Types of Kopeyka carburetors

Jets for carburetors of VAZ 2101, VAZ 2103, VAZ 2106, VAZ 2107

During the production of the VAZ 2101, several modifications of carburetors were installed in its system. They differ in the size of the jets, as well as the presence or absence of a vacuum corrector. In early Zhiguli models, a carburetor was installed with an ignition system without a vacuum corrector.

The most common carburetor on the VAZ 2101 car is the DAAZ carburetor model 2101-1107010. A vacuum corrector system is already used here. All modifications of carburetors can be adjusted using a similar scheme. But it is impossible to install a model with a vacuum corrector instead of a design without it, or vice versa. Carburetors of well-known brands DAAZ/Weber, Ozone, Solex are also often used; among non-standard carburetors, I would like to highlight Solex 21073 and Solex 21083.

Calibration data for DAAZ carburetors 2101-1107010-01, 2101-1107010-03, 2105-1107010-20, 2105-1107010 10:

| Parameter | Carburetor model and chamber number | |||||

| 2101-1107010-01 | 2101-1107010-03 | 2105-1107010-20, 2105-1107010 10 | ||||

| 1st | 2nd | 1st | 2nd | 1st | 2nd | |

| Diameter, mm: | ||||||

| diffuser | 23 | 23 | 23 | 23 | 21 | 25 |

| main fuel jet | 1.30 | 1.25 | 1.30 | 1,30 | 1.07′ | 1.62 |

| main air jet | 1.50 | 1,90 | 1.50 | 2,00 | 1.70 | 1.70 |

| idle fuel jet and transition system | 0.50 | 0.45 | 0.45 | 0.60 | 0.50 | 0.60 |

| idle air jet and transition system | 1.70 | 0.70 | 1,70 | 0.70 | 1.70 | 0.70 |

| accelerator pump nozzle hole | 0.40 | 0,40 | 0.40 | |||

| accelerator pump bypass jet | 0,40 | — | 0.40 | — | 0.40 | |

| ecomostat fuel jet | — | 1.50 | — | 1.50 | — | 1.50 |

| air jet econoepta | 0.90 | — | 0.90 | 1.20 | ||

| econostat emulsion jet | 1.70 | — | 1.70 | — | 1.50 | |

| starter air jet | 0.70 | — | 0.70 | 0.70 | — | |

| jet of the pneumatic drive of the throttle valve of the second chamber | — | — | — | 1.20 | 1.00 | |

| Spray calibration number | 4 | 4.5 | 4 | 4 | 3.5 | 4.5 |

| Emulsion tube calibration number | FI5 | FI5 | F15 | FI5 | F15 | F15 |

| Accelerator pump flow for 10 full strokes, cm3 | 7±0.25% | 7±0.25% | 7±0.25% | |||

| Distance of the float from the carburetor cover with gasket, mm | 7.5±0.25 | 6.5±0.25 | 6.5±0.25 | |||

| Clearance at the dampers for regulating the starting device, mm: | ||||||

| air damper | 8±0.5 | 7±0.25 | 5 | |||

| throttle valve | 0.75 | 0.85 | 0.75 | 0.85 | 0.7 | 0.8 |

Adjustment and design of the carburetor on the VAZ 2101

The carburetor on the VAZ 2101 requires periodic tuning and adjustment. Otherwise, the engine will not operate stably at idle or during acceleration. Starting difficulties may also occur. Setting up a carburetor requires some knowledge. However, knowing the technology of how the VAZ 2101 carburetor is adjusted, or as it is popularly called “Kopeyki”, you can perform the entire procedure with your own hands.

When is adjustment needed?

Adjusting the carburetor unit is no more difficult than adjusting the clutch drive on a VAZ 2107, since it only involves adjusting the jets. In some cases, they need to be cleaned of resins and other contaminants; the presence of contaminants is felt by power dips in the process of accelerating. Many car owners claim that Ozone carburetors are not a very good option and recommend replacing them with Solex.

However, the signs that the device has begun to prepare an enriched mixture and needs to be adjusted are the same for both types of units:

- Increased fuel consumption.

- Frequent overheating of the motor.

- Black smoke from the exhaust pipe and pops.

- Loss of power.

The preparation of a lean mixture is characterized by the following characteristics:

- Popping sounds in the carburetor.

- Loss of power.

- Engine overheating.

Of course, you don’t always need to immediately grab a screwdriver and turn the adjusting screws - perhaps it’s something else. For example, when the idle speed floats, air may leak through the intake manifold gasket, or there may be a breakdown of the brake booster diaphragm. But even the reasons listed are not all the options, so specific recipes for eliminating certain problems cannot be given. The issue should be addressed comprehensively, taking into account the connection between vehicle systems.

Float system adjustment:

Before you begin this work, you need to make sure that the needle valve is working reliably.

- We take a measurement between the float and the gasket. This distance should be 6.5 millimeters. A slight deviation of 0.25 millimeters is allowed. You can also simply use a suitable drill bit to measure.

- The clearance is adjusted by changing the angle of the float tongue.

- Turn the float all the way. We measure the distance to the gasket in this position. It should be equal to 8 millimeters. Using the tongue we achieve the desired value.

Carburetor adjustment

The carburetor adjustment process will improve engine performance and extend its service life.

Therefore, it is so important to carry it out more often, without waiting until obvious signs of a malfunction appear, for example, failures in engine operation or a distinct smell of gasoline in the cabin.

A few preliminary steps that will help facilitate and optimize your work:

Before you start setting up, you need to remove the mechanism, wash and blow it out. Prepare tools: a set of wrenches, Phillips and flathead screwdrivers. It is also important to find the instructions for the VAZ 2105 so that all the necessary characteristics are before your eyes.

When everything is ready, you can proceed directly to the setup. Of all the systems that make up the carburetor, only the following are subject to adjustment:

- Device launch system;

- Idle move;

- Maintaining the level of the fuel mixture (related to setting the float mechanism);

- CO2 level.

Next, we will consider all stages in more detail.

Setting the float mechanism

Before tuning, you should let the car idle. Once you have done this, proceed to the next steps:

- Remove the cover from the carburetor.

- Check the fuel fluid level (the value should be 28 mm).

