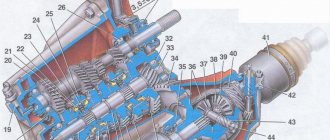

Rice. 3. Gear shift diagram: a – for a four-speed gearbox; b – for a five-speed gearbox

In Fig. Figure 3 shows a shift diagram for a four-speed (a) and five-speed (b) gearbox. To confidently control the gearbox, remember the difference between first and reverse gears. To reverse, engage reverse gear only when the car is completely stopped, pausing for about 3 seconds after pressing the clutch pedal. When selecting reverse gear, the gear shift lever moves from the neutral position in the same direction as for selecting first gear, and then moves with increased resistance all the way to the left and forward to engage the gear.

VAZ-2109 is a fairly popular car in Russia and the CIS. Serial production of the car started in 1987. Over all the years of production, the “nine” was equipped with only two types of boxes. Both were mechanical. Over the years of operation, these gearboxes on the VAZ-2109 caused many problems and complaints among motorists. Well, let's take a closer look at this box and look at its typical problems.

Characteristic

As we said earlier, a 4-speed transmission was also installed on the car. The assembly of the gearbox for the VAZ-2109 of this type did not last long. Therefore, it is now very difficult to meet “short-winged” cars with a 4-speed manual transmission. It's practically a rarity. 95 percent of the “nines” came with a more modern, 5-speed manual transmission. It was two-shaft, with synchronizers in all gears (except reverse). Structurally, this gearbox is combined with the main gear and differential. It differed from the 4-mortar in a different location of the crankcase ventilation pipe. It was located on the clutch housing (previously it was on the rear cover). A dipstick also appeared. But the gear ratios remained the same.

In Russia, these cars stopped being produced back in 2004. But you can still find spare parts for the VAZ-2109 gearbox in stores. Their price is quite reasonable. If necessary, you can buy a complete transmission for 5-6 thousand rubles.

How to increase comfort in the VAZ 21099 interior?

When considering how you can increase the comfort of staying in a car, we note the following points:

1. It all starts with insulation improvements. The vehicle in question has ineffective standard insulation. This moment determines that the car is cold in winter, hot in summer, the interior takes a long time to heat up, and a constant hum is heard when driving. The situation can be changed by insulating the body. You can do this work yourself using available tools and special materials. However, some materials can be found at very low prices. Note that any major tuning is not complete without changing the interior of the vehicle

Therefore, we recommend that you pay attention to this method of increasing the comfort of staying in a car and examine the issue in more detail.

2. In addition, do not forget about the constant squeaking and crickets, which make long-distance movement almost unbearable. It is worth considering that even high-quality insulation does not solve the problem, since it does not come from the outside, but from the inside. Unreliable fastening of panels, cheap plastic and many other reasons lead to the problem. This can be solved by sealing the voids, for example, with the same insulating material, and checking all connections. Over time, the bolts and screws become loose and the fastening weakens, which leads to noise and squeaking.

3. In order to make the car comfortable in winter, a new stove is installed, which will heat the interior faster than the standard one. The new stove is installed quite simply, the main thing is to connect it correctly. However, in some cases, it is possible to increase the degree of heating of the car interior only after improving the cooling system, since the supplied air is heated by the liquid that cools the engine.

4. A fairly popular way to increase comfort in a vehicle interior is to install high-quality acoustics. At the same time, such a modification can be fully appreciated only with high-quality insulation of the body. Despite the fact that such tuning is carried out quite often, only a few perform it well. There are quite a few problems with connecting acoustics. To begin with, you should remember that truly high-quality sound can only be achieved by placing several speakers around the perimeter of the body. This way you can achieve a surround sound effect.

Device

This transmission consists of several elements:

- Primary and secondary shaft of the VAZ-2109 gearbox.

- Transmission box housing.

- Synchronizers.

- Axles with reverse intermediate gear.

- Differential, which changes the gear shift drive.

- Aluminum cover with breather. For better heat dissipation, its surface was ribbed.

So, we looked at the design of a typical VAZ-2109 gearbox. This transmission may need to be repaired for several reasons. Below we will look at the main faults and how to fix them.

The difference between the five-speed gearbox

The main difference between this type of box is that more elongated secondary shafts are installed at the exit from the crankcase, but otherwise the device is the same. Two gears are mounted on these extended shafts:

- presenter;

- driven, for fifth gear, combined with synchronizer.

