VAZ Oka with a 0.75 liter engine is a popular small passenger car of the nineties and 2000s, which won the hearts of many motorists due to its maneuverability, fairly high cross-country ability and efficiency. But fuel consumption could not always be the same; it largely depended on how the Oka 11113 carburetor was configured.

Currently, these small cars are still on the roads of our country, and spare parts for cars are in demand. Also for Okushka they sell carburetor units (CU) of various modifications, repair kits, jets, gaskets and other parts; they can be bought in specialized stores, and the adjustment and repair of the fuel system is carried out not only by specialists, but also by many car owners themselves.

Oka carburetor design

Cars under the Oka brand were produced from 1987 until 2008, at first the VAZ-1111 was modified (with a 0.65-liter two-cylinder engine). The updated VAZ-11113 model was launched into production in 1995, and it received a 749 cm³ engine. Initially, for 0.65-liter engines, the Dimitrovgrad Automobile Unit Plant developed the DAAZ carburetor series 1111, which combined elements of the Ozone and Solex type HRVs. Later, the DAAZ-11113 model began to be produced for the 0.75-liter internal combustion engine (ICE), which later underwent a slight modernization.

Carburetor 11113 is a device for creating an air-fuel mixture in a certain proportion, which sets the stable operation of a car engine in all modes. The body of this unit consists of 3 parts: the top cover, the middle (main) part where the float chamber is located, and the bottom part with throttles (flaps), the carburetor device itself is a 2-chamber one, with sequential opening of the throttles.

The carburetor assembly includes:

- the main dosing system (abbreviated as GDS), operating in all modes, which includes diffusers, fuel/air supply jets for both chambers;

- idle speed system (abbreviated as XX), which allows the engine to operate stably at minimum speed and consume fuel economically;

- economizer, which enriches the fuel mixture at high speeds and heavy loads;

- accelerator pump, its main function is to ensure uniform operation without failures with any, even the most sharp, pressing of the accelerator (gas) pedal;

- a starting device that allows you to smoothly start a cold engine at low air temperatures;

- float chamber, due to which a constant level of gasoline in the carburetor is maintained, required for stable operation of the internal combustion engine.

- a transition system that makes it possible to achieve a smooth increase in speed, without jerking, during the opening of the secondary chamber.

Each of the systems in this unit performs its own specific task, and configuration and adjustment are carried out using adjusting screws, selection of jets, setting the angles of the throttle and air damper.

Principle of operation

The VAZ-11113 carburetor works on the same principle as the Solex. The essence of the operation is very simple - the float chamber constantly contains gasoline, which, due to rarefaction through the gas pump, is mixed with the air flow, forming together with it an air-fuel mixture.

It all works like this - the driver uses the gas pedal to act on the throttles, thereby changing the flow rate of air sucked into the cylinders.

The air flow passing through the diffusers creates a vacuum in the nozzles, which causes the fuel in the float chamber to be sucked in. The gasoline sucked in by the flow passes through the fuel nozzle, which, thanks to the small cross-section of the hole, breaks the liquid into small droplets, which makes it easy to evaporate. And already in evaporated form, gasoline is mixed into the air through a sprayer.

The engine operates in different modes, to which the GDS does not always have time to adapt (it needs to dispense the amount of gasoline), which can cause dips and jerks.

To eliminate such problems, an economizer and an accelerator pump are included in the carburetor design. The first provides an increased amount of gasoline at high engine loads. This is done by supplying part of the fuel to the atomizer, bypassing the fuel nozzle.

The accelerator pump is responsible for supplying the required amount of gasoline when the throttles are opened sharply. He does this by injecting fuel through an additional nozzle. That is, when you sharply press the gas, gasoline is supplied into the air flow not only through the hydraulic system, but also through the accelerator atomizer.

Engine operation at idle is ensured by the idle speed system. It consists of channels through which fuel is supplied to the lower dampers. The air required for engine operation when the throttles are closed enters through holes made in the dampers. Therefore, even with the accelerator fully released, the combustion chambers are supplied with the air-fuel mixture necessary for the engine to operate at the lowest possible speed.

Do-it-yourself cleaning of the VAZ Oka carburetor

The most common problem with the failure of the normal operation of the Okushka engine is clogging of the carburetor unit, and both the jets and various channels can become clogged with debris and dirt. This raises all sorts of problems:

- idle speed disappears;

- The internal combustion engine does not develop speed;

- the motor is troublesome;

- fuel consumption increases;

- Black smoke comes out of the muffler exhaust pipe.

