VAZ 2114 cars were equipped with several types of engines: 8 valves of 1.5 liters and 1.6 liters, as well as 16 valves of 1.6 liters. Until 2005, January 5 series ECUs were installed on the motors, then the manufacturer updated the controllers. Since 2006, these machines have been equipped with a January 7 series ECU, or imported analogues of BOSCH 7.9.7. Why do you need this information? Depending on the version of the ECU, mass air flow sensors on the VAZ 2114 were of different types. This causes some difficulties when replacing the sensor, but detailed information can be found in the car's passport.

- Air flow sensors of the 004 series were installed on early versions of cars.

- Then an updated mass air flow sensor was introduced for the VAZ 2114, series 037. The measuring channel on it was modified to reduce air flow pulsations. The new flow meter with modified characteristics is fully compatible with old ECUs with an oxygen sensor, so the replacement did not lead to changes in calibrations in the fuel-air mixture formation system.

- After switching to the January 7 series and BOSCH 7.9.7 controllers, we also had to change the air flow sensor on the VAZ 2114. The new version with index 116 is produced with an updated design. The calibration of the sensor has also been updated, so there is no backward compatibility.

The BOSCH 116 air sensor has many analogues, including the Russian Itelma and Avtel.

Information: There is an opinion among VAZ 2114 owners that the air flow sensor of the 116 series is better than the 037, and it can be replaced to increase engine output. In fact, this is not the case; the calibration of the mass air flow sensor is developed for a specific motor and is taken into account when programming the ECU.

As an example, the graph in the illustration:

Obviously, when the air flow rate is more than 100 kg per hour, the voltage that the VAZ 2114 series 116 air sensor produces changes by 0.2 volts. When the data is read by the engine controller, this makes a significant correction in the proportions of the fuel mixture.

What is a DMRV?

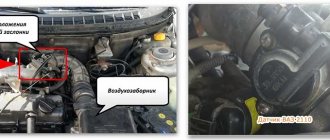

Air flow meter location.

The air flow meter of the VAZ-2110-2112 (as well as all Togliatti injection engines without exception) is installed immediately behind the air filter at the entrance to the intake tract.

Its task is to measure the amount and temperature of the air that the engine consumes.

These readings are of paramount importance for preparing a flammable mixture . The flow meter sends data to the engine ECU, which in turn instructs the injectors to prepare a richer or leaner mixture. This is without subtleties.

Sensor device

The sensor itself is a combination of two sensors - control and working, as well as a heating resistor.

View of the flow meter from the grid side.

The sensor is disassembled.

The platinum thread is visible in this photo.

As a result, air flow and temperature are converted into electrical impulses understandable to the ECU. This is a very gentle and accurate device; it allows you to calculate the cyclic filling of the cylinders with air and updates the parameters every 0.1 s.

Mass air flow sensor diagram.

The working body of the sensor is a heated platinum thread. It heats up to operating temperature (from 100 to 1000 degrees), and when air enters, it cools down. The amount by which the filament temperature drops is converted into an electrical signal and, based on this value, the ECU calculates the mass and temperature of the air entering the combustion chamber. And based on this data, it prepares the required portion of fuel. In short - yes.

Due to a breakdown of the mass air flow sensor, the operation of the entire engine is disrupted: I show you how to check it yourself

Greetings, dear readers!

We all try to monitor the condition of our car, especially its heart - the engine.

It can be very unpleasant when, due to a small part, the operation of, for example, the entire motor is disrupted.

- Indeed, there is a mass fuel flow sensor (MAF), on which engine power and fuel consumption greatly depend.

- This sensor is located under the hood, between the air filter and the pipe, and it is responsible for sending data on the amount of absorbed air to the control unit, where its supply is already regulated.

Today I will tell you how you can test this sensor yourself without any equipment.

Functions of mass air flow sensor

What is the VAZ 2114 mass air flow sensor and what functions does it perform? The primary task of the regulator is to create arrogance from air and fuel vapors.

The regulator can measure two interconnected parameters, namely:

- reaction time;

- volume of air used.

In accordance with the information received, the correction device determines the required volume of components to create the mixture. If incorrect data is provided, the mixture will not be able to correspond to the operating mode of the power unit; accordingly, its power may decrease and fuel consumption may increase.

DMRV 2114 device diagram

What happens if the mass air flow sensor is faulty?

I’ll say right away that the mass air flow sensor is almost never repaired, but simply replaced with a new one.

- As for the device, the DMRV is not at all complicated. The sensor consists of a housing, inside of which a hot-wire anemometer is located (responsible for measuring air flow).

It is easy to damage this sensor; it can simply fail during installation, but most often it breaks due to old age.

When the mass air flow sensor is faulty, it supplies incorrect data to the control unit, due to which air does not enter the combustible mixture in the required volume.

Purpose and principle of operation

Many car owners are concerned about how much it costs to purchase such a sensor. It turns out that the DMRV 2114 has a considerable cost, it varies between 2-3 thousand. In this case, you can use both imported products and domestically produced parts. You shouldn’t be surprised that there are corresponding reviews about domestic models.

But you shouldn’t always trust reviews; it’s better to try the products in practice. Although you can find a lot of negative reviews about domestic sensors, they are more affordable.

This sensor allows the engine to operate in different operating modes, involving different loads. If we consider the operation of the device, it consists in creating a working mixture of air and gasoline. More precisely, the mixture includes gasoline vapors. The direct task of the product is to measure two indicators that are interconnected:

- Reaction time.

- The amount of air that is consumed for the reaction.

If the measurements are accurate, the device can determine what mixture the engine requires. This allows the system to obtain information about the required proportions. There are also situations when the sensor does not work correctly, producing incorrect values.

In this case, the mixture created in the system will not correspond to the current operating mode. As a result, power may decrease and consumption will likely increase. Among the possible consequences may be a deterioration in the dynamics of the car and a disruption in the response of the car.

Attention! The response of parts from different manufacturers may vary significantly. It is important to take this point into account when checking the operation of the sensor.

Checking the mass air flow sensor

The mass air flow sensor is checked using special diagnostic devices, but not every car owner has such an expensive gadget. Therefore, there is another fairly effective method for checking the mass air flow sensor - checking with a multimeter.

To check, you will need an electronic multimeter.

The verification is carried out in two stages. The first stage is checking the sensor control circuit. The second stage is checking the sensor itself. So, let's start checking.

Checking the power circuit

- We set the multimeter switch to the mode for measuring direct voltage up to 20V (as shown in the photo).

- Turn on the car ignition.

- We connect the black wire of the multimeter to the motor housing, and connect the second red wire to pin No. 2 on the sensor power connector (there is a number on the plug). The voltage between these points (case and pin No. 2) must be at least 12V.

- Then we carry out the measurement in the same way, only with pin No. 4. The voltage in this area must be at least 5V.

If the readings in your case vary and are significantly less than the required values, then the battery is most likely discharged.

If there are no readings at all, then it is necessary to check the integrity of the sensor’s power circuit.

Sensor check

After the power circuit has been checked, connect the connector back to the sensor.

- We set the multimeter switch to a voltage measurement value equal to 2000 mV or 2V (it’s different for all multimeters).