Also different from this system is the absence of a transmission bushing on the switch. The number of gears in the main transmission element may vary and depend on the manufacturer. The numbers are marked on the driven gears of the transmitting elements; they are marked with special paint.

In addition, the ball bearings of the shafts of the secondary and primary shaft systems are located in the crankcase sockets, they are covered with a special plate. The plate part is attached to the crankcase cover with four screws. The cover of the rear part of the transmission type system is made of a deeper shape. A synchronizer is installed on the fifth transmission feed of the VAZ 2109, which is equipped with one locking ring, because it has only a single transmission element. A special fifth gear is installed on the primary shaft splines.

The transmission goes out

If you lose speed while driving, the gear assembly is most likely worn out. The locks on the gear and clutch also fail. These elements are replaced entirely with new ones.

It is worth noting that the gear on the “nine” can also fall out due to too fast shifting. The manufacturer recommends a two-second pause when switching to increased speed. If you continue to ignore this problem, you may encounter failure of the synchronizers.

Each box has its own noise limit, which is not a symptom of a malfunction. The transmission has gears that constantly rub against each other. And no matter how technologically advanced the design is, it is impossible to completely eliminate sound. As for the 5th gearbox VAZ-2109, its noise regulation is 78 dB. Anything higher is equivalent to a malfunction. And the box may make noise due to insufficient oil level in the box. As you know, gear oil has a higher viscosity than motor oil. And it is not sprayed by the pump. This oil is located in the gearbox housing. When the gear rotates, it dips itself into the lubricant. If the liquid level is below the permissible level, the element will run dry. This entails increased gear wear and wear. As a result, even if the oil level is restored, the problem will not disappear.

Advice from experts on manual transmission operation

Like any other complex vehicle mechanism, a manual transmission must be operated in strict compliance with the rules of the vehicle manufacturer. Following these simple rules, as the practice of the Favorit Motors Group of Companies specialists shows, can slow down the wear of parts and reduce the frequency of breakdowns in units.

- It is advisable to change gears in accordance with the manufacturers' recommendations regarding the permitted minimum and maximum speeds intended for each gear. In addition, the manufacturer usually provides instructions on how to operate the vehicle economically. For example, for a Volkswagen Polo car (1.6 engine, 110 hp, 5 manual transmission) there are recommendations for economical fuel consumption: switch to second gear at a speed of 20 km/h, to third when reaching 30 km/h, to fourth at 40 km/h and in fifth at 50 km/h.

- Shifting into reverse gear (reverse movement) should only be done when the vehicle is completely stationary. Even at low speeds, shifting into reverse gear is unacceptable.

- It is recommended to depress the clutch pedal quickly and release it slowly and without jerking. This reduces the friction force on the release bearing and delays the need for repairs.

- When driving on a slippery road (ice), you should not drop the clutch or put the gearbox in neutral.

- It is not recommended to change gears during sharp turns; this leads to rapid wear of the mechanisms.

- Any vehicle needs constant monitoring of the amount of oil in the manual transmission crankcase. If the working fluid is not added and replaced as necessary, the oil becomes saturated with metal dust, which increases wear.

As you can see, it is quite possible to extend the “life” of a manual transmission. To do this, you just need to follow all the manufacturer’s recommendations, and at the first doubt about the quality of work, contact the specialists of Favorit Motors Group of Companies.

The company's technical centers are equipped with all the necessary diagnostic equipment and specialized tools for diagnosing faults and repairing manual transmissions. To perform repair and restoration work, Favorit Motors Group of Companies specialists use technologies recommended by the manufacturer and high-quality certified spare parts.

Auto service technicians have many years of experience and specialized knowledge, which allows them to quickly diagnose faults and carry out any type of repair of manual transmissions. Each specialist regularly undergoes retraining at the training centers of manufacturing plants and receives a certificate for the right to repair and service a certain brand of car.

Customers of the Favorit Motors car service can enjoy convenient work hours, online booking for maintenance and repairs, a flexible loyalty program, a warranty on spare parts and all types of manual transmission repairs. All necessary components and consumables are available at the company’s warehouse.

The price of manual transmission repair depends on the type of breakdown and the amount of repair and restoration work required. By contacting Favorit Motors Group of Companies, you can be sure that the functionality of the “mechanics” will be restored as soon as possible, and the cost of services will not negatively affect the family or corporate budget.