In some cases, repairs as such are not required; you can only get by by cleaning the carburetor. One of the most common problems with VAZ small cars is clogging of the GDS channels, when the engine does not pick up speed when the damper of the first carburetor chamber is open, although the idle speed is not lost. Here, quite often it is possible to blow out the heat exchanger with compressed air on site, without removing the fuel mixing device itself. We perform this operation with our own hands approximately this way:

- with the engine turned off, open the hood, first of all dismantle the air filter housing (AHF);

- We use compressed air (using a hand pump, blower or compressor) to blow through the HDS channels;

- after such cleaning, we start the engine, check how the engine picks up speed;

If the operation of the internal combustion engine has returned to normal after the operation, you can replace the air filter; if not, repeat the purging again.

Adjusting the gasoline level Oka 11113

If the fuel level in the float chamber (FC) is significantly less than required, the fuel mixture will be lean, the car may accelerate poorly, and there is a possibility of increased fuel consumption. With an increased level, gasoline consumption also increases; in both cases, it is necessary to adjust the position of the float to the desired level. If the carburetor floods, the cause of the problem is most likely not related to the adjustment, but to a loose fit of the locking needle to the seat, and in this case the locking mechanism in the PC will need to be replaced.

The adjustment is quite simple even for a driver with basic plumbing skills; this is done as follows:

- just as in the case of purging, first remove the CWF;

- then disconnect the choke cable:

- disconnect the fuel hoses (“return” and main);

- unscrew the five screws securing the top carburetor cover;

- remove the cover and gasket to the side;

- take a caliper or a specially cut piece of a ruler, measure the distance from the top edge of the body to the surface of the gasoline, it should be within 22-23 mm;

- if the readings obtained differ from the norm, we bend the float tongue in one direction or another, achieving the desired result;

- If it was possible to adjust normally, close the lid and replace the housing assembly with the air filter.

When performing all these operations, one nuance must be taken into account: when removing and installing the carburetor cover 11113, the shut-off needle falls out of it; removal must be done carefully so as not to lose the part, but installed by creating a vacuum (for example, using a rubber bulb, due to vacuum the needle holds and does not fall).

Design features

Despite the fact that the Solex from the Eight was taken as the basis for its creation, the Oka carburetor has some design features:

- The float and shut-off needle are separated. The first element is installed in the float chamber, the second is located in the lid. Because of this, the technology for adjusting the fuel level differs from the usual Solex;

- There is only one float chamber, and it is located on the side of the main dosing system (and not on the sides, like the Solex);

- The float is fixed in the chamber in such a way that a constant normal supply of gasoline is ensured during acceleration and upward movements;

- The calibration (hole cross-section) of the jets is smaller than that of the DAAZ from 2108.

As for the differences between the carburetors of the Oka models 1111 and 11113, they only come down to different calibrations of the jets.

Model 1111 uses fuel jets with a calibration of 95 (on the 1st and 2nd chambers) and air jets with a calibration of 190 (1st chamber) and 95 (2nd).

Version 11113 has 95 fuel jets (on both chambers) and 170 (1st), 85 (2nd chamber).

Since the dimensional parameters of Solex jets are identical and only the sections differ, it is possible to upgrade the Oka carburetor to increase power by installing jets of larger sections (but at the same time, gasoline consumption will also increase).

Idle adjustment

Loss of idle speed, instability at low speeds, and frequent engine stops cause a lot of trouble for car owners; to eliminate such malfunctions, the carburetor has to be removed. But in some cases, you can do without disassembling/assembling the HRSG, limiting yourself to only purging.

Cleaning the XX channel can be done as follows:

- Having turned off the engine, removed the KVF and disconnected the supply wire, unscrew the XX solenoid valve;

- plugging the channel with your finger in the place where the electromagnetic valve (EMV) was turned out, start the internal combustion engine, apply gas, let the engine run for a while;

- we blow through the jet and the EMG itself, put the parts in place, connect the wiring;

- use the quantity screw to add a little speed and start the engine;

- if the cleaning was successful, the engine will already operate at idle, but at increased speed;

- Now, turning the quality screw, we adjust the fuel mixture, turn it until the engine begins to slow down somewhat and “fail”;

- slightly unscrewing the quality screw, having achieved stable functioning of the engine, use the quantity screw to set XX within the prescribed norm (850-900 rpm).