If a different indicator is detected, the float mechanism must be adjusted. For this:

- We place the lid vertically so that the fitting through which the fuel is supplied faces upward. The float tongue should be perpendicular to the axis of the needle valve. If you have different indicators, bend it with pliers.

- The distance from the float to the cardboard spacer is 6-7 mm. Otherwise, we bend the bracket on which the float is held to the required values.

- After adjusting the mechanism is completed, return the cover back.

Adjusting the starter

To configure the device, do the following:

Close the choke (for convenience, secure with a paper clip). Pay attention to how the telescopic rod is installed. Using your finger, pull the thrust lever until it stops. We measure the gap of the slightly open upper flap

Standard – 5 mm along the bottom slot. For convenience, you can measure with a drill of a suitable size. If the value does not correspond to the specified one, then set the required gap by rotating a special adjusting screw located on the generator starting device.

Idle speed adjustment

Adjustment is necessary when idle speed disappears

It is important not to make mistakes here, so you cannot repair the mechanism without knowing its structure or at least first reading the instructions. What do you need for this?

- Unscrew the quality screw (three or three and a half turns). Turn the quantity screw back six to seven turns.

- We start the engine. Reduce crankshaft speed if it is too high.

- After the engine has warmed up, set the tachometer to 900 rpm, turning the quantitative screw.

- Ten minutes later we turn off the car. Checking the spark plug electrodes. If there is no soot, the setting is successful.

- If soot appears, clean the electrodes and tighten the quality screw 0.5 - 1 turn. Next, we repeat the previous steps until the soot on the candles disappears.

Malfunctions that may precede carburetor adjustment

Adjusting the VAZ-2101 carburetor may be necessary even before the car owner can notice the first signs of a malfunction. For example, unstable operation of the power unit at idle, changes in crankshaft speed, or regular “damping” of the engine are not always problems that arise from the carburetor. The above device can only be blamed when such problems arose out of nowhere, without prerequisites.

For some reason, a failed carburetor or its assembly needs urgent adjustment, even if the changes did not occur too dramatically. As a rule, floating idle speed appears if there is a problem with the solenoid valve.

A motorist who does not know how to adjust the solenoid valve must disconnect the wire supplying this element and apply the “plus” to the valve contact via the battery. If the winding is functioning normally, a soft click will be heard at the moment of connection. At the same time, you need to check the voltage that is on the wire connected to the electric valve. If there is no voltage, the wiring is damaged. Most likely, such a break is located in the section of the wire that goes from the ignition switch to the valve.

Engine malfunctions are not always signs of the need for carburetor adjustment

The need to adjust the carburetor may also arise in a situation where there is a large amount of carbon deposits in the spark plug electrodes. Because of this circumstance, the spark power will not be enough, which will not allow the gasoline-air mixture to ignite. Even the carburetor can affect the carbon deposits accumulated on the electrodes. Performing its function, it transfers a huge amount of mixture to the combustion chambers. In addition, burnout of the intake valve may occur.

First, you need to adjust the fuel level on a VAZ-2101 car. The motorist will have to adjust the position of the float. Problems can appear to a greater extent only at high speeds. Most likely, it is not the carburetor that is to blame, but the fuel supply. In a used VAZ-2101, the fuel pump diaphragm often wears out and the fuel pump rod wears out.

How to adjust carburetor idle speed?

Idle speed is adjusted on a warm engine according to the following scheme:

- bring the internal combustion engine to 850 rpm using the quantity screw;

- then set the speed to maximum using the quality screw;

- reduce the speed to the previous level (up to 850) and raise it again to the maximum;

- turn the quality regulator at 850 rpm to the “motor shaking” position.

After all these operations, the quality screw is slowly unscrewed until the internal combustion engine operates stable.

If all the settings are made correctly, the “five” will not “eat” more than 9 liters of fuel when driving around the city, and on country highways the fuel consumption will be about 7.5 liters.

The process of adjusting the VAZ-2105 carburetor is a simple task that can be completed by any car owner who knows the device and the sequence of necessary operations. consists of creating a fuel-air mixture by mixing gasoline with oxygen and then feeding it into the combustion chamber. In this article we will get acquainted with the design, features and advantages, and also take a detailed look at how to adjust this unit with your own hands.

Today in the car market, carburetor engines are in less demand than injection units. This is due to the trend created by world leaders in the field of mechanical engineering. They offer a new filling with a wider range of capabilities and improved characteristics. However, carburetors have a number of advantages that make them most effective in certain situations. Only they can ensure success. A small volume of vapor is retained in the inlet manifold, which allows you to start the engine on the first try at low temperatures. Also, on domestic VAZ-2105 cars there is a choke. With its help, the fuel system is enriched, the concentration of the combustible mixture is increased, thanks to which the engine warms up much faster.

Introduction

Owners of domestic vehicles, such as, for example, the VAZ-2103, quite often try to fix the car with their own hands. Despite the fact that modern service stations are located on almost every corner and by turning to qualified specialists one could avoid wasting one’s own time, many are in no hurry to solve their problems in this way. Some self-taught craftsmen independently carry out such complex operations, which include adjusting the VAZ-2103 carburetor. Of course, in order to do something like this with your own hands, you need not only free time and patience, but also important and useful knowledge regarding the design features of the device in question.

To adjust the VAZ-2103 carburetor, free time, patience and knowledge are required

In the material below, we will consider the principle of the design of the carburetor of the domestic VAZ-2103, its configuration and adjustment.

What do we have after proper adjustment of the carburetor unit of the “six”?

Checking the adjustments of the fuel mixture preparation unit is the same important maintenance step as monitoring the condition of the car battery. An integrated approach to setting up the carburetor guarantees not only a comfortable mode of movement, but also a lot of useful points:

- An increase in power and a confident increase in speed.

- No failures in the operation of the internal combustion engine in the low and medium speed sector.

- Improved dynamic characteristics - the car picks up speed faster and accelerates in a short time.

- Optimal engine response, which is expressed in the responsiveness of the gas pedal.

The listed qualities make it possible to effectively use the combustible mixture, which is necessary both in urban traffic jams and on country roads. Therefore, proper adjustment of the carburetor unit will help the car gain speed in a timely manner and complete the planned maneuver.

