The peculiarity of the VAZ-2110 brake system is that the circuits are divided diagonally; it is this mechanism that ensures a high level of driving safety.

The brake located in front and the left one at the rear operate from a single hydraulic drive, the remaining 2 are also from a joint, but different one. Thus, if one circuit of the brake system has failed to function, you can solve the problem by replacing it.

Why is the rear brake mechanism acting up?

The hydraulic drive built into the VAZ-2110 combines in its internal design a booster and a dual-circuit pressure controller designed to control the rear brakes.

If the rear cylinder is not working correctly, problems can provoke and create an emergency situation at any time when the vehicle is moving along the roadway. To prevent this from happening, the part should be repaired in a timely manner. There is nothing surprising in replacing an old type of rear brake cylinder (RBC) with a new one; nothing lasts forever. Auto parts stores offer car enthusiasts the opportunity to purchase parts from the best manufacturers that will last a long time and guarantee safety on the road.

Installation

Installation of the new element is carried out in the reverse order. Before installation, you need to thoroughly clean the brake mechanism from dirt using sandpaper. Degrease the seat with white spirit.

So, first you need to open the hood and add brake fluid to the maximum level. It is not recommended to mix different classes of products. Cars of the “tenth” family are filled with RosDot-4 class fluid. Please note that during pumping the level in the tank will drop. As soon as it drops 1.5 centimeters, you need to top it up again. Next we need an assistant. He will press the brake pedal at your command. So, unscrew the cap from the bleeder fitting and put the hose on it. We put its second end into a plastic bottle. We give the command to the assistant. He must press the pedal 5 times and at the last stage press it “to the floor”. At this time, you will observe how aired liquid flows out of the fitting.

How does it work?

The operating principle of the system is to use a hydraulic drive. When the driver presses the pedal, pressure is generated in the system. The rod presses on the piston. This, in turn, transfers forces to the liquid.

Traffic safety depends on the proper operation of this system. Therefore, you need to be able to diagnose a malfunction in a timely manner. How to do it? Let's look further.

Repair kit for rear brake cylinder VAZ 2110

Usually, when the rear brake cylinder fails on VAZ 2110 vehicles, you can observe a decrease in the level of brake fluid in the reservoir. This occurs due to a violation of the tightness of the piston and its rubber. To fix this problem, you need to replace the cylinder with a new one. There is nothing complicated in this procedure, and to perform it you will need the following tools: A 10-point socket with a ratchet and a wrench A special wrench for unscrewing the brake pipes (the so-called split wrench) First, you need to remove the brake drum and rear pads, since access to the cylinder cannot be obtained otherwise. After this, using a split wrench, we unscrew the tube that fits the cylinder from the reverse side: To prevent brake fluid from leaking out, you can plug its end for a while. Then we take the head with a knob and unscrew the two fastening bolts, again from the rear side, as is more clearly demonstrated in the photo below: After which you can safely remove the rear brake cylinder of the VAZ 2110 from the outside, since it is not attached to anything else. The price of a new part produced by VIS is about 300 rubles per piece. If you change in pairs, then naturally you will have to pay about 600 rubles. Installation is carried out in reverse order. If, after installing everything new, the braking efficiency has decreased, and when you press the brake pedal, it sinks more than necessary, it is necessary to pump the fluid through the system. Leaking brake cylinders of the rear wheels of VAZ 2108, 2109, 21099 cars are a very common malfunction.

Required Tools

- 10 mm spanner

- 12 mm spanner

- 13 mm spanner

- a special wrench for unscrewing the brake pipe

Preparatory work

— place the car in the pit, the handbrake should be lowered, the wheels should be supported

— loosen the rear wheel bolts, jack it up and remove it

— weaken the tension of the parking brake cable (handbrake)

To facilitate this operation and improve access to the parking brake actuator adjusting nut, you can disconnect the connection between the muffler and the resonator. Using a 13 mm wrench, unscrew the nuts securing the clamp at their connection and disconnect it.

Using a 13 mm wrench, unscrew the lock nut on the handbrake rod with another 13 mm wrench while holding the adjusting nut. Using the same wrench, unscrew the adjusting nut while holding the handbrake rod with pliers.