Overfills the carburetor

Often on the Oka a situation arises when the carburetor floods; with such a malfunction it is usually very difficult to start the car, and in other cases the engine does not start at all. There may be several reasons for the problem:

- does not hold the needle valve;

- the fuel pump creates too much fuel pressure (if a return line is not installed);

- the level in the PC is set incorrectly (more than normal);

- The float is not sealed.

Finding the cause of the defect usually begins with inspecting the parts of the float chamber, and if there is significant overflow and smells of gasoline, first of all you should pay attention to the locking mechanism.

What to prepare

The return is done through a tee. A hose that can withstand gasoline pressure is also used. Its length of 70 cm will be sufficient. You will need a check valve from the V8, a fuel pump filter and about a dozen metal clamps.

It is also recommended to use a 125 carburetor fuel jet. You just need to modernize it - make a thread, carefully work on the fitting. You need to make a smaller hole in the plug than in the fitting.

The price of parts that will be used in the modernization process will not exceed 100 rubles. You can use old hose and filter. They're probably lying around in the garage.

Installation of Solex on Oka

It is often possible to achieve fuel economy and more stable engine operation by repairing the carburetor, replacing the repair kit, and making proper adjustments. But not all owners of small cars are satisfied with the dynamics of the engine and its throttle response, so some drivers perform tuning - install a Solex control unit from cars 2108-09. The price of this unit is relatively low, and many can afford this installation, but it will require some additional parts and minor modifications. Spare parts needed:

- thick spacer for the carburetor;

- 2 thin gaskets;

- clamps;

- fuel pipes (if necessary).

In any case, you will need to do something with the air filter housing: either upgrade an existing part, or purchase it from the VAZ-2108 (09) model. It's all about price, and if you want to save money, then it is better, of course, to modernize. Replacing a standard carburetor unit with a Solex is done as follows:

- remove the old HRSG (dismantle the air filter assembly, disconnect the fuel hoses, gas draft, choke cable, unscrew the four fastening nuts);

- We install thin gaskets on the collector platform, and a spacer between them;

- fasten the Solex with four nuts;

- we attach the gas rod, there should be no problems, adjustments are usually not required here;

- connect the EMG wire;

- we secure the fuel pipes with clamps; if there is no return line on the machine, we install a plug on the corresponding fitting;

- the choke cable will need to be “thrown over”, otherwise it will not be long enough;

- Having connected and installed everything except the “air”, we pump fuel into the float chamber with a gas pump, and try to start the engine.

Idle speed adjustment should be carried out only after the internal combustion engine has completely warmed up; idle speed is adjusted by tightening and unscrewing the quality and quantity screws. First, by using “quantity,” we raise the speed a little (to about 1000), then we tighten the quality screw until the engine runs quieter and small interruptions appear. We “add quality” a little, turning the screw a little, and using “quantity” we achieve speed within the standard range of 850-900 rpm.

Finally, we install the “air” in place and conduct tests on the road. If fuel consumption seems high, or the idle speed is not satisfactory, idle speed can always be adjusted on site, without removing the air filter housing.

Oka cars, due to their compact size and stable operation of the power unit, have been quite popular in Russia over the past decades. And today their operation does not cause any complaints from owners. However, over time, each vehicle will need high-quality repairs and adjustment of basic operating parameters. In particular, the carburetor on the Oka is the most sensitive unit in the car’s equipment, so it requires special attention.

What carburetors are installed on Oka cars?

To equip the power units of Oka cars, carburetors produced by the Dimitrovgrad Automotive Unit are used; DAAZ carburetors of a special series are produced.

The DAAZ-1111 carburetor has some specific differences from similar devices . Thus, the float chamber of the mechanism is placed not along the carburetor, but across it. Thanks to this device, the carburetor mechanism can receive additional enrichment of the mixture immediately at the moment of sudden acceleration or braking.

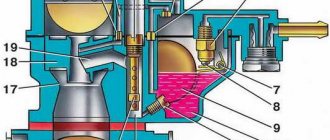

Carburetor mechanism used to equip Oka cars

The DAAZ-1111 itself has a simplified design, as it contains a minimum number of electronic components. The main parts of the unit are:

engine starting device;

two internal combustion chambers;

float chamber and float.

