The main function of a car clutch is to ensure smooth gearing by briefly disconnecting the engine from the transmission. The consequence of this is a smooth start of the car without overloading the engine. This helps prevent premature wear of the gearbox and engine parts. In the case of a poorly functioning clutch, the cause of overload is the inertial moment, which is a consequence of the operation of engine parts during a sudden strong deceleration of the crankshaft speed.

During repairs, the VAZ 2106 clutch disc is usually immediately replaced, as well as the clutch basket is replaced. It is worth noting that in order to do this, certain skills are required. Therefore, if you don’t have confidence in your abilities, and you only know how to replace spark plugs yourself, you should entrust the installation of a new clutch to specialists.

There are two ways to replace the clutch: the first requires removing