The carburetor is one of the most complex components of the fuel system of any gasoline unit. Its purpose is to prepare the air-fuel mass by saturating gasoline with oxygen in the required proportions with further supply of the finished mixture to the cylinders. Mixing of ingredients is carried out in the required consistency, corresponding to the operating modes of the motor. In this article we will look at the basics of how a carburetor works, analyze its design in detail and describe the main elements.

Jets

For some reason, the instructions categorically do not recommend increasing the jets, but the risk is justified and in some cases the improvements are obvious.

Of course, it is dangerous to immediately change all existing combinations at once, so changes should be made gradually. So, the primary camera:

- GTZh (main fuel jet) - 125.

- GVZh (main air jet) - 150.

We leave the secondary camera as is and check it. Acceleration will be better.

Let's move on to the second chamber:

- GTZ - 162.

- GVZh - 190.

The result of the changes will be a feeling as if the gas pedal is pressed until the secondary chamber opens and the turbo is turned on, while the engine easily spins up to 6000–6500 rpm. Fuel consumption may increase slightly. This is due to the fact that, when moving around the city, you will not accelerate strongly at traffic lights every time, so you will be able to save gasoline only on the highway or in the case of empty city roads.

If you approach tuning your original five wisely, you can refine it to excellent condition. The car will serve you for many more years and will delight you with its improved characteristics.

Sources

- remam.ru/tune/tyuning-karbyuratora-vaz-2105.html

- ladaautos.ru/vaz-2105/kak-delaetsya-regulirovka-karbyuratora-vaz-2105.html

- carnovato.ru/karbjurator-zhiklery-vaz-2105/

- drive2.ru/b/2232459/

- swapmotor.ru/ustrojstvo-dvigatelya/karbyurator-vaz-2105.html

- bumper.guru/klassicheskie-modeli-vaz/toplivnaya-sistema/karbyurator-vaz-2105.html

Replacement instructions

For the procedure, you should use an overpass or inspection hole. To raise the car, you can use a jack, lifting the front end and placing it on supports. Replacement is carried out only on a cold machine.

Required Tools

Replacing a timing belt and chain is a complex and lengthy procedure. To complete it as quickly as possible, you need to properly prepare for it and prepare in advance:

- a set of keys;

- set of heads;

- knob;

- screwdriver

To make consumables last longer, you should buy originals.

Stages

- First, turn off the power to the car by removing the negative terminal from the battery.

- If protection is installed, it must be removed.

- Then you need to drain the coolant from the system.

- At the next stage, you need to dismantle the radiator, cooling system fan, and pump pulley.

- Then you need to remove the drive belts for the power steering, air conditioning compressor, and generator.

- Next, unscrew the spark plugs.

- Then we remove the distributor protection screen and disconnect the tube connecting it to the timing belt from the air collector sleeve.

- By turning the crankshaft by the bolt securing its pulley, you should set the marks. The mark on the timing belt pulley must coincide with the casting on the camshaft; accordingly, the installation mark on the crankshaft gear must align with the mark on the oil pump housing. In the video you can see how to set the tags correctly.

- Using a special tool, you need to unscrew the mounting bolt and remove the crankshaft pulley.

- Then you need to remove the lower and middle timing protection covers.

- By unscrewing the tensioner mounting bolt and turning it counterclockwise, we loosen the tension on the timing belt and remove the latter.

- Now you should change the roller and start tightening the VAZ 2105 timing belt.

Changing the tension roller

Before doing this, all parts should be cleaned of dirt.

- The belt should first be pulled onto the crankshaft pulley, then onto the oil pump drive pulley, and lastly onto the camshaft pulley.

Pulling the belt onto the camshaft pulley

- Having put the belt on the tensioner, you need to tighten the bracket and install the spring.

When installing the timing belt, do not rotate the camshaft and crankshaft so as not to knock off the marks.

- After turning the crankshaft two turns, you need to check that all installation marks match, tension the belt and tighten the tensioner bracket mounting bolts.

- Next, assembly is carried out in reverse order.

After the procedure for changing the timing belt or chain of the VAZ 2105, you should start the car and check the performance of the engine.

VAZ 2105 speed fluctuates

Unread message from Olezhek » Fri Oct 02, 2009 6:46:31 AM

People believe nothing so firmly as what they know least about, and no one speaks with such self-confidence as writers of all sorts of fables - for example, astrologers, fortune tellers, palmists. Religion, superstitions. Michel Montaigne

why did the industrial brains say so because many people have such a problem after 30,000 and when I was on my car they were replaced with new ones of the same type and the engine operation became completely different i.e. when the throttle is opened sharply it does not choke (this is with new brains and with it gets stuck on mine) but no one drives xx, it just might stall at a traffic light or when you are coasting (without gas supply) about the spark plugs there was and is the same soot on all of them, they were normal, I bought it, I didn’t spare the money, let’s just say I don’t remember the name

Added after 24 seconds:

why did the industrial brains say so because many people have such a problem after 30,000 and when I was on my car they were replaced with new ones of the same type and the engine operation became completely different i.e. when the throttle is opened sharply it does not choke (this is with new brains and with it gets stuck on mine) but no one drives xx, it just might stall at a traffic light or when you are coasting (without gas supply) about the spark plugs there was and is the same soot on all of them, they were normal, I bought it, I didn’t spare the money, let’s just say I don’t remember the name

Expert advice

After completing the procedure for adjusting the VAZ-2105 carburetor device, experienced auto mechanics recommend paying attention to the following critical points:

- Valve location - is in the retracted position, with the idle speed jet touching the seat in the carburetor body.

- Lubricating the rubber seal with special motor oil.

- The location of the air damper intended for cold passage is in a vertical plane, while the suction handle is lowered.

- The condition of the solenoid valve - the presence of damage and malfunctions is checked as follows:

- turn on the ignition;

- remove and put the connector on the valve;

- listen to the sounds coming from the solenoid valve.

If clicks are heard during the inspection process, the part is in full working order.

Preparatory activities

If a motorist is interested in adjusting the Solex VAZ-2107 carburetor with his own hands, he must first carry out a number of preparatory steps.

Initially, you need to warm up the power unit to operating condition (temperature 85–90 degrees).

In the next step, you need to squeeze the handle of the air damper drive mechanism all the way; people simply call it “choke.” After this, the damper should be in a position in which the air channel is completely free, i.e., located in the direction of air movement.

This video tells you how to install it

Today Nail Poroshin will tell and show the main nuances of the installation

53rd Carburetor

to the Classics! Everyone...

If there is a tachometer, the device must be connected to the engine being turned off. Otherwise, if there is no unit, the item should be skipped. The positive side of the device should go to the ignition coil, and the negative side should go to the “ground” of the vehicle (body, engine or battery negative). Before connecting the device, you should read the operating instructions.

The last action should be to start the engine, turn on the high beam optics and the heating device.

Main parts

To perform its tasks, the VAZ 2105 carburetor consists of the following mechanisms and systems:

- Engine starting and warming up system.

