Even if you follow all the instructions that can be found in the car operation and repair manual, replacing a VAZ 2109 gearbox is not easy. The reason is that removing the gearbox requires many step-by-step actions to disassemble and reassemble vehicle systems and components.

If you decide to go to a service station, the gearbox will be removed in literally one hour, but the cost will not please you (removal and installation of gearboxes for front-wheel drive cars averages 1,500-2,000 rubles ). It should also be noted that the manufacturer’s auto standards for removing a VAZ 2109 gearbox are 4.2 hours, but doing this task yourself will most likely take a whole day, or even two.

Signs of a faulty VAZ 2109 gearbox

- noise in the gearbox;

- difficult gear shifting;

- spontaneous transmission shutdown;

- “crackling” when the gear is engaged;

- increased noise when disengaging the clutch.

These signs may indicate a serious breakdown of the gearbox, which will require replacement.

It should be remembered that the gearbox of the VAZ 2109 (aka VAZ 2108 and the rest of the family) weighs a decent amount from 32.7 to 33 kg. The piece of iron is heavy. And if you also take into account that you need to remove the box from a level above your head, then you should calculate your strength, especially if you work alone. It is necessary to prepare a place for the box in advance so that you do not have to lift the gearbox from the bottom of the inspection hole.

Where to buy a used box for a Zhiguli?

Any vehicle unit, the gearbox, is no exception, has its own safety margin and amount of working resources. At the end of the latter, it is time to think about replacing the transmission unit. Today, several options are available to solve the problem. The simplest and first thing that comes to a car owner’s mind is buying a new box. But enthusiasm in this regard often dries up after a short monitoring of prices for these units. A new box requires a serious investment. Is there a way to save money?

Let's go to the secondary market

Logic dictates that spare parts can be found cheaper on the secondary market. And indeed it is. to buy a used manual transmission or gearbox for a VAZ 21099, the price of which is determined by its condition. A large number of offers are found on the Internet. Conventionally, the secondary market can be divided into three sectors:

- private;

- garage;

- professional.

The first two provide for the implementation of transmission units either by the Zhiguli owners themselves or by individual craftsmen. Such offers can attract the buyer's attention based on financial criteria. But if you are looking for a product for the request “ gearbox for VAZ 2108, 2109, 21099, price, used 5-mortar ”, do not rush to choose based on cost. Assess all the risks and benefits of each proposal.

In the professional sector, it is also easy to find out how much a gearbox costs for a VAZ 2108, 2109, 21099; the price varies depending on the current safety factor of the unit. Refurbished components are offered for sale, fully ready for use. The choice in favor of such a box can be considered rational. Unlike private owners, professionals provide a guarantee on used units.

Choosing a service provider

If you need a used gearbox for a VAZ 21093, the price of which is reasonable and the quality is high, contact our workshop. We will also select transmission units for nines and ninety-nines.

All units offered for sale have been restored by our craftsmen. When performing major repairs, original VAZ spare parts were used. Complex troubleshooting is carried out using a special tool. The techniques used allow us to guarantee the quality of the overhaul.

By purchasing a transmission for your car from us, you are guaranteed to receive a working, efficient transmission unit with a significant margin of safety. Additionally, we offer unit replacement services at a special price. Our auto mechanics will promptly dismantle the original box and install the unit after major repairs. You will have to spend very little time getting your car back on the track.

Used boxes for VAZs are almost always available in our workshop. This allows you to optimize the replacement process and simplify the ordering of units. Do you want to purchase a used box to replace one that is worn out or damaged in an accident? Contact us by phone, mail, or come directly to the workshop to discuss the details of the transaction!

Replacing the VAZ 2109 gearbox

To replace the VAZ 2109 box you will need:

- wrenches 8, 10, 13, 15 mm;

- torque wrench, 13mm socket;

- jack;

- container for draining oil;

- place for repairs (inspection pit or overpass);

- flat screwdriver.

The side gear is fixed using a technological plug used when transporting the differential, or using an old internal CV joint. Otherwise, the loose side gear may fall into the gearbox housing.

Install the gearbox in the reverse order of removal, tightening the bolts and nuts to the correct torques, taking into account the following:

- Before connecting the wheel drive shafts to the side gears, make sure that the retaining rings on the internal joints are replaced with new ones. This is very important, since when installing old rings, spontaneous separation of the wheel drives and side gears is possible when the car is moving;

- Before installing the gearbox, apply a thin layer of transmission oil to the splined end of the input shaft and CV joint-4 grease to the outer surface of the clutch release bearing clutch guide sleeve. Then center the clutch driven disc using mandrel A.70081.

After installing the gearbox, adjust the full travel of the clutch pedal and the gear shift control drive in the following order:

- working from below the car, with the tie rod clamp loosened, set the rod to the neutral position;

- With a raised decorative cover, install the gear shift lever so that its lower part is perpendicular to the floor of the body, and the handle is located from the right seat at a distance equal to 1/3 of the distance between the seats. In this position, tighten the tie rod nut. Then fill the gearbox with the recommended oil.

When connecting the shift drive to the gearbox, make sure that there is no twisting or deformation of the corrugations of the protective cover. Setting the gear shift lever to the required position.

