VAZ 2109 replacement of the rear brake cylinder - useful to know

The rear brake cylinders push the pads onto the brake drum and the car stops. They only work when you press the brake pedal. Fixing the parking brake does not activate the cylinders, and the handbrake cable pushes the shoe onto the drum. Over time, the cylinders wear out and brake fluid begins to leak through the seals, causing the brakes to become less effective. The amount of fluid gradually decreases, and complete emptying of the tank threatens failure of the brake system. Be careful, monitor the fluid in the tank and top up if necessary. And in today’s article we will look at the process of replacing brake cylinders.

Note! You will need the following tools: wrenches, spanners, screwdrivers, a hammer with a rubber head, a metal one will do, but you will need a spacer (for example, a small one), a special wrench for bleeding the brakes, a bottle, a short hose, new cylinders to replace the old brake ones .

Cylinder location

There are two of them (one on each side) and they are located under the brake drums. Bolted to the brake shield. In the photo below, the cylinder is indicated by a blue arrow. Along the edges there are pistons (indicated by red arrows) - the working part of the brake cylinder. The pistons move when you press the pedal, namely they move apart, thereby pushing the brake pads onto the drum, and as a result the car stops.

When to change?

- In case of brake fluid leaks, for example, when it is found on the rear wheel (see photo below). This is a signal of a malfunction in the braking system, and the possible causes are the following: pistons, poorly tightened bleeder fitting, poorly screwed brake pipe. First of all, check these parts, and if everything is normal with them, then most likely the cylinder is leaking. The places where liquid leaks most often are indicated in the photo above with yellow arrows.

- The pistons and the sliding and pushing brake pads have become sour. This happens when the car sits for a long time and is not used.

Note! In winter, this often happens: you put the car on the handbrake for a long time, then you are going to drive it, and the rear pads are frozen to the drum. You'll have to go get hot water and water the brake drums, or drive several kilometers waiting for the wheels to unlock.

Symptoms of problems

The general technical condition of the car (including the brake system) can be checked using a personal diagnostic adapter - a car scanner. These types of devices are widespread and have a wide price range.

We would like to draw your attention to the budget model of Korean production Scan Tool Pro Black Edition

At a cost of about 2 thousand rubles. This scanner is capable of fully diagnosing your car (engine, gearbox, transmission, abs, srs and much more), which will pay for itself in 1-2 trips to the service station. The adapter is quite easy to use, has Russian-language software and is compatible with most cars produced in 1993. The device will also be useful when buying a used car, as it can show its real mileage and VIN.

The fluid brake system consists of many parts that can become unusable: pipes, wheel cylinders, calipers, drums and pads. Typical signs of a faulty master cylinder:

- After pressing the pedal, the car stops slowly. The reason is that the cuffs of one or two pistons have lost their tightness - they have cracked or “floated”.

- To slow down, you need to press the brake pedal hard. The phenomenon occurs due to swelling of the rubber of the piston seals.

- The brake pedal travel is too short. The fluid inside the cylinder has nowhere to go because the compensation hole is clogged. Another option is that the passage is blocked by a swollen rubber seal.

- A common symptom is pedal failure, the brakes coming on at the end of the stroke. This indicates complete wear of the cuffs; as a result, liquid penetrates behind the piston and rushes into the expansion tank - the cylinder “bypasses.”

- The pads do not release the brake discs and drums and get very hot when driving. Options: one of the pistons is jammed or the bypass hole is clogged.

The listed symptoms of a GTZ malfunction are similar to malfunctions of other elements. Pedal failure also occurs when a large amount of air enters the tubes or loss of fluid in one of the working cylinders. Sluggish deceleration and increased force on the pedal are often caused by a breakdown of the vacuum booster - a cracked membrane or a lack of tightness at the joints of the hose that takes off engine vacuum.

There are signs that clearly indicate the performance of the main hydraulic cylinder and the malfunction of other elements:

- during braking, the car pulls to the side - the problem lies in a certain circuit or wheel;

- jamming of the brake mechanisms of one wheel;

- creaking and squeaking when braking;

- heating the discs and pads on one wheel.

If you eliminate these symptoms, it will become easier to check the brake master cylinder in a garage. This also includes obvious brake fluid leaks and the knocking sound of worn calipers.

How to replace the brake cylinder on a VAZ 2109

Leaking brake cylinders of the rear wheels of VAZ 2108, 2109, 21099 cars are a very common malfunction.

The reason is wear of the sealing rings (cuffs) on their pistons. By purchasing a cheap repair kit for rear brake cylinders (several rubber rings), you can carry out simple repairs and extend their performance for a while. The only condition is that the inner surface of the brake cylinder (mirror) is in good condition. Corrosion and risks on the mirror will not allow for quality repairs. In this case, it is necessary to replace the rear wheel brake cylinder with a new one.

Required Tools

- hammer

- 10 mm spanner

- 12 mm spanner

- 13 mm spanner

- a special wrench for unscrewing the brake pipe

- pliers

Preparatory work

— place the car in the pit, the handbrake should be lowered, the wheels should be supported

— loosen the rear wheel bolts, jack it up and remove it

— weaken the tension of the parking brake cable (handbrake)

To facilitate this operation and improve access to the parking brake actuator adjusting nut, you can disconnect the connection between the muffler and the resonator. Using a 13 mm wrench, unscrew the nuts securing the clamp at their connection and disconnect it.