- System for maintaining the required fuel level.

- System XX (idle);

- Econostat system.

- Acceleration pump.

- Main dosing system.

There are three systems that can be configured - they are first on the list. The VAZ 2105 carburetor can be adjusted without removing the device from the car. Due to the fact that the carburetors of the fifth and seventh models are identical in structure and differ only in the diameters of the holes of the air and fuel jets, since the carburetor on a VAZ 2107 can be adjusted using the same method.

Briefly about the features and structure of the “six” carburetor unit

Before adjusting the carburetor on a VAZ 2106, it doesn’t hurt to know its design features. After 1980, Ozone and Solex began to be installed on Tolyatti cars. The purpose of the unit’s operation is to prepare a combustible mixture before feeding it into the car’s cylinders. Down to the subtleties, this is not a driving school, we will not disassemble the design, it is enough to familiarize yourself with the main components that ensure optimal operation of a carburetor internal combustion engine:

- Fuel dosing system.

- Mechanisms for controlling throttle valves and enriching the mixture.

- Idle system.

- Accelerator pump and econostat.

- Float chamber.

A chamber with a float and a needle valve is responsible for the stability of the fuel level. Next, gasoline, flowing through the spray tube, enters the chamber, where it mixes with air from the inlet pipe. The amount of mixture is adjusted by the throttle valve, which is connected to the accelerator pedal.

Precise adjustment allows you to prepare the correct mixture of gasoline and air in a ratio of 1:15. During long-term operation of the car, the settings get lost and you have to think about how to adjust the carburetor on a VAZ 2106 on your own. The adjustment technology is the same for both Solex and Ozone.

Adjustment instructions

To set up a cleaned and functional carburetor, you should prepare the following tool:

- short flat screwdrivers with narrow and wide slots;

- open-end wrench size 10 mm;

- the same, size 8 mm;

- narrow pliers.

The primary adjustment consists of adjusting the trigger cable and the gas pedal linkage. The latter is easily adjusted: the plastic tip is positioned opposite the hinge on the carburetor axis by twisting it along the thread. Fixation is carried out with a nut for a 10 mm wrench size.

The cable housing is attached with the air damper fully open.

The choke cable is adjusted as follows:

- Push the lever in the cabin all the way, set the air damper in a vertical position.

- Pass the cable through the eye of the cover and insert the end into the hole in the latch.

- Hold the barrel with pliers and tighten the bolt with a wrench.

- By moving the choke lever, make sure that the damper opens and closes completely.

The next step is to check the opening of the secondary chamber throttle. The stroke of the membrane and the rod should be enough for the damper to open 90°, otherwise unscrew the nut on the rod and adjust its length.

To shorten or lengthen the drive rod, you need to loosen the fixing nut

The support screw heads are fixed at the factory using special paint

The accelerator pump does not require additional adjustment. Make sure that the lever wheel is adjacent to the rotating sector, and the end is adjacent to the “heel” of the membrane. If you want to improve acceleration dynamics, replace the standard nozzle marked “40” with an enlarged one “50”.

The idle speed is adjusted in the following order:

- Turn out the quality screw by 3-3.5 turns, the quantity screw by 6-7 turns. Using the starter, start the engine. If the crankshaft speed is too high, reduce it with the quantity screw.

- Let the engine warm up, remove the choke and adjust the crankshaft speed to 900 rpm using the quantitative screw, using the tachometer as a guide.

- After 5 minutes, turn off the engine and check the condition of the spark plug electrodes. If there is no soot, the adjustment is complete.

- If black deposits appear on the spark plug, clean the electrodes, start the engine and tighten the quality screw 0.5-1 turn. Set the tachometer reading to 900 rpm using the second screw. Let the engine run and check the spark plugs again.

The best way to set up a DAAZ 2105 carburetor is to connect a gas analyzer to the exhaust pipe that measures the CO level. To achieve optimal gasoline consumption, you need to achieve readings of 0.7-1.2 at idle and 0.8-2 at 2000 rpm. Remember, the adjusting screws do not affect gasoline consumption at high crankshaft speeds. If the gas analyzer readings exceed 2 CO units, then the size of the fuel nozzle of the primary chamber should be reduced.

Ozone carburetors of the DAAZ 2105 model are considered relatively easy to repair and adjust. The main problem is the considerable age of these units, produced since the times of the USSR. Some copies have reached the required service life, as evidenced by large play in the throttle valve axles. Severely worn carburetors cannot be adjusted, so they have to be replaced entirely.

Malfunctions and solutions

Adjusting the carburetor with screws does not help to get rid of problems and is done only once - during the setup process. Therefore, if a malfunction occurs, you cannot mindlessly turn the screws; the situation will only worsen. Find out the true cause of the breakdown, eliminate it, and then proceed to adjustment (if necessary).

Before you begin repairing the carburetor, make sure that the culprit of the problem is not the ignition system, the fuel pump, or weak compression in the engine cylinders. A common misconception: shots from a muffler or carburetor are often mistaken for a problem with the unit, although there is an ignition problem - the spark on the spark plug forms too late or early.

What malfunctions are directly related to the carburetor:

- the engine does not start - it seizes and immediately stalls;

- the engine does not idle;

- “dips” when sharply pressing the accelerator pedal;

- the power unit “does not pull” or functions unstable;

- increased gasoline consumption, accompanied by black smoke from the exhaust pipe and the formation of soot on the electrodes of the spark plugs.

The listed problems have several causes, so it is proposed to consider them separately.

Difficulty starting the engine

If the cylinder-piston group of the VAZ 2105 engine is in working condition, then sufficient vacuum is created in the manifold to suck in the combustible mixture. The following carburetor malfunctions can make starting difficult:

- When the engine starts and immediately stalls when cold, check the condition of the starter membrane. It does not open the air damper slightly and the power unit “chokes” from excess fuel.

Checking the fuel in the float chamber is done without disassembling: remove the air filter cover and pull the primary throttle rod, simulating the gas pedal. If there is gasoline, the accelerator pump nozzle, located above the primary diffuser, should spray out in a dense stream.

When the level of gasoline in the carburetor chamber exceeds the permissible level, fuel may flow into the manifold spontaneously. A hot engine will not start - it first needs to throw excess fuel from the cylinders into the exhaust tract. To adjust the level, follow these steps:

- Remove the air filter housing and unscrew the 5 carburetor cover screws.

- Disconnect the fuel line from the fitting and remove the cover by disconnecting the telescopic rod.

- Shake out any remaining fuel from the element, turn it upside down and check the functionality of the needle valve. The simplest way is to suck air from the fitting with your mouth; a working “needle” will not allow this.

- By bending the brass tongue, adjust the height of the float above the plane of the lid.

With the needle valve closed, the distance between the float and the cardboard spacer should be 6.5 mm, and the stroke on the axis should be about 8 mm.

Video: adjusting the fuel level in the float chamber

No idle speed

If the engine stalls at idle, look for the problem in this order:

- The first step is to unscrew and bleed the idle fuel jet located on the right side of the middle part of the carburetor.