Adjustment of the VAZ carburetor may be required in various cases: after its repair, after repair of the gas distribution mechanism, ignition system, and even after changing a dirty air filter. Another reason is the transition to winter operating conditions of the car or, conversely, to summer operation. It should be borne in mind that it is possible to correctly and accurately adjust the VAZ carburetor only with the help of a special device - a gas analyzer.

Such a device is available to service station workers who perform work on repairing and adjusting carburetors.

How to adjust a VAZ carburetor with your own hands without special instruments? Before you begin adjusting the VAZ-2106 carburetor, as well as to adjust the VAZ-2104 carburetor, several prerequisites must be met. First: the engine gas distribution mechanism must be in good working order and its valve clearances must be adjusted. Second: work must be performed with a working ignition system and new or fully working spark plugs installed

The third important condition is that the Ozone carburetor itself must be in good working order, its float chamber must be cleaned and adjusted

Adjusting the fuel level in the float chamber is shown in a video by car enthusiast Konstantin Ovchinnikov from Ukraine.

Actually adjusting the VAZ-2105 carburetor consists of setting stable idle speed in a given range. A special feature of Ozone carburetors is an autonomous idle system, that is, fuel is supplied to the engine in this mode bypassing the throttle valves. The idle speed is adjusted using the screws for the amount of fuel mixture (1) and the quality of the fuel mixture (2).

It must be performed with the engine warmed up to operating temperature (about 80 degrees). This can also be done during the carburetor adjustment process. With the engine not running, both screws are screwed in all the way, and then the mixture quantity screw is turned back 3 turns, and the mixture quality screw 4-5 turns. The engine is started and the engine speed is set to around 800 rpm using the quantity screw (by tightening or unscrewing it). It is better if this value can be determined using a strobe light or tachometer on the dashboard. After this, by tightening the mixture quality screw (thereby depleting the fuel-air mixture), we determine at what position the engine speed begins to fall and becomes unstable. From this position, unscrew the mixture quality screw by 0.5 - 1 turn, slightly enriching the mixture for stable engine operation at idle speed. You can try revving the engine to make sure that the idle speed remains stable and is in the range of 800 (+50-50) rpm.

The above operations can be repeated 2-3 times to ensure the correct result. Generally speaking, the task of adjusting the carburetor is to ensure stable engine operation at the appropriate idle speed with the leanest possible fuel-air mixture and, accordingly, the lowest CO level.

Everything described is also true for adjusting the VAZ-2121 carburetor. The VAZ-2107 car is equipped with Ozone with a forced idle economizer, but the VAZ-2107 carburetor is adjusted in the same way. But the adjustment of the VAZ-21213 carburetor is somewhat different, because This model has a Solex carburetor.

Adjusting the VAZ 2101 carburetor - Do-it-yourself VAZ repair

Adjusting the VAZ 2101 carburetor is a very important procedure, without which any car, and even more so, one as old as a “penny”, will not be able to function normally.

It is important to note that carburetor adjustments have been taught for more than one year, and there is even such a profession as a carburetor technician, but we firmly believe that with a certain package of knowledge and without fear of “getting your hands dirty,” absolutely every car owner can handle it.

It is for this reason that we decided to compile quite detailed instructions for you so that you can save your money and continue to enjoy trips on real domestic classics.

If you are tired of tuning and repairing the carburetor, as well as the solid fuel consumption of your penny, you should pay attention to the eleventh generation Corolla cars at toyota-ua.com/models/new-corolla. The 2013 Toyota Corolla delivers significant fuel economy thanks to fuel injector, which delivers consistent, efficient engine performance and lower emissions.

Adjusting the throttle position

The first step in adjusting the carburetor on a “penny” is to set the correct throttle position. To do this job correctly, you must perform the following simple manipulations:

Step 1: In manual mode, rotate the throttle control lever counterclockwise until the throttle valve is fully open.

Step 2: measure the distance to the primary chamber, it should be between 12.5 and 13.5 millimeters. If this is not the case, correct it by bending the rod tendril.

Step 3: measure the maximum throttle opening, it should be between 14.5 and 15.5 millimeters. If this is not the case, then you should correct it by tightening the pneumatic actuator rod.

Correcting the starting device

At the second stage, adjusting the VAZ 2101 carburetor involves adjusting the starting device. As in the previous case, we will provide step-by-step instructions that will help you complete the task easily and simply.

Step 1: In manual mode, turn the secondary throttle lever counterclockwise until it closes.

Step 2: Check that the tip of the thrust lever is firmly attached to the primary throttle shaft and is located at the very end of the trigger rod. If you find that this is not the case, then you will need to correct its position by bending the rod.

Important! You need to bend the rod very carefully, as too much pressure can break it off.

Adjusting the performance of the pump accelerator

The third stage of adjusting the operation of the carburetor on the VAZ 2101 is to control and debug the pump accelerator.

You need to start working with it by checking its functionality. To do this, you must collect the fuel in a beaker that will be generated in 10 full cycles of operating the throttle control lever.

You should get between 5.25 and 8.75 cubic centimeters of fuel. If this is not the case, then you will need to fully bleed the pump 9-10 times, and then measure again.

If this does not help, then you will have to completely change the fuel pump accelerator.

Setting the correct idle speed for the car engine

Adjusting the VAZ 2101 carburetor at the final stage involves setting the correct engine idle speed. To do this, you must follow these simple steps.

Step 1: Warm up the engine for 10-15 minutes.

Step 2: Stop the engine and close the quality screw and quantity screw all the way.

Step 3: Loosen the quantity screw 3 turns and the quality screw 5 turns.

Step 4: Start the engine and use the speed screw to set the engine speed to 800 rpm.

Step 5: Begin to slowly tighten the quality screw, thereby reducing the richness of the fuel mixture. This must be done until the revolutions begin to drop.

Adjusting the idle speed of a car engine with carburetors 2105, 2107 Ozone

Adjusting the idle speed of carburetors 2105, 2107 Ozone and their modifications is one of the most frequently performed operations in carburetor maintenance. As a result, it is necessary to achieve stable engine operation at a crankshaft speed of 850-900 rpm, as well as to normalize the content of CO and CH in the exhaust gases. Tools necessary for adjusting the XX speed

— tachometer (you can use the one built into the instrument panel) — slotted screwdriver (3 mm) If you don’t have a tachometer, you can adjust the idle speed by ear. But for this you must have at least some experience in car repair, since it is necessary to distinguish when the speed is normal and when it is increased or decreased.