- unscrew the guide pins of the brake drum and remove it

If the pins do not turn away, lightly tap them with a hammer. If the drum cannot be removed, we also tap it with a hammer on all sides through a wooden spacer. We clean its mounting hole from contamination and treat it with a high-pressure spray.

Reasons why the brakes might fail

Any problems during the braking process reduce its effectiveness, which can lead to dire consequences for everyone - the driver, passengers, and other road users. Very often, problems arise simply because the driver uses low-quality brake fluid.

If your car suddenly loses brakes, this may be due to several reasons, the main thing is not to blame the master cylinder for all the problems. Below are the reasons why the brakes on a car fail:

- One of the main causes is usually a leaking slave cylinder. Gradually, slowly or quickly, all the contained liquid flows out of it.

- You should also check the level of brake fluid in the reservoir and the condition of the main brake.

- If traces of smudges are noticeable on the main brake, then this is the reason.

- Another possible cause of brake failure could be that the brake line is torn. For example, rubber brake hoses could fray, partially rot in some places, or get punctures.

- The working cylinders may have jammed;

If it is nevertheless noticed that the main brake cylinder is not working:

- it will show where traces of brake fluid leaks appeared;

- it will be impossible to press the brake pedal;

- on the contrary, the brake pedal can move on its own without the driver making any effort to do so.

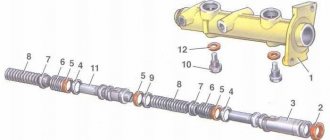

Master brake cylinder with reservoir: 1 — master cylinder body; 2 ~low pressure sealing ring; 3 — drive piston of the “left front-right rear brake” circuit; 4 - spacer ring; 5 - high pressure sealing ring; 6 — pressure spring of the sealing ring; 7 — spring plate; 8 — piston return spring; 9 — washer; 10 — locking screw; 11 — drive piston of the “right front-left rear brake” circuit; 12 — connecting sleeve; 13 - tank; 14 - emergency brake fluid level sensor; A - gap.

Therefore, it is possible to repair the VAZ 2110 brake cylinder, but not always. Most often, if it leaks, a repair kit will help fix the problem and restore the cylinder’s functionality. If the internal mirror in the cylinder is damaged, then, unfortunately, nothing can be corrected, since grinding is prohibited. If everything is not so scary and repairs are possible, you can do it yourself, because the price of the repair kit is quite reasonable, and almost every motorist can afford it.

What tools are required to replace a brake master cylinder?

- key to 17;

- key to 10;

- half-liter bottle of brake fluid;

- syringe;

- brake fluid.

Determination of breakdowns of the GTZ VAZ-2110

You can determine the faulty part yourself; to do this, you just need to know what to look for:

- Leaks in the brake fluid on the vacuum booster at the junction with the main brake cylinder indicate that the cuff in the cylinder is worn out.

Leaks on the vacuum booster indicate wear on the seal in the cylinder.

In any case, you need to determine for yourself whether it’s worth bothering with disassembling the GTZ and repairing it or immediately installing a new part.

Is it worth buying a repair kit and is it profitable?

Buying a repair kit can save the money spent several times, but it will increase the time costs.

Based on the cost of the GTZ at 1,000 rubles, you need to think carefully about whether it is worth disassembling the brake cylinder for such a sum. Repair kits can be incomplete or complete. In any case, you need to purchase a complete one, since no one will measure the forces on the return springs.

You can also repair the brake master cylinder yourself.

An attempt to save money will result in a long procedure of disassembling, washing and drying all parts. When washing, you need to make sure that no gasoline or oil gets on the rubber parts, as this can damage them.

Therefore, the use of a repair kit can only be justified in the following cases:

- The assembled part is not available for sale.

- Inability to allocate 1,000 rubles for a purchase.

- The desire to understand the brake system with your own hands from beginning to end.

In other cases, it is better to immediately install the assembled part.

Components

Master cylinder

Varieties:

1. Number of circuits:

- single-circuit – almost never seen now;

- dual-circuit - placement of two mechanisms in a single housing.