If the previous recommendations do not resolve the problem, try blowing aerosol fluid into the hole in the throttle body. To do this, dismantle the mixture quantity adjustment block together with the flange by unscrewing 2 M4 screws. Pour detergent into the opened hole, do not turn the quantity screw itself! If the result is negative, which happens quite rarely, contact a carburetor technician or completely disassemble the unit, which will be discussed below.

The culprit of unstable engine operation at idle speed is rarely the carburetor. In particularly advanced cases, air leaks into the manifold from under the “sole” of the unit, between sections of the housing, or through a crack that has formed. To detect and fix the problem, the carburetor must be disassembled.

How to get rid of "failures"

In the vast majority of cases, the culprit of “failures” when sharply pressing the accelerator pedal is the carburetor accelerator pump. To fix this annoying problem, follow these steps:

- Place a rag under the lever pressing the pump membrane, unscrew the 4 M4 screws and remove the flange. Remove the membrane and check its integrity, replace it with a new one if necessary.

In old, heavily worn carburetors, problems can be caused by a lever whose working surface has been significantly worn out and does not press the “penny” of the diaphragm. Such a lever should be changed or the worn end should be carefully unfastened.

Small jerks when pressing the accelerator “all the way” indicate contamination of the channels and jets of the transition system. Since its device is identical to CXX, fix the problem according to the instructions presented above.

Video: cleaning the accelerator pump ball valve

Drop in engine power and sluggish acceleration

There are 2 reasons why the engine loses power - lack of fuel and failure of the large membrane that opens the throttle of the secondary chamber. The last breakdown is easy to detect: unscrew the 3 M4 screws securing the vacuum drive cover and get to the rubber diaphragm. If it is cracked, install a new part and reassemble the drive.

In the vacuum drive flange there is an air channel outlet, sealed with a small rubber ring. When disassembling, pay attention to the condition of the seal and change it if necessary.

If the secondary throttle drive is working properly, look for the problem elsewhere:

- Using a 19 mm wrench, unscrew the plug on the cover (located near the fitting). Remove and clean the filter mesh.

- Remove the unit cover and unscrew all the main jets - fuel and air (do not mix them up). Using tweezers, remove the emulsion tubes from the wells and blow in the washing liquid.

The reason for the lack of fuel may be a low level of gasoline in the float chamber. How to adjust it correctly is described above in the corresponding section.

Problems with increased gas consumption

Supplying too rich a mixture to the cylinders is one of the most common problems. There is a way to make sure that it is the carburetor that is to blame: at idle engine speed, fully tighten the quality screw, counting the revolutions. If the engine does not stall, get ready for repairs - the power unit pulls fuel from the float chamber, bypassing the idle system.

To begin with, try to get by with a little blood: remove the cover, unscrew all the jets and generously treat the accessible holes with an aerosol. After a few minutes (precisely indicated on the can), blow out all channels with a compressor developing a pressure of 6-8 bar. Reassemble the carburetor and do a test run.

An over-enriched mixture makes itself felt by black soot on the spark plug electrodes. Before the test run, clean the spark plugs, and upon return, check the condition of the electrodes again.

If local flushing does not produce results, disassemble the carburetor in this order:

- Disconnect the fuel pipe, the gas pedal linkage, the starter cable and 2 tubes - crankcase ventilation and distributor vacuum.

The next task is to thoroughly wash all channels, chamber walls and diffusers. When directing the canister tube into the channel openings, make sure that the foam comes out from the other end. Perform the same operation with compressed air.

After blowing, hold the bottom part up to the light and make sure there are no gaps between the throttle valves and the chamber walls. If any are found, the dampers or lower block assembly will have to be replaced, since the engine draws fuel uncontrollably through the cracks. Entrust the operation of replacing chokes to a specialist.

When performing a complete disassembly of the DAAZ 2105 carburetor, it is recommended to perform the entire range of operations listed in the previous section: clean the jets, check and change the membranes, adjust the fuel level in the float chamber, and so on. Otherwise, you risk finding yourself in a situation where one breakdown endlessly replaces another.

As a rule, the lower plane of the middle block is arched due to heating. The flange must be ground in on a large grinding wheel, having previously pulled out the bronze bushings. The remaining surfaces should not be sanded. When assembling, use only new cardboard spacers. Reinstall the carburetor and proceed to setup.

Video: complete disassembly and repair of the Ozone carburetor

The following problems are also possible:

- Excessive (low) gasoline level in the float chamber.

- The air filter is clogged (here you can save yourself with a regular replacement).

In modern cars with an injection engine and electronic fuel injection, such as the VAZ 2110-2115, no less reasons can be identified. In this case, problems are often associated with the breakdown of one of the sensors.

What happens? The electronic control unit tries to read information and does not receive it. As a result, malfunctions in the operation of the power unit appear, and instability in speed appears.

But let's highlight all the main reasons. There are several of them:

- Problems with spark plugs (poor quality, wear, contamination);

- interruptions in the air supply (failure of the mass air flow sensor);

- air intake from outside into the intake system;

- damage (defect) of high-voltage wires;

- failure of the XX regulator;

- EGR sensor malfunction.

When the idle speed is floating, the first thing to do is check the idle speed control. Most often it is located next to another sensor that controls the throttle position. Checking is carried out using a multimeter.

If the sensor resistance is outside the normal range (40-80 Ohms), then there is a high probability of IAC failure.

If everything is normal with the idle speed control, you can move on to the next “suspect” - the mass air flow sensor.

To check the device, you need to disconnect the connector from it and start the engine. In this case, the engine speed will be around 1,500 rpm. If the dynamics only improve while driving, then the mass air flow sensor is really faulty.

The EGR valve is responsible for the movement of exhaust gases. The sensor's task is to return some of the gases back to the combustion chamber. This is necessary to ensure complete combustion of fuel and minimal harm from exhaust gases. Cleaning the valve seat is often enough to fix the problem.

3. In diesel cars, the cause of floating idle speed may be the appearance of corrosion on the moving blades in the power pump. As a result, they simply jam and stop coping with their function.

To prevent this from happening, you need to add at least a little motor oil to the fuel tank (200-250 grams is enough). This is enough to protect the metal elements with a thin layer of oil.

Now floating idle speeds will not cause you to panic, because you know what causes them and what needs to be done. Good luck on the roads and of course no breakdowns.

How to adjust the carburetor on a VAZ 2101

What is needed for adjustment

First you need to prepare the appropriate repair kit for the VAZ 2101 carburetor. You will also need new cuffs, carburetor jets and other spare parts. To adjust the carburetor, you will need, which includes the following tools:

- Spanners.

- Rags.

- Screwdrivers (phillips, flat).

- Protective gloves.

- Solvent.

- Toothpicks.

- Compressed air can or pump.

After appropriate preparation of the repair kit, you can begin adjusting the VAZ-2101 carburetor. This does not require much effort. All actions must be careful and precise.