It is difficult or crunching to engage the gear

The problem is a consequence of the failure of synchronizers. The first and second gear synchronizers often wear out. At first, the driver notices difficulties when turning on the desired speed. Then all this begins to be accompanied by a crunch, like on the 53rd LAWN. Do not forcefully press the lever - this will damage the gear block. If there is a problem with the synchronizers, use double squeezing with re-throttle. This is the only way to preserve the gearbox elements while moving to the repair site.

If the box begins to knock when moving, most likely a tooth on the shaft gear or main pair has broken. The element cannot be repaired and must be replaced entirely.

Salon

The interior of the Nine was developed in the last century, so today it cannot be called a model. To make it more modern, there are many tuning options. Do not forget that it is ugly when the external tuning of a car is done very well, but when you open its doors, you see a worn-out interior. You can make the following interior changes with your own hands:

- additional sound insulation helps make the car more comfortable. To protect the interior from external noise, additional pasting is carried out on the partition separating the engine from the interior, bottom, doors, and engine compartment. For this, a special noise-insulating material is used, the thickness of which is 1.5–2 mm. It is made from butyl rubber composite sealant. The material has an adhesive layer with which it is attached to the car body;

The lever is dangling

If the gearshift lever on a VAZ-2109 is loose, you should check the serviceability of the gearbox hinge (cardan). They have a tapered bolt that can unscrew. In most cases, the problem is solved by tightening it. Note that this bolt is tightly tightened from the factory. It is unscrewed to adjust the scenes.

Backlash also occurs due to a broken return spring, which is located in the gearbox mechanism. It usually changes every 4 years or 100 thousand kilometers.

The cone bolt also unscrews. It is smaller in size than the cardan and is located inside the box itself under the gear shift element.

How to set preload

Preload adjustment is carried out by installing a package of special spring washers that push the gears inside the lock. A complete package of such special washers, when folded together, is 1 cm thick, but all the washers are different in thickness so that you can adjust the differential preload moment.

To adjust the preload you will need:

- pointer torque wrench (a wrench with clicks is not suitable, it will take a long time to set up);

- a homemade special part made from a simple internal grenade (cut off and a bolt welded to it) - see the video below;

- set of spring washers (rings);

Procedure for adjusting preload:

- Disassemble the locking differential (remember the sequence). After removing the cover, pull out the axle shaft auger gear; behind it comes a narrow gear with a large internal hole, but which has a side; then come those same adjusting spring washers. You can pull out the screw satellites (the preloads themselves) to check how much wear they have.

- Install new washers.

- Collect.

- Using a torque wrench and a special homemade part, we determine the tightening torque. When the key begins to turn, at this moment the arrow shows the tension torque.

This video discusses the option of adjusting the locking washers of a VAZ 2108 car.

A preload of up to 5 kg does not flatten the washer to a flat state; such a tension moment is considered a resource tension. Locking with a tension of up to 5 kg will help not significantly lose its characteristics for about 4 years. Any blocking with tension in the first couple of months loses about 1 kg of tension.

Experts recommend making a preload of no more than 5 kg for a self-locking front differential, and no more than 7 kg for a rear differential. At a maximum differential preload of, for example, 9 kg, all spring washers will already be pressed and the effect of the springs will be lost.

Backstage

If the gearbox on a VAZ-2109 is ringing, don’t be upset. All owners of "nines" have this problem. Moreover, the rocker rings both on “killed” and on relatively fresh cars. The AvtoVAZ representative office itself is aware of this defect. And vibration occurs due to the incorrect location of the support points of the internal combustion engine and the gearbox. As a result, the nodes vibrate, and the ringing is transmitted to all other parts, including the slide. Some solve this problem by installing an o-ring in the rocker area, others get used to it and drive like that, with a ringing sound.

Interior

There are no specific principles here, with the exception of sports tuning, when improvements are aimed at increasing functionality, safety and reducing weight. In this case, everything unnecessary is removed (rear seats, panels, etc.), the driver's seat and seat belts are changed, sports equipment and other equipment are installed.

In other cases, it all depends on the preferences and means of the user: you can tune the VAZ-2109 panel by replacing instruments, reupholster the interior, improve sound insulation, install multimedia equipment, etc. These works vary in labor intensity, and the ability to perform them independently is determined by the skills of the performer .

Oil disappears

Unlike engine oil, rarely does anyone check the transmission oil level. But in vain, because sometimes you can simply get a dry dipstick. If measures are not taken in time, increased noise will appear (since the gears are running dry). For what reasons does oil leak from the box? There are several factors:

- The crankcase cover does not fit tightly.

- Worn shaft seals.

- Loose oil drain cap.