What air flow should be on a VAZ 2114?

A 1.5 liter VAZ 2114 engine with a working mass air flow sensor at 850-950 rpm consumes from 10±0.5 kg of air per hour of operation, and at 2000 rpm - from 19 kg to 21 kg. If the amount of air consumed at the same speed decreases, the dynamics of the car also decreases, but fuel is saved. Conversely, increased air consumption leads to increased dynamics and higher fuel consumption. In this case, it may be difficult to start the engine in cold weather. If the sensor readings deviate from the real ones by 2-4 kg, the engine will begin to become very capricious and “dull”. Disabling the sensor will force the motor to continue operating in emergency mode.

VAZ 2114 car models

| Car model | Option code | Body type | Execution | Engine | Engine capacity | Toxicity standards | Controller |

| VAZ 2114-20 | 10 ->06.05 | Hatchback | Standard | 2111-86 | 1,5 | R83-02 | 2111-1411020-60 2111-1411020-61 2111-1411020-62 |

| 30 | Hatchback | Standard | 2111-80 | 1,5 | Euro-3 | 2111-1411020-80 2111-1411020-81 2111-1411020-82 | |

| 40 | Hatchback | Standard | 2111-75 | 1,5 | Euro 4 | 2111-1411020-30 | |

| 110 ->02.05 | Hatchback | Standard | 2111-86 | 1,5 | Euro 2 | 2111-1411020-40 | |

| 120 | Hatchback | Standard | 2111-80 | 1,5 | Euro-3 | 2111-1411020-80 2111-1411020-81 2111-1411020-82 | |

| VAZ 2114-21 | 10 ->06.05 | Hatchback | Norm | 2111-86 | 1,5 | R83-02 | 2111-1411020-60 2111-1411020-61 2111-1411020-62 |

| 30 | Hatchback | Norm | 2111-80 | 1,5 | Euro-3 | 2111-1411020-80 2111-1411020-81 2111-1411020-82 | |

| 40 | Hatchback | Norm | 2111-75 | 1,5 | Euro 4 | 2111-1411020-30 | |

| VAZ 2114-22 | 10 ->06.05 | Hatchback | Lux | 2111-86 | 1,5 | R83-02 | 2111-1411020-60 2111-1411020-61 2111-1411020-62 |

| 30 | Hatchback | Lux | 2111-80 | 1,5 | Euro-3 | 2111-1411020-80 2111-1411020-81 2111-1411020-82 | |

| 40 | Hatchback | Lux | 2111-75 | 1,5 | Euro 4 | 2111-1411020-30 | |

| VAZ 2114-22 | 110 ->02.05 | Hatchback | Lux | 2111-86 | 1,5 | Euro 2 | 2111-1411020-40 |

| 120 | Hatchback | Lux | 2111-80 | 1,5 | Euro-3 | 2111-1411020-80 2111-1411020-81 2111-1411020-82 | |

| VAZ 21144-20 | 10 | Hatchback | Standard | 11183-30 | 1.6 | Euro-3 | 21114-1411020-10 21114-1411020-11 |

| 20 | Hatchback | Standard | 11183-20 | 1,6 | Euro 2 | 21114-1411020-30 21114-1411020-31 21114-1411020-32 | |

| 110 | Hatchback | Standard | 11183-20 | 1,6 | Euro 2 | 21114-1411020-30 21114-1411020-31 21114-1411020-32 | |

| VAZ 21144-22 | 10 | Hatchback | Lux | 11183-30 | 1.6 | Euro-3 | 21114-1411020-10 21114-1411020-11 |

| 20 | Hatchback | Lux | 11183-20 | 1.6 | Euro 2 | 21114-1411020-30 21114-1411020-31 21114-1411020-32 | |

| 110 | Hatchback | Lux | 11183-20 | 1,6 | Euro 2 | 21114-1411020-30 21114-1411020-31 21114-1411020-32 |

Diagnosis of failure

If the air flow sensor breaks down, the symptoms of the malfunction can be very different. First of all, fuel consumption will increase; another symptom may be floating engine speed.

In addition to these signs of failure, the following can be identified:

- failures in the operation of the power unit;

- slower car acceleration, poor dynamics;

- the power unit can turn off when changing gears;

- decrease in power and increase in gasoline consumption;

- a heated internal combustion engine is more difficult to start;

- the Check light appears on the control panel.

The last symptom may not appear if the controller fails completely. How to check the MAF on your own? Diagnostics consists of identifying the impulse.

If the impulse is low, this indicates:

- possible short circuit or broken wiring;

- regulator failure;

- incorrect operation of the ECU;

- oxidation of contacts;

- that the controller is not connected.

Clogged air flow regulator

What temperature sensors are installed on the VAZ 2115

Modern cars are equipped with controllers to receive data of a certain content and send impulses to the electronic control unit for further processing and decision-making. Sensors are used in almost all systems and mechanical components of a vehicle to monitor:

- temperature of the environment in the system;

- amount of fuel;

- air pressure and flow;

- exhaust gas composition;

- outside air temperature.

There are not many temperature sensors installed in the VAZ 2115 car.

DTOZH (coolant temperature sensor).

It is characterized by simplicity of design and durability. It is a resistor that changes the resistance value depending on fluctuations in the temperature of the liquid phase: at low temperature readings, the resistance will be high and, vice versa.

The electronic unit uses information received from the thermostat to control the crankshaft speed and the air-fuel mixture ratio, as well as to select the ignition timing.

In most cases, temperature sensors fail due to internal problems, sending false information to the control unit. This can lead to problematic engine starting and incorrect operation of the machine in idle mode.

The thermocouple is a thermistor, providing information about the state of the antifreeze. When the element is strongly heated, its resistance sharply decreases, and when cooled, on the contrary, the resistance value will increase. The sensor is located next to the cylinder block near the thermostat. The impulse from the controller is transmitted to the car’s on-board computer and the radiator cooling fan.

Possible reasons for a non-functioning coolant temperature sensor:

- contact break inside;

- violation of tightness;

- breakage of supply electrical wires. They can be caught by a cable coming from the gas pedal at a very close distance.

As a result, the ECU assumes a decrease in temperature and gives an indication to pump in additional air. And after a while the driver will receive a message about antifreeze overheating. A faulty sensor in hot weather, giving false information to the unit, can cause a decrease in engine performance or its complete stop.

Mass air flow temperature sensor (MAF).

Another important monitoring device is the engine mass air flow sensor. It is installed directly in the fuel system of the power plant, namely in the incoming fuel line.

Most car owners consider this sensor to be the most important because it is responsible for proper fuel injection. If this element begins to act up, then the light on the dashboard starts to light up.

The main signs by which a sensor is judged to be faulty:

- reduction in engine power level;

- drop in speed when driving;

- fuel consumption increases;

- malfunctions in the power plant.

You can determine whether the device is operating correctly in the following ways:

- disconnecting the device from the system;

- during external examination;

- using a multimeter.

Often, the presence of contamination inside the device is a direct sign of a malfunction. As a rule, the problem occurs when the car owner forgets to change the air filter on time. Oil leaks also significantly reduce the life of the controller.

