For the normal functioning of the motor, many components and mechanisms are used. One of these elements is the throttle valve. What is a throttle position sensor, what is its device and how to determine its malfunction? We will tell you more about this device below.

DPDZ area of responsibility

In this article we will look at the features of this part and provide detailed instructions for its repair, adjustment and replacement. But before moving directly to the practical part, you should pay a little attention to theory and consider what the throttle valve and its sensor are, what functions they perform and where they are located. So, the damper itself is a structural component of the engine intake system. Its functions include adjusting the amount of incoming air, i.e. it is responsible for the quality of the fuel-air mixture.

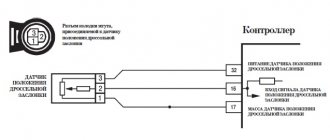

The throttle position sensor provides information to the manifold about the state of the bypass valve. This is obvious from its name. The sensor can be film or non-contact (magnetic). Its design is similar to an air valve, and when it is open, the pressure in the system is equal to atmospheric pressure. But as soon as the element moves to the closed position, the value of the above characteristic immediately decreases to a vacuum state.

Throttle position sensor

The throttle sensor consists of constant and variable resistors, the resistance of which reaches 8 ohms. The voltage at its output, depending on the position of the damper itself, constantly changes. The entire process is monitored by a controller, and the amount of fuel is adjusted depending on the data received. If the TPS does not work correctly and produces distorted data, then not enough fuel will enter the system or there will be an excess of it, which will lead to disruption of the engine and even sometimes its failure. In addition, the correct operation of the gearbox and ignition timing depend on this device. We will not calculate how much it will cost to repair these mechanisms.

To diagnose any unit or part, you need to know its location. The throttle position sensor is located in the engine compartment. You can get to it after you find the throttle pipe, on which the TPS is fixed.

Varieties

There are two types of TPS. What are these elements? This can be a part with a mechanical or electrical drive. The first is often used on budget cars. All its constituent elements are combined into a separate block, which includes such details as:

- Frame.

- Throttle valve.

- Sensor.

- IAC (idle air control).

The damper body is included in the vehicle's cooling system. There are also pipes here that ensure the operation of gasoline vapor recovery and crankcase ventilation systems.

The idle speed regulator maintains the engine crankshaft speed when the throttle is closed during engine startup and warm-up or when additional equipment is operating. The IAC consists of a stepper motor and a valve. These two parts regulate the flow of air that enters the intake system bypassing the damper.

However, in the last few years, more and more automakers are equipping their vehicles with electrically operated throttle bodies. Such elements have their own electronic control system, which ensures the optimal amount of torque at all speed ranges and loads of the machine. This not only increases power and dynamics, but also reduces fuel consumption and exhaust emissions.

Why might we need to repair the sensor?

Nothing eternal has yet been invented, and this element is also breaking. Let's consider what reasons can provoke its failure and how this can be noticed. Throttle position sensor malfunctions are mainly caused by normal wear and tear. Thus, the sprayed base layer along which the slide moves wears out. As a result, the device gives incorrect readings. Another reason for incorrect operation may be the failure of the movable core. And if one of the tips is damaged, then a number of scratches will appear on the substrate, which will lead to breakage of the remaining elements. This will cause deterioration of contact between the resistive layer and the slider, and in some cases, its absence.

Worn throttle position sensor

You can understand that it’s time to contact a service center or carry out independent diagnostics and, if necessary, repairs, based on the following signs. First of all, listen to your car while idling; if the speed “floats”, then do not hesitate to check the device. Another warning sign should be the engine stopping when the pedal is suddenly released. And when accelerating, it may seem that fuel is not getting into the system, the car twitches and jerks appear.

Article on the topic: How to find, check and replace the oil pressure sensor on the Volkswagen Passat B3 and other modifications

Sometimes the revolutions seem to hang in one range (1.5–3 thousand) and do not change their position even when switching to neutral gear. In addition, the dynamics deteriorate. In general, the slightest disturbance in engine operation should alert you. By the way, pay attention to the dashboard, the “Check engine” warning light should light up on it. If this happens, then your car automatically goes into emergency mode, and after doing computer diagnostics, you will see that the reason lies precisely in the sensor.

What are the causes and signs of TPS failures on Lanos?

If you suspect a malfunction of the TPS, then the first thing you need to look for is the presence of a number of the following symptoms:

- Reduced engine power

- Increased fuel consumption

- Delayed engine response to pressing the accelerator pedal

- Jerking occurs when accelerating hard

- Problems starting the engine

- The “Check Engine” indicator lights up, indicating an engine error.

The described symptoms do not indicate 100% that the cause of the malfunction is the damper sensor. That is why it is additionally recommended to check the device. Absolutely every driver can perform a TPS check on Lanos, and for this it is not at all necessary to visit a car service center. How to check the damper sensor on Lanos, we will find out in detail.