You also need to inspect the components on which the operation of the motor may depend. You need to inspect the spark plugs. By their appearance you can tell in what proportions the fuel is mixed with air.

The carburetor needs to be cleaned. To do this, dismantle its top cover. The float and vacuum valve are removed. The interior of the chambers needs to be cleaned. Soot and dirt accumulate here. Cleaning is carried out using an air can or a pump.

Another mandatory action is to check the gap between the distributor electrodes, as well as the high-voltage coil and wires. The adjustment is carried out only after the engine has warmed up to 90ºС. Cars are put on handbrake.

Throttle valve adjustment

Adjusting the VAZ-2101 carburetor begins with adjusting the throttle valve. This is a simple procedure. It can be done in three stages. Manually turn the damper control lever counterclockwise. It opens completely.

The distance to the primary chamber is measured. The carburetor design suggests that this figure is 12.5-13.5 mm. If the result is different, you need to bend the rod antennae. Throttle adjustment involves determining the opening value of the throttle valve. It should be 14.5-15.5 mm. Otherwise, you will need to tighten the pneumatic drive rod.

Starter battery correction

At the second stage, you will need to adjust the operation of the starting device. The throttle lever on the secondary chamber is manually turned counterclockwise. It will close. The tip of the thrust lever should fit snugly against the axis of the primary chamber throttle valve.

At the very end there should be a starter rod. Otherwise, you will need to adjust its position. To do this, the rod is bent. This device in carburetor engines is fragile. If you apply too much force to it, the rod will break off.

Checking the pump accelerator and repairing it

You need to start checking by testing the functionality of the system. You need to collect in a beaker the fuel that will be generated during 10 cycles of operation of the throttle lever. From 5.2 to 8.7 cm³ of fuel should accumulate. If this is not the case, you need to clean the VAZ 2101 carburetor jets. To do this, bleed the pump. This will help clear clogged injectors. This procedure is performed about 10 times. Then the fuel is measured again.

If the purging procedure does not give the desired result, the accelerator will need to be completely replaced.

If the engine malfunctions at high speeds, you need to check the pump diaphragm. It could wear out. The fuel pump rod often wears out.

Idle speed adjustment

Adjusting the fuel system involves adjusting the idle speed at the final stage. You will need to warm up the engine for 15 minutes. Then the engine must be turned off. The quantity and quality screws are tightened until they stop. The first of them needs to be released 3 turns. The quality screw is unscrewed 5 turns.

The motor starts. The quantity screw sets the speed, which is about 800 per minute. Then the quality screw is slowly tightened. This way you can reduce the enrichment of the fuel mixture. This procedure is carried out until the speed begins to drop. After this, the quality screw must be unscrewed another half turn and fixed in this position.

Knowing how the carburetor adjustment procedure is carried out, you can do the job well yourself. The engine will operate stably, and the VAZ 2101 will operate in normal mode.

Nuances of the VAZ-2105 carburetor adjustment process

Experts immediately warn inexperienced car enthusiasts: if you don’t know where the carburetor is located in the car and what it consists of, then you shouldn’t even start adjusting. By incorrectly changing the parameters of the fuel system, the entire vehicle can be damaged. It is best to entrust this procedure to qualified auto mechanics from a service station.

So, to begin adjusting the carburetor of a certain vehicle model, you need to study its structure. Thus, the VAZ-2105 carburetor contains several important systems:

- dosing;

- starting and warming up the engine;

- maintaining an optimal level of fuel fluid;

- starting idle;

- econostat system;

- accelerator pump.

Three of all the listed systems are subject to standard adjustment:

- Starting and warming up the internal combustion engine (the starting device is configured).

- Maintaining the fuel fluid level (the float mechanism is adjusted).

- Idle speed (speed calibration is performed using a specific screw).

Stages of setting up a VAZ 2015 carburetor

Without knowing the design of the car and without any experience in repairing, disassembling or assembling the fuel system of a car, it is not recommended to make adjustments. Changing the settings incorrectly may worsen the problem or damage the device. If you are familiar with the design of your car's carburetor, adjusting it will not be difficult. Adjusting the carburetor 2105 can significantly improve the efficiency of the vehicle and increase the performance of the power unit. These so-called performance upgrades do not have any detrimental effect on the device. On the contrary, they are a mandatory procedure that guarantees long, uninterrupted operation.

Screws for adjusting the idle speed system of the VAZ 2105 carburetor: 1 - mixture quantity screw; 2 - mixture quality screw

The carburetor on any vehicle is one of the components of the fuel system of an internal combustion engine. It mixes air with fuel liquid, and this mixture is supplied to the cylinders of the internal combustion engine. As you can see, this automotive part plays a very important role in the functioning of the vehicle as a whole. Therefore, the carburetor must be adjusted periodically. You will learn how to do this correctly on a VAZ-2105 from this article.

Fuel mixture quality adjustment screw Solex 21083

Why do you need a Solex 21083 carburetor quality screw?

The quality screw is necessary to change the composition of the fuel mixture entering the car engine at idle (idle). By turning the screw we lean the fuel mixture, by turning it away we enrich it. In this way, you can adjust the air/gasoline ratio to ensure it operates at a minimum stable idle speed.

Where is the quality screw installed on the Solex 21083 carburetor?

The fuel mixture quality adjustment screw is installed in the lower part of the carburetor body, at the outlet of the emulsion channel. The screw is screwed into a special channel at the bottom of the carburetor body. It changes the flow area of the outlet.

The outlet of the CXX Solex 21083 through which the fuel mixture is sprayed, the composition of which is regulated by a quality screw.

How does a Solex 21083 quality screw work?

The Solex 21083 carburetor quality screw is a metal screw of a certain shape with a thread. A rubber O-ring is installed on it to prevent excess air from entering the CXX channel. One end of the screw has the shape of a needle; the other has a cut for a 3 mm slotted screwdriver. See photo at the beginning of the article.

How does the fuel mixture quality adjustment screw work?

The easiest way to see how the quality screw works is in the Solex 21083 CXX diagram.

Under the number “14” is the quality screw.

A mixture of air and gasoline (fuel emulsion) is formed at the CXX fuel nozzle, where gasoline entering the carburetor CXX from the float chamber and air from the air duct are mixed. Under the influence of vacuum at the edge of the throttle valve of the first chamber, it is pulled through the emulsion channel and the CXX outlet into the engine intake manifold. The engine runs on this fuel mixture.

If we tighten the quality screw all the way, we will completely block the outlet of the emulsion channel of the idle system. Fuel stops flowing into the engine and it stalls.

If you turn the quality screw out a little, fuel will begin to flow into the engine and it will idle.

In order for the car engine to operate stably at idle, you should unscrew the quality screw at least half a turn from the stop and adjust the idle speed with setting the position of the fuel mixture quantity screw. It is necessary to achieve such a mutual position of these two screws that the idle speed is 650-700 rpm and the CO content in the exhaust gases is within normal limits.