All elements of the device are combined in a common housing cup. Protection from dirt, dust adhesion and unfavorable climatic conditions is provided by the housing cover.

For ease of operation and maintenance, the carburetor is divided into three parts:

The upper one, which consists of a cover with a flange, studs for fastening the air filter element and a fuel fitting.

The middle one is the carburetor body itself, which contains diffusers and a float chamber.

The lower one consists of throttle valves and drive rods.

The carburetor on the Oka performs its functions in exactly the same way as similar mechanisms installed on other vehicles. The fuel is supplied to the cavity of the float chamber, from where it is sent to the first or second chamber for air enrichment. Special sprayers crush gasoline droplets, so they easily mix with air and turn into an air-fuel mixture. This mixture enters the carburetor through diffusers and then into the engine.

Table: parameters of DAAZ-1111–1107010 carburetor dosing systems

Design

Carburetor Oka

The carburetor on an OKA car is quite simple, since it includes a minimum of electronics. Among its main elements are:

- Starting device;

- Valve;

- Lever for adjusting the mixture ratio at low speeds and its block;

- Union;

- Throttle valves;

- The axes of the dampers of the first and second chambers;

- Starting mechanism lever;

- Air damper cable lock on the starting mechanism lever;

- Exhaust gas supply fitting;

- Cable lock for damper control.

In addition, the mechanism is combined in one integral housing, on top of which there is a lid. This design allows for reliable operation of the entire engine in all weather conditions. And if any problems arise, you can try to fix it with a minimum set of tools.

Device repair

Self-repair of a carburetor device requires a clear identification of the malfunction, the ability to properly dismantle the mechanism and wash it. In addition, in case of severe wear, it may be necessary to replace one or another structural element.

If the car owner does not have practical experience in servicing cars, it is not recommended to take any actions independently.

Video: performing repair work on the DAAZ-1111 with your own hands

Malfunctions and their diagnosis

The specificity of the structure of the cavities of the DAAZ-1111 carburetor is that exhaust gases are not removed immediately, but gradually. That is, the engine unit is forced to experience some difficulties when operating at high speeds. In addition, the entire design of the DAAZ-1111 does not prevent lubricating fluids from entering the carburetor, which can quickly lead to its contamination.

If the ignition system operates without interruption, the following malfunctions may occur on the Oka carburetor:

instability of the engine unit (this may be due to carbon deposits on the fuel nozzles or malfunctions of the economizer);

incorrect operation of the gas pedal while driving (the nozzle holes are clogged);

deterioration in the dynamic qualities of the car occurs due to a critical decrease in the fuel level in the float chamber - the engine simply does not have enough fuel to fully operate at high speeds;

jerks during movement indicate that carbon deposits have formed in the float chamber, therefore the normal movement of fuel in the system is disrupted;

instability of revolutions indicates that the carburetor trigger needs to be adjusted.

However, the main sign that indicates a malfunction of the carburetor can be considered a sharp increase in fuel consumption.

Maintenance, adjustment

Thanks to its simple design and minimal amount of electronics, the Oka carburetor is a fairly reliable unit. But to keep it in full working order, periodic maintenance is required.

Signs that the Oka carburetor needs repair are the following symptoms:

- Difficulty starting the engine;

- Unstable operation at XX;

- The occurrence of dips, jerks under load, sudden opening of the throttles;

- Power drop;

Since problems with the ignition system have the same symptoms, it would be a good idea to check its performance together with the power system.

The main disadvantage of the carburetor is the presence of a large number of channels and components with small cross-section holes, which over time become clogged with debris and resinous deposits contained in the fuel are deposited in them.

Carburetor maintenance involves complete disassembly, washing and purging of channels, jets, and tubes. At the same time, it is not recommended to use metal objects (needles, awls) for cleaning, so as not to affect the cross-section of the holes, although the use of wooden objects (toothpicks) for cleaning is allowed.

For mild contamination, special products also help. products for cleaning carburetors, the use of which does not require dismantling and disassembling the unit - washing is carried out with the carburetor installed and the engine running.