Then it is necessary to dismantle the sensor itself. It's easy to replace the sensor. Simply unplug the connector.

Although the sensor cannot be repaired, some drivers manage to clean it. To do this, you will need a soft brush, a Phillips screwdriver and carburetor cleaner.

DNTV

It was securely hidden behind the front bumper of the car, so much so that not every experienced driver is able to immediately detect it. It has the same functions as DTOZH and measures the air temperature “outside” the car.

| Gearbox type | Price in rubles | Price in rubles |

| New | Major renovation | |

| 01M | From 150000 | From 89000 |

| TF-61SN, TF-62SN | From 150000 | From 85000 |

| DQ250\02E, DQ500 (0BH\0BT) | From 150000 | From 88000 |

| *price indicated as of April 2022 |

Causes of malfunction

Common to most domestic cars, the reason why the VAZ 2114 air flow sensor breaks is hidden in the crankcase ventilation system. It has two circuits that ensure operation with the throttle valve open or closed. If the throttle is buried, crankcase gases are discharged along the line (d=1.5 mm) into the space available behind it. A certain percentage of these gases accumulates in the idle line, where it comes into contact with the film-coated MAF resistor. It is also sensitive to fluctuations in the gas mixture in the intake system. The resin settles on the surface of the resistor, and the sensor begins to “lie.” Because of this, the idle air control sticks, and it begins to jam when starting the engine.

We recommend: 6 tips on how to deal with icing on car windows

Lada Largus does not start, the starter turns

To start a car engine, it is necessary to have a spark and a fuel mixture in the cylinders at the right time. Problems with starting the Lada Largus engine may occur if one or more elements of the vehicle systems fail. This article lists the reasons and solutions for cases when the starter turns, but the engine does not start.. Possible malfunction

| Diagnostics | Remedies | |

| There is no gasoline in the tank | On the instrument cluster the fuel level arrow is at zero. | Pour gasoline |

| Battery is low | The voltage at the battery terminals with consumers turned off is less than 12V. When trying to start the engine, a cracking noise is heard from under the hood. | Charge the battery or replace it with a new one |

| Oxidation of battery terminals or wire terminals, their fit is not tight | When you try to start the car, the voltage in the on-board network drops much more than at the battery terminals. In this case, a crash may be heard under the hood. | Clean the contacts, lubricate them with petroleum jelly and tighten the terminals |

| Unreliable connection of electrical circuits of engine control and power supply systems | Check the connections of the connectors and the reliability of the contacts in the blocks. | Fix faulty wire connections |

| Increased resistance to rotation of the crankshaft (scores on the shafts, bearing shells, cylinder-piston parts, deformation of the shafts, frozen engine oil, jammed generator, jammed coolant pump) | The crankshaft turns slowly. If the engine is started in severe frost, and the engine was working properly the day before, then most likely the engine oil has frozen. If you hear extraneous noise when starting the engine, check the free rotation of the pump and generator pulleys. | Use the recommended engine oil. Repair the engine. Replace the pump and generator. |

| Malfunction in the ignition system | Check for spark. | Check the circuits and devices of the ignition system. Replace faulty system elements. |

| HV wires are connected in the wrong order or the wire is disconnected (on K7M engine) | Inspect. | Connect the wires in the correct order |

| The timing belt is broken or the belt teeth are cut off | Open the front timing cover and check. | Replace timing belt |

| Disturbed valve timing | Check the marks on the crankshaft and camshaft pulleys. | Set the correct shaft position |

| Malfunction of the ECU (electronic engine control unit), its circuits, crankshaft position sensor or coolant temperature | Check the supply of +12V to the ECU, the sensor circuit, and the absence of damage to the sensors themselves. | Replace ECU, sensors. |

| The idle air regulator (IAC) or its circuits are faulty | Check IAC. When starting the engine, lightly press the gas pedal. If the car starts and stalls when you release the gas pedal, then the sensor is faulty. | Replace sensor |

| The fuse is blown or the main relay of the control system is faulty | Check fuse and relay. | Eliminate the cause of the blown fuse. Replace fuse and relay |

| Fuse blown, fuel pump relay. Circuit, relay or pump is faulty. | When the ignition is turned on, there is no sound of the pump running. Check the fuse. Apply voltage to the pump from the battery. | Clean contacts, replace faulty circuits, replace fuse, pump and relay. |

| The fuel filter is dirty, the water in the fuel line is frozen, the fuel line is damaged | Check the pressure in the fuel rail and the condition of the fuel lines. | Replace the filter, blow out or replace the fuel lines. |

| Insufficient pressure in the fuel rail | Check the pressure in the fuel rail, the pump strainer and the condition of the fuel lines. | Clean the filter. Replace the pump, fuel pressure regulator (RDT) |

| Faulty injectors or their power supply circuits | Check the injector windings with an ohmmeter. Check the chains for breaks. | Replace injectors, replace chains |

| Air leak into the intake tract | Inspect the joints and fittings of the hoses and clamps. During start-up, turn off the vacuum brake booster (VUT) and plug the receiver fitting. | Eliminate air leaks, replace vacuum booster |

Lada Largus starts and immediately stalls:

- Ignition coil electrical connections are loose or damaged.

- Insufficient pressure in the fuel rail.

- The connections of the intake tract parts are leaking (catalytic manifold or intake manifold receiver).

- The engine control system is faulty. Run diagnostics.

Symptoms of a problem

A non-working VAZ 2114 mass air flow sensor leads to the appearance of a number of symptoms in the behavior of the injection engine. The malfunction appears gradually, starting with an increase in fuel consumption and floating speed, ultimately destabilizing engine operation.

From personal experience using a front-wheel drive car as an example, I can say that I encountered the following problem: first the injector icon came on, then the speed began to fluctuate greatly and fuel consumption almost doubled.

You can calculate a non-working VAZ 2114 air sensor using the following criteria:

- failures when idling and under load;

- The internal combustion engine stalls when trying to change gear;

- decreased dynamics, the car accelerates slowly;

- fuel consumption increased;

- engine power has dropped;

- Badly ;

- The Check Engine signal appears.

If the mass air flow sensor is already dead, the Check Engine light may not come on. Then the malfunction can be determined by the error generated by the on-board computer. Diagnostics of the MAF signal level will also help. A low level may indicate the following:

- There is no MAF connection;

- malfunction in the sensor connection circuit (break);

- the ground in the connection circuit is broken or oxidized;

- the signal wires are broken or incorrectly connected, perhaps they are short-circuited;

- engine control unit malfunction;

- DMRV does not work.

If you notice the above signs, do not rush to buy a new sensor. It is by no means the cheapest and will cost 1500-4000 rubles. First of all, make sure that this is the reason. You can check and clean the old one at a service center or yourself if you have the necessary equipment.

DMRV error code

The following errors may indicate a malfunction in the operation of the mass air flow sensor:

- P0100 - damage to the electrical circuit connecting the sensor. To eliminate the breakdown, you need to check the wiring for integrity, since accidental disconnection of the connector or damage to the electrical contacts is possible.