Malfunction of the fuel mixture quality screw

There are only two malfunctions: clogging of the idle air system outlet and damage to the rubber O-ring on the screw.

Over time, the idle air system outlet becomes clogged with deposits and soot from the engine intake manifold. The quality screw needle ceases to play the role of a locking device, since the hole is already clogged. Depending on the degree of contamination, the engine begins to idle unsteadily or the idle speed disappears altogether. When turning the quality screw when adjusting the XX speed, the reaction will be weak or not at all.

You can quickly clean the outlet, quality screw and emulsion channel yourself without disassembling the carburetor using a cleaning aerosol. Details about the cleaning procedure: “Cleaning the idle system of the Solex carburetor 2108, 21081, 21083.”

The channel where the quality screw is installed leads directly to the CXX emulsion channel and its outlet. Therefore, this is one of the places where foreign air is likely to “suck” into the carburetor. Foreign air depletes the fuel mixture, as a result of which the engine does not have enough energy to rotate the crankshaft at idle, and it begins to “triple” and tries to stall. The reason for the air leak is a worn rubber o-ring on the quality screw. It may fail due to age or careless repairs.

Replacing the ring with a new one will help correct the problem of air “sucking” into the carburetor and restore normal idle speed of the car engine.

Notes and additions

If, with the quality screw fully tightened, the car engine does not stall, but continues to run, you should look for places where fuel is likely to enter the engine in addition to the carburetor idle system

Or pay attention to the position of the throttle valve of the first chamber. Perhaps it is very slightly open and in addition to the outlet hole of the CXX, underneath it there is an exit slot of the transition system of the first chamber and the fuel is drawn out of it by vacuum

The position of the throttle valve is regulated by the quantity screw, which with its tip rests on the lever on its axis.

How to adjust the carburetor on a VAZ 2101

What is needed for adjustment

First you need to prepare the appropriate repair kit for the VAZ 2101 carburetor. You will also need new cuffs, carburetor jets and other spare parts. To adjust the carburetor, you will need a repair kit, which includes the following tools:

- Spanners.

- Rags.

- Screwdrivers (phillips, flat).

- Protective gloves.

- Solvent.

- Toothpicks.

- Compressed air can or pump.

After appropriate preparation of the repair kit, you can begin adjusting the VAZ-2101 carburetor. This does not require much effort. All actions must be careful and precise.

You also need to inspect the components on which the operation of the motor may depend. You need to inspect the spark plugs. By their appearance you can tell in what proportions the fuel is mixed with air.

The carburetor needs to be cleaned. To do this, dismantle its top cover. The float and vacuum valve are removed. The interior of the chambers needs to be cleaned. Soot and dirt accumulate here. Cleaning is carried out using an air can or a pump.

Another mandatory action is to check the gap between the distributor electrodes, as well as the high-voltage coil and wires. The adjustment is carried out only after the engine has warmed up to 90ºС. Cars are put on handbrake.

Throttle valve adjustment

Adjusting the VAZ-2101 carburetor begins with adjusting the throttle valve. This is a simple procedure. It can be done in three stages. Manually turn the damper control lever counterclockwise. It opens completely.

The distance to the primary chamber is measured. The carburetor design suggests that this figure is 12.5-13.5 mm. If the result is different, you need to bend the rod antennae. Throttle adjustment involves determining the opening value of the throttle valve. It should be 14.5-15.5 mm. Otherwise, you will need to tighten the pneumatic drive rod.

Starter battery correction

At the second stage, you will need to adjust the operation of the starting device. The throttle lever on the secondary chamber is manually turned counterclockwise. It will close. The tip of the thrust lever should fit snugly against the axis of the primary chamber throttle valve.

At the very end there should be a starter rod. Otherwise, you will need to adjust its position. To do this, the rod is bent. This device in carburetor engines is fragile. If you apply too much force to it, the rod will break off.

Checking the pump accelerator and repairing it

You need to start checking by testing the functionality of the system. You need to collect in a beaker the fuel that will be generated during 10 cycles of operation of the throttle lever. From 5.2 to 8.7 cm³ of fuel should accumulate. If this is not the case, you need to clean the VAZ 2101 carburetor jets. To do this, bleed the pump. This will help clear clogged injectors. This procedure is performed about 10 times. Then the fuel is measured again.

If the purging procedure does not give the desired result, the accelerator will need to be completely replaced.

If the engine malfunctions at high speeds, you need to check the pump diaphragm. It could wear out. The fuel pump rod often wears out.

Modifications of carburetors installed on the VAZ 2105

On the “five” or VAZ 21053, 3 types of carburetors can be installed. All models are supplied in an unfinished form. Let's look at how they differ from each other.

DAAZ

The DAAZ or Weber carburetor is probably the sportiest type of carburetor, as it is equipped with large and maximally open, non-clamped jets. Car service experts say that this model is affordable and very reliable. There are no unnecessary bells and whistles here. With it, the car starts perfectly, drives well, and the idle system is easier to adjust.

"Ozone"

An improved model of the old, classic DAAZ. It received the name “Ozone” due to its environmental friendliness, because a perfectly tuned carburetor of this type allows you to reduce gasoline consumption to 7 liters per 100 km.

The downside of Ozone is its complex design, which often leads to problems with the secondary chamber. This malfunction is associated with the fact that the additional camera is activated not mechanically, as on Webers, but using a pneumatic valve. Also, Ozone carburetors are highly sensitive to contamination. As a result, the adjustments are disrupted, the second chamber begins to open with a delay or does not close completely. What does this lead to? Acceleration dynamics deteriorate, engine output decreases, and maximum speed decreases.

"Solex"

Licensed products from Solex. A carburetor of this type has proven itself on the VAZ 2105, 21054 and other classics only on the good side. It turned out to be economical and at the same time dynamic. The design is completely different from DAAZ. There is a “return” - a fuel return supply system, as well as a number of additional auxiliary electronic systems.

Despite such advantages, the Solex carburetor, especially found in the CIS, turned out to be somewhat problematic. For example, the fuel channels on it quickly become clogged, since they are narrow. If this model is not serviced in a timely manner, failures in the neutral system will begin.

In some cases, a carburetor of a non-standard or non-standard type may be installed on the “five”. This installation requires certain modifications followed by proper adjustment. For example, such options are carburetors 21073 and 21083.

Carburetors OZONE

An ozone carburetor was installed on domestic cars for a long time.

Fuel supply systems of this type were produced in three designs:

- Bubbler;

- Needle-shaped;

- Float mechanism.

The first two types are practically no longer used; their production has been discontinued. On cars of brands 2107, 2105, an ozone carburetor was installed, the device of which became widespread. The modification replaced the Italian invention “Weber”. At the Volzhsky Automobile Plant, the ozone carburetor received modifications, thereby increasing power and more stable operation. The DAAZ OZONE carburetor, for which it is a predecessor, is more technologically advanced and was installed on cars of different families.

How to adjust carburetor idle speed?