Possible breakdowns of the unit include:

- Failure of the solenoid valve;

- Accelerator pump diaphragm rupture;

- Wear of the mounting holes of the throttle axles;

- Warping of the throttle body plane due to uneven tightening;

There are not so many settings for the DAAZ “Oka” - the level in the float chamber and the idle speed are regulated.

The first operation is performed like this:

- Remove the cover;

- We measure the height of the protrusion of the top of the locking needle above the plane of the lid, holding the lid strictly horizontally (so that the needle “looks” down). The normal protrusion height is 10 mm. If the indicator does not correspond, you need to add a gasket under the needle seat;

- Put the cover in place;

- Manually pumping the pump pumps fuel into the carburetor (you need to fill it completely);

- Remove the cover;

- We measure the distance from the surface of the fuel to the upper plane of the body. With normal adjustment, this figure should correspond to 23-24 mm. If the distance is greater or less, we adjust it by bending the tongue on the float (to reduce the quantity, bend it up, and to increase it, bend it down).

The XX speed adjustment is carried out using a quality screw. Work should be performed with a warm engine and with electrical appliances turned on (to create a load). The essence of the adjustment comes down to the fact that you need to rotate the screw to achieve engine speed at 800-1000 rpm.

How to remove

The removal procedure is quite simple, but it is recommended to follow a clear action plan so as not to damage the internal components of the carburetor during the dismantling process. To successfully carry out the work, you will need only three tools:

open-end wrench 8;

open-end wrench 13;

Before starting work, you must disconnect the wire from the negative terminal of the battery. This action will protect you from possible electric shock.

The procedure for dismantling the DAAZ-1111 carburetor is as follows:

Installing a carburetor on the Oka

Reinstalling the carburetor mechanism on a vehicle after cleaning and repair can be a labor-intensive procedure. In order for the power unit to operate in normal mode, it is necessary to correctly connect all the components of the carburetor and securely fix them.

Getting started with installing the DAAZ-1111 is based on installing the gasket. The element is put on the studs and pressed tightly against the surface of the intake manifold. After which the carburetor itself is installed in its place:

First, screw in the two fastening nuts on the front side.

The other two nuts are tightened on the back side, after which the economizer valve can be returned to its previous position.

The first step is to connect the pipe that supplies fuel to the mechanism. It is recommended to use a new clamp to secure it.

Next, connect the vacuum regulator hose.

The connector that comes from the engine is connected to the forced idle economizer valve. Before connecting, it is advisable to make sure that the connector is clean and free of deformations.

The crankcase ventilation hose is connected to the fitting.

The tip of the intermediate rod of the lever is screwed to the corresponding place on the carburetor.

The drive rod is returned to its place and connected to the lines.

Next, it is recommended to install the air filter in place and check the operation of the system. If gasoline leaks out at the joints, you need to carefully tighten them again.

Adjusting the throttle valve drive

You will need: keys for “8” and “13” (two), a screwdriver.

Before starting work, remove the air filter (see Subsection 3.9).

The actuator is adjusted by the throttle valve of the first chamber of the carburetor. The throttle valve of the second chamber is actuated by the throttle lever of the first chamber.

Fully depress the accelerator pedal. In this case, the throttle valves must open fully (the throttle lever must move towards the front of the car until it stops).

Make sure the doors are completely open. To do this, press on the tip of the intermediate link. If it can be moved further, the unit must be adjusted.

Release the accelerator pedal and the throttles should close completely. The throttle lever should rotate, moving the intermediate link all the way in the opposite direction. If this does not happen, the drive must be adjusted.

To adjust, loosen one of the adjusting nuts. As you tighten another nut, make sure the damper is fully open and closed.

Notice that when you tighten nut 1, the door opens and nut 2 closes. Then tighten the loose nut.

If the rod is not long enough, adjust the position of the throttles (in this case, the throttle valve does not close completely).

. loosen the locknuts at the ends of the intermediate links.

. Remove the end of the rod from the intermediate transmission lever.

.. Attach the end of the stem shell to the bracket approximately in the middle.

. by unscrewing or screwing the ends, change the length of the intermediate link so that.

. could be connected without moving the levers. Secure the ends with locknuts. Then recheck and, if necessary, adjust the throttle valve to full opening using the rod.