2. Availability of an amplifier:

- absent;

- installed.

Typically, the GTZ is installed on top of the vacuum booster cover. A fairly simple design includes:

- cylindrical body;

- pistons;

- return springs;

- storage tank;

- sealing cuffs.

Two pistons installed one behind the other inside a hollow cast body create the required pressure and form working sections. Their return and retention in the initial position is ensured by springs. The reservoir is designed to store and also add liquid when it is reduced. Usually located on top, connected to the mechanism by bypass and compensation channels.

The liquid level is controlled using marks on the transparent walls. In addition, there is a sensor inside that, when the level drops, turns on a light on the instrument panel.

When braking, the front piston moves, blocking the compensation channel. Due to the resulting tightness, the pressure increases. The rear piston also begins to move, the fluid is compressed, and the compensation channel is closed. The space behind the pistons is filled with liquid through open bypass channels. As a result of the increase in pressure, the RTCs are activated, activating the actuators on the wheels.

When the brakes are released, the pistons return to their initial position under the action of springs. Removing the brakes is performed smoothly due to the fluid remaining in the cavity behind the pistons and leaving there gradually. In the initial state, with the compensation channel open, the pressure is compared with atmospheric pressure.

Working cylinder

Varieties:

- drum system - an autonomous device for expanding the pads. It consists of a hollow body and pistons with a liquid-filled space between them. Connection to the system through the brake pipe fitting (M10x1 or M10x1.25);

- disc mechanisms - a device as part of a brake caliper for pressing the pads. Consists of a cylindrical cavity and an inserted piston. Connection to the brake system through a fitting located behind the piston.

As braking begins, the pressure increases and the incoming fluid moves the piston. In a drum system, the pistons move in different directions and press on the pads. In a disk mechanism, they move out of the cavities with the pads pressed.

When the brakes are released, the pressure decreases and the pistons return to their original position.

How to check the condition of the VAZ-2110 air conditioning center

Before you begin replacing the brake cylinder located at the rear, you need to inspect the car and establish an accurate “diagnosis”, especially since no special equipment is required for this - just a set of basic knowledge and your desire to understand the breakdown of the VAZ-2110 brake system.

See if the car has malfunctions and problems that are direct symptoms that the rear brake cylinder cannot be restored:

- Poor brake performance. For example, when pressed, the pedal easily falls down, and checking the brake system and adjusting its individual mechanisms did not give a positive effect.

- Brake fluid is coming out of the cylinder and there are marks on the shield. Even disassembling the unit and replacing the cuffs will be unsuccessful; the part will have to be replaced.

Some tips

- If you start having problems with the brakes, first of all you need to carry out an external inspection of the vehicle: check the fluid level in the reservoir, make sure that the front/rear cylinders are not leaking. There should not even be stains of brake fluid in the brake hydraulics.

- “Brake fluid” must be filled with the same brand; it is recommended to completely replace the brake fluid at least once every two years.

- If faults are identified in the gas turbine engine, and it has already served for at least a year, it is more advisable to replace it completely than to repair it. The same can be said about the rear working cylinders.

- Before changing the turbocharger, the brake fluid should be removed from it; this operation is usually done using a syringe.

- Usually a leak in the master cylinder is not visible, but if there is any suspicion that this part is faulty, you should remove the main cylinder - there will be traces of leaks at the rear, and this indicates its faulty condition.

- If, during an external inspection, cracks were found on the brake hoses, it is better not to take risks and immediately replace the defective parts.

Didn't find the information you are looking for? on our forum.

We recommend reading:

Which gasoline is better for VAZ 2114

Air leakage through injectors symptoms of VAZ 2114. Possible malfunctions, cleaning and adjustment

Vibration in the cabin when idling VAZ 2114 injector causes

Repair of the underbody of a VAZ 2107

VAZ 2114 injector boils, reasons

Error p1602 vaz 2114 how to fix

What is an ESD for a VAZ or an ECU for a VAZ 2114

Master cylinder, slave and clutch VAZ 2101. Replacement and repair, fluid pumping

Features of the brake system on the VAZ-2110

The brakes on the VAZ-2110 have diagonal separation of the contours.