The device and its main features

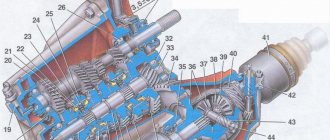

All elements of the VAZ 2108 four-speed gearbox:

1 – gearbox housing; 2 – filler and control hole plug; 3 – drain plug; 4 – adjusting ring; 5 – left front wheel drive; 6 – driven gear of the 1st gear of the secondary shaft; 7 – synchronizer clutch for 1st and 2nd gears with reverse gear; 8 – driven gear of the second gear of the secondary shaft; 9 – retaining ring; 10 – persistent half ring; 11 – driven gear of the third gear of the secondary shaft; 12 – synchronizer clutch hub for 3rd and 4th gears; 13 – driven gear of the 4th gear of the secondary shaft; 14 – needle bearing of the secondary shaft gears; 15 – thrust washer of the 4th gear gear; 16 – ball bearing of the secondary shaft; 17 – rear cover of the gearbox; 18 – ball bearing of the input shaft; 19 – breather; 20 – synchronizer blocking ring; 21 – sliding clutch for synchronizer of 3rd and 4th gears; 22 – retainer block; 23 – input shaft; 24 – locking ball; 25 – fork of the sliding clutch for the synchronizer of 3rd and 4th gears; 26 – roller bearing of the input shaft; 27 – clutch release fork lever; 28 – clutch release fork bushing; 29 – clutch housing; 30 – clutch release fork; 31 – clutch release bearing; 32 – roller bearing of the secondary shaft; 33 – secondary shaft; 34 – driven gear of the main gear; 35 – tapered roller bearing of the differential; 36 – differential box; 37 – satellite; 38 – locking ring of the side gear; 39 – semi-axial gear; 40 – speedometer drive gear; 41 – drive of the right front wheel; 42 – speedometer drive; 43 – satellite axis; 44 – retaining ring of the satellite axis; 45 – protective cover for the gear shift drive hinge.

About important characteristics

Through drive 41 and 5, located on the front wheels, torque from this product is transmitted to the drive wheels. Disassembling the gearbox is carried out in different ways, depending on the design of the part.

For example, the main malfunctions of the four-stage option may involve working with the following parts:

- Drive design that helps change gears.

- Differential.

- The most important detail of the transfer.

- The reverse gear has its own intermediate gear, it is located on a separate axis.

- Two synchronizers.

- No design can do without secondary and primary shafts.

- Carter 1.

An aluminum-based alloy is always used to make the crankcase. This must also be taken into account if gearbox noise elimination is required. The back cover helps hide everything. A breather is pressed into its socket. The bearing housings are located at the rear. There are also two holes that are closed with plugs. The secrets of repair are to work correctly with each of the elements.

The primary shaft is located in the crankcase and is mounted on two bearings. This shaft itself is made in the form of gears and reverse gears, a gear block.

Replacing a gearbox bearing requires interaction with such devices.

Reverse speed repairs must take into account that the secondary shaft and the gear on the main gear create a single composition. It rotates in the space between the roller and ball bearings. The gears responsible for 4,3, 2 and 1 gears can be found on the belts of the secondary shaft, on needle-type bearings. A detailed repair manual will also tell you that the splines on which the hubs are attached to the 12 synchronizers are cut using 2 small-sized belts.

All elements of the secondary shaft:

1 – nut; 2 – ball bearing; 3 – thrust washer; 4 – bearing sleeve; 5 – needle bearing; 6 – 4th gear gear; 7 – bearing spacer ring; 8 – synchronizer blocking ring; 9 – sliding clutch for synchronizer of 3rd and 4th gears; 10 – sliding coupling hub; 11 – third gear gear; 12 – retaining ring; 13 – thrust half-rings of the secondary shaft; 14 – 2nd gear gear; 15 – sliding clutch for synchronizer of 1st and 2nd gears with reverse gear; 16 – retaining ring of the synchronizer hub; 17 – hub of the sliding clutch for the synchronizer of 1st and 2nd gears; 18 – synchronizer spring; 19 – cracker; 20 – retainer; 21 – 1st gear gear; 22 – roller bearing; 23* – thrust washer; 24* – bearing sleeve; 25* – 5th gear gear; 26* – sliding clutch hub; 27* – sliding clutch for 5th gear synchronizer; 28* – thrust plate.

From 23 to 28 the parts of the VAZ 2108 five-speed gearbox are marked.

Each gear must have two teeth:

- Straight-toothed.

- Helical.

Crown designs with oblique teeth provide constant traction for the gears on the input shaft. When the gear is engaged, a connection occurs between the synchronizing clutches and the rims, which have straight teeth. This is also part of such a design as the gear selection mechanism at the gearbox.

Repairing the backstage affects other parts. The gears switch silently to each other thanks to the work of the synchronizer. On the primary and secondary shafts, the angular speeds for the gears are constantly equalized to achieve the desired result. The primary and secondary shafts themselves contain several elements. Each transmission repair diagram contains references to them.

- Each gear has a ring gear.

- The latch operates on springs.

- Three crackers with balls.

- Two Rings responsible for blocking.

- Part of the coupling that can slide.

- A hub mounted on the splines of the secondary shaft.

Where can I get my gearbox repaired? You can do it in your own garage - it’s a fairly simple job. Different types of synchronizers may be found in different gears, but they are not very different from each other.

The process of installing the first gear driven gear.