Adjusting the Oka carburetor after repair with your own hands

After the DAAZ-1111 carburetor has been repaired, adjustment of the starting device is usually required. For these purposes you will need a simple set of tools:

open-end wrench 7;

It is necessary to adjust the starting device with the carburetor removed from the engine, since otherwise it will not be possible to fully carry out the adjustment. The proposed instructions will be able to ensure a stable and quick start of the engine “in the cold”. To do this, you will need to adjust the operation of two dampers in the primary chamber:

Turn the choke control lever counterclockwise until it stops. Hold the lever in this position until the damper is completely closed.

Using a screwdriver, lower the starter rod. When the rod is lowered, the air damper will gradually rise.

At this point you will need to check the thickness between the bottom of the choke and the carburetor wall. A drill with a diameter of 2.2 mm should fit into the gap. If the gap is larger/smaller, it is recommended to lower the rod until the hole exactly matches the thickness of the drill.

After this, without releasing the choke lever, you will need to turn the carburetor body over. A drill with a diameter of 0.8 mm also checks the gap between the throttle valve and the chamber wall. It is necessary to adjust the thickness of the gap by rotating the stop screw.

When the recommended values are achieved, the adjustment of the starting device can be considered complete.

Video instruction: adjustment procedure

Carrying out work with the DAAZ-1111 carburetor due to the simplicity of its design is not considered a difficult task. With a minimum number of tools and practical experience working with carburetor mechanisms, the car owner can cope with the task on his own. Most often, it is necessary to clean the carburetor elements from carbon deposits, as well as adjust some operating parameters. Attentiveness and accuracy when performing the necessary actions can be considered the key to high-quality performance of all work to optimize the operation of the DAAZ-1111.

A clogged carburetor becomes a source of headache for any car owner. The driver of an OKA car is no exception in this sense. If the carburetor is not repaired in time, you can forget about a comfortable ride. Can I repair this device myself? Of course.

VAZ 11113

Adjusting the carburetor drive

Performed when replacing a carburetor, as well as when drive parts are worn or replaced.

- When the gas pedal is fully pressed, the throttle valves should be fully open, and when released, they should be closed.

- If this is not the case, by unscrewing or tightening the adjusting nuts on the front end of the drive cable (carburetor side), we achieve the correct position of the throttle valves.

- The tension of the cable with the pedal fully released is checked as follows: we pull the cable in the middle of the branch near the carburetor by about 10 mm, while the throttle valves should not open. If you pull the branch back a large amount (about 15 mm), they should begin to open slightly.

Adjusting the fuel level in the float chamber

Performed when replacing a needle valve or float (see also “Diagnostics of engine malfunctions”).

- We remove the carburetor cover (see "Disassembling the carburetor") and measure the protrusion of the needle valve above the cover, which should be 10 mm. If this is not the case, replace the gasket or valve with gasket.

- Having placed the float with its lower part on a flat surface, measure the distance from it to the center of the float axis. It should be 23.1 mm. We adjust the size by bending the lever.

- We measure the distance from the tongue to the top plane of the float, which should be 2.0 mm.

- A drill can be used as a gauge.

- We adjust the distance by bending the tongue. In this case, its supporting surface must be perpendicular to the axis of the needle valve.

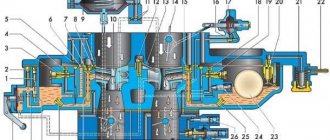

Adjusting the starter

Performed on a removed carburetor.

- When turning the choke control lever counterclockwise all the way, the choke should close completely. If it does not close, eliminate the cause of the jam (or straighten the deformed valve).

- With the air damper completely closed, the throttle valve of the first chamber must be slightly open to the starting gap C (see figure).

- This gap is adjusted by turning the screw on the throttle drive lever with a thin slotted screwdriver.

- With the air damper completely closed, press manually (you can use a screwdriver, stick, etc.) on the trigger rod until it stops. In this case, the air damper should open slightly to the starting gap (see table above). We use a drill as a gauge.

- To adjust the gap, use an “8” wrench to loosen the lock nut of the screw located on the starter cover. Inserting a thin slotted screwdriver into the slot, unscrew (to increase the gap) or tighten (to decrease the gap) the screw, and then tighten the locknut.