- Cracks in the transmission pan (solved by replacing the element).

It is worth noting that if there is no or insufficient oil level, the box does not operate at its temperature range. Because in addition to its lubricating properties, this liquid takes on part of the temperature loads. If there are oil leaks, the box may simply overheat.

Advanced tuning

The advanced column includes many modifications at once, among which are tuning the VAZ 2109 engine, replacing shock absorbers, brake pads, discs themselves, and visual modifications, such as replacing bumpers and painting.

It is important to understand that all this makes sense to do only if the car was initially in fairly good condition, and we are now talking to me about individual parts, but about the base - the body and its components

If the car has often spent the winter outside, the process of body rot may eventually begin, which, without proper attention, is the beginning of the end of the car.

That is why, before making any expensive modifications, it is worth doing a thorough inspection of the entire car.

The car jerks when starting, it is impossible to shift into gear

The cause of the malfunction is not always the VAZ-2109 gearbox itself. Repairing it may not save it if the clutch assembly is faulty. But it is this system that interacts with the gearbox and engine. It is through the clutch disc that torque is transmitted from the flywheel to the transmission shaft. Typically, this unit serves at least 120 thousand kilometers. But many “nines” have old-style odometers, which reset to zero at 100 thousand.

It is difficult for the driver to control when this or that part in the clutch has been replaced. If the car jerks at start-up and the transmission is difficult to turn on, most likely the disc has been worn out. The plates wear out on it and the damper springs fly out. The petals on the clutch basket are also bent. We have already said about bearings that they are noisy. All this together affects the behavior of the car on the road.

Tuning the VAZ 21099 suspension is a necessary necessity

Every driver knows that the condition of the suspension has a significant impact on the driving performance of the car. For example, a low-quality shock absorber will double the braking distance. That is why modernizing the suspension of the “ninety-nine” is a topic that will be useful to everyone.

The service life of standard shock absorber struts is very low, and if we take into account the quality of our roads, the situation becomes even more deplorable. Basic tuning involves replacing the factory telescopic hydraulic shock absorbers with two- or one-pipe gas-filled analogues

This achieves improved stability and controllability of the vehicle.

The stiffness of the new shock absorbers will slightly reduce the smoothness of the ride, but you shouldn’t get hung up on this, as you get much more benefits. When choosing new shock absorbers, you should look at the table of interchangeability of shock-absorbing devices. This will allow you to select equipment that fully corresponds to the overall installation dimensions and requirements of your machine.

Standard springs, working in conjunction with shock absorbers, have a number of their own shortcomings, which can only be eliminated by replacing them with new ones. Therefore, we install springs with a progressive action characteristic on the rear axle. This will improve the smoothness of the car and, as a result, overall driving comfort.

Repair features

This process is carried out on the box removed from the car. The operation consists of several stages:

- Removing the dipstick from the gearbox.

- Removing the clutch cable bracket and rear cover.

- Unscrewing the fifth-speed fork bolt, as well as the primary and secondary shaft nuts.

- Removing the fifth gear gear with the secondary shaft fork and synchronizer.

- Removing the thrust plate and bushing from the secondary shaft.

- Removing the fifth gear gear.

- Unscrewing the screws of the secondary shaft thrust washers and bearing retaining rings.

- Removing the plugs, springs and balls of the reverse locks. The process is carried out on an inclined box.

- Unscrewing the mounting bolt and 12 nuts of the transmission housing. The element is separated from the clutch housing with a slotted screwdriver.

After disassembling the VAZ-2109 gearbox, you need to replace all worn elements:

- Bearings.

- Shafts.

- Gears.

- Gear shift rod.

- Seal of axle shafts and shafts.

The VAZ-2109 gearbox is assembled in the reverse order. The crankcase is sitting on the new sealant.

The fundamental principle that the design of the VAZ 2109 gearbox must meet is to achieve an increase in the operational characteristics of the vehicle in conjunction with minimizing fuel consumption. The main tools for implementing these tasks in mechanical transmissions in general, and in the VAZ 2109 manual transmission in particular, are:

Rational selection of the number of gears.

Optimization of gear ratios.

Increase in the quality level of the gear shifting process.

The importance of the latter can hardly be overestimated, since smooth switching guarantees not only a significant increase in the degree of reliability of the vehicle’s systems, components and assemblies, but also a reduction in the driver’s asthenicity (fatigue). The device that ensures smooth shifting is the VAZ 2109 gearbox synchronizer, the diagram of which is presented below.