Using a 13 mm wrench, unscrew the lock nut on the handbrake rod with another 13 mm wrench while holding the adjusting nut. Using the same wrench, unscrew the adjusting nut while holding the handbrake rod with pliers.

- unscrew the guide pins of the brake drum and remove it

If the pins do not turn away, lightly tap them with a hammer. If the drum cannot be removed, we also tap it with a hammer on all sides through a wooden spacer. We clean its mounting hole from contamination and treat it with a high-pressure spray.

— alternately remove the thrust ends of the brake pads from the slots in the cylinder pistons

— lightly press the brake pedal so that the pistons move out of the brake cylinder as far as possible

— unscrew the fastening of the brake pipe to the cylinder

We use a special key for this. After disconnecting, put a rubber cap on the tip of the tube to prevent brake fluid from leaking out.

— unscrew the two bolts securing the brake cylinder to the brake mechanism shield and remove it

We use a 10mm spanner.

If the tip of the brake pipe is rusty and when you try to unscrew it, it may break off along with the brake pipe, then unscrew it after removing the brake cylinder. At the same time, hold the tip with a “10” key or a special key, and rotate the brake cylinder itself.

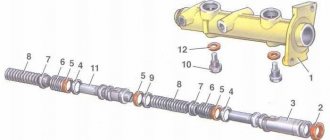

Replacement of sealing rings (cuffs) of the rear wheel brake cylinder of VAZ 2108, 2109, 21099 cars

— remove the rubber boots from both pistons of the brake cylinder

- use pliers to pull the pistons out of the cylinder body

The operation requires considerable effort, since it is necessary to overcome the resistance of the steel rings of the automatic gap maintenance device installed on each of the pistons.

If it is not possible to pull the pistons out of the cylinder, then we simply knock them out of it. We drive one of the pistons into the cylinder with a hammer, the second one falls out. We put on the mandrel and knock out the second piston.

- remove the old cuffs and install new ones

You can use a screwdriver or an awl for removal and installation. Before installation, lubricate the rubber cuffs, pistons and cylinder mirror with brake fluid.

- drive the pistons into the cylinder and reassemble in the reverse order

Diagnostics and repair

From the signs listed above, it is easy to understand that in most cases there is only one source of problems - rubber products that have become unusable. The cuffs crack and swell, as a result they leak liquid and close the discharge holes. Hence the recommendation: all “rubber bands” of the brake system should be changed at intervals of approximately 100 thousand km, without waiting for critical wear.

Before checking the GTZ for operability, make sure there are no other faults:

- Inspect the wheel assemblies from the inside for leakage of brake fluid from the working cylinders.

- Check the integrity of the expansion tank and the fluid level in it.

- Start the engine and at idle speed, press the vacuum take-off pipe to the amplifier. If the engine speed has increased noticeably, there is an air leak and the master cylinder is most likely working.

A clear symptom indicating a breakdown of the main hydraulic cylinder is drops of brake fluid on the body. If you discover a leak, feel free to dismantle the unit and disassemble it to look for the cause. Another common problem - fluid flowing through the seals - is diagnosed as follows:

- Open the cover of the expansion tank and place an assistant in the driver's seat.

- Listening to sounds in the tank, give the command to an assistant to press the pedal.

- If the pedal moves easily and gurgling is heard in the reservoir, liquid is entering there. The reason is that worn cuffs are unable to create pressure in the circuits; liquid seeps through the leaks and enters the container.

Also, problems with the GTZ are indicated by jamming or too little pedal travel.

Sit behind the wheel, press it several times, and start the engine while holding the pedal with your foot. If it sinks to the floor or does not budge, disassemble the hydraulic cylinder. To replace or repair the master brake cylinder, you need to remove the unit from the vehicle. Work is carried out in the following order:

- Suck out the liquid from the tank with a syringe. If the cuffs are leaking, press the pedal several times and suck out the excess fluid.

- Remove the expansion tank.

- It is not necessary to drain all brake circuits. Substituting a small container, unscrew the nut of the first tube and carefully move it to the side, plugging it with a wooden stick.

- Repeat the operation with the second tube, unscrew the fastening of the GTZ flange and remove the unit.

Further actions depend on the design of the master cylinder. If the element is completely disassembled, change the rubber seals. Otherwise, you will have to replace the pistons assemblies. Pre-wash the body and all openings with alcohol; do not use gasoline. After assembly, add fluid and bleed the brake system to remove air.

Basics of vehicle operation

Malfunctions of a vehicle's braking system fundamentally undermine road safety. For example, inadequate braking can cause an accident, making the distance to the vehicle in front insufficient for an accident-free stop.

But what if there is a need to use emergency braking? That is why the operation and repair of the brake system is an important part of the driver’s responsibilities.