The device of the brake system of the VAZ-2110.

This allows if one brake circuit fails, it can only be repaired. Often car owners have to change the brake cylinder on one of the rear wheels. The first problem that novice car enthusiasts face is finding the location of this very cylinder. To see it, just remove the brake drum.

Brake cylinder location.

It is the brake cylinder that pushes the pads, forcing them to press against the walls of the drum.

Signs of a broken brake cylinder

A faulty rear wheel cylinder can be detected as follows:

- The wheel stopped braking.

- The wheel is jammed or jammed.

- The brake cylinder is leaking.

If the first two points are quite obvious, and the cylinder malfunction can be determined visually, then in the third case everything is much more complicated.

Brake fluid leaks on the inside of the wheel.

A cylinder leak will sooner or later lead to it jamming, and if this happens on the road, then major troubles cannot be avoided. To detect a leak, you need to pay attention to indirect signs. If there are visible leaks of brake fluid on the wheel, and the fluid itself runs out very quickly, you need to urgently remove the rear wheel and drum.

Wheel leaks do not always mean a broken rear brake cylinder. Most often, this is a brake hose that has burst or frayed.

Required spare parts

Just 10 years ago, old pads were not replaced; they were glued on, linings were changed, or they were riveted. Today on the market you can easily purchase the entire mechanism. To replace, you need to prepare new pads. Experts believe that it is better to install replacement factory parts, article number 2110-3501080-60 (TIIR-260), 21100350180082 or 2110-3501080. There are other opinions. Some motorists believe that pads from well-known brands provide the best braking parameters on the VAZ 2110, 2111, 2112. These are parts from brands such as Brembo, ABS, Ferodo, TRW, Bosch, Optimal or Delphi.

How to extend the service life of a new fuel pump

Before installing the part, you need to know the rules that will further extend the service life of the part:

- Choose the best products in the store, created by experienced manufacturers you can trust. By saving on brakes, you won't end up cheap.

- Pay attention to marriage. A defective product is characterized by the pistons coming out of the cylinder structure by a couple of millimeters. However, this is quite enough to cause another breakdown and replacement of the part.

- Buy good brake fluid.

- Ideally, you need to change not one cylinder, but two at once. As practice shows, if one element of the system has already failed, the second one will not be long in coming either.

Main elements of the front brake system

This:

- Brake disc – position 1 in the photo.

- Caliper, pos. 3.

- Brake pads – 4.

- Cylinder – 5.

- Piston – 6.

For the front wheel, the brake mechanism has automatic adjustment of the gap between the disc and pads, with a pad wear indicator and a floating caliper. The bracket includes the front brake cylinder of the VAZ 2110 and the caliper; they are secured to each other with bolts. The piston is installed in the cylinder cavity with an o-ring. The optimal clearance between the brake disc and pads is maintained due to the elasticity of the installed ring. How to change the brake cylinder of a device with your own hands is suggested in the article.

Nuances of repair

O-rings require special attention. The time the rings are in isopropyl alcohol should not exceed twenty seconds, after which they should be dried immediately using a compressor.

The surfaces of the mirror, as well as the piston elements, must be completely clean and free of rust. Every disassembly and repair of a faulty brake master cylinder must be accompanied by replacement of the O-rings, even if they are in good condition. The cuffs of the device also require attention; if they are swollen and frayed, they must be replaced.

After all, it is necessary to check the elasticity of the piston springs; this should be done under load. The length of the spring under load should be 39.01–45.9 N (3.8–4.8 kgf) - 41 mm, with another option the following indicators should be 82.01–99.48 N (8.35–10 .15 kgf) – 21 mm. When free, the spring should have a length of 59.8 mm. If the springs do not have such indicators, then they must be replaced.

Is it possible to repair the rear brake cylinder?

This is indeed possible, you just need to have the skills to disassemble the part and know the design features. To properly disassemble the product, repeat the following steps:

- Remove the protective caps.

- Remove the pistons and elements that regulate the automatic gap from the body; this mechanism appears between the drum and the brake pads.