Gearbox ratio of VAZ 2109

Gear ratios of the gearboxes of these machines: 1 - 3.636; 2 - 1.95; 3 - 1.357; 4 - 0.941; 5 - 0.784; reverse gear - 3.53. Main gears: 2108 and 2109 - 3.9; 21081 and 21091 - 4.13; 21083 and 21093 and 21099 - 3.7 or 3.9.

Replacing the main pair (secondary shaft and differential main gear) in the five-speed gearbox of the VAZ 2108-2112 family, with a gear ratio of 3.7 or 3.94 (standard) to 4.13 for the once produced “chisels” with 1100 engines and a 5-speed gearbox The gearbox opens up the opportunity to improve the dynamics of your car without resorting to boosting the engine.

In the city, fuel consumption will not change, on the highway it is possible to increase by 3% when driving at maximum speed, which is not significant, but the dynamics will noticeably improve, it will be easier for the engine to reach maximum speed, fifth gear will become more efficient, smooth pickup will appear in all gears, it will become It’s easier to get moving, climb steep hills, and you’ll have to change gears less often when driving quietly or when driving in city traffic.

It is important! VAZ dealers have received a circular that actually announces the start of a recall of all VAZ cars equipped with the 2110 gearbox and manufactured before May 2000. The reason is a design defect in the gearbox, or rather a hollow secondary shaft inside of which there is a through channel. A flat snap ring on the output shaft can break the shaft in half. The defect is dangerous: debris gets caught in the gears and the gearbox jams. There have been cases when fragments of the secondary shaft pierced the gearbox housing (the so-called “hand of friendship”). After additional tests, VAZ changed the shape of the retaining ring, which, according to plant representatives, resolved the problem. In fact, the problem was not fundamentally solved, because... only replacing a hollow 2110 gearbox secondary shaft with a solid 21083 can give a 100% guarantee. Unfortunately, the output shafts continue to break. That is why I recommend switching to a 4.13 GP with a solid secondary shaft, I emphasize once again - with a solid one, maybe. There are cheaper options on the market for the 4.13 GP with a hollow secondary shaft 2110. Please do not try to save money; in the end, replacing the gearbox housing with all the stuffing will be significantly more expensive.

PS Why 4.13?! 1. does not require the installation of a rather expensive and loaded 6th row. 2. acceleration dynamics are really improved, without increasing fuel consumption 3. speed at maximum speed will increase by only 500 rpm 4. maximum speed is achieved precisely from 4.13 to 5th and it will in no case be less than standard gearbox, on the contrary, the pair will allow you to turn the engine to maximum speed and accordingly increase the maximum speed. If you repeat the mistakes of “smart mechanics” who recommend installing a pair of 4.3 on a standard row, then you will really lose the maximum speed, due to the fact that the engine speed at maximum speed will increase by about 1000 rpm and the engine will simply “spin.” The gears will be shortened so much that you can start in 2nd, and the first one will turn into a super low-speed gear, like on a good SUV. This option is especially recommended for those wishing to use the machine as a tractor for the development of virgin lands.

To achieve maximum acceleration dynamics on 1.5 liter engines. and above, it is recommended to install an 18-row gearbox with a 3.9 main pair. Thanks to this, you will get 1st long (on it you can accelerate to 60 km/h, which is very convenient in the city, traffic light racing and street racing - this significantly saves time on switching and allows you to significantly get ahead of your opponent) and 2,3,4,5 close shortened gears. This will allow you to keep the engine in the optimal operating range (not lower than the maximum torque speed) and when switching, lose a minimum number of revolutions due to closer gears. Owners of front-wheel drive cars with standard. The gearbox probably knows that even if the engine is cranked hard in 1st gear, when switching to 2nd gear the speed drops significantly and the acceleration dynamics are reduced. The reason for this is that the gap between the gear ratios is too large. The 18th row of the gearbox is designed in such a way as to ensure confident, uniform acceleration in all gears (1st and 2nd are taken as an example, in fact all gears are close together. Since the gears are close together, the load on the synchronizers is significantly reduced (and this one of the most loaded, capricious and fragile elements of the gearbox) and the service life of the gearbox is significantly increased. Suffice it to recall the standard defect of the gearbox 2108-2112: problems with engaging the 2nd gear, since the gear ratios of the 1st and 2nd gears are very distant from each other, and a large the load on the 2nd gear synchronizer is what first of all “kills" it. When a worn synchronizer fails to cope with its duties, it makes an unpleasant noise and when shifting gears a characteristic click is heard, and sometimes a crackling sound, because the ring cannot equalize speed of the shaft and gear. When operating a gearbox with such synchronizers, the gearbox gears very quickly fail because the teeth and splines are chipped. The gearbox begins to hum and howl and subsequently jams. The 18th row is also good because it allows you to save on the main pair , because The GP on which it is installed is 3.9, which is standard for most gearboxes. ...All about transmission in tuning