Starting device: 1 - starting device lever; 2 — throttle valve; 3 - thrust screw for opening the throttle valve; 4 — lever on the axis of the throttle valve of the first chamber; 5 — starter control cable: 6 — lower edge of the cam groove; 7 — upper edge of the cam groove: 8 — air damper spring; 9 - air damper: 10-lever on the air damper axis; 11 — trigger diaphragm rod: 12 — trigger diaphragm: 13 — diaphragm thrust (adjusting) screw; 14 — screw for fastening the trigger lever; B - starting gap of the air damper; C - starting gap of the throttle valve.

Adjusting the idle system

Performed during maintenance and engine malfunctions (see “Diagnostics of faults”).

- The adjustment is performed on a warm engine. At the factory, the engine is adjusted to a minimum crankshaft speed of 820-900 rpm and a carbon monoxide (CO) content of 0.5-1.2%, after which a restrictive plastic sleeve is pressed onto the screw head. If by turning the bushings it is not possible to restore the factory adjustment parameters, we unscrew the screw, breaking the bushing, then by rotating the quantity screw we set the crankshaft speed, and by turning the quality screw we set the content of carbon monoxide in the exhaust gases.

- When you press the gas pedal, the engine should increase the crankshaft speed without interruption, and when you release the pedal, it should not stall.

- When turning the quantity screw clockwise, the crankshaft speed increases.

- When turning the quality screw clockwise, the CO content in the exhaust gases increases.

VAZ Oka with a 0.75 liter engine is a popular small passenger car of the nineties and 2000s, which won the hearts of many motorists due to its maneuverability, fairly high cross-country ability and efficiency. But fuel consumption could not always be the same; it largely depended on how the Oka 11113 carburetor was configured.

Currently, these small cars are still on the roads of our country, and spare parts for cars are in demand. Also for Okushka they sell carburetor units (CU) of various modifications, repair kits, jets, gaskets and other parts; they can be bought in specialized stores, and the adjustment and repair of the fuel system is carried out not only by specialists, but also by many car owners themselves.

Models of carburetors for OKA cars

There are several modifications of OKA cars. The very first car of this brand was model 1111. It was produced at the VAZ and KamAZ factories. This model had an engine capacity of 0.65 liters and was equipped with a DMZ brand carburetor, which was produced at the auto parts plant in Dimitrovgrad.

Main elements of the DAAZ 1111 carburetor for the OKA car

Then a new OKA car model appeared - 11113. The engine capacity of this car was slightly larger and amounted to 0.75 liters. Accordingly, the carburetor has also changed slightly. Model 11113 is equipped with DAAZ 1111 carburetors. This device is produced at the same plant in Dimitrovgrad. This carburetor differs from its predecessor only in the increased size of the mixing chamber. In all other respects, the device has not undergone any changes.

Common carburetor malfunctions and their causes

- the carburetor fires. This is the most common malfunction associated with the carburetors of OKA vehicles. Usually the problem occurs due to low-quality gasoline. Because of it, a too lean fuel mixture begins to flow into the carburetor, after which the driver hears a loud bang under the hood, reminiscent of a pistol shot. To fix the problem, you should drain the low-quality fuel, change the gas station and clean the carburetor jets;

- excess gasoline in the carburetor. If too much gasoline enters the device, it is very difficult to start the car: the engine starts, but immediately stalls. To eliminate this problem, you need to fine-tune the carburetor, and if the problem persists, install a new set of spark plugs;

- there is no gasoline in the carburetor. If gasoline does not enter the carburetor, the car simply will not start. Typically, fuel stops flowing due to a blockage in one of the chambers of the device or due to poor adjustment. There is only one solution: remove the carburetor, completely disassemble it and wash it;

- Condensation has formed in the carburetor. This problem is rare, but it cannot be ignored. Most often, condensation appears in the carburetor in winter, during severe frosts. After this the car starts very hard. If you still manage to start, you need to warm up the engine properly for 10–15 minutes. Usually this is enough to completely eliminate condensation.

Dismantling the carburetor OKA 11113

Before proceeding with dismantling the carburetor, you should decide on the necessary tools.

Tools and materials

- set of open-end wrenches;

- flat screwdriver, medium size;

- set of spanners.

Sequence of operations

- The hood of the car is opened and the negative terminal is removed from the battery.

- The air damper is attached to the rod using a 12mm bolt. This bolt is slightly loosened with an open-end wrench.

The carburetor choke bolt of an OKA car is loosened using an open-end wrench.