Idle speed is adjusted on a warm engine according to the following scheme:

- bring the internal combustion engine to 850 rpm using the quantity screw;

- then set the speed to maximum using the quality screw;

- reduce the speed to the previous level (up to 850) and raise it again to the maximum;

- turn the quality regulator at 850 rpm to the “motor shaking” position.

After all these operations, the quality screw is slowly unscrewed until the internal combustion engine operates stable.

If all the settings are made correctly, the “five” will not “eat” more than 9 liters of fuel when driving around the city, and on country highways the fuel consumption will be about 7.5 liters.

Now about the setup itself

Maintaining the required fuel level in this device is ensured by a float mechanism.

Setting the float mechanism

- Start the car engine and let it idle for 2-3 minutes;

- Remove the carburetor cover;

- Check the fuel level in the float chamber. It should be 28 mm.

In case of deviation, we perform the following actions:

- Measure and adjust the distance between the cover gasket and the float when the float tongue touches the needle valve ball. It should be 6.5±0.25 mm. Adjust by bending the tongue;

- Check the maximum valve needle travel. It should be 8 mm. To check, it is necessary to measure the distance between the cover gasket and the maximum retracted float. It should be 14±0.5 mm. The deviation is eliminated by acting on the bracket;

- Visually check that the tongue of the needle valve axis is perpendicular and that the float is parallel to the bottom plane of the cover. If there are any violations, correct them.

If all of the above steps fail to achieve a stable fuel level (28 mm) in the float chamber, then the needle valve must be replaced.

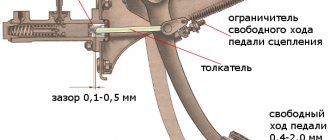

Adjusting the starting device of the VAZ 2105 carburetor

- Using the thrust handle located in the cabin, close the air damper;

- Check that the rod shank is at the end of the carburetor trigger rod groove. If there is a violation, correct it by bending the rod;

- Remove the cover and measure the gap between the edge of the air damper and the chamber wall with the starter rod recessed (we recess the rod using a screwdriver with the rod disconnected). It should be 5.0-5.5 mm. We adjust by rotating the adjusting screw of the starting device.

Idle adjustment

This type of work should be carried out on a warm engine.

- Use the mixture quantity screw to bring the engine to 850 rpm;

- Use the quality screw to bring the speed to the maximum level;

- Use the quantity screw to reduce the speed to 850;

- Use the quality screw to bring it to maximum again;

- Having thus achieved 850 rpm, tighten the quality screw until the engine “shakes”;

- By unscrewing the quality screw, achieve stable engine operation.

With proper adjustment of the VAZ 2105 carburetor, fuel consumption in the summer should not exceed:

- outside the city on the highway at a speed of 90 km/h – 7 – 7.5 liters per 100 km;

- during the urban driving cycle - 8.5 - 9 liters.

If you cannot do this work on your own, it is better not to torture yourself and the car, but contact the AvtoVAZ service center.

The VAZ 2105 “Ozone” carburetor is used to operate the engine of the “five” known to many Russians, which was produced in 1980–2010.

Third stage - idle speed adjustment

- The motor is brought out using rotational movements of the mixture quantity screw - the norm is 850 rpm:

- to increase the speed, you need to rotate the mixture quality screw (to the maximum level);

- to reduce the speed you need to rotate the quantity screw (to the desired level of 850).

- Tighten the quality screw as far as it will go (rotational movements are performed until the motor stops shaking).

- Unscrew the same screw in the opposite direction three turns.

In this way, the VAZ-2105 carburetor is adjusted at idle. Auto mechanics call all of the above actions calibration of the crankshaft idle speed.

Setting up and checking the launch system

This system is used to start a cold engine and ensures its warming up by approximately 1.5-2.5 thousand revolutions. When the engine warms up, the system is turned off manually and the engine starts idling at a speed of about 800-900 rpm. The second important gap is between the air damper and the wall of the primary chamber. When the damper is closed, this gap should be about 5-5.5 mm. It is adjusted by a screw, which is located under the brass threaded plug on the body of the vacuum air damper position regulator. The functionality of the starting system is checked with the air filter installed and the engine cold.

Device

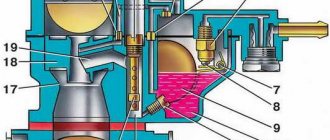

The DAAZ carburetor, developed by analogy with the product of the Italian brand Weber, is designed to dose the gas-air mixture in all engine operating modes without the participation of electronics. It consists of three main parts:

- covers with semi-automatic starting system;

- main or middle block with camera;

- additional or lower block with throttle valves.

The device cover includes important parts of the carburetor: flaps, a fitting for connecting a gasoline supply hose, a filter mesh, a needle float, an econostat tube, and an accelerator pump. The upper part of the carb is connected to the main block using several screws (M5).

The middle block consists of the main chamber, diffusers, jets, and a sprayer (helicopter). All the necessary channels responsible for certain engine operating modes are installed here.

The lower or additional block is equipped with throttles and adjusting screws, thanks to which it is possible to adjust the quality and quantity of the sprayed combustible mixture. There are also many different output channels available here. Like the upper part, it is connected to the main unit via screws.

It is easier to consider the carburetor design by looking at the operation of individual subsystems:

- A special place in the carburetor is occupied by the starting device system or SPU. It comes into operation when the engine starts. It is activated due to the vacuum created as a result of the movement of the cable when the diffuser opens. The SPU closely interacts with the gas pedal;

- Idle system. Its functions are clear by its name. On Weber it is of the classic type, on Ozone it is autonomous and works independently of the carburetor. On standard systems there is a special calibration screw that adjusts the throttle or air. It makes it possible to increase or decrease the number of idle speeds. There is also a mixture quality screw located in a different place, in a recess. By rotating it, you can supply the engine with exactly the amount of gasoline it needs;

- A transition system responsible for a smooth transition from idle to operation of the main jets. There is also a separate jet, which can also be attributed to this system. It stabilizes engine operation at high speeds;

- Main metering system based on the operation of the emulsion tube, fuel nozzle and chokes. It is in this mode that it is possible to open both throttles and the maximum speed of the car;

- Accelerator pump system. It controls the mixture, preventing air from entering more than normal. This makes it possible to avoid throttle failures during sudden car starts from a standstill and other maneuvers;

- Econostat that increases engine thrust at maximum speed. Consists of three jets: fuel, emulsion and air;

- A float mechanism system that maintains a constant fuel level in the chamber. Equipped with an adjustable needle valve. When the fuel in the chamber decreases, the float moves down, the valve opens and gasoline from the tank begins to flow through the fitting.

Work algorithm

Without a general understanding of the operating principle of a carburetor, it is difficult to repair and adjust it. Actions at random will not give a positive result or will cause more harm.

The principle of carburetion is based on the supply of fuel due to the vacuum created by the pistons of an atmospheric gasoline engine. Dosage is carried out by jets - parts with calibrated holes built inside the channels and capable of passing a certain amount of air and gasoline.