The most popular malfunctions of the VAZ-2109 brake system include:

- inefficiency (both working and parking vehicles);

- brake fluid leak;

- increasing the idle speed of the hydraulic drive pedal;

- withdrawal (displacement) of the car from straight-line motion at the moment of braking;

- increasing the required force on the brake pedal.

Most often, vehicle repairs are caused by wear and failure of pads, discs or drums, hydraulic drive elements (main or wheel cylinders, hoses).

Brake device VAZ 2108,09,10-15

The brake drive of the VAZ-2109 car has a classic version, based on a dual-circuit hydraulic (liquid) operating principle. The drive circuit includes:

- brake pedal;

- expansion tank (with liquid level sensor);

- vacuum brake booster;

- master cylinder;

- hoses and pipelines;

- wheel cylinders;

- pressure regulator.

Compared to rear-wheel drive models, the VAZ-2109 brake system has some improvements in components and assemblies - master and working cylinders, vacuum booster, pressure regulator, mechanical parts, etc.

However, these changes are of a highly specialized nature and are understandable only to professionals who provide car service and repair.

Although there is a more significant innovation. Unlike “classic” models, the VAZ-2109 brake system has a slightly different operating principle for the drive.

The service braking system of domestic front-wheel drive cars uses a diagonal division of drive circuits: one of the circuits is responsible for the operation of the right front and rear left mechanisms, and the other - the front left and right rear.

Such a scheme for the functioning of independent circuits significantly increases the safety of braking and minimizes the possibility of a general failure in the operation of the braking system. It allows you to compensate for faults in one circuit by redistributing functions to another circuit.

The parking brake system of the VAZ-2109 (in driver's parlance - “handbrake”) is based on the mechanical cable principle of extending the rear shoes and blocking the brake drums. It has some improved technical solutions (compared to the “classics”), which greatly facilitates its repair.

Traffic regulations requirements for the serviceability of a vehicle

Traffic regulations exclude the possibility of driving if the service brake system is malfunctioning (ineffective or leaking). The driver must repair the working vehicle on site or refuse to operate the vehicle altogether, using towing (if permitted by Section 20 of the Rules) or transportation (transportation by tow truck).

The ineffectiveness of the handbrake is determined by specific fixed indicators associated with the stationary state of the vehicle. Thus, a VAZ-2109 car with a full load must remain stationary on a slope of at least 16%, and in equipped condition (ready for movement - with a driver, but without load) - at least 23%.

If the specified requirements are not met (and, consequently, the parking brake system is malfunctioning), the driver is also obliged to refrain from operating the vehicle. However, at the same time, he is allowed to move, subject to precautions, to the place where the car will be parked or repaired.

Thus, the braking system of the VAZ-2109 has proven its effectiveness during operation. That is why it was extended to other front-wheel drive models of the famous domestic brand. Thus, the braking system of the VAZ-2110 and the entire family of “tenths” is an exact copy of the “nine” vehicle. » alt=»»>

The brake system of the VAZ 2109 is the same as that of all cars produced in the distant 90s. To this day, it has not undergone significant changes.

The system can already be considered classic, for the simple reason that it uses a hydraulic drive and a dual-circuit design.

The main disadvantage of such a system can be considered the high pressure, which requires the use of reliably reinforced hoses and metal tubes. If these elements are neglected, fluid leakage may occur.

The advantage is that if one hose breaks, it will not affect braking and it will be carried out in the same way on both wheels. This allows you to avoid emergency situations, and in extreme cases it becomes possible to use the parking brake.

The operating principle of the GTZ in simple words

The process is activated by pressing the brake pedal. The result of mechanical force is a load inside the cylinder, carried out using a rod. It directs the pistons along the desired path, overcoming the force of the return spring. The movement of the pistons is accompanied by the closure of the compensation channels, which causes the opening of the bypass channel and sealing of the entire circuit.

At the same time, pressure is created that drives the caliper. Part of the liquid flows into the pipelines, activating the vehicle, the other pushes the second piston, which, when moving, performs the same functions.

The calipers compress the brake discs with the help of the pads, and the car stops. The pistons return through the compensation hole to the initial position after depressing the brake pedal. The initial mode of the pistons inside the circuits is established by the action of springs. Having returned to their original position, the pistons again open the compensation channels, thereby equalizing the pressure in the vehicle. The waste liquid slowly flows back into its reservoir.

How to repair a handbrake lever

Repairing the device consists of replacing the worn mechanism with a new one after removing it from the VAZ 2109 car. Damage can be: wear of the locking teeth, jamming or breakage of the lever, failure of the locking mechanism. So:

- The battery is turned off.

- Under the car, the nuts securing the equalizer to the drive cable are unscrewed, first the lock nut is unscrewed, then the adjusting nut.

- The equalizer is removed from the handbrake lever rod.

- In the car interior, all decorative trim between the front seats is removed. The plastic cover of the tunnel is removed, before this the cover is removed from the handle for shifting gears. The hatch into the tunnel is removed.

- The carpet is moved to the side.

- The retaining ring and drive rod are removed from the axle.

Repair of handbrake drive lever

- If necessary, the handle is unscrewed and removed, and the tension spring is changed.

- Assembly of the mechanism is performed in reverse order.