IT would seem that everything is simple: if you want dynamics, “charge” the engine, increase the maximum power it develops. Here, any more or less savvy tuner will lay out a whole bunch of recipes for you. You can “cut” the cylinders and increase the piston stroke - the working volume will increase. Filling can be improved by refining the shape of the intake and exhaust channels and selecting optimal valve timing. In the end, you can equip the engine with supercharging or the notorious nitros...

But there is one point here that may disappoint many. The fact is that maximum power (the same figure that manufacturers proudly indicate in the technical data of a car) has the least impact on its dynamic characteristics! Why? Because the engine produces its “maximum” under a strictly defined combination of external conditions. Firstly, it must operate at very specific speeds. Therefore, when talking about power, they must indicate the rotation speed at which the engine produces it: if the passport says that the engine develops, for example, 333 hp. at 6000 rpm, then at 5800 or 6200 rpm it will be less.

The second important condition, which is not always met during normal driving, is full load, that is, the throttle valve is fully open. Accelerating with the throttle wide open is no problem. But achieving a combination of both conditions (which means getting maximum power from the engine) is possible only during one almost elusive moment, when the tachometer needle is opposite the cherished number.

“Of course, power during acceleration is not the main thing,” some will think. “Maximum torque is much more important here.” Not at all. The highest torque, like peak power, is achieved only at strictly defined speeds, and during acceleration this mode turns out to be just as short-lived. So, in order for a car to be playful, not just high power and torque are needed. It is also desirable that the engine output remains high throughout the entire speed range. And the main problem is that with internal combustion engines, especially highly accelerated ones, this is incredibly difficult to achieve. And it turns out that a truly dynamic car often turns out to be one that, although not the most powerful, has an engine that operates most of the time in the most favorable modes.

What kind of modes are these? Looking ahead, let's remember the so-called external speed characteristic of the engine - the one that is taken on the stand with the throttle fully open. In principle, it quite accurately reflects the operation of the engine during intense acceleration with the pedal to the floor. At first, as the speed increases, the torque and power gradually increase. Further, at a certain rotation speed (for an “average” engine this is 3500-4500 rpm), the torque reaches its maximum and begins to gradually fall. But the power (it is proportional to the product of the current torque and the rotation speed) continues to increase - the speed is growing! Ultimately, their growth ceases to compensate for the drop in torque, and the power also begins to decrease - you can still “turn” the engine further (the limiter will work a little later), but it is useless.

The practical benefit of knowing the nature of a particular motor is this. It turns out that if the driver manages to constantly keep the tachometer needle in the interval from the maximum torque revolutions to the maximum power revolutions, then the acceleration will be the most intense. And why, having mentioned the external speed characteristic, did I make a reservation? that we are a little ahead of the curve - doesn't it have something to do with dynamics? It has, and what else. But about engines and methods for increasing their power - a little later. And today we will remember the units that allow this power to be used correctly. That is, about the transmission.

ORDINARY ARITHMETICS

So, for the best acceleration dynamics, the transmission should allow the engine to operate in the “right” zone of the tachometer scale for as long as possible. In principle, this is not difficult to achieve: you just need to ensure that the gear ratios of each gear are close to each other. Then, when shifting “up,” the revolutions will not drop much, the engine will again be “in the moment” and will be able to quickly accelerate the car. The “close” gearbox steps will also help when shifting “down”: even at a relatively high speed, if necessary, you can safely engage a lower gear and make acceleration more intense, without risking jumping into the red zone on the tachometer.

Of course, production car designers know this as well as you and I. But the rows of gear ratios of standard gearboxes often have huge “holes” between adjacent steps. For example, the most characteristic defect in the gearbox of VAZ “nines” and “tens” is wear of the second gear synchronizer. And it arises, among other things, because there is a large difference between the gear ratios of the first and second stages, and the synchronizer has to equalize the sharply different angular velocities of the primary and secondary shafts. The driver also gets it: in order to provide the car with any acceptable reserve of traction after switching to second gear, you need to “unscrew” it thoroughly while still in first, listening to the roar of the engine.