The bolt on the OKA carburetor bracket is loosened with an open-end wrench

The choke rod of the carburetor of the OKA car is removed manually

The intermediate rod of the OKA carburetor is removed using a flat screwdriver

The ventilation hose from the carburetor of an OKA car is removed manually

The wires of the OKA car idle economizer are disconnected manually

Manually removing the vacuum regulator hose on the OKA carburetor

Using a screwdriver to loosen the clamp of the main fuel hose of the carburetor on an OKA car

The OKA car air filter bracket is removed manually

After unscrewing the fastening nuts, the carburetor is removed from the OKA car manually

Cleaning the carburetor from carbon deposits and dirt

Most carburetor problems occur due to poor quality fuel. This is what causes plaque and soot to appear. It also causes blockages in the fuel channels. To eliminate all this, you will have to use a special cleaning fluid for carburetors. It is a spray can. The cylinder is usually accompanied by a set of nozzles for flushing the carburetor channels. There are many manufacturers of fluid, but HG3177 fluid is especially popular among car enthusiasts, allowing you to perfectly flush the carburetor in a few minutes.

Tools and Supplies

- rags;

- several toothpicks;

- a piece of thin steel wire 30 cm long;

- compressed air cylinder;

- protective rubber gloves and glasses;

- set of open-end wrenches;

- flat screwdriver;

- carburetor cleaning fluid.

Sequencing

- Once removed from the vehicle, the carburetor is completely disassembled.

Completely disassembled and prepared for cleaning, the DAAZ 1111 carburetor for the OKA car

Adjusting the OKA carburetor

- The choke lever is turned counterclockwise all the way and held. In this position, the carburetor air damper should be tightly closed.

In the lowest position of the lever, the carburetor flap of the OKA car must be completely closed

The carburetor starting rod on the OKA car is recessed with a flat screwdriver until it stops

The gap on the air damper of the carburetor OKA is measured with a feeler gauge

The air damper clearance on an OKA car is adjusted by rotating a stop screw

The throttle valve clearance on an OKA carburetor is measured using a feeler gauge

The clearance on the throttle valves of the OKA carburetor is adjusted by rotating the thrust screw

Adjusting the carburetor clearances of an OKA car - video

Removing and adjusting the carburetor of an OKA car is not an easy task. However, even a novice car enthusiast can do it. Provided that he follows these instructions exactly. Particular attention should be paid to checking carburetor clearances. If at least one of them is not set correctly, new problems with the carburetor cannot be avoided.

| Diffuser diameter, mm | 20 | 25 |

| Mixing chamber diameter, mm | 28 | 36 |

| Calibrating the main fuel jet | 95 | 95(102,5)* |

| Calibrating the main air jet | 170 | 85 |

| Calibration of the fuel jet of the idle jet and the diameter of the transition system of the second chamber | 41 | 0,50 |

| Diameter of idle air jets and transition system of the second chamber, mm | 1,5 | 0,7 |

| Econostat fuel jet diameter, mm | — | 0,95 |

| Diameter of accelerator pump nozzles, mm | 0,40 | 0,35 |

| Fuel supply by accelerator pump, cm3 per 10 strokes | 8,0+2,0 | |

| Starting gaps of dampers, mm air throttle | ||

| 2,2+0,2 | ||

| 0,7–0,8 | ||

Adjusting the air damper drive

If the engine does not produce full power and does not have sufficient throttle response, it may be due to the air in the carburetor or throttle valves not opening fully.

One of the reasons for the difficult starting of the engine could be incomplete closing of the air damper.

You will need: Key "8".

Before starting work, remove the air filter (see Subsection 3.9).

Pull out the choke control on the instrument panel until it stops.

. The air damper must close completely.

Fully press the choke control. In this case, the air damper must open completely. This can be checked.

. on the lever lock ball, which should fit into the hole in the lever. If the damper does not open or close completely, its actuator must be adjusted.

To adjust, loosen the bolt securing the linkage to the starter control lever.

Rotate the choke lever until it is fully open.

Pull the rod completely out of the housing and tighten the bolt securing the rod to the air control lever (make sure there is no flex in the rod).

Pull out the choke control (on the instrument panel) until it stops. If the air damper is not completely closed, unscrew the bolt securing the thrust housing.

Move the cover until the damper is completely closed. Tighten the casing bolt. After this, check again and, if necessary, adjust the full opening of the air damper using the rod.