Front brake mechanism of VAZ 2110 car

For road safety, the serviceability of the front, rear and hand brakes is of great importance. The brake system of the VAZ 2110 car has a diagonal separation of circuits, which increases reliability and safety when driving a car. If one circuit fails, another effectively replaces it.

Why is the rear brake mechanism acting up?

The hydraulic drive built into the VAZ-2110 combines in its internal design a booster and a dual-circuit pressure controller designed to control the rear brakes.

If the rear cylinder is not working correctly, problems can provoke and create an emergency situation at any time when the vehicle is moving along the roadway. To prevent this from happening, the part should be repaired in a timely manner. There is nothing surprising in replacing an old type of rear brake cylinder (RBC) with a new one; nothing lasts forever. Auto parts stores offer car enthusiasts the opportunity to purchase parts from the best manufacturers that will last a long time and guarantee safety on the road.

Hydraulic brake circuit diagram

1 – front wheel brake mechanism; 2 – pipeline of the “left front–right rear brake” circuit; 3 – main cylinder for hydraulic brakes; 4 – pipeline of the “right front–left rear brake” circuit; 5 – master cylinder reservoir; 6 – vacuum booster; 7 – rear wheel brake mechanism; 8 – elastic lever of the pressure regulator drive; 9 – pressure regulator; 10 – pressure regulator drive lever; 11 – brake pedal; A – flexible hose of the front brake; B – flexible rear brake hose

The car uses a working brake system with diagonally separated circuits, which ensures high active safety of the car. One hydraulic drive circuit ensures the operation of the right front and left rear brake mechanisms, the other - the left front and right rear.

If one of the circuits of the service brake system fails, the second circuit is used to stop the vehicle with sufficient efficiency.

The hydraulic drive includes a vacuum booster 6 and a dual-circuit pressure regulator 9 for the rear brakes.

The parking brake system is driven by the brake mechanisms of the rear wheels.

Installation

Installation of the new element is carried out in the reverse order. Before installation, you need to thoroughly clean the brake mechanism from dirt using sandpaper. Degrease the seat with white spirit.

So, first you need to open the hood and add brake fluid to the maximum level. It is not recommended to mix different classes of products. Cars of the “tenth” family are filled with RosDot-4 class fluid. Please note that during pumping the level in the tank will drop. As soon as it drops 1.5 centimeters, you need to top it up again. Next we need an assistant. He will press the brake pedal at your command. So, unscrew the cap from the bleeder fitting and put the hose on it. We put its second end into a plastic bottle. We give the command to the assistant. He must press the pedal 5 times and at the last stage press it “to the floor”. At this time, you will observe how aired liquid flows out of the fitting.

Malfunctions and ways to check them

It is possible that you may need to replace the vacuum booster on your VAZ 2110. The cause may be various malfunctions, the characteristic symptoms of which are as follows:

- When you press the brake pedal, a hissing noise occurs, and at the same time, the engine speed often increases;

- The car starts to shake;

- Spark plugs stop working efficiently;

- Fuel consumption increases noticeably.

You yourself understand perfectly well that if the vacuum brake booster hisses on a VAZ 2110, there is nothing good about it. Therefore, it is necessary to take appropriate action. This applies to all malfunctions that may occur.

Before replacing the vacuum booster on a VAZ 2110, it should be checked.

This procedure is performed as follows:

- As with normal bleeding of brakes, with the engine not running, press the gas pedal several times;

- After 5 or 6 presses, keep the pedal in the down position, resting it on the floor, and start the engine;

- After starting, the pedal itself will move forward a little.

This situation is typical only for a working vacuum amplifier. Therefore, if a vacuum has not formed, check the connections and the hose for leaks, plus examine the condition of the check valve. Often the reason lies in the destruction or deformation of rubber components, which can be easily replaced.

There is also a high probability of damage to the diaphragm, on which a hole is formed over time. You can purchase the diaphragm with a repair kit, the cost of which is no more than 500 rubles.

Replacement

To replace an element, you need to understand the main issue - how to remove the vacuum booster from a VAZ 2110. Directly replacing the old element with a new one will not be difficult, just like the reassembly process.

Therefore, we will tell you about the main thing - dismantling the amplifier. Let's start with the fact that the procedure is not complicated, but it requires accuracy and sequence of steps. If you follow the recommendations, the work will take little time and will not take much effort.