It is clear that VAZ engineers selected such a series neither out of malice nor out of good life. After all, a “civilian” car must not only have acceptable dynamics, but also satisfy many other requirements. Firstly, he must confidently develop the maximum speed available for a motor of a given power. To do this, the gear in which he reaches it must be quite “long”, with a small gear ratio. Secondly, the car must confidently move away on a steep climb with a full load, and this requires “short” low gears.

The requirements for the efficiency and environmental friendliness of machines make life very difficult for designers. Back in the seventies, during the oil crisis, step-up “upper” stages in boxes came into fashion. The idea was this: maximum speed should be achieved, for example, in fourth gear, and fifth would be, as it were, “super-high” - for leisurely, economical movement without sudden acceleration. We still feel the echoes of this decision, which is completely unacceptable for modern cars with small and “inflexible” engines. For example, fifth gear on the same VAZ cars turns out to be absolutely useless: in it the car is completely deprived of the traction reserve necessary for overtaking and changing lanes. The savings turned out to be illusory, but the dynamics suffered greatly.

Indeed, on low-power vans, a number of gear ratios are already “stretched” beyond measure (for confident starting with a load, a “short” first gear is required here), and the “extra” gear, vitally necessary for bringing the stages closer together, turned out to be unused.

How to deal with this? There is only one way out: while preserving the box body (remaking it is too expensive), re-manufacture the original shafts and gears. This work is extremely labor-intensive and therefore expensive. Somewhere in America, a person who wanted to change the gear ratios of the standard transmission of his Mercedes would be looked at as if he were crazy. And for owners of domestic cars there is one very pleasant circumstance: in our country, experience in this kind of alterations has been accumulated, and considerable. Here, as usual, motorsportsmen were in the vanguard: a huge number of different series and main pairs were developed for rally, cross-country and “ring” - primarily for front-wheel drive Tolyatti cars.

A little later, the art of creating unique units became popular - numerous options for tuning transmissions for “eights”, “nines” and “tens”, developed using sports experience, appeared on the market. There are many different rows now offered: “fifth”, “sixth”, “seventh”, “eighth”, “eleventh”, “eighteenth”... They differ, naturally, in their gear ratios, and therefore in the character they impart to the car. For example, the “eighth” and “twelfth” rows are close to the serial ones and, together with serial or slightly boosted engines, are well suited for relatively leisurely driving. The “sixth” and “seventh” are a completely different matter. Both have six stages, are perfectly matched with the most “charged” engines and allow you not only to drive dynamically, but also to compete.

Despite the differences, all tuning series are built, in general, according to the same principle. The lower gears here are significantly “longer,” that is, faster than those of serial gearboxes. And the higher ones, on the contrary, are “shorter” and closer to each other. This selection of gear ratios slightly complicates the process of starting from a stop, but then the behavior of the car changes in a simply fabulous way: already in first or second, having “twisted” the engine to the cutoff, you can accelerate to a speed where fourth, fifth and even sixth gears would be quite appropriate! Fast driving becomes no less interesting. For example, even if fifth gear is already “in good shape” and the speed is quite high, you can easily switch not even to fourth, but immediately to third gear and make acceleration even more intense.

When installing a new “filling” into the box, you just need to remember that not every row will be able to “get along” with the standard final drive. However, a lot of options have also been developed here: tuning “pairs” with a gear ratio of 4.33 can be installed in a standard crankcase; 4.5; 4.7; 5.0, and even 5.125. You can also install a so-called short “slide”, which changes the gear ratio of the shift drive. It’s not expensive, but it will be much easier to operate the box.

Are there options even more extreme than simply replacing a row? It turns out that the Russian market, like Greece, has everything. For a separate and quite considerable fee (about $3,000), those interested will be able to assemble a real racing cam “six-speed.” This box allows riders to shift without pressing the clutch and significantly reduces acceleration time. But to ride a “cam”, money alone is not enough, you also need to know how to use it. And such a transmission makes a lot of noise - about the same as a serial one without oil. However, there are cam boxes that do not require special “racing” skills (though, unfortunately, they are not installed on domestic cars).