Preparatory work

Before making adjustments, you must first make sure that the ignition timing is set correctly. The distributor cover, breaker contacts, armored wire and spark plugs are in good condition.

If the carburetor is after disassembly and reassembly or you simply need to set the initial value of the adjustment screws, then first tighten them completely, and then turn out the “quality” screw by 2-3 turns, and the “quantity” screw by 3-4.

— Warm up the engine to operating temperature (85-95). — With the engine stopped, connect the tachometer and start it again.

procedure for connecting an autotester (tachometer)

Adjusting the idle speed of an engine with a carburetor 2105, 2107 Ozone We carry out the adjustment in four steps.

1. Turn the “quality” screw and set the maximum idle speed.

Rotate the screw counterclockwise.

turn the “quality” screw of the fuel mixture of the carburetor 2105, 2107 Ozone counterclockwise, thereby increasing the supply of gasoline to the fuel-air mixture

2. Use the “quantity” screw to set an even higher rotation speed. For example, 80 rpm more. Rotate the screw counterclockwise.

rotate the “amount” screw of the fuel mixture counterclockwise, increasing the total amount of fuel mixture entering the engine cylinders

3. We check with the “quality” screw whether these revolutions are the maximum for the given position of the “quantity” screw.

Simply rotating it back and forth.

We check by rotating the “quality” screw in different directions whether the set idle speed is maximum

If not, then we carry out the above adjustments again.

4. Keeping the position of the “quantity” screw of the fuel mixture unchanged, tighten the “quality” screw so much that the speed drops to 850-900 rpm.

Adjustment in this way is very simple, but at the same time convenient, since it does not require special equipment.

If, after such an adjustment, the content of CO and CH emissions does not correspond to the norm or the idle speed cannot be adjusted, then it is necessary to check:

— whether the fuel and air jets of the main dosing system are dirty; — whether the main fuel jets of the first and second chambers are reversed; — whether the fuel level in the float chamber is increased; — Is the needle valve working? - Is the fuel jet of the idle system clogged; — whether the holder of the fuel jet of the idle system or the solenoid valve has turned away; — whether the tubes have come off the electro-pneumatic valve; — whether the rubber o-ring on the fuel mixture “quality” screw is damaged.

— In some cases, it makes sense to modify the carburetor idle system. See “Modification of the idle system of Solex and Ozone carburetors.”

Five more articles on the site on adjusting and tuning carburetors 2105, 2107 Ozone

We adjust the speed on the VAZ 2101-VAZ 2107

Check out the photo below:

Note! The photo shows the screws that carry out the adjustment. They are located deep in the carburetor throttle body, so the screw under the number “1” is not visible in the image. On some cars, bushings are pressed onto both screws, thanks to which the screws can only be turned half a turn. If the bushings prevent the idle speed screw from turning properly, remove the screws and break the bushing heads. Wipe off the remaining broken bushings and screw the screws in their place.

Gas analyzer to the rescue!

First, start the car and let it warm up to operating temperature of “90-95 ° C”. Afterwards, using a screwdriver, start rotating the screw under the number “2”, rotate it until the crankshaft speed reaches “750-800 min”.

Note! Tightening the screw leads to a decrease in the crankshaft speed, and unscrewing it leads to an increase!

Now smoothly proceed to adjusting the “CO” content in the exhaust gases: turn screw number “1” in the photo above. When tightening the screw, the “CO” in the exhaust gases will gradually decrease, and unscrewing it will increase accordingly.

Note! It is required to regulate the CO content in the exhaust in accordance with GOST today. There is no need to lower “CO” below the norm, otherwise the content of unburned hydrocarbons “CH” may increase sharply. By the way, adjusting screw “1” changes the crankshaft speed.

Finally, turn screw “2”, bringing the crankshaft rotation speed back to normal. Check the amount of CO in the exhaust using the device. Adjust the screws until engine operation and CO emissions into the atmosphere reach normal levels.

Note! After all the manipulations, get into the car, sharply press the gas pedal and release. Make sure that the engine runs smoothly, and when you release the pedal, the car engine should not stall. Is it stalling? – increase the crankshaft speed to “800 rpm” with screw No. 2.

What models are installed on VAZ 2106/2107 cars

All types of carburetor mechanisms equipped with the VAZ 2106/2107 are aimed at reducing fuel consumption and giving the car maximum dynamism. In addition, an important role is played by such an indicator as environmental friendliness. For a decade, AvtoVAZ engineers gave preference to the most environmentally friendly types of carburetors.

Carburetors of three different models were installed on modern VAZ 2106/2107, as well as on cars produced in previous years:

- Manufacturer: Dimitrovgrad Automobile Assembly Plant (or DAAZ). It should be noted that the company produced carburetors under license from Weber. Structurally, these devices were as simple as possible both in operation and in further maintenance. In addition, their main advantage was to provide excellent speed performance for cars of the sixth and seventh VAZ models. At the same time, DAAZ carburetors consume a very large amount of gasoline - from 10 to 14 liters per 100 kilometers.

- Manufacturer: DAAZ, modification “Ozone”. This is a more advanced version of the first type of DAAZ, which has high environmental performance. The device provides good acceleration characteristics and consumes less than 10 liters of fuel per 100 kilometers. However, the disadvantage of this model is that it comes with a second camera. In its operation, a pneumatic valve plays an important role, which, in case of contamination or poor-quality adjustment, can stop the carburetor from working.

- Manufacturer: DAAZ, modification 21053, which is produced under license from Solex. One of the most modern types of carburetors for equipping the VAZ 2106/2107. Maximum environmentally friendly and productive. It has a more complex design; the first in the DAAZ line is equipped with a reverse fuel supply system, which makes it as economical as possible. However, Solexes are demanding on the quality of gasoline - otherwise the fuel nozzles become clogged very quickly.

Modern VAZ 2107 models are equipped with this unit.

Common features in the design of carburetors for the VAZ Six and VAZ Seven

The carburetor mechanisms that are equipped with all VAZ 2106/2107 models throughout the entire production period of the car are two-chamber, that is, they have two internal combustion chambers. Structurally, all carburetors have three indivisible parts:

- at the top there is a cover of the device, which protects the mechanism from dirt, and fuel fittings;

- the middle part is a housing, inside which the chambers and diffusers themselves are located, transfers the air-fuel mixture to the engine;

- The float compartment and throttle valves are located in the lower part.