- Disconnect the block with wires, which includes brake fluid level sensors in its design.

- Hold the booster check valve with one hand and carefully disconnect the hose with the other. It is advisable to disconnect the hose with a strong hand, since this will require a lot of force.

- Remove the two bolts connecting the booster and master cylinder.

- Carefully remove the cylinder from the amplifier.

- There is no point in disconnecting the brake lines.

- Give access to the dashboard, which will allow you to unscrew the nuts holding the brake pedal bracket. There should be 4 of them.

- It is recommended to dismantle the bracket and amplifier through the engine compartment, since there is enough free space for such manipulations.

- Remove the pin lock plate. To do this, pry the finger with a screwdriver and squeeze it out.

- Now you can easily disable the brake pedal and booster.

- To disconnect the amplifier and bracket, you will have to unscrew the two nuts on the mount.

- A new one is installed in place of the dismantled old vacuum amplifier, and the reassembly procedure is performed in strict sequence of the dismantling process.

Repair kit for rear brake cylinder VAZ 2110

Usually, when the rear brake cylinder fails on VAZ 2110 vehicles, you can observe a decrease in the level of brake fluid in the reservoir. This occurs due to a violation of the tightness of the piston and its rubber. To fix this problem, you need to replace the cylinder with a new one. There is nothing complicated in this procedure, and to perform it you will need the following tools: A 10-point socket with a ratchet and a wrench A special wrench for unscrewing the brake pipes (the so-called split wrench) First, you need to remove the brake drum and rear pads, since access to the cylinder cannot be obtained otherwise. After this, using a split wrench, we unscrew the tube that fits the cylinder from the reverse side: To prevent brake fluid from leaking out, you can plug its end for a while. Then we take the head with a knob and unscrew the two fastening bolts, again from the rear side, as is more clearly demonstrated in the photo below: After which you can safely remove the rear brake cylinder of the VAZ 2110 from the outside, since it is not attached to anything else. The price of a new part produced by VIS is about 300 rubles per piece. If you change in pairs, then naturally you will have to pay about 600 rubles. Installation is carried out in reverse order. If, after installing everything new, the braking efficiency has decreased, and when you press the brake pedal, it sinks more than necessary, it is necessary to pump the fluid through the system. Leaking brake cylinders of the rear wheels of VAZ 2108, 2109, 21099 cars are a very common malfunction.

Required Tools

- 10 mm spanner

- 12 mm spanner

- 13 mm spanner

- a special wrench for unscrewing the brake pipe

Preparatory work

— place the car in the pit, the handbrake should be lowered, the wheels should be supported

— loosen the rear wheel bolts, jack it up and remove it

— weaken the tension of the parking brake cable (handbrake)

To facilitate this operation and improve access to the parking brake actuator adjusting nut, you can disconnect the connection between the muffler and the resonator. Using a 13 mm wrench, unscrew the nuts securing the clamp at their connection and disconnect it.

Using a 13 mm wrench, unscrew the lock nut on the handbrake rod with another 13 mm wrench while holding the adjusting nut. Using the same wrench, unscrew the adjusting nut while holding the handbrake rod with pliers.

- unscrew the guide pins of the brake drum and remove it

If the pins do not turn away, lightly tap them with a hammer. If the drum cannot be removed, we also tap it with a hammer on all sides through a wooden spacer. We clean its mounting hole from contamination and treat it with a high-pressure spray.

Main causes of malfunction

The VAZ 2110 caliper is structurally an element that holds the brake pads and is responsible for the degree of their pressure on the brake discs. It is also responsible for uniform wear of the brake pads and guarantees the driver reliable braking in extreme situations. Thus, the importance of the caliper in the operation of the car is difficult to overestimate.

If by this time you have a completely reasonable question, what can happen to the caliper on a VAZ 2110 (2112), we will be happy to answer you. The main cause of malfunctions is “acidification” of the moving elements, coating them with an oxide film, clogging due to the destruction of protective boots or the use of improper lubricant, namely:

- acidification of the main piston mechanism;

- acidification of guides.