- After turning the piston and fixing it, you can already unscrew the stop screw.

- Slide out the O-ring and spring support cup.

- Disconnect the thrust ring and screw from each other.

Now carefully inspect the details:

- All surfaces must be smooth; scratches and roughness are unacceptable, as this will cause brake fluid to leak.

- If there are defects on the mirror base, use grinding or lapping - the latter method is gentle. The inner diameter of the cylinder must retain its dimension.

- Replace seals and protective caps.

Step-by-step video instructions for replacing the rear brake cylinder are presented below:

The process of replacing the VAZ-2110 brake cylinder

If the cause of the non-functioning brakes on one of the rear wheels is determined, then you need to begin the replacement process. First you need to dismantle the old part. It happens like this:

- First you need to remove the rear wheel.

We unscrew the wheel by jacking up the car and placing additional support under the bottom.

It is better to unscrew the tip of the brake pipe with a slotted wrench.

It is more convenient to unscrew the brake cylinder mounting bolts using a ratchet head.

When working with fittings and tubes, the main thing is not to break the threads, otherwise you will have to change them too.

Old brake cylinder.

If the parts are difficult to unscrew, it is better to spray them generously with WD-40. When rotating the nuts, you need to make sure that they rotate without tubes. If the tube turns together with the nut, it means it is rusty and stuck to the nut. This part is not allowed for use and must be replaced.

The process of installing a new cylinder

Before you begin the cylinder installation procedure, it is imperative to clean the entire rear wheel brake mechanism from dirt. If you really had to climb into the drum, then you need to carefully examine its condition, at the same time inspecting the pads. If worn, they must be replaced.

- If there has been a cylinder leak, then before installing it, you need to thoroughly clean the pads from all traces of brake fluid. To do this, you can use a file or sandpaper. Under no circumstances should stripping machines be used, as the pad can be seriously damaged.

- The inside of the rear brake drum also needs to be cleaned of dirt, rust and degreased from traces of brake fluid. If the liquid remains in the drum, the shoe will slide during operation. Only after thorough cleaning of all mechanisms can a new cylinder be installed. The assembly procedure takes place in the reverse order of disassembly.

Troubleshooting possible replacement problems

There are relatively few difficulties when replacing brake pads. As a rule, they are associated with souring of bolts due to rust. The drum elements that are most susceptible to corrosion are the mounting pins. In case of possible difficulties, the drum is removed along with the rear wheel hub, and when unscrewing the studs, it is allowed to use a penetrating lubricant such as WD-40

However, when working with brake mechanisms, lubricants should be used extremely carefully, avoiding their contact with the working surface of the pads or disc (in the case of the front wheels). Otherwise, the efficiency of the brakes can be significantly reduced, up to severe slipping between the working surfaces of the pad and the drum linings or the disc. To summarize, we can note the ease of replacing brake pads on a VAZ-2110

The procedure does not require special skills or tools; it can be done in an ordinary garage without any particular difficulties. Knowing the order of operations when replacing allows you to complete this procedure quickly and efficiently

To summarize, we can note the ease of replacing brake pads on a VAZ-2110. The procedure does not require special skills or tools; it can be done in an ordinary garage without any particular difficulties. Knowing the order of operations when replacing allows you to complete this procedure quickly and efficiently.

Home →

Maintenance and Repair →

Tools that will be needed during the replacement process

To replace the brake cylinder you will need a tool.

Before starting any repair work, you should prepare thoroughly. Replacing the brake master cylinder is no exception. To replace this part you will need:

- Set of keys. Having a variety of sockets and socket wrenches will be a huge advantage.

- Screwdriver Set.

- Round nose pliers will help when changing cuffs.

- Special “brake” wrench for 10.

In addition, during the replacement process, brake fluid will spill out, which is generally advisable to replace with new one. DOT-4 brake fluid is suitable for the VAZ-2110.