- P0102 - the vehicle control unit began to receive a low signal, which was recorded at the input of the mass air flow sensor power line. To eliminate the cause of the breakdown, it is necessary to check the electrical wiring and the insulating layer of the cable; oxidation of the contacts of the wiring connector (the so-called chips) is possible.

- P0103 - critically high signal detected at the input of the mass air flow sensor power line. If the cause of the malfunction is not the wiring, then a visual inspection and cleaning of the flow meter will be required or it will have to be replaced with a new one.

Characteristic signs of failure of the mass air flow sensor

Symptoms of DMRV malfunctions:

- Unstable engine operation at idle;

- reduction in acceleration dynamics;

- spontaneous change in speed in all operating modes;

- difficulty starting;

- Check Engine light turns on.

If an additional trip computer is installed on a VAZ 2114 car, then during diagnostics, in addition to direct sensor errors, codes indicating misfires and lean mixture conditions are possible.

Symptoms of a malfunction of the mass air flow sensor on a VAZ-2110

Now about the symptoms of a malfunction of the mass air flow sensor. You need to understand that you can definitely blame the mass air flow sensor only after accurate computer diagnostics of the engine management system. Even the on-board computer can easily make mistakes. However, we will try to identify the breakdown without involving specialists.

Symptoms of a sensor malfunction may coincide with symptoms of other malfunctions :

- Increased or floating idle speed.

- It is impossible to adjust the CO level at idle.

- The engine stalls immediately after starting, the speed is maintained only when the throttle is open.

- Increased fuel consumption.

- The Check Engine light comes on.

- Dips when changing speed, loss of power and dynamics.

The symptoms, as we see, are standard for any malfunction of the power and ignition systems. This means that a more detailed check and verification of the parameters with the nominal ones is necessary.

Check: parameters and compatibility

Sensor for Bosch M 7.9.7 controller – number 0 280 212 116 according to the VAZ catalog.

The difficulty in calculating the parameters and ratings of the sensor lies in the fact that different devices with different ratings were installed at VAZ at different times and on different engines . These ratings were programmed into the electronic control unit and if we install a sensor of a different type (although visually it may be exactly the same), the control system will no longer work correctly. Dozens were equipped with sensors from GM, Bosch, Siemens , and a domestic sensor from Arzamas or Saratov .

The calibration for each of them is different. Only after 2004 did VAZ decide on the type of sensor and its ratings - this is a Bosch device of the HFM5 type in three modifications:

- the first was the mass air flow sensor HFM5-4.7 , according to the Bosch catalog its number is 0 280 212 004, and according to the VAZ catalog it is 21083-1130010-01;

- HFM5-4.7 with article number 0 280 212 037 (21083-1130010-10 according to the VAZ catalogue);

- HFM5-CL , catalog number 0 280 212 116 or 21083-1130003-20 according to the VAZ book.

Peculiarities

We conclude that the sensor is selected not by the number of valves or engine size, but solely by the firmware version and ECU model.

Bosch sensor (21083-1130010-01) for controller January version 5.1.

For example, for the Bosch M7.9.7 ECU it is necessary to use the Bosch mass air flow sensor 0 280 212 116, and for the January controller version 5.1 - only Bosch 21083-1130010-01. That is, even if a sensor is installed from the factory that does not correspond to the ECU firmware, you cannot expect correct engine operation and normal fuel consumption. By the way, there are often cases when sensors were installed from the factory that do not correspond to the firmware version. Therefore, the first check is for compatibility. And then we take a multimeter and go into battle.

Is it possible to do without a mass air flow sensor?

Of course, you can refuse, but the “check” indicator will work constantly, and the engine will continue to work. If the ECU firmware program is new, it may not see the signal and will increase the idle speed. The program for ensuring damage to the sensor entails either a drop in dynamics or high fuel consumption. But this happens on relatively recent versions of the program. If an error occurs, this is an important reason to check the sensor. First you need to measure the voltage.

At the first manifestation of a problem with the mass air flow sensor on a VAZ 2114, there is no need to run to the store and purchase a new device. After all, the price of a new sensor fluctuates around 4,000 rubles. But postponing inspection and repair until later is also not an option. Make sure that the engine is running poorly due to air flow and try to repair it or send it for service. The sooner you identify the causes, the greater the chances of avoiding serious damage. Buy a multimeter; it will help you diagnose yourself much faster. Do not forget to regularly check the ECM and do not ignore any malfunctions in the operation of the mass air flow sensor.

We check the mass air flow sensor on a VAZ-2110 with a multimeter

The sensor block, the first wire may not be there - this is normal.

To do this, we need to understand the pinout and the sensor connection diagram. As you can see, the block has only five wires:

- + 12 Volt.

- + 5 Volts.

- Total ground (green wire).

- Air temperature output signal.

- Air flow signal output (yellow wire).

Electrical diagram for connecting the mass air flow sensor.

The pinout may differ in different firmware versions and on different sensors. Everything is clear with the first two contacts - take a multimeter and check the presence of voltage when the ignition is on. If there is no signal, we look for the cause either in broken wires or in poor contact. Now we check the main indicator - the accuracy and magnitude of the air flow signal. By the way, this can be checked without a multimeter, using the on-board computer, if one is installed:

- We go to the menu, look for sensor parameters.

- Find the voltage Udmrv.

- The rating for all of the above modifications is from 0.996 to 1.01 V.

The platinum thread gets tired over time and distorts the impulse upward. A change of even one hundredth of a Volt is unacceptable. If the computer is not installed, we use a multimeter. We check the voltage between 3 and 5 (minus) contacts , setting the measurement limits on the multimeter to 2 V. Turn on the ignition, but do not start the engine.

The scale shows 1.00 - the sensor is in excellent condition.

On a scale of 1.26 – the sensor is “dead”.

Check table

We evaluate the result using this table:

| 0.99-1.02 V | The condition of the air flow sensor is excellent, close to new |

| 1.02-1.03 V | Sensor in good condition |

| 1.04-1.05 V | The platinum thread is worn out, you need to think about replacing the sensor |

| More than 1.05 V | The sensor does not work, urgent replacement is necessary |

Examination

There are several ways to check the functionality of the flow sensor. But first you need to determine where the desired object is located.

And our hero is in the engine compartment. Find the air filter pipe there. It is on this that the mass air flow sensor is located, which monitors the air flow passing through the filter. Replacing it is simple - just dismantle the device by removing it from its fasteners and putting a new one in place.

Now regarding the verification.

- Disconnect the sensor by disconnecting the wiring harness from the connector. Press the latch at the bottom and you'll be good to go. Now start the engine and raise the speed to at least 1500 rpm. By turning off the sensor, the car will perceive this as an emergency condition, so the mixture will be prepared depending on the current throttle position. Drive a short distance. If the car accelerates faster than usual, the mass air flow sensor has definitely failed.

- Replace the firmware. The original firmware of the electronic control unit is often changed. Therefore, we cannot find out which sensor operation algorithm was prescribed in the case of the first verification method. The throttle valve has a stop; a plate approximately 1 millimeter thick should be placed under it. This will increase the speed. Now the chip with the sensor is disabled. If the mass air flow sensor does not work, the engine will stall. If this does not happen, then the firmware is not original, the steps of the idle speed control are written incorrectly.