Piston mechanism and caliper guides VAZ 2110

A clear sign of problems that the caliper can cause on VAZ cars is uneven wear of the brake pads and an increased braking distance. In this case, the VAZ pads must be changed, and the caliper mechanism itself must be subjected to comprehensive diagnostics:

- check the condition of the piston, its degree of freedom, the presence of moisture, metal oxide, oxide formations and build-ups, the condition of the protective boots;

- Similarly, check the condition of the guides, make sure that there are no uncharacteristic scuffs, abrasions or deformations of the rod on the surface.

We must also not forget about regularly replacing the brake fluid in the system. This should be done approximately every 40 thousand km. mileage of VAZ-2110.

Since brake fluid is hygroscopic, it easily absorbs moisture, thereby oxidizing the piston mechanism and causing it to fail. The piston stroke becomes difficult and uneven wear of the brake pads and wheel wedge occurs.

Please note that the repair kit offered in stores for self-service of VAZ 2110 (2112) calipers contains special lubricant for both the main piston and the guides. The use of Lithol or graphite lubricant leads to swelling of the protective shock absorbers and further souring of the guides. This kind of repair is unlikely to benefit your car.

Determination of breakdowns of the GTZ VAZ-2110

You can determine the faulty part yourself; to do this, you just need to know what to look for:

- Leaks in the brake fluid on the vacuum booster at the junction with the main brake cylinder indicate that the cuff in the cylinder is worn out.

Leaks on the vacuum booster indicate wear on the seal in the cylinder.

In any case, you need to determine for yourself whether it’s worth bothering with disassembling the GTZ and repairing it or immediately installing a new part.

Is it worth buying a repair kit and is it profitable?

Buying a repair kit can save the money spent several times, but it will increase the time costs.

Based on the cost of the GTZ at 1,000 rubles, you need to think carefully about whether it is worth disassembling the brake cylinder for such a sum. Repair kits can be incomplete or complete. In any case, you need to purchase a complete one, since no one will measure the forces on the return springs.

You can also repair the brake master cylinder yourself.

An attempt to save money will result in a long procedure of disassembling, washing and drying all parts. When washing, you need to make sure that no gasoline or oil gets on the rubber parts, as this can damage them.

Therefore, the use of a repair kit can only be justified in the following cases:

- The assembled part is not available for sale.

- Inability to allocate 1,000 rubles for a purchase.

- The desire to understand the brake system with your own hands from beginning to end.

In other cases, it is better to immediately install the assembled part.

How to check the condition of the VAZ-2110 air conditioning center

Before you begin replacing the brake cylinder located at the rear, you need to inspect the car and establish an accurate “diagnosis”, especially since no special equipment is required for this - just a set of basic knowledge and your desire to understand the breakdown of the VAZ-2110 brake system.

See if the car has malfunctions and problems that are direct symptoms that the rear brake cylinder cannot be restored:

- Poor brake performance. For example, when pressed, the pedal easily falls down, and checking the brake system and adjusting its individual mechanisms did not give a positive effect.

- Brake fluid is coming out of the cylinder and there are marks on the shield. Even disassembling the unit and replacing the cuffs will be unsuccessful; the part will have to be replaced.

Repair of brake caliper VAZ 2110

When the piston jams in the brake cylinder, one of the wheels of the VAZ 2110 can turn very difficult. In this case, you need to drive into a pit or overpass and check the main components of the brake system. If, after another check on a pit or lift, you find that brake fluid is leaking from the caliper, then you should take care of it immediately. You have two ways out of this situation: restoring and repairing the brake caliper or replacing it. The brake cylinder may need to be replaced directly.

Features of the brake system on the VAZ-2110

The brakes on the VAZ-2110 have diagonal separation of the contours.

The device of the brake system of the VAZ-2110.

This allows if one brake circuit fails, it can only be repaired. Often car owners have to change the brake cylinder on one of the rear wheels. The first problem that novice car enthusiasts face is finding the location of this very cylinder. To see it, just remove the brake drum.

Brake cylinder location.

It is the brake cylinder that pushes the pads, forcing them to press against the walls of the drum.

Signs of a broken brake cylinder

A faulty rear wheel cylinder can be detected as follows:

- The wheel stopped braking.

- The wheel is jammed or jammed.

- The brake cylinder is leaking.

If the first two points are quite obvious, and the cylinder malfunction can be determined visually, then in the third case everything is much more complicated.

Brake fluid leaks on the inside of the wheel.