The process of removing the old part

In order to remove the brake master cylinder, you need to open the hood and do the following:

- To get to the part, you will first have to remove the sound insulation. You should not try to tear it off, as it is secured with bolts. Therefore, you should arm yourself with a screwdriver and unscrew all the fasteners. If the sound insulation is not removed after this, it means that not all fasteners have been unscrewed. If you pull the element, it can be damaged. After this, you can start replacing.

We unscrew several screws using a Phillips screwdriver to remove the sound insulation.

Disconnect the terminal with wires.

We disconnect the tubes and put rubber caps on them.

Unscrew the fastening bolts.

Remove the brake cylinder.

At this point, the dismantling process can be considered complete.

Instructions

So, how to replace the rear brake cylinder yourself? The VAZ needs to be placed on a flat area and the rear part must be jacked up, having first removed the wheel bolts. Next, remove the wheel itself. Getting to the brake cylinder is quite difficult. To do this we need to remove the drum and also remove the pads. In addition, the brake fluid hose is unscrewed.

How to remove the drum? Before dismantling it, you need to thoroughly clean it with a wire brush, removing all rust and dirt. After this, unscrew the 2 guide pins with a wrench. Next, remove the drum from its seat. This is done using a special puller. If this is not available, you can use 2 M8 bolts 6-7 centimeters long. We evenly tighten them with a wrench into the holes. This way the drum is compressed from the hub.

Now we need to remove the rear brake cylinder itself. So, remove the plastic protective cap and unscrew the bleeder fitting itself. To do this we need a key “8”. To remove the tube, you must use a 10mm socket. We break the tightening on the fitting and unscrew the element. Be careful - brake fluid will flow out of the tube. Wear protective rubber gloves when working. Next, unscrew the bolts securing the rear brake cylinder itself.

Which cylinder is best to buy for replacement?

Rear brake cylinder from Kraft.

If you definitely decide for yourself that you will not go to a service station for repairs, then the spare part necessary for repairs will need to be purchased at a car store. Since spare parts for domestic cars are inexpensive, there will be no problems when purchasing.

When purchasing, you can buy both the original, which has the article number 21050-3502040-00, and a “non-original” from another company. Unlike spare parts for foreign cars, where the original spare part is always better, the situation with spare parts for VAZ is the opposite. It often happens that non-original spare parts turn out to be of higher quality than the original.

Where can I buy

Popular models and new items can be purchased in showrooms that sell accessories and spare parts for cars. Consultants will tell you what types of devices there are, how to choose, which company is better to buy, how much they cost, and how they differ.

If it is not possible to buy the necessary parts at your place of residence, the best inexpensive budget models can be ordered online from the online store of a manufacturer or auto parts dealer. This is available using the Yandex.Market aggregator or marketplaces that offer to purchase goods by type of vehicle, make or model of car. There are also descriptions, technical specifications, photos, as well as customer reviews. In addition, it is possible to select analogues of original parts.

In Moscow you can buy:

- GTZ at prices from 300 rubles (rear BELMAG 2105 (Bi-Bi)) to 21,992 rubles (VAG 2E0611917E (Autoperts777.ru));

- RTC - from 279 rubles (TTIALLI CF 701 (CARDONE)) to 6,597 rubles (DT SPARE PARTS 461850 (Autoperts777.ru)).

Rear brake cylinder replacement instructions

Replacing the rear brake cylinder of a VAZ-2110 looks like this:

- Raise the car on the lift.

- To securely secure the VAZ-2110, lock the front wheels.

- Unscrew the fasteners and remove the rear wheels.

- Using a rubber hammer, remove the brake disc.

- Carefully remove the end of the tension spring installed at the top, this spring is located right next to the brake pad.

- Lift the handbrake lever all the way to the top, you will see how the pads have moved apart, now they can be removed without any problems.

- Unscrew the brake pipe from the cylinder.

- Remove the broken cylinder and install a new one in its place.

- Assemble the knot following the reverse order of these instructions (starting from the last point to the first).

- Replacing the rear brake cylinder of a VAZ-2110 involves pumping the brakes at the final stage.