In the operation of DAAZ carburetors, small parts are of great importance - gaskets, jets, float, economizer or dampers. All elements of the system are interconnected and failures in one part will inevitably lead to failure of the entire device.

The DAAZ carburetor on the VAZ 2106/2107 works according to the following principle:

- Gasoline enters the float chamber through the inlet valve.

- The required fuel level is regulated by the needle of the forced idle economizer or power stroke economizer - in any case, fuel enters the chamber in a strictly defined proportion.

- Next, the fuel is sent to emulsion chamber No. 1 through nozzles.

- In the chamber (or VBC), gasoline is crushed into small parts and mixed with air.

- When the torque increases during acceleration, internal combustion chamber No. 2 may also be activated.

- After the formation of the air-fuel mixture, the pump directs it to the diffusers, and through them to the engine.

That is, the main task of the carburetor is to form the air-fuel mixture in a strictly adjusted proportion to ensure smooth operation of the engine.

The presence of many small elements ensures reliable operation

Purpose of an important node

Many motorists who have no idea how to adjust the carburetor on a VAZ-2103 simply do not understand the principle of operation and design of this device. The function of any carburetor is to mix gasoline and air together. Thanks to this simple device, a special mixture appears in the car at the moment the power unit is activated, transported into the engine cylinders. In fact, how efficiently the vehicle itself operates depends on how well the engine is supplied with gasoline.

Among other components of the device in question, it is worth noting such elements as air and throttle valves, mixing chambers and idle air valve. Of course, these are not all the components of the VAZ-2103 carburetor; in the material below we will consider in detail the operation and principle of setting each individual unit.

The function of the VAZ-2103 carburetor is to mix gasoline and air together

The functionality of any power unit that interacts with a carburetor depends on several important criteria:

- starting and warming up the engine;

- idle devices;

- design responsible for controlling the amount of fuel;

- accelerator pump (how quickly the car can accelerate depends on it);

- the performance of the elements located in the central dosing chamber;

- econostat (located in one of the internal combustion chambers of the engine).

What is a carburetor

The carburetor is installed in the center of the engine under the hood of the “seven” car. To clean the air, an air filter is placed on top of it. Air intake occurs through the front grille, as well as additional hood grilles.

Domestic VAZ cars have carburetors called standard:

All of these types are very popular among car enthusiasts, they last a long time and rarely break down.

The principle of their operation is largely similar, it consists in creating a combustible mixture by mixing fuel with air, then subsequently distributing and uniformly supplying this substance one by one to the engine cylinders.

There are three main types of carburetors: float, needle, bubbler. The latter is very rare and is practically never used.

For clarity, we will analyze the design and functional characteristics of the most popular VAZ carburetor with a float produced.

Before you begin to study its design, you need to understand that the versions of these devices may have serious differences, and therefore are installed strictly on certain machines.

The main elements of the carburetor that perform the work of providing and distributing the combustible mixture are gasoline and air nozzles, a VTS sprayer, a diffuser, an emulsion tube, and a well. All of these products are placed in the main dosing chamber.

Before you start cleaning yourself, you should very clearly understand and remember the basic rule of a car mechanic: never touch those spare parts that cannot break.

General information about the VAZ-2105 carburetor

Listed below are basic information about the carburetors used on the 2105 VAZ model.

- Purpose. To obtain gasoline from the fuel system, mix it with air and transfer it to the engine cylinders.

- Operating modes. There are four of them: preheating, idle load, medium speed, increased power.

- Carburetor type: 2105-1107010 for engines with a power of 1.3 liters. The marking is applied to a special plate that manufacturers attach to various places on the outside of the device. The most popular modifications presented on the Russian market are DAAZ, Ozon, Solex. They are selected according to the volume of the car engine.

- A carburetor is a complex system of interconnected structural parts for various purposes. His main responsibility is to ensure correct fuel consumption and efficient engine operation.

The quality of operation of the 2105 device depends on the modification of the product, the reliability of its components, the brand and quality of gasoline, compliance of the settings with the technical requirements of the operation of the vehicle, sanitary condition, etc. Features of the functioning of carburetors affect the operation of the engine and can change the speed of acceleration and movement car, average gasoline consumption, ignition features.

Write a review

Your feedback:

Attention: HTML is not supported! Use plain text. Grade:

Grade:

Bad Good

Enter the code shown in the picture:

Question: Is this an original DAAZ carburetor, not a fake?

Answer: The carburetors are original.

Carburetors from other manufacturers are often mistaken for fakes: AT, LSA, Road Map, PEKAR

These manufacturers have their own markings and appearance.

We have no information about cases of counterfeit carburetors of the main models produced by OJSC DAAZ. There is no protection on the carburetors either. It is better to make the purchase in the presence of an experienced motorist, who will be able to determine by appearance that the product is counterfeit. Start your purchase by inspecting the carburetor packaging.

Boxes for packaging carburetors are universal, with designations of carburetors that can be packed in them. A mark is made against the designation of the carburetor actually packed in the box, usually in the form of a tick.

All distinctive features, markings, appearance, etc. You can watch the video review on the product page

Question: What color is the box?

Answer: Carburetors come in boxes from LADA Image JSC and OAT Group

Packaging design of JSC "LADA Image":

Packaging design "Group OAT":

Question: There is a version that the original DAAZ products are packaged only in a red and white box, and everything else is fake.

Answer: The official website already has answers to similar questions. You can also find tips and tricks on setting up carburetors there.

Answer:

Answer:

Answer:

1) Why increase the speed much higher than recommended by the car manual?

2) When changing the idle mode only due to one adjusting element, inevitably, the mixture composition will go beyond the optimal range and unstable speed will appear.

Answer:

Question: I have a SOLEKS 21053 carburetor, should the float chamber needle keep the fuel flow if the return line is plugged? Answer: The float and needle valve are capable of maintaining a constant fuel level up to a pressure of 0.45 kg/cm2.