A cylinder leak will sooner or later lead to it jamming, and if this happens on the road, then major troubles cannot be avoided. To detect a leak, you need to pay attention to indirect signs. If there are visible leaks of brake fluid on the wheel, and the fluid itself runs out very quickly, you need to urgently remove the rear wheel and drum.

Wheel leaks do not always mean a broken rear brake cylinder. Most often, this is a brake hose that has burst or frayed.

Main causes of malfunction

The VAZ 2110 caliper is structurally an element that holds the brake pads and is responsible for the degree of their pressure on the brake discs. It is also responsible for uniform wear of the brake pads and guarantees the driver reliable braking in extreme situations. Thus, the importance of the caliper in the operation of the car is difficult to overestimate.

If by this time you have a completely reasonable question, what can happen to the caliper on a VAZ 2110 (2112), we will be happy to answer you. The main cause of malfunctions is “acidification” of the moving elements, coating them with an oxide film, clogging due to the destruction of protective boots or the use of improper lubricant, namely:

- acidification of the main piston mechanism;

- acidification of guides.

A clear sign of problems that the caliper can cause on VAZ cars is uneven wear of the brake pads and an increased braking distance. In this case, the VAZ pads must be changed, and the caliper mechanism itself must be subjected to comprehensive diagnostics:

- check the condition of the piston, its degree of freedom, the presence of moisture, metal oxide, oxide formations and build-ups, the condition of the protective boots;

- Similarly, check the condition of the guides, make sure that there are no uncharacteristic scuffs, abrasions or deformations of the rod on the surface.

We must also not forget about regularly replacing the brake fluid in the system. This should be done approximately every 40 thousand km. mileage of VAZ-2110.

Since brake fluid is hygroscopic, it easily absorbs moisture, thereby oxidizing the piston mechanism and causing it to fail. The piston stroke becomes difficult and uneven wear of the brake pads and wheel wedge occurs.

How to extend the service life of a new fuel pump

Before installing the part, you need to know the rules that will further extend the service life of the part:

- Choose the best products in the store, created by experienced manufacturers you can trust. By saving on brakes, you won't end up cheap.

- Pay attention to marriage. A defective product is characterized by the pistons coming out of the cylinder structure by a couple of millimeters. However, this is quite enough to cause another breakdown and replacement of the part.

- Buy good brake fluid.

- Ideally, you need to change not one cylinder, but two at once. As practice shows, if one element of the system has already failed, the second one will not be long in coming either.

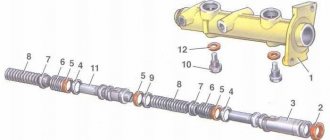

Master cylinder with reservoir

1 – main cylinder body; 2 – low pressure sealing ring; 3 – drive piston of the “left front–right rear brake” circuit; 4 – spacer ring; 5 – high pressure sealing ring; 6 – pressure spring of the sealing ring; 7 – spring plate; 8 – piston return spring; 9 – washer; 10 – locking screw; 11 – drive piston of the “right front–left rear brake” circuit; 12 – connecting sleeve; 13 – tank; 14 – brake fluid emergency level sensor; A – gap

Master cylinder with sequential pistons. A tank 13 is mounted on the master cylinder body, in the filler neck of which a sensor 14 for emergency brake fluid level is installed. The high pressure O-rings 5 and the rear wheel cylinder rings are interchangeable.

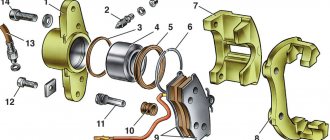

Main elements of the front brake system

This:

- Brake disc – position 1 in the photo.

- Caliper, pos. 3.

- Brake pads – 4.

- Cylinder – 5.

- Piston – 6.

For the front wheel, the brake mechanism has automatic adjustment of the gap between the disc and pads, with a pad wear indicator and a floating caliper. The bracket includes the front brake cylinder of the VAZ 2110 and the caliper; they are secured to each other with bolts. The piston is installed in the cylinder cavity with an o-ring. The optimal clearance between the brake disc and pads is maintained due to the elasticity of the installed ring. How to change the brake cylinder of a device with your own hands is suggested in the article.