Carburetion is based on mixing air with gasoline under the influence of vacuum from the engine

The operation of the DAAZ 2105 carburetor begins with a cold start:

- The air supply is shut off by a damper (the driver pulls the choke lever), and the throttle of the primary chamber is slightly opened by a telescopic rod.

- The engine draws the richest mixture from the float chamber through the main fuel jet and small diffuser, and then starts.

- To prevent the engine from “choking” with a large amount of gasoline, the starting system membrane is triggered by the vacuum, slightly opening the air damper of the primary chamber.

- After the engine warms up, the driver pushes the choke lever, and the idle speed system (IAC) begins to supply the fuel mixture to the cylinders.

The starter choke closes the chamber until the engine starts.

On a car with a working power unit and carburetor, a cold start is performed without pressing the gas pedal with the choke lever fully extended.

At idle speed, the throttles of both chambers are tightly closed. The combustible mixture is sucked through a hole in the wall of the primary chamber, where the CXX channel exits. An important point: in addition to the dosing jets, inside this channel there are quantity and quality adjusting screws. Please note: these controls do not affect the operation of the main metering system, which operates when the gas pedal is pressed.

When idling, fuel enters through the lower hole located under the throttle

The further algorithm of the carburetor operation looks like this:

- After pressing the accelerator pedal, the throttle of the primary chamber opens. The engine begins to suck in fuel through a small diffuser and main jets. Note: The CXX is not turned off, it continues to operate in conjunction with the main fuel supply.

- When you sharply press the gas, the accelerator pump membrane is activated, injecting a portion of gasoline through the nozzle nozzle and the open throttle directly into the manifold. This eliminates “dips” in the process of accelerating the car.

- A further increase in crankshaft speed causes an increase in the vacuum in the manifold. The force of the vacuum begins to draw in a large membrane, which opens the secondary chamber with traction. The second diffuser with its own pair of jets comes into operation.

- When both dampers are fully open and the engine does not have enough fuel to develop maximum power, gasoline begins to be sucked directly from the float chamber through the econostat tube.

When the throttle is opened, the fuel emulsion enters the manifold through the idle channels and through the main diffuser

To prevent a “failure” from occurring when the secondary damper opens, a transition system is used in the carburetor. It is identical in structure to the CXX and is located on the other side of the unit. Only a small hole for fuel supply is made above the closed throttle valve of the secondary chamber.

This is interesting: How to charge a maintenance-free car battery - there is nothing complicated!

Do-it-yourself idle speed adjustment on a VAZ

The main task is to tune the engine for minimal gasoline consumption and CO2 emissions, while maintaining its stable operation.

We heat the engine to operating temperature, set the lowest value for idle speed - 900 minutes. -1 (quality screw), listening carefully to how the car behaves.

After this, adjusting the quantity screw, add idle about 100-150 rpm. in a minute. Again, turning the quality screw, we reduce them by the same amount, determining what number of revolutions is optimal for it and deciding that everything is enough, we finish the operation of adjusting the idle speed.

There can be many models of carburetors on a VAZ and they can be in different conditions, but when tuning, the most important thing is to listen to the car. How smoothly the engine runs is a much more significant indicator than strictly following the instructions when adjusting

How to reinstall the carburetor

After the device has been washed and repaired, you will need to reinstall the carburetor. To do this, first a new seal is applied to the installation site, and the carburetor itself is installed on it. Nuts are screwed onto the four mounting studs, ensuring a tight fit of the carburetor body to the engine manifold:

- Then you will need to connect two thin hoses for vacuum and ventilation to two fittings that are located in the upper part of the carburetor.

- A fuel supply hose is connected to the inlet valve; it is recommended to replace the clamp with a new product.

- The return hose is screwed on the reverse side.

- Next, the EPHH wire is connected to the solenoid valve.

- It is better to install the throttle return spring before connecting the throttle and air valves.

Installation and connection of the DAAZ carburetor is considered complete.

Basic operations for removing/reinstalling, flushing and adjusting the carburetor are available to drivers with any level of training and experience. It should be borne in mind that the mechanisms are considered to be quite capricious, so all stages of the procedures you perform will require increased concentration.

Common causes of floating revolutions

So, we figured out the main symptoms. Now let's move on to the reasons. Let us immediately note that floating idle speed is often a problem with injection engines. The fact is that a complex ECM system is responsible for idling in this case.

This system assumes the presence of a controller, sensors and actuators. The control unit receives signals from sensors and transmits commands to actuators (for example, IAC), maintaining stable engine speeds at idle and other modes, regardless of the load on the internal combustion engine.

However, any failures that are associated with the supply of air, fuel, a violation of the composition of the working fuel-air mixture or its ignition, as well as various mechanical breakdowns will lead to floating speed.

As a rule, in practice, the idle air regulator causes a lot of problems for drivers. In fact, this is a stepper motor that has a conical locking needle. When the throttle valve is closed, air bypasses the valve through a channel that is closed by the needle.

If malfunctions occur in the operation of the device, the ECU is not able to correctly “select” the mixture composition at idle, as a result, the speed floats.

The mass air flow sensor also deserves special attention. During operation, the air flow sensor may become dirty or break down.

How is the carburetor float device adjusted?

Experts say that it is possible to adjust the carburetor without necessarily removing it from the vehicle. A float mechanism is responsible for ensuring the required volume of fuel in the described device, which is adjusted as follows:

- the engine is started and it idles for several minutes;

- The carburetor cover is removed and the fuel level is measured, which should be 28 millimeters.

If these same 28 mm are not observed, perform:

- bending the float tongue touching the needle valve (more precisely, its ball) to a value of 6.2 to 6.75 mm;

- After visual inspection, align the parallelism of the float with respect to the lower level of the cover, as well as the perpendicularity of its tongue to the axis of the valve (needle);

- align the position of the bracket in situations where the distance between the float, allocated to the greatest length, and the cover gasket does not fall within the range of 13.5–14.5 mm.

We learn to adjust the carburetor VAZ 2103, 2105, 2106, 2107 independently

- We learn to adjust the carburetor VAZ 2103, 2105, 2106, 2107 independently

- How does a VAZ 2107 carburetor work?

- Carburetor components

- Carburetor systems

- How to set up a carburetor

- Checking the condition of the mesh filter

- Setting up the float chamber

- Adjusting the starting system

- Adjusting the idle speed of the VAZ carburetor

Owners of VAZ 2103, 2105, 2106, 2107 cars have probably encountered the need to adjust the carburetor. The first desire that arises in your mind is to stop by the service station and solve all your problems. But there is no need to rush to the experts, because you can do the adjustment of the VAZ 2107 carburetor yourself. You will need time, patience and some knowledge of the design and operation of this unit.

- How does a VAZ 2107 carburetor work? Carburetor components

- Carburetor systems

How to set up a carburetor

- Checking the condition of the mesh filter

Adjusting the float chamber Adjusting the starting system Adjusting the idle speed of the VAZ carburetor

How does a VAZ 2107 carburetor work?