Question: I bought a carburetor 21053-1107010-20 for a VAZ-21053, and there are three vacuum distributor fittings. Which of these fittings (upper, lower or middle) should it be connected to, and what are the two additional fittings for? Answer: The lower fitting is intended for connecting the vacuum ignition timing corrector on the distributor-distributor. The two upper fittings should be plugged, because they are designed to control the exhaust gas recirculation valve, which your vehicle does not have.

Question: I read most of the “questions and answers”, but did not find an answer to my question. Which jets need to be changed on Solex 21053-1107010-20 for a 1.2l engine?

Answer: For a 1.2 liter engine. You need a carburetor 21051-107010 (currently not produced due to lack of demand) with 23x23 diffusers. On the carburetor 21051-1107010-20, you should install the fuel jet GDS 1 chamber 102.5 or 105, if there are comments on your fuel consumption.

Question: I have several questions about carburetors. 1. When installing a 21053 carburetor on a classic, what kind of textolite gasket should be used, thin or thick, between the carb and the intake manifold, and what will result from an incorrect installation (now the thick one seems to be from 8, but in your FAK I saw a message that you need to install 4mm) . 2. I have an engine displacement of 1650, compression 13-14, is carburetor 21053 suitable? Or is it better to put Ozone? 3. I was interested in why the second chamber in carburetor 21053 is very lean? (110/165) no other has such depletion, what is this connected with and wouldn’t it be better to put at least 115/165? 4.How does the level in the float chamber affect the flow rate? If it is less, then the consumption is also less and vice versa? How to correctly set the floats, in the literature there is a template according to which the level is set and at the same time it is said that from the gasket to the floats when the ball is pressed there should be 2mm and this somewhat contradicts the template. Why am I asking all this, I just found out experimentally that the jets in the first chamber exactly correspond to the factory ones (107.5/145 (slightly leaner)), but I haven’t really picked up the 2nd chamber yet... the dynamics are generally satisfactory, but the fuel consumption is slightly increased, sometimes 15l/ 100 km in the city, maybe it’s worth putting Ozone on my volume?

Carburetor VAZ 2101

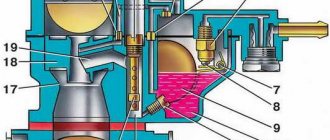

Diagram of the main metering system of the VAZ 2101 carburetor and econostat: The VAZ 2101 econostat is located in the secondary chamber of the carburetor. In the diagram it is conventionally shown in the primary chamber. 1 – Econostat emulsion jet; 2 – emulsion channel of the econostat; 3 – air jet of the main dosing system; 4 – econostat air jet; 5 – econostat fuel jet; 6 – needle valve; 7 – float axis; 8 – locking needle ball; 9 – float; 10 – float chamber; 11 – main fuel jet; 12 – emulsion well; 13 – emulsion tube; 14 – axis of the throttle valve of the primary chamber; 15 – spool groove; 16 – spool; 17 – large diffuser; 18 – small diffuser; 19 – sprayer.

Idle speed of the carburetor VAZ 2101

Diagram of the VAZ 2101 carburetor idle system: 1 – throttle body; 2 – throttle valve of the primary chamber; 3 – holes for transition modes; 4 – hole, adjustable with a screw; 5 – air supply channel; 6 – adjusting screw for the amount of mixture; 7 – adjusting screw for the composition (quality) of the mixture; 8 – emulsion channel of the idle system; 9 – additional air adjusting screw; 10 – carburetor body cover; 11 – air jet of the idle system; 12 – fuel jet of the idle system; 13 – fuel channel of the idle system; 14 – emulsion well.

Acceleration pump VAZ 2101

Diagram of the accelerator pump of the VAZ 2101 carburetor: 1 – screw valve; 2 – sprayer; 3 – fuel channel; 4 – bypass jet; 5 – float chamber; 6 – accelerator pump drive cam; 7 – drive lever; 8 – return spring; 9 – diaphragm cup; 10 – pump diaphragm; 11 – inlet ball valve; 12 – gasoline vapor chamber.

VAZ 2101 carburetor starting device

VAZ 2101 diagram of a diaphragm starting device: 1 – air damper drive lever; 2 – air damper; 3 – air pipe of the primary chamber of the carburetor; 4 – traction; 5 – starting rod; 6 – starting device diaphragm; 7 – adjusting screw of the starting device; 8 – cavity communicating with the throttle space; 9 – telescopic rod; 10 – damper control lever; 11 – lever; 12 – axis of the throttle valve of the primary chamber; 13 – lever on the axis of the primary chamber damper; 14 – lever; 15 – axis of the throttle valve of the secondary chamber; 16 – throttle valve of the secondary chamber; 17 – throttle body; 18 – throttle control lever of the secondary chamber; 19 – thrust; 20 – pneumatic drive.

Throttle valve of the second chamber of the VAZ 2101

Diagram of the pneumatic drive of the VAZ 2101 throttle valve of the secondary chamber: 1 – pneumatic drive nozzle located in the diffuser of the primary chamber; 2 – damper control lever; 3 – lever rigidly connected to the axis of the throttle valve of the primary chamber; 4 – lever that limits the opening of the throttle valve of the secondary chamber; 5 – pneumatic drive nozzle located in the diffuser of the secondary chamber; 6 – lever connected to lever 9 through a spring; 7 – axis of the throttle valve of the secondary chamber; 8 – pneumatic drive rod; 9 – throttle control lever of the secondary chamber; 10 – channel for supplying vacuum to the pneumatic drive; 11 – rod bushing; 12 – pneumatic drive of the throttle valve of the secondary chamber.

Adjusting the throttle drive

The figures below show the positions of the air damper with the choke recessed and extended.

Adjusting the air damper of the carburetor VAZ 2104, 2105, 2106 and 2107 is as follows:

- We recess the suction.

- Using a slotted screwdriver, unscrew the screw securing the rod (the spring sets it vertically).

- Tighten the screw.

- We check the movement of the air damper.

If you feel that the engine response is extremely low, and the acceleration dynamics leave much to be desired, then we recommend that you pay attention to adjusting the throttle valve drive, in other words, the “gas” drive. It is better to use a partner in this adjustment.

The tools we need are a screwdriver, a flashlight, a caliper and a 8mm wrench.

- Turn down the choke completely or close the air damper.

- Next, the partner must fully depress the gas pedal all the way to the floor. In this case, the air damper should open completely, as shown in the figure below. After releasing the gas pedal, the damper should close completely without any residual gaps.