A similar system under the brand name SGSM was developed by the Moscow company Sportmobile specifically for Mitsubishi Lanсer Evolution cars. It was created on the basis of the Hewland sequential gearbox, which is often installed on all-wheel drive rally cars. And the salt of the Moscow design is in the cleverly organized engine control: the Motec microprocessor “brain” regulates the engine speed during gear changes, independently of the driver. Moreover, it does this in such a way that the engagement of the claw clutches in the box, despite the “closed” clutch, occurs without any shocks or impacts. By the way, until now we haven’t said anything about clutch. Are there really no problems with it when tuning transmissions? If we are talking about domestic cars, “charged” without the use of supercharging, then we can say that no - 150-170 Nm of torque, developed by the best tuning engines in VAZ cars, is easily digested by the standard mechanism.

We can only recommend using a high-quality “basket” and driven disk from a reliable company - for example, Valeo. But what problems really happen with are differentials...

NO SLIPPING

It would seem, what problems could there be with them? After all, most ordinary cars drive just fine with ordinary conical “differs”. But the beauty of tuning as a process lies in the fact that its fruits - cars are not at all ordinary. And when “eights” with more than 120-horsepower engines appeared, it became obvious that realizing such power through two drive wheels was far from an easy matter.

Of course, the best way out of this situation is all-wheel drive. But its use would entail a complete redesign of the entire car. A solution was found in the use of an albeit not so radical, but long-proven solution - a self-locking cross-axle differential. Unlike a traditional conical wheel, it continues to rotate both wheels even when one of them is on a slippery surface and slips.

Naturally, this decision also came from sports, where the engines are more powerful than “civilian” ones, and the conditions of tire adhesion to the surface are often worse than on public asphalt roads. There are many options for locking, but the most widely used is the Quife type worm mechanism. The principle of its operation resembles that of a conventional differential, but the satellites here are not conical, but cylindrical, and have spiral teeth. When the wheels rotate at very different frequencies, the forces generated on the teeth of the satellites press their ends against the differential housing and prevent them from turning - this reduces wheel slip.

What does this give? First of all, a sharp increase in the traction properties of the car. After all, with a lock in the transmission on a slippery road (and with a powerful engine, even dry asphalt sometimes seems very slippery), not one wheel “rows”, as is the case with a free differential, but both at once. But this effect lies, so to speak, on the surface. But blocking has one more property, which is not so obvious. It turns out that it greatly affects the handling of the car.

Imagine what will happen if you suddenly open the throttle in a fast corner in a powerful front-wheel drive car. That's right, the drive wheels will slip. The nuance is that a conventional bevel differential, having torn off the inner, unloaded wheel, protects the outer wheel from stalling, which “fuels” the car into a turn.

With a lock, the situation is different - the breakdown occurs, albeit later than with a free differential, but it happens much more sharply and on both wheels at once. Naturally, the car strives to go straight - the control forces on the broken wheels tend to zero. This mode of movement is called front axle drift. What if the rear starts to skid? This is where the locking help will come in very handy: when the driver competently “catches” the car by turning the steering wheel in the direction of the skid and increasing the fuel supply, the car with such a differential “rakes away” much more willingly.

In conclusion, I would like to remember this. All the modifications described are not an end in themselves and not a way to stand out from the crowd, but an accurate and subtle tool that allows an active and experienced driver to implement a certain driving style. Are you okay with this? Do you know what you want from a car? Then until the next meeting, when we will talk about methods for modifying engines...

We create a salon for people

Tuning the interior of the VAZ 21099 begins with sound insulation. Work is being carried out on the bottom and wheel arches of the body

In addition, increased attention is paid to reliable fastening of the door trim. Most often, the sources of squeaks are located in the doors

Only after carrying out the described work can you begin to improve the dashboard and replace the steering wheel.

Note that the standard steering wheel from the “ninety-nine” is quite comfortable. Experts believe that the best tuning option in this case is to install a leather braid. This will improve hand contact with the surface of the steering wheel. And if you are tired of the old steering wheel, then the market offers a huge selection of sports steering wheels for every taste and color. But remember that the steering wheel is an important element of safe movement, so some design delights should be rejected. However, the interior of 21099 with the unusual steering wheel shown in the photo looks very, very chic...

The interior of any car becomes cozy and comfortable if you don’t spare money on upholstery with high-quality material. The cost of working with the material varies between 20 - 30 thousand rubles. But the following things take on a new look: the ceiling, doors, body pillars, handbrake lever, gear shift, dashboard, speakers and rear shelves.

From a practical point of view, it is worth recognizing the anti-slip floor plate and pads on the brake, clutch and gas pedals as useful. This will protect the interior upholstery during periods of precipitation. The final stage of interior tuning is comfortable seats equipped with lateral support. The comfort of the seats opens up new possibilities for placing speakers, while the quality of music perception increases significantly.