Front wheel brake

Rice. 6-20. Pressure regulator performance test diagram: Pi

— pressure at the inlets to chambers A and D (see Fig. 6-18) of the pressure regulator, MPa (kg/cm 2 );

Pr

—pressure at the outlet of chamber B, MPa (kg/cm2);

Re

is the pressure at the outlet of the chamber C, MPa (kg/cm2);

1 - nominal pressure value Pr;

2 - upper limit of pressure

Pr;

3 - lower limit of pressure

Pr;

4 - the pressure

of the Re

manometer Mg) should fit into the shaded area (Fig. 6-20).

The readings of pressure gauges Мз and Мг (see Fig. 6-19) should not differ by more than 0.4 MPa (4 kgf/cm2) in the pressure range from 0 to 10 MPa (from 0 to 100 kgf/cm2) at regulator inputs.

Front wheel brake

Withdrawal. Raise the front of the car, place it on stands and remove the wheel. Unscrew the pipeline fitting and disconnect the flexible hose from the line; Plug the holes in the hose and tube to prevent brake fluid from leaking. Remove the hose from the guide bracket.

Is it possible to repair the rear brake cylinder?

This is indeed possible, you just need to have the skills to disassemble the part and know the design features. To properly disassemble the product, repeat the following steps:

- Remove the protective caps.

- Remove the pistons and elements that regulate the automatic gap from the body; this mechanism appears between the drum and the brake pads.

- After turning the piston and fixing it, you can already unscrew the stop screw.

- Slide out the O-ring and spring support cup.

- Disconnect the thrust ring and screw from each other.

Now carefully inspect the details:

- All surfaces must be smooth; scratches and roughness are unacceptable, as this will cause brake fluid to leak.

- If there are defects on the mirror base, use grinding or lapping - the latter method is gentle. The inner diameter of the cylinder must retain its dimension.

- Replace seals and protective caps.

Step-by-step video instructions for replacing the rear brake cylinder are presented below:

The process of replacing the VAZ-2110 brake cylinder

If the cause of the non-functioning brakes on one of the rear wheels is determined, then you need to begin the replacement process. First you need to dismantle the old part. It happens like this:

- First you need to remove the rear wheel.

We unscrew the wheel by jacking up the car and placing additional support under the bottom.

It is better to unscrew the tip of the brake pipe with a slotted wrench.

It is more convenient to unscrew the brake cylinder mounting bolts using a ratchet head.

When working with fittings and tubes, the main thing is not to break the threads, otherwise you will have to change them too.

Old brake cylinder.

If the parts are difficult to unscrew, it is better to spray them generously with WD-40. When rotating the nuts, you need to make sure that they rotate without tubes. If the tube turns together with the nut, it means it is rusty and stuck to the nut. This part is not allowed for use and must be replaced.

The process of installing a new cylinder

Before you begin the cylinder installation procedure, it is imperative to clean the entire rear wheel brake mechanism from dirt. If you really had to climb into the drum, then you need to carefully examine its condition, at the same time inspecting the pads. If worn, they must be replaced.

- If there has been a cylinder leak, then before installing it, you need to thoroughly clean the pads from all traces of brake fluid. To do this, you can use a file or sandpaper. Under no circumstances should stripping machines be used, as the pad can be seriously damaged.

- The inside of the rear brake drum also needs to be cleaned of dirt, rust and degreased from traces of brake fluid. If the liquid remains in the drum, the shoe will slide during operation. Only after thorough cleaning of all mechanisms can a new cylinder be installed. The assembly procedure takes place in the reverse order of disassembly.

How to repair a brake caliper

For repair you will need:

- Jack and wheel wrench.

- A set of keys, a clamp and a couple of screwdrivers.

- Rags and degreaser.

- Repair kit for caliper repair, high-temperature grease for calipers.

- Liter of brake fluid

- New copper washers for brake hoses

- Drill or screwdriver, set of brushes.

First, let's jack up the car and remove the wheel, and then we will need to remove the caliper and disassemble it. Details of the process in the photo.

To remove the caliper, you need to press in the piston, open the lid of the brake fluid reservoir to make the process easier, then insert a large screwdriver between the caliper and the pads, after which you need to pull the screwdriver towards you.

When the pads are released, unscrew the two bolts at the top and bottom of the caliper guides.

Remove the retaining ring from the caliper boot.

Then remove the boot. Since I did it myself at the service center, I had a compressor with which I pressed out the piston.