- Using a caliper, we measure the length of the rod - it should be eight centimeters. For traction, it is adjusted by rotating the tips, having previously unscrewed the lock nuts.

- We put the rod in place and re-check the degree of opening of the air damper using the gas pedal.

In this article, we described to you how to independently adjust the carburetor of a VAZ 2104, 2105, 2106, 2107. We hope that our article was useful to you.

If you don't take care of the drive, the car may stall. To do this, you will need a simple Phillips screwdriver and a 7 mm open-end wrench.

The positions of the damper are shown above with the “suction” extended and recessed.

To adjust the drive, do the following:

- drown the “suction”;

- Unscrew the rod fixing screw with a screwdriver (the spring will push it out vertically)

- Tighten the screw;

- Check the valve stroke.

If this drive is incorrectly configured, the car's engine response drops and acceleration dynamics deteriorate. The setup is done with an assistant.

You will need the following tools: a screwdriver, an 8-mm open-end wrench, a flashlight, a ruler or a caliper.

- Turn down the “choke” (air damper drive) completely.

- Have your assistant press the gas pedal all the way to the floor. The throttle valve will open completely, as shown in the picture below, you can shine a flashlight into the first chamber. When you release the pedal, the damper should completely close the first chamber without any gaps. If there are gaps, then proceed to the next step.

- Next, we measure the length of the rod with a caliper; it should be exactly 8 cm. To adjust the length of the rod to the required size, rotate the tips by unscrewing the lock nuts.

After all these operations have been completed, put the rod in place and repeat the check. Nowadays, rods are made of low-quality plastic, which shrinks over time. Therefore, you need to check the operation of the traction after a week or two.

We looked at all the ways to adjust the carburetor yourself. We hope this article helped you, if you have any questions, ask them in the comments and we will definitely answer.

Adjusting the float of the "nine" carburetor

Setting up floats in Solex chambers is a simple procedure that does not require the use of specialized tools or special skills.

However, in the factory, this procedure is partially automated and is performed using a special template, which significantly simplifies the adjustment. But if you do the work yourself, you don’t need a template, but we will need the following tools and equipment:

- two screwdrivers, with a flat head and a Phillips head;

- a caliper or ruler (it is better not to use metal, wood or plastic);

- a piece of wire with a diameter of no more than 2 mm (you can use a thin drill or a similar round rod).

This set is sufficient to perform the entire range of adjustment procedures.

Adjustment instructions

To set up a cleaned and functional carburetor, you should prepare the following tool:

- short flat screwdrivers with narrow and wide slots;

- open-end wrench size 10 mm;

- the same, size 8 mm;

- narrow pliers.

The primary adjustment consists of adjusting the trigger cable and the gas pedal linkage. The latter is easily adjusted: the plastic tip is positioned opposite the hinge on the carburetor axis by twisting it along the thread. Fixation is carried out with a nut for a 10 mm wrench size.

The cable housing is attached with the air damper fully open.

The choke cable is adjusted as follows:

- Push the lever in the cabin all the way, set the air damper in a vertical position.

- Pass the cable through the eye of the cover and insert the end into the hole in the latch.

- Hold the barrel with pliers and tighten the bolt with a wrench.

- By moving the choke lever, make sure that the damper opens and closes completely.

The next step is to check the opening of the secondary chamber throttle. The stroke of the membrane and the rod should be enough for the damper to open 90°, otherwise unscrew the nut on the rod and adjust its length.

To shorten or lengthen the drive rod, you need to loosen the fixing nut

The support screw heads are fixed at the factory using special paint

The accelerator pump does not require additional adjustment. Make sure that the lever wheel is adjacent to the rotating sector, and the end is adjacent to the “heel” of the membrane. If you want to improve acceleration dynamics, replace the standard nozzle marked “40” with an enlarged one “50”.

The idle speed is adjusted in the following order:

- Turn out the quality screw by 3-3.5 turns, the quantity screw by 6-7 turns. Using the starter, start the engine. If the crankshaft speed is too high, reduce it with the quantity screw.

- Let the engine warm up, remove the choke and adjust the crankshaft speed to 900 rpm using the quantitative screw, using the tachometer as a guide.

- After 5 minutes, turn off the engine and check the condition of the spark plug electrodes. If there is no soot, the adjustment is complete.

- If black deposits appear on the spark plug, clean the electrodes, start the engine and tighten the quality screw 0.5-1 turn. Set the tachometer reading to 900 rpm using the second screw. Let the engine run and check the spark plugs again.

The best way to set up a DAAZ 2105 carburetor is to connect a gas analyzer to the exhaust pipe that measures the CO level. To achieve optimal gasoline consumption, you need to achieve readings of 0.7-1.2 at idle and 0.8-2 at 2000 rpm. Remember, the adjusting screws do not affect gasoline consumption at high crankshaft speeds. If the gas analyzer readings exceed 2 CO units, then the size of the fuel nozzle of the primary chamber should be reduced.

Ozone carburetors of the DAAZ 2105 model are considered relatively easy to repair and adjust. The main problem is the considerable age of these units, produced since the times of the USSR. Some copies have reached the required service life, as evidenced by large play in the throttle valve axles. Severely worn carburetors cannot be adjusted, so they have to be replaced entirely.

The principle of setting up the VAZ-2103 carburetor

Before you begin repairing the VAZ-2103 carburetor, you should make sure that it is correctly adjusted. If the owner of a domestic vehicle is sure that the VAZ-2103 carburetor urgently needs repair, do not rush to premature conclusions.

Quite often, a simple but competent adjustment is enough for the machine to start functioning as before. Setting up such a unit, by the way, requires the knowledge of the master regarding all calibration data (set values). For carburetor tuning to be successful, it is important to adjust all components of the system. Typically, such actions should begin with external control components. You should make sure that the throttle valves are working properly: if the gas pedal is not under pressure, they should be closed. As soon as the gas pedal is pressed, the dampers should open as smoothly as possible (not jerkily). The next step, which involves correctly setting up the VAZ-2103 carburetor, should be checking the air damper. If the drive is recessed, the structural element being tested must be vertical so that the passage leading to the throttle valve does not block.