Checking with a multimeter

To do this, you will have to use a multimeter. And how can I check the functionality of the sensor using this method? Select the DC voltage measurement mode on the device and set the maximum value to 2V.

Check with a multimeter

Separately, you should familiarize yourself with the connection diagram in the case of the VAZ 2114.

| Subsequence | Wire color | Meaning |

| 1 | Yellow | Incoming signal |

| 2 | Gray-white | Power output |

| 3 | Green | Grounding |

| 4 | Pink-black | Main relay output |

In some cases, the color may differ, but the sequence always remains the same. This will prevent you from getting confused.

Turn on the ignition with the engine off. The positive probe of the multimeter is connected to the yellow output of the sensor, and the black, that is, positive, goes to the green.

The probes of the measuring device should be inserted through the rubber seals of the connectors without damaging the insulation. The probes should be moistened with the almighty WD 40. Now measure the voltage readings. Compare the result obtained with the data from the table.

| Voltage indicator | Air flow sensor condition |

| 1.01-1.02V | The air flow sensor is in good working order, almost new condition, can serve for a long time |

| 1.02-1.03V | The sensor is in good condition, although old. There are no complaints about performance |

| 1,03-1,04 | The air flow sensor is in poor condition, has almost expired and will require immediate replacement |

| 1,04-1,05 | The condition is critical, the resource is exhausted. It is recommended to replace it as soon as possible to avoid troubles. |

If you install a new sensor, it will initially show readings in the region of 0.996-1.01 V, but over time the voltage will begin to increase. This indicates wear.

What does a faulty air flow sensor cause?

Operating an engine with an inoperative/faulty flow meter causes detonation of the fuel mixture in the combustion chamber. This affects the operation of the crank mechanism (crank mechanism) and destroys the piston surface, which can cause a “wedge” in the engine.

What indications should a working mass air flow sensor give?

The voltage of the analog-to-digital converter (ADC) of the flow meter when the engine is not running should be 0.996 V. Indicators of 1.016 and 1.025 V are acceptable, but if they reach more than 1.035 volts, it means that the sensing element of the mass air flow sensor is clogged.

We recommend: Chip tuning - what is it, advantages and disadvantages

It is important to know

To accurately determine the degree of deviation of the operating flow meter values from normal values, it is necessary to evaluate the engine operation at different speeds.

For example, for an injection 1.5-liter VAZ 2111 engine, if it is in good condition, at idle (860–920 rpm) the correct readings are 9.5–10 kg/hour, and at 2 thousand rpm - 19 –21 kg/hour. If the flow meter at 2 thousand rpm shows about 17–18 kg, then the car will drive stably. If the values are from 22 to 24 kg/hour, then the vehicle will move steadily, but the fuel consumption per 100 km will be approximately 10–11 liters. In addition, the car will have difficulty starting in cold weather due to fuel overflow when the engine warms up.

What sensors can be located in the engine

Different motors may have different numbers of sensors, the health of which can have different effects on the start and operation of the power unit. Generally speaking, any indicator can affect the good start of the engine. But, if you take it apart, each sensor has its own purpose, and therefore not all of them can affect the start of the car’s heart. Let's consider each sensor separately and its purpose in the operation of the car.

So let's start from the beginning. A motorist poured fuel into a car. Many modern cars are equipped with a fuel quality sensor. Such sensors can especially be found on German and American cars that are not adapted for our region.

When bad fuel enters the fuel system, the analyzer determines how high-quality fuel has entered the car. If the “bodyaga” has been flooded, the engine may start with difficulty or may not start at all. This analyzer can be located before or after the fuel filter.

The second most important indicator that can affect engine starting is the coolant temperature sensor. It is the malfunction of this indicator that can lead to the fact that the power unit will take a long time to start. This is due to the fact that the electronic control unit thinks that the engine is hot and injects insufficient fuel. Typically, this sensor is the most susceptible to failure.

The next indicator that directly affects the normal start of the engine is the idle air control sensor. It determines how much of the fuel-air mixture is needed for normal engine operation at idle and during engine starting.

The knock sensor also affects the start of the unit. Typically, it is installed at the top of the engine and picks up the vibrations generated by the engine. If the sensor sends a signal to the computer that detonation actions can harm the engine, the control unit blocks the supply of the air-fuel mixture and the spark. In this case, the engine may crank the crank several times for the first time, and then stall and not start at all.

Throttle position sensor (TPS). This indicator monitors the position of the throttle, as well as the process of adjusting it to force air into the combustion chambers. The TPS is inextricably linked with the mass air flow sensor.

Crankshaft position sensor. It calculates the position of the crankshaft relative to the position of the cylinders. If it fails, the control unit receives stable data and forcibly stops the motor.

The oxygen sensor directly affects the formation of the air-fuel mixture, as well as fuel consumption. It measures the oxygen concentration in the exhaust gases, which directly controls the supply of fuel to the combustion chambers. The indicator reading varies from approximately 0.1 V (high oxygen - lean mixture) to 0.9 V (low oxygen - rich mixture).

And at the rear of the cylinder head there is a phase sensor. It determines the position of the 1st piston at top dead center. Designed and based on the action of a Hall sensor.

Another representative of air indicators is the mass air flow sensor (MAF). It is located in front of the throttle valve and with its help the amount of air that enters the combustion chamber is controlled.

This indicator analyzes the position of the throttle valve to supply and regulate the amount of air supplied to the cylinders. Usually, when the sensor fails, the amount of forced air for different engine operating modes does not change, and the power unit simply suffocates when adding the amount of fuel and revolutions.

Additional sensors can be considered - a coolant temperature sensor located on the radiator and an electronics diagnostic sensor. These indicators are installed on cars with so-called “heavy electronics”, where all engine control processes are carried out by an on-board computer.

An integral part of the engine start control sensor is the power unit control unit. It is he who controls all the processes occurring in the engine, and also adjusts the settings for optimal starting. Failure of this element will result in the engine simply not starting.

How to check the air sensor yourself

So, if the driver exhibits the signs discussed above, then the sensor needs to be checked. By the way, it is important to understand that the symptoms of a malfunction of the VAZ 2114 DMVR can be very similar to the symptoms of malfunctions of other components of the car. For this reason, diagnostics are necessary before starting repair work.

To do this, you need to know how to check the mass air flow sensor on a VAZ 2114. Let us immediately note that this can be done with a multimeter. To check the mass air flow sensor, you do not need to go to a service station; it is enough to purchase a regular tester (multimeter) and know the pinout of the contact group.

DMRV pinout:

- contact “5” - supplying an incoming signal from the electronic control unit (yellow wire);

- pin “4” - power supply to the device (gray or white wire);

- contact “3” - grounding (green wire);

- contact “2” - transfer of information from the sensor to the main relay (pink-black wire).

To check the VAZ 2114 mass air flow sensor using a multimeter, do the following:

- Set the multimeter to DC measurement mode up to 20 V.

- connect the red wire from the multimeter to pin “5”, and the black wire to pin “3”;

- Turn the ignition on without starting the car and look at the multimeter readings.