Sources

- https://avto-lover.ru/drugoe/remkomplekt-tormoznogo-cilindra-vaz-2.html

- https://AutoBroker-sng.ru/kalina/zamena-zadnego-tormoznogo-cilindra-vaz.html

- https://k-SportRacing.ru/avtoservis/zamena-zadnih-tormoznyh-cilindrov-vaz-2111.html

- https://litezona.ru/remont-zadnih-tormoznyh-cilindrov-vaz-2110/

- https://autobryansk.info/remont-zadnih-tormoznyh-cilindrov-vaz-2110.html

[collapse]

Vacuum booster

The braking system of a car certainly cannot be called perfect, so it has to be supplemented with devices that help improve efficiency. One of them is a vacuum booster.

Application and purpose

Today, a vacuum amplifier is in great demand because it is highly efficient. Its tasks are extensive, but the amplifier copes with them all perfectly:

- The degree of resistance of the brake pedal increases;

- Reduces the load on the brake system;

- Acts as a highly efficient auxiliary unit;

- Has a positive effect on the service life of the brake system, etc.

This element has the following components:

- Dense body, for the manufacture of which a high-strength polymer is used;

- The diaphragm, which is also called the collecting node;

- Monitoring or control specialized valve;

- Pusher. It allows you to return the engine elements to their original position when there is no power;

- Main piston rod of the brake system cylinder (main);

- Switch return spring.

The body of this spring has two cellular divisions, which are divided into vacuum and atmospheric. Cells are often called chambers.

- The vacuum chamber is a cell directly connected to the brake master cylinder.

- The atmospheric chamber is a cell located opposite the brake pedal. Its open part of the body rests on the brake pedal.

It is also worth noting the diaphragm, which performs two very important tasks:

- Corrects the position of the piston in space;

- Pumps brake fluid to the main brake cylinders.

Installing a vacuum booster involves a serious change in the sensitivity of the pedal, so it is strongly recommended not to apply a large and sudden force to it in the “first couple”. Pressing should be done carefully and smoothly.

Malfunctions and ways to check them

It is possible that you may need to replace the vacuum booster on your VAZ 2110. The cause may be various malfunctions, the characteristic symptoms of which are as follows:

- When you press the brake pedal, a hissing noise occurs, and at the same time, the engine speed often increases;

- The car starts to shake;

- Spark plugs stop working efficiently;

- Fuel consumption increases noticeably.

Before replacing the vacuum booster on a VAZ 2110, it should be checked. This procedure is performed as follows:

- As with normal bleeding of brakes, with the engine not running, press the gas pedal several times;

- After 5 or 6 presses, keep the pedal in the down position, resting it on the floor, and start the engine;

- After starting, the pedal itself will move forward a little.

There is also a high probability of damage to the diaphragm, which forms a hole over time. You can purchase a diaphragm with a repair kit, the cost of which is no more than 500 rubles.

Replacement

To replace an element, you need to understand the main issue - how to remove the vacuum booster from a VAZ 2110. Directly replacing the old element with a new one will not be difficult, just like the reassembly process.

Therefore, we will tell you about the main thing - dismantling the amplifier. Let's start with the fact that the procedure is not complicated, but it requires accuracy and sequence of steps. If you follow the recommendations, the work will take little time and will not take much effort.

- Disconnect the block with wires, which includes brake fluid level sensors in its design.

- Hold the booster check valve with one hand and carefully disconnect the hose with the other. It is advisable to disconnect the hose with a strong hand, since this will require a lot of force.

- Remove the two bolts connecting the booster and master cylinder.

- Carefully remove the cylinder from the amplifier.

- There is no point in disconnecting the brake lines.

- Give access to the dashboard, which will allow you to unscrew the nuts holding the brake pedal bracket. There should be 4 of them.

- It is recommended to dismantle the bracket and amplifier through the engine compartment, since there is enough free space for such manipulations.

- Remove the pin lock plate. To do this, pry the finger with a screwdriver and squeeze it out.

- Now you can easily disable the brake pedal and booster.

- To disconnect the amplifier and bracket, you will have to unscrew the two nuts on the mount.

- A new one is installed in place of the dismantled old vacuum amplifier, and the reassembly procedure is performed in strict sequence of the dismantling process.