonation in the engine.

Location

The knock sensor is located on the block in the middle, it can be seen between the 2nd and 3rd cylinders.

Signs of malfunction:

- Fingers knocking;

- Loss of vehicle dynamics;

- High fuel consumption;

Sensors VAZ 2109

The Nine managed to make a lot of noise among the people, in the 90s “bandits” drove it, and in the 2000s it was used by young people, but even today there are more than enough of these cars.

Initially, in 1993, the VAZ 2109 was equipped with a carburetor engine, but progress did not stand still and in the late 90s the nine received an injection engine, which had a positive effect on its technical characteristics. As you know, for proper and reliable operation, an injection engine requires a large number of sensors and a “brain” that will manage it all. There are a lot of sensors on the VAZ 2109 and they are all interconnected in their own way.

This article will focus specifically on the sensors of the injector system on the VAZ 2109, namely, their purpose, location and signs of malfunction.

Air flow sensor

The mass air flow sensor, also known as MAF, is probably the most famous and most recognizable sensor of all the sensors in a car. Its purpose is to count the air entering the engine. Air counting is necessary to create the air-fuel mixture in the correct proportions.

Location

The VAZ 2109 air flow sensor is located on the intake corrugation between the throttle valve and the air filter housing.

Signs of malfunction:

- Idle speed fluctuates;

- The car does not pull well;

- The engine stalls spontaneously;

Location and principle of operation of the meter

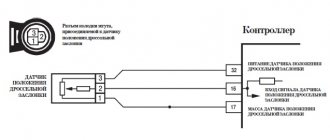

The sensor is installed on the throttle valve block and is mechanically connected to its axis. Thanks to this, the device is able to solve 3 problems:

- inform the controller at what angle the throttle is currently open;

- signal that the air supply is completely closed (the driver has released the accelerator pedal);

- monitor the speed at which the damper opens.

Based on this information, the electronic powertrain control unit (ECU) makes a decision to increase or decrease the fuel supply and fuel injection for intense acceleration when the gas pedal is sharply pressed.

Reference. Two types of TPS are installed on cars: resistive and non-contact. The first ones are cheaper and therefore are found on all budget cars. The latter are more reliable and more expensive, and are installed on cars of medium and high price categories.

The operating algorithm of the resistive sensor is as follows:

- At idle, the damper is closed and air flows into the engine through a separate channel. The voltage at the output of the device does not exceed 0.5 volts; the controller supplies fuel to maintain engine idle speed.

- When the driver presses the gas pedal, the sensor slider moves along the resistive film. The resistance of the electrical circuit into which the device is connected in series decreases.

- The ECU “sees” the increase in voltage in the meter circuit, makes a calculation, prepares the air-fuel mixture in the required quantity and supplies it to the cylinders. The maximum voltage at wide open throttle is about 4.5 V.

- When the driver sharply presses the accelerator pedal, the controller notes a similar voltage surge and delivers a portion of the enriched mixture for dynamic acceleration.

Note. The operating voltage values are indicated for a common Russian car - VAZ 2110.

The non-contact throttle position sensor functions identically. The difference lies in the method of influencing the electrical circuit. A resistive device changes resistance using a slider moving across the film, while a non-contact device changes resistance due to the magnetic-resistive effect. Thanks to this principle of operation, the TPS lasts much longer and does not create problems for the owner of the car.

Throttle position sensor

This sensor is necessary to determine the opening angle of the throttle valve. These readings are necessary to correctly determine the air supply to the engine. TPS works in tandem with IAC and mass air flow sensor. Since the sensor is made of a rheostatic type, that is, it changes its resistance with each opening of the throttle, it quite often fails.

Location

The TPS is located on the throttle valve of the VAZ 2109.

Signs of malfunction:

- The speed ranges from 500 to 2500 rpm;

- The engine starts poorly;

- No idle;

Why is it necessary to modernize the throttle valve on VAZ-2109, 2110, 2115

Spare parts stores sell throttle assemblies with valves of increased diameter (52, 54 and 56 mm) for VAZ-2109, 2110 or 2115 cars. According to the sellers, by installing such a valve instead of the standard 46 mm one, the car owner will receive significant advantages: the car becomes more responsive to the gas pedal, problems with idle speed disappear, the car's dynamics improve, and this is especially noticeable if you replace the standard air filter with a zero-resistance filter. The main argument that they try to convince car owners is that the engine requires more air to operate efficiently, for which it is necessary to replace the standard throttle assembly with an improved one. They even give figures: the diameter of the VAZ-2109 or VAZ-2110 receiver is 53 mm, and a damper with a diameter of 46 mm allegedly “strangles” the engine.

Idle speed control

The idle speed sensor is a DC motor with a “cap” on its shaft that acts as a valve. This valve closes the channel in the throttle valve, thereby opening or closing the air supply to idle. The IAC only works at idle and at high speeds, when the throttle valve is open, it does not participate.

Location

The VAZ 2109 idle speed regulator is located on the throttle valve on the reverse side.

Signs of malfunction:

- Idle speed fluctuates;

- The engine stalls at idle;

Lada 2109 [On the air] › Logbook › Cleaning the throttle valve

Hello dear friends