Checking the sensor without the help of an auto electrician

Checking the throttle position sensor is quite easy, and anyone can cope with such a task, especially since for this you only need a multimeter, and when you don’t have one, a simple voltmeter will do. Next, perform all the steps below.

Checking the throttle position sensor with a multimeter

Turn the key in the ignition and measure the voltage between the slider contact and the minus. Its value should not exceed 0.7 V. Then we open the damper, turning the plastic sector, and take measurements again. Now the device should show more than 4 V. Turn on the ignition completely, after which the connector is pulled out and the resistance between any terminal and the slide is checked.

Now we slowly rotate the sector and observe the indicators of the measuring device. Its needle should also smoothly change its position, and any jumps are a sign of a sensor malfunction. There is a little trick. If you don’t want to disconnect the wires, you can simply pierce them with a thin needle, although it’s better not to be lazy and do everything as expected.

Adjustment in your garage

Even a novice car enthusiast can adjust the throttle position sensors; the main thing is to strictly follow the instructions given below. Moreover, this operation does not depend on the operating principle of the TPS – non-contact or not. So, first we carry out the preparatory work. We disconnect the corrugated tube through which air passes and thoroughly rinse it with alcohol, gasoline or another strong solvent. But one liquid is not always enough; to achieve a better effect, you should also wipe the tube with a soft cloth. We carry out the same operation with the damper itself and with the intake manifold. In addition, do not forget to carry out visual inspection, especially for the damper.

Operating principle of TPS

So, no mechanical damage was detected? Then we proceed directly to adjusting the throttle position sensor. First, take the key and loosen the screws. Then we raise the damper and sharply lower it all the way, keep in mind that you should hear a blow, otherwise repeat the operation again. Loosen the screws until the part stops “biting.” And only then can the position of the fasteners be secured with nuts. Next, unscrew the bolted connections of the TPS and rotate the device body. Next, we set the throttle position sensor so that the voltage changes only when the valve opens. The setup is complete, all that remains is to return everything to its place, tighten the bolts and enjoy driving your favorite car.

Differences between an electric damper

How does this part differ from its mechanical counterparts? Its main differences lie in the absence of a mechanical connection between the gas pedal and the throttle valve, as well as in the regulation of idle speed by moving the damper itself.

But that's not all of its features. Since there is no rigid connection between the gas pedal and the throttle valve, the electronic system itself can influence the amount of torque of the internal combustion engine, even if the driver does not press the accelerator. All these changes occur due to the actions of the input sensors, control unit and actuator.

In addition to the TPS, the electronic control system contains an accelerator pedal position sensor, as well as a brake and clutch position switch. Thus, the engine control unit responds to all signals from the sensors and converts these impulses into control actions on the damper module.

Replacement and selection of sensor - non-contact or film?

If the element fails, then its complete replacement will most likely save the situation. One of the important points of this stage is the correct choice of a new device. Of course, if you do not want to carry out all the operations again in a short period of time, then you should give preference only to high-quality products, and even more so avoid cheap Chinese counterfeits. In addition, do not stop your choice on film-resistive models. They are short-lived, and such savings can cost you a pretty penny. But contactless throttle position sensors are more reliable. They only cost a few dollars.

Article on the topic: Knock sensor: what is it

Non-contact TPS

The film model has resistive tracks, while the non-contact model works on the principle of the magnetic effect. Its components are a stator, a rotor and a magnet. On the first, the magnetic field has a huge impact. The material of the second one is chosen such that the magnet does not have any influence on it. The distance between the TPS elements does not change and is selected at the assembly stage. Needless to say, the contactless sensor cannot be repaired.

The replacement itself will take you much less time than choosing a device. But despite the fact that the process is quite simple, let’s consider it in detail. We prepare a Phillips screwdriver, an O-ring for the throttle pipe and, of course, the part itself. The replacement begins by turning off the ignition if the car has been started. Open the hood and do not forget to disconnect the battery. To do this, remove the negative terminal.

Installation of TPS

Now we find the sensor on the throttle pipe and remove the block with wires from it; most likely you will have to press out the special plastic latch. Then unscrew the mounting bolts and dismantle the device. There is a foam ring between the TPS and the pipe, and it definitely needs to be replaced. And only after this can the sensor itself be installed. Fix the device firmly with bolts, otherwise the vibration will not do it any good and will cause failure. Reconnect the block with all the wires. Sometimes people forget to disconnect the battery; in this case, it is necessary to de-energize it for at least five minutes after installing the new device and connecting the plug to it.

You can check whether the element is working correctly as follows. Open the damper and pull the throttle cables to turn the TPS drive sector. If the position of the sector does not change, then the sensor should be installed again. At the same time, we rotate it 90 degrees relative to the damper axis. And finally, check the voltage with a tester; if its values coincide with those indicated above, then the device is working.