Decoding multimeter readings:

- tester reading from 0.006 V to 1.01 V - the voltage of the new sensors, after several operating weeks the voltage increases by several hundredths of units;

- tester reading from 1.01 V to 1.02 V – normal operating voltage of the sensor under normal operating conditions;

- We also recommend reading the article about what TPS is and how the sensor works. From this article you will learn what signs of a malfunction of the throttle position sensor can be identified and how the TPS is repaired or replaced.

- tester reading from 1.03 V to 1.04 V - the sensor has used up its working life by only half;

- tester reading from 1.04 V to 1.05 V – the sensor is badly worn and requires replacement;

- the tester reading is above 1.05 V - the sensor does not work at all or does not work correctly (the signals sent to the computer are highly distorted).

Then, based on the indications, appropriate repair work is carried out. In some cases, you can limit yourself to cleaning, checking contacts, etc. Others will require a complete replacement with a new device.

How to restore the mass air flow sensor?

The optimal solution for problems with the mass air flow sensor is to replace the faulty sensor with a new one. But since the cost of the device is about 2500-3900 rubles, many owners are trying to “revive” the old part.

There are four recovery methods:

- installation of additional resistance;

- blocking part of the air supply channel to the thermistor with aluminum tape;

- updating the engine control unit firmware;

- washing the sensor body and housing from dirt.

Installing additional resistance

Additional resistances are installed in the circuit connecting the sensor to the control unit. When an electric current passes, the voltage decreases, which can be brought to the required limits. The resistance value is selected experimentally. Most often, a 1 kOhm resistor is soldered to the yellow wire and a 15 kOhm element to the green wire.

Blocking part of the air supply channel

The repair principle is based on partially cutting off the air supply to the thermistor. Due to this, less intensive cooling is ensured and it is possible to bring the voltage value to the state of a working device. The cross section is selected experimentally with voltage monitoring using a multimeter. In some cases, owners block the supply channel by 70-80%. Aluminum tape is used for gluing.

Sealing the canal with tape

The photo clearly shows the area of the closed channel

Correcting the firmware of the engine control unit

An adjustment means a change in the calibration or operating schedule of the mass air flow sensor stored in the unit’s memory. The dependence graph is constructed in such a way that at a sensor voltage of 0.996 volts, the flow rate is considered equal to zero. But if the sensor fails and the starting voltage is 1.055 volts, then the control unit considers the air supply to be 1.8 kg when the engine is not running. Changing the graph using the MAF Corrector utility will allow you to set the flow rate to 0, which will improve engine performance. This method can be recommended to owners who are well versed in the control unit software.

Do-it-yourself cleaning of the air flow sensor

The air volume sensor is cleaned after it is detected that it is not working correctly. The procedure is performed by partially disassembling and removing the device body with active elements. At the same time, the body is washed and cleaned from remaining leaves and dirt deposits. In many cases, washing the air flow sensor on a VAZ 2114 does not help restore the device’s parameters.

Mechanical methods of cleaning the mass air flow sensor on the VAZ 2114 are prohibited, as is blowing dust with compressed air.

What products should be used to clean the sensor?

To clean sensors, there are special liquids supplied in pressurized aerosol cans. An example of such a product is a special air flow sensor cleaner Luftmassensor-Reiniger from Liqui Moly. There are similar liquids from other manufacturers. You can wash the sensor with a mixture of 70% isopropyl alcohol and 30% distilled water, after warming the device to 60-70 ºС with a hair dryer.

When washing the mass flow sensor it is prohibited:

- try to clean the sensor with cotton balls, hard objects and brushes;

- use household cleaning products;

- Use carburetor cleaners based on acetone or ether.

Cleaners based on heavy petroleum products, for example, WD40, will remove plaque from working parts, but will leave a greasy film that must be washed off with isopropyl alcohol. The use of ether-containing substances is not recommended due to the destruction of the compound filling and electronic components.

Algorithm of actions

Sequence of steps when washing the mass air flow sensor:

- Remove the sensor together with the housing from the engine air duct. The device is attached with a clamp to the channel and two bolts to the air filter housing.

- Unscrew the two screws securing the sensor to the housing. The bolts have a star head, but many owners unscrew them with pliers.

- Wash the measuring thermistors and the air passage channels with a cleaning agent. If the cleaning method with alcohol is used, the removed sensor is heated with a stream of warm air and placed in a container. The alcohol-water mixture is also heated to 60-70 degrees.

- Dry the sensor.

- Wash the sensor housing with warm soapy water. Rinse under running water and dry.

- Assemble the sensor and install it in place.

Photo gallery

The photographs show some of the steps for flushing the air flow sensor of a VAZ 2114.

Unscrewing screws with pliers

Disassembled mass air flow sensor. Appearance of the working element. Sensor from another angle.

The second element is clearly visible in the channel

First flush point

Second flush point

Third flush point

The inside of the washed body

General view of the case

Checking and repairing at home

There are eight ways to independently check amplitude and frequency mass flow sensors.

Method No. 1 - disabling the air flow meter

The method consists of disconnecting the sensor from the fuel system of the car and checking the functionality of the system without it. To do this, you need to disconnect the device from the connector and start the engine. Without a mass air flow sensor, the controller receives a signal to switch to emergency operation mode. It prepares the air-fuel mixture only based on the throttle position. If the car moves faster and does not stall, it means that the device is faulty and requires repair or replacement.

Method No. 2 - flashing the electronic control unit

If the standard firmware has been changed, then it is unknown what reaction of the controller is programmed in it in case of an emergency. In this case, you should try to insert a 1mm thick plate under the throttle stop. The turnover should increase. Now you need to pull out the chip from the air flow meter. If the power unit continues to work, then the cause of the malfunction is the firmware.

Method No. 3 - installing a working sensor

Install a known good part and start the engine. If after replacement it begins to work better, the motor does not stall, then replacement or repair of the device is required.

Method No. 4 - visual inspection

To do this, use a Phillips screwdriver to unscrew the clamp holding the air collector corrugation. Then you need to disconnect the corrugation and inspect the internal surfaces of the air collector corrugation and the sensor.

Inspection of duct corrugation

There should be no traces of oil or condensation on them, the surfaces should be dry and clean. If you do not take care of the air filter and change it rarely, then dirt can get on the sensitive element of the sensor and cause it to break. This is the most common malfunction. Traces of oil may appear in the flow meter if the oil level in the crankcase is high, or if the oil sump of the crankcase ventilation system is clogged. If necessary, you need to clean the surfaces using special cleaning products.

Method No. 5 - checking the mass air flow sensor with a multimeter

To do this, you need to turn on the tester in a mode in which constant voltage is checked. The limit value for measurements should be set to 2V.

DMRV operation diagram

Sensor pinout:

- The yellow wire is located closer to the windshield. It serves as an input for a signal from the flow meter.

- The white-gray wire is the sensor voltage output.

- The black and pink wire leads to the main relay.

- The green wire is used to ground the sensors, that is, it goes to ground.

The wires may have different colors, but their location is unchanged. To check, you need to turn on the ignition, but do not start the car. The red probe from the multimeter must be connected to the yellow wire, and the black one must be connected to ground, that is, to the green wire. We measure the voltage between these two outputs. Multimeter probes make it possible to connect without disturbing the insulation of the wires.