Carburetor tuning begins with checking external control components

The accelerator pump deserves no less attention. Its functionality helps to detect sudden pedal input. The condition of the pneumatic drive diaphragm should also be determined. Only after the motorist is confident in the normal operation of the elements (after an external check), it will be necessary to spend some time cleaning the jets and sprayers. First of all, you should get rid of the cover of the device being adjusted, then, using a pump, free the float chamber from various sediments. If there is heavily hardened sediment, you can resort to a metal or wood spatula.

Proper adjustment and cleaning of the carburetor should include the absence of any rags that could clog the jet. As a result, the jets and channels will have to be flushed with clean fuel and purged with air. In order to make sure that all components are completely clean, you need to dismantle them before flushing all the channels. It is important to monitor the order in which the jets will be removed, since subsequent incorrect installation will lead to failure of the power unit. All openings can be freed from harmful accumulations with wire.

It is necessary to completely clean all components: dismantle them and wash all channels

Strainer performance

Adjusting the VAZ-2103 carburetor requires checking the strainer. This element is responsible for the cleanliness of the fuel that enters directly into the float chamber. To clean it, you will have to remove the plug and filter, then free the mesh from any unpleasant stuck particles and blow out the filter itself so that air flows in the direction opposite to the movement of fuel. In this case, any mechanical impact should be avoided.

Before you return the element to be cleaned to its place, you will have to make sure that the fuel nozzle is functioning well. If necessary, it can be blown out. Typically, the float chamber should be drained of gasoline and its needle valve should be open. Before the strainer returns to its rightful location, you need to check the sealing gasket, which can prevent fuel from leaking.

Adjusting the VAZ-2103 carburetor is not complete without cleaning the strainer

Checking the functionality of the float chamber

If you need to adjust the VAZ-2103 carburetor, you will have to pay some attention to the float chamber. If the owner of a vehicle notices increased gas consumption, most likely the reason will be hidden in the too high level of fuel that is in the system being tested. If a completely opposite malfunction is noticed (lack of gasoline), you should check the level of gasoline in the float chamber and the functioning of its needle valve.

First of all, you should get rid of the carburetor cover and, after it is in a horizontal position, adjust the gap that will be formed between the floats and the place where the device being removed will be attached to its base (the distance should not exceed 6.5 mm ). This is exactly the gap that should exist at the maximum possible level of gasoline in the float chamber. To adjust the system, you need to use the float tongue. After this, it is important to check the functionality of the needle valve by removing the float axes and dismantling the valve itself. Both elements must not have mechanical damage.

Float chamber of the VAZ-2103 carburetor

After the adjusting element of the system is installed in place, you should use a bulb to ensure that gasoline flows through the filter. The driver's task is to move freely through the needle valve. The floats should be in place, then it is important to re-pump the gasoline to make sure that there are no leaks anywhere. The result of the work should be installing the cover and checking the gasket (located in the middle between the structure and its cover). The latter must be positioned in such a way that it cannot interfere with blocking the channel and at the same time is located in the mounting holes. The lid should be tightened so that there is no overtightening (there should be no deformation). Otherwise, a deformed part of the system will cause air leaks or gasoline leakage.

It is worth noting that adjusting the VAZ-2103 carburetor is advisable only after warming up the engine and pressing the choke button.

Setting up the starter

The starting system can be configured both with the unit removed and while it is in the car.

Adjustment of the VAZ-2103 carburetor will not be complete if the motorist forgets to adjust the starting system. It is worth noting that a similar procedure can be performed both on a previously removed unit, and directly while it is in the car. If the car owner decides to adjust the starting device without removing the carburetor, he will first have to take care of dismantling the air filter, activating the power unit and slightly raising the choke. As a rule, engine speed should not fall below 3200 per minute.

As soon as the above recommendations are completed, it will be necessary to forcibly raise the air damper (at least by a third). Thanks to this manipulation, the number of revolutions should decrease by 300 units.

The clearance of the VAZ-2103 carburetor should be about 5.5 mm

There are times when such actions are not enough. The driver will have to adjust the speed using the thrust from the pneumatic drive by adjusting the length of the thrust. Adjusting the same structural element on a removed carburetor requires adjusting the distance between the opposite sides of the air damper.

If you are thinking about how to adjust the carburetor on a VAZ-2103, you should not forget about the need to take into account the gap (it should be about 5.5 mm). In view of this circumstance, you need to remove the starting unit tube and use a thin screwdriver to turn the adjusting element of the structure. If you start tightening this screw, the gap will gradually become smaller, otherwise it will become larger. If a motorist independently adjusts the carburetor of the domestic VAZ-2103, he must control the gap that remains between the throttle valve and the diffuser. This gap should not exceed 0.8 mm.

Idling of the device

If the idle speed is set correctly, the number of revolutions will not fluctuate up and down.

Often people who are interested in adjusting the VAZ-2103 carburetor mean by performing the process only adjusting the idle speed. Before you begin this procedure, you need to activate and slightly warm up the power unit (it should reach a temperature of 90 °C). As a rule, adjusting the idle speed of the device in question is impossible without the participation of two screws (quantity, as well as composition of the combustible mixture). One of the screws must be closed with a plug, after which the motor must be activated. Using the screw responsible for the amount of mixture, you should increase the engine speed to 1000 units. And use the mixture composition screw to reduce the adjustable value by 200 units. If configured correctly, the motor will function stably, vibrations should not appear, and the number of revolutions should not vary up and down.

Adjusting the idle speed on Ozone carburetors

Before you begin adjustment work, you should warm up the internal combustion engine to operating temperature; it is also important that the carburetor is clean, without clogged channels. Next we proceed as follows:

- start the engine at idle speed (XX);

- using the quantity screw, unscrewing it, we increase the speed by 100 more than the normal norm;

- we begin to tighten the quality screw until the engine begins to work less steadily, then we turn it back a little, achieving stable operation;

- we find the optimal operating mode of the motor at idle with the quality screw tightened as much as possible, while 850 rpm is considered the norm (from 800 to 1000 is allowed).

With proper adjustment, gasoline consumption in urban areas averages 8.5-9.5 l/100 km, but the engine must be in good working order and the ignition must be set correctly. Even on Ozone carburetors, the solenoid valve jet often becomes clogged; before adjusting the idle mixture, it should be checked and, if necessary, cleaned.