To independently adjust the carburetor, it is useful to know what components and systems it consists of. To provide the engine with high-quality fuel, the carburetor systems must work “like a clock.”

Carburetor components

The components of the VAZ 2107 carburetor are:

• Float chamber.

• Idle air valve.

• Crankcase gas exhaust compartment.

• Air and fuel jets.

Carburetor systems

For high-quality operation of the car engine, you will need flawless operation of the carburetor systems:

1. Engine starting and warming up system.

2. Idle system.

3. Constant fuel level monitoring system.

4. Acceleration pump (to guarantee acceleration of the car).

5. Large diffuser in the carburetor body, VTS sprayer, air and fuel jets, emulsion tube and emulsion well. Their location is the main dosing chamber.

6. Econostat system. This is an enrichment device in the second internal combustion chamber of the engine.

To adjust the carburetor, you need calibration data, which describes all the necessary values for adjusting the VAZ 2107 carburetor. Having started adjusting the carburetor, you need to check the operation of all components and systems that control the operation of the carburetor. To do this, the check must begin with external control elements. Check the throttle valve actuator for full travel of the throttle valve actuator lever. When the gas pedal is released, the throttle valves in both mixing chambers must be completely closed. The gas pedal is depressed to make sure that the throttle valves operate smoothly and without jerking, sequentially (first in the primary chamber, and then in the secondary chamber, they fully open and become vertical, opening the throat completely).

Nuances of the work

The Ozone carburetor is adjusted when replacing elements of the device. If the guide handle is extended, the choke must be closed. In case of deviations from the norm, it will be necessary to lubricate the cable with engine oil. After this, rearrange the end of the cable in the damper block and unscrew the screw. The lever is completely lowered. At the same time, the air damper closes and the VAZ 2105 carburetor rod is located at the bottom of the rod groove. If the last element moves, it will be necessary to straighten the deformed parts by adjusting the length of the link.

How to disassemble a carburetor

If the air damper is completely closed, the throttle analogue of the 1st chamber should be slightly open by 0.8-0.9 mm. This indicator may change due to fluctuations in the bending of the rod. When the rod is moved inside the VAZ 2105 carburetor body all the way, the air damper opens slightly by 5.5 mm. The distance can be adjusted by unscrewing the cover screw. A similar block is installed under it, the rotation of which sets the gap. Once the cap is installed, the ozone carburetor adjustment is complete.

The carburetor needs to be adjusted only when the engine is warm. In this case, the suction button must be completely recessed.

At the factory, the procedure is performed at a minimum crankshaft speed of 850 rpm. In this case, the carbon monoxide content should be 0.05 g 2%. The bushings are pressed onto the screw heads. If you turn the bushings there is no way to restore the factory settings, the screws come loose and the bushings are broken. This will make the appropriate settings.

Repairing a VAZ 2105 carburetor: how to set up the injection system?

The fifth Lada model was produced from 1980 to 1995 and was in great demand. The main engine installed on these cars was a four-cylinder internal combustion engine with a displacement of 1.29, 1.45 or 1.57 liters. To prepare the combustible mixture for engine operation, domestic ozone carburetors and their modifications were installed. We will tell you how to adjust and repair a VAZ 2105 carburetor with your own hands.

First, let's take a closer look at the device itself, which mixes fuel with air in certain proportions. After mixing, the working mixture enters the engine cylinders and determines the normal operation of the unit in different modes. A carburetor is a rather complex and very precise unit, so the accurate implementation of the main functions depends on strict adherence to the parameters set at the factory and their subsequent adjustment.

Throttle manipulation

First, remove the springs from the carburetor primary chamber throttle vacuum actuator. These actions will allow you to immediately feel the improvement in car dynamics while driving; fuel consumption per 100 km will increase by less than a liter.

By modifying the carburetor on the Lada 2105, you can increase power and dynamics

Refinement of the VAZ-2105 carburetor also involves replacing the vacuum drive of the secondary chamber throttle valve with a mechanical one. It's not as difficult as it seems.

To do this, take a small piece of straight wire and bend it into a ring at one end, push it under the nut that holds the throttle drive lever of the second chamber.

As a result, the protrusion of the outer chamber arm should be between the wire and the second drive arm. Tighten the nut firmly.

These simple tuning steps for the VAZ-2105 carburetor will improve dynamics, while fuel consumption will remain the same.

Basic mechanisms and systems

To perform its functions, the carburetor has the following systems and mechanisms:

- System for maintaining the required fuel level;

- System for starting and warming up a cold engine;

- Idle system;

- Main dosing system;

- Acceleration pump;

- Econostat system.

Good old VAZ: love for life The three systems listed first in the list are subject to configuration. The VAZ 2105 carburetor in question can be adjusted without removing it from the car. Since the units of cars of models 2105 and 2107 are identical in structure and differ only in the diameters of the holes of the fuel and air nozzles, in the same way it will not be difficult to make a similar adjustment for the VAZ 2107.

Why does the cylinders flood?

Also look carefully at the spark plugs; if they have heavy carbon deposits on them, the engine will run unstably. But if a lot of gasoline enters the combustion chambers, then most likely it is necessary to adjust the level in the float chamber. How to adjust the level will be discussed a little below. The saddest thing is if the reason that the cylinders are flooded is a burnt out valve.

In this case, the cylinder head will have to be repaired. If the engine runs unstable, as well as stops at high speeds, look for a fault first of all not in the carburetor, but in the fuel pump and its drive. But you need to look at the carburetor of the VAZ 2105; adjustment will not hurt it.

Modification of turbocharging (pseudo-turbocharging)

Not all car enthusiasts agree to take such a serious step. But nevertheless, this tuning of the VAZ-2105 carburetor adds good dynamics, so it can still sometimes be found on domestic cars.

So, how do you make pseudo-turbocharging? Instead of the usual hose that supplies warm air to the air filter, we install one of the same diameter, but longer in length. This is done in order to bring it directly to the fan. Air currents will directly enter the hose in a constant flow.

Now let's talk about the dangers and consequences of this tuning. Since the air is supplied directly, dirty droplets entering the hose are sent directly to the air filter. Which can delay the entry of all debris, but some of it is still sent to the cylinders. And this, over time, ensures wear of the piston group. Therefore, think carefully before upgrading your car in this way.

Carburetor Basics

Contrary to popular belief, the suction of fuel from the carburetor does not occur due to the internal operating thrust of the engine. To perform this function, the device is equipped with a diffuser.

This element is not a separate element, but a narrowed part of the carburetor neck. When an air flow passes through it, due to the difference in width, a vacuum occurs, a drop in pressure. Near this place there is a small hole for supplying gasoline. Thanks to the resulting vacuum, atmospheric pressure acts on gasoline by displacing it from the float chamber through a special passage into the carburetor neck. In it, fuel is mixed with air and enters the engine cylinders through the intake manifold. The VAZ-2105 or 2106 engine, like any other automotive power unit, is capable of operating in several modes, each of which requires the appropriate type of air-fuel mixture.