I advise you to place a rag in the caliper and then carefully, smoothly and slowly press the brake pedal. After the piston came out to clamp the brake hose so that a lot of fluid did not escape, I used a clamp for this purpose.

We unscrew the brake hose from the caliper and carry the caliper in a vice.

We fix the caliper in a vice.

Use a screwdriver to pry the o-ring off the cylinder and remove it.

Since caliper repair is a unit repair, and quality repair of a unit is 70 percent clean, I decided to clean it of dirt. To do this, I took a set of drill brushes and a screwdriver. You can also use brake cleaner.

We clean the caliper carefully, do not under any circumstances clean the working surface of the cylinder!

After cleaning, wash all parts in degreaser and dry.

Next, install a new piston seal.

Lubricate everything with a special lubricant or paste. (Or just brake fluid).

And carefully insert the piston, aligning it with both hands and pressing it in.

Do not hammer the piston with a hammer or anything else. There is a high probability of damaging the seal and all the work will be in vain.

And the boot retaining ring.

We install the caliper in place and bleed the brakes.

For a logical conclusion, I put a rubber ring from the nozzle on the grease fitting so that the threads do not become clogged with dirt.

Source

Tools that will be needed during the replacement process

To replace the brake cylinder you will need a tool.

Before starting any repair work, you should prepare thoroughly. Replacing the brake master cylinder is no exception. To replace this part you will need:

- Set of keys. Having a variety of sockets and socket wrenches will be a huge advantage.

- Screwdriver Set.

- Round nose pliers will help when changing cuffs.

- Special “brake” wrench for 10.

In addition, during the replacement process, brake fluid will spill out, which is generally advisable to replace with new one. DOT-4 brake fluid is suitable for the VAZ-2110.

The process of removing the old part

In order to remove the brake master cylinder, you need to open the hood and do the following:

- To get to the part, you will first have to remove the sound insulation. You should not try to tear it off, as it is secured with bolts. Therefore, you should arm yourself with a screwdriver and unscrew all the fasteners. If the sound insulation is not removed after this, it means that not all fasteners have been unscrewed. If you pull the element, it can be damaged. After this, you can start replacing.

We unscrew several screws using a Phillips screwdriver to remove the sound insulation.

Disconnect the terminal with wires.

We disconnect the tubes and put rubber caps on them.

Unscrew the fastening bolts.

Remove the brake cylinder.

At this point, the dismantling process can be considered complete.

Which cylinder is best to buy for replacement?

Rear brake cylinder from Kraft.

If you definitely decide for yourself that you will not go to a service station for repairs, then the spare part necessary for repairs will need to be purchased at a car store. Since spare parts for domestic cars are inexpensive, there will be no problems when purchasing.

When purchasing, you can buy both the original, which has the article number 21050-3502040-00, and a “non-original” from another company. Unlike spare parts for foreign cars, where the original spare part is always better, the situation with spare parts for VAZ is the opposite. It often happens that non-original spare parts turn out to be of higher quality than the original.

Rear brake cylinder replacement instructions

Replacing the rear brake cylinder of a VAZ-2110 looks like this:

- Raise the car on the lift.

- To securely secure the VAZ-2110, lock the front wheels.

- Unscrew the fasteners and remove the rear wheels.

- Using a rubber hammer, remove the brake disc.

- Carefully remove the end of the tension spring installed at the top, this spring is located right next to the brake pad.

- Lift the handbrake lever all the way to the top, you will see how the pads have moved apart, now they can be removed without any problems.

- Unscrew the brake pipe from the cylinder.

- Remove the broken cylinder and install a new one in its place.

- Assemble the knot following the reverse order of these instructions (starting from the last point to the first).

- Replacing the rear brake cylinder of a VAZ-2110 involves pumping the brakes at the final stage.

Sources

- https://avto-lover.ru/drugoe/remkomplekt-tormoznogo-cilindra-vaz-2.html

- https://AutoBroker-sng.ru/kalina/zamena-zadnego-tormoznogo-cilindra-vaz.html

- https://k-SportRacing.ru/avtoservis/zamena-zadnih-tormoznyh-cilindrov-vaz-2111.html

- https://litezona.ru/remont-zadnih-tormoznyh-cilindrov-vaz-2110/

- https://autobryansk.info/remont-zadnih-tormoznyh-cilindrov-vaz-2110.html

[collapse]