On the new device, the output voltage ranges from 0.996 to 1.01 V.

During operation, this voltage gradually increases and by its value one can judge the wear of the flow meter:

- if the sensor is in good condition, the voltage is from 1.01 to 1.02 V;

- in satisfactory condition - from 1.02 to 1.03 V;

- the sensor resource ends if the voltage is in the range from 1.03 to 1.04 V;

- a value in the range from 1.04 to 1.05 indicates a near-death state; if there are no contraindications, then you can continue to use the sensor;

- if the voltage exceeds 1.05 V, the mass air flow sensor requires replacement.

ADC flow meter readings

Diagnostics of the mass air flow sensor "Tseshkoy" is not difficult and can be done with your own hands.

If there is dirt on the removed sensor, you can clean it yourself. You can use WD-40 to wash it. To clean the mass air flow sensor, you must first remove the pipe from it, and then dismantle the device itself. Inside the device there is a mesh and several wires - sensors.

We recommend: Cooling system for VAZ 2109 and 21099 (carburetor and injector): design and principle of operation, replacing the radiator with your own hands

They need to be sprayed with cleaning agent and washed. Then let the liquid dry. If dirt remains, the procedure should be repeated. You need to clean the pipe with the same product. It must be free of dirt and oil stains. After replacing the air filter, all parts must be returned to their place. After the cleaning procedure, the functionality of the device can be restored to 80%, the error about the reduced sensor signal level disappears (the author of the video is “24 hours”).

Flushing the sensor will help avoid costly repairs.

Method number 6 - checking with a scanner

Test method:

- Install a diagnostic program on your phone (smartphone), tablet or laptop computer (for example, Torque Pro, Opendiag, BMWhat, OBD Auto Doctor).

- Connect your mobile device or laptop to the diagnostic connector located on the vehicle's electronic control unit using a special cable, Bluetooth channel.

- Launch the diagnostic utility on your phone (smartphone) or computer.

- Wait until the program finishes scanning all vehicle components. As a result, the utility will check the serviceability of each vehicle unit.

- Decipher the error codes that the program will show after the diagnostics are completed.

To perform this method, testers are used:

- K-Line 409/1;

- Scanmatic;

- ELM (ELM) 327;

- OP-COM.

Method No. 7 - checking by Vasya the Diagnosticist

To identify a malfunction of the mass air flow sensor without removing it from the car, you need to:

- Install a program called “VASYA diagnostician” on your laptop (laptop) and run it.

- Connect the adapter to the vehicle's diagnostic port.

- Select the item “Electronics 1” or “01 – Engine electronics” from the “Control unit” tabs to connect to the vehicle’s control unit.

- Go to “Custom Groups”.

- Select 211, 212 (passport value) and 213 (current value).

- Compare current indicators with passport data. If the deviations are high, then it is necessary to replace the mass air flow sensor.

Method No. 8 - using a motor tester

Good to know

This method is used to test frequency-type flowmeters.

To check the mass air flow sensor with a motor tester (oscilloscope), you need to connect it to the sensor (depending on the car brand) and start the engine.

Mass air flow sensor check parameters:

- transient time when the ignition is on;

- air consumption readings at idle and a sharp increase in engine speed;

- voltage in the sensor network.

It is important to know

The output data is individual for different types of engines. Before diagnosis, you should check the current indications with an official representative.

Three ways to check the sensor.

Method one: disabling the mass air flow sensor.

- You need to disconnect the sensor and try to start the engine.

- The controller is operating in emergency mode.

- The fuel-air mixture is prepared taking into account the position of the throttle valve, which the ECU informs about its position sensor.

- We set the engine speed at 1500 rpm and try to drive a little; if the dynamics have improved and the acceleration has become a little faster, then the mass air flow sensor is faulty.

Method two: visual inspection.

The clamp attached to the air collector is removed from the corrugation. The surface of it and the mass air flow sensor is checked for traces of oils and condensate.

Method three (suitable only for modern mass air flow sensors) - how to check the VAZ 2114 mass air flow sensor with a multimeter?

The device sets a limit of 2 Volts.

- a black and pink wire leads to the main relay;

- to the signal input – yellow;

- the green wire is grounding;

- white-gray wiring – voltage output.

Attention! Colors may vary depending on the sensor manufacturer.

Now turn on the ignition, but do not start the engine.

Connect the red probe of the multimeter to the yellow signal wire, the black probe to the green one.

The voltage at the output of the device can fluctuate between 0.966-1.01 V. Over time, this voltage can increase and the higher the value, the more faulty the mass air flow sensor. Now let’s take a closer look at the measurements themselves and what they mean:

- the sensor is working - the indicator is “0.1-1.02”;

- there is slight wear on the sensor – the indicator is “1.02-1.03”;

- the sensor will soon fail - the indicator is “1.03-1.05”;

- The sensor needs to be replaced - the indicator is “more than 1.05”.

Replacing the air flow sensor

To replace the sensor with your own hands, you need to prepare a shaped screwdriver and a “10” key.

The replacement procedure consists of the following steps:

- First you need to turn off the ignition and open the hood.

- Then you need to disconnect the negative terminal on the battery.

- At the next stage, you need to loosen the clamp with which the corrugation is attached to the mass air flow sensor.

- Next, remove the corrugation from the pipe.

- Then you need to bend the comb and disconnect the sensor connector.

- Disconnecting the sensor connector

- Then, using a key set to “10”, you need to unscrew the sensor mounting bolts to the air filter housing.

- Now you can remove the mass air flow sensor.

- Installing the sensor yourself is carried out in the reverse order.

Thus, if the car stalls and has all the signs of a breakdown of the mass air flow sensor, then before you start repairing it, you should check the level of its signal, it should not be low, perform a full diagnosis of the car and repair all faulty components and parts.

It is important to undergo regular vehicle inspections and perform timely maintenance, then the parts and components will last longer.

Replacing the sensor - instructions

Using a screwdriver, unscrew the clamp of the air intake corrugation at the sensor outlet, pull it off and carefully inspect the internal surfaces of the sensor itself and the corrugation. These surfaces must be dry and clean; traces of condensation and oil are unacceptable. If the air filter is changed rarely, then dirt getting on the sensitive element of the sensor is the most common cause of its breakdown in VAZ cars.

There may be oil in the mass air flow sensor as a result of an increased oil level in the engine crankcase, or the oil sump of the crankcase ventilation system is clogged.

Next, unscrew the 2 screws of the sensor with a 10mm wrench and remove it from the air filter housing. There should be a rubber sealing ring on its front part (at the entrance edge). It prevents unfiltered air from being sucked into the intake tract through the sensor.

If the ring is out of place and stuck somewhere in the air filter housing, then there will be a thin layer of dust on the inlet mesh of the sensor itself. This is the second reason that destroys the mass air flow sensor ahead of time.

Correct assembly should take place in the following sequence: put a sealing rubber band on the sensor, check the sealing skirt, then insert everything together into the filter housing.

This concludes the visual check of the mass air flow sensor at home. You can check its operation 100% only with the help of special equipment in a car service center. For example, using a technique for assessing the oscillogram when the throttle is sharply opened to the cutoff mode (a motor tester is needed), or assessing the oscillogram when the ignition is turned on.

Resuscitation of a damaged air flow sensor is successful in no more than 5% of cases. In extreme cases, you can rinse with ethereal liquid to clean matrices and optics. It will evaporate without a trace. After making sure that there is no more dust or debris in the device, you can dry it thoroughly and put it back in place. Sometimes after such a simple procedure the device will work.

On most foreign cars, a mass air flow sensor was installed until 2000; subsequent generations of models began to be equipped with a pressure controller. Replacing a non-working sensor is simple and can be done on your own without any problems, you just need to buy a mass air flow sensor that matches the ECU firmware version. Its price is around 3,000 rubles, depending on the manufacturer.

Source

Cleaning instructions

As practice shows, cleaning the mass air flow sensor is one of the most effective methods of restoring the functionality of the controller. Therefore, if the sensor breaks down, it is not necessary to change it, especially since such a pleasure today is not cheap. This procedure is necessary because over time it becomes dirty and shows other parameters.

So, how to clean the mass air flow sensor at home with your own hands:

- You will need a Phillips head screwdriver; use it to loosen the clamp securing the line from the air intake.

- Next, dismantle the corrugation and visually assess the condition of the system. You may see condensation or traces of engine fluid under the corrugation.

- Carefully inspect the inside of the controller. If everything is normal with the system, then there will be no traces of leaks or contamination. As practice shows, the sensitive element often breaks precisely due to an excess of contamination. In order not to avoid problems of this kind in the future, it is necessary to periodically replace the air filter. This procedure is carried out in accordance with technical regulations. Engine fluid may enter the controller as a result of an increased level of consumables in the crankcase. Accordingly, this occurs as a result of a clogged oil separator in the ventilation system.

- The regulator itself is fixed with two bolts on the line. The removal procedure is carried out using an open-end wrench. At this stage, if you are sure that the device has failed, you can replace it.

- You can see the entrance on which there will be a sealing rubber band designed to protect the device from the suction of dirty air flow. If you do not have a seal, it may have caught on the filter element. Accordingly, this will lead to the regulator input grid being contaminated.

- Clean the mesh using available materials. To do this, you can use a regular toothpick or toothbrush. After cleaning, the seal can be put back and the regulator can be put back in place.

Prevention of breakdowns and cleaning of the air flow sensor of the VAZ 2114

The flow meter sensor is located in a vulnerable place: exposure to temperature changes, moisture, dust.

Precision electronics located in the measuring channel fail when foreign objects enter.

- untimely replacement of the air filter;

- the use of so-called “zero” filters;

- loose connection of the mass air flow sensor with the air duct flanges;

- moisture entering the air intake;

- Debris left in the ductwork or filter housing after repairs and maintenance.

How to clean the mass air flow sensor if contamination does not render it inoperable

The sensor must be removed, the protective nets removed, and blown with clean compressed air. If there is dried dirt or oil stains, washing with special means for mass air flow sensor is required. Of course, it is necessary to clean the air duct itself with the filter housing.

In most cases, such prevention brings the flow meter back to life.

What's the result?

As you can see, if there are signs of problems and the first symptoms of the DMVR VAZ 2114 or another car appear, you should check the device as soon as possible for possible breakdown. In this case, you can quickly diagnose the air flow sensor with a multimeter in a regular garage.

We also recommend reading the article about what a car engine knock sensor is. From this article you will learn about the purpose, design, as well as signs of malfunction or malfunction of the engine knock sensor. Based on the readings obtained from the device, it is possible to determine the malfunction (if a breakdown is confirmed) or to exclude the mass air flow sensor from the list of possible problem elements. One way or another, it is important to understand that this sensor is actively involved in mixture formation and affects the operation of the engine as a whole.

For this reason, it is necessary to perform regular checks of the ECM, scan for errors, and also pay attention to any failures and symptoms of malfunctions of the sensors of the electronic engine control system (TSP, DPKV, etc.).

Sources

- https://carfrance.ru/proveryaem-dmrv-na-vaz-2110-multimetrom-svoimi-rukami/

- https://labavto.com/vaz/2114/dmrv-diagnostika-i-chistka/

- https://remontvazov.com/dmrv-vaz-2114

- https://NaDomkrat.ru/ustroistvo-avtomobiley/elektrooborudovaniye/datchik-massovogo-rashoda-vozduha-vaz-2114

- https://avtozam.com/elektronika/sensor/dmrv-priznak-neispravnosti/

- https://KrutiMotor.ru/dmrv-vaz-2114-proverka/

Sensor verification:

If you have any of the symptoms described above, then it’s time to start checking, which I’ll tell you about now:

1. Open the hood and remove the connector from the mass air flow sensor. Once removed, the hood can be closed.

2. Now you need to start the engine. At the same time, the CHECK light will light up, but you should not be afraid of this. In this operating mode, the amount of air will be regulated by the position of the throttle valve.

3. Next, we need to pay attention to the operation of the engine, as well as drive it and evaluate the dynamics compared to when the sensor was connected. If, after turning off the mass air flow sensor, the engine begins to idle smoother and the dynamics improve, then we can safely say that there are problems with this sensor.

As you can see, checking the mass air flow sensor is really not difficult, so you can quickly identify the problem and fix it.

And if you are interested in the topic of Cars and tricks related to them, then SUBSCRIBE TO MY CHANNEL.

Source

Checking with a multimeter

Of the entire list of sensors in a car, the DMRV is the most expensive. Its cost in auto parts stores reaches 3000-4000 rubles. There is also a possibility of purchasing a counterfeit or inappropriate spare part model. Before the replacement procedure, you should make sure that the element gives the correct readings on the multimeter. A step-by-step check of the sensor using a multimeter looks like this:

- To begin, set the multimeter to DC measurement mode (readings up to 20 V);

- Use a red probe to connect to contact number 5, and connect a black probe to the third contact;

- Without starting the engine, turn the ignition key to the last position.

For a convenient interpretation of the readings from the multimeter, we will provide a complete table of voltage showing the wear of the part.

This element is quite sensitive to dirt, oil and other debris. To prevent its early failure, you should change the air filter more often and monitor the wear of the engine piston group. When there is a lot of wear, oil begins to seep into the intake system, which makes it impossible to take accurate readings of the incoming air. You can change the mass air flow sensor yourself in a matter of minutes, so there is no need to rush and purchase a new part. Often the problem with floating speed and periodic engine shutdown at idle lies in other malfunctions. Make sure the wiring is intact, the readings are correct, and only then proceed to replacing the element. Below we present the air volume indicators that correspond to the normal operation of the 2114 engine.

Price and article number DMRA VAZ 2114

Below is a table with prices for a mass air flow sensor for the VAZ 2114.

| Manufacturer | Type | vendor code | Price, (rubles) |

| BOSCH | Without E-GAS | 21083-1130010-20 | 3775 |

| BOSCH | S E-GAS | 21700-1130010-00 | 2830 |

| Baker | Without E-GAS | 21083-1130010-20 | 2900 |

| Kaluga | Without E-GAS | DMRV-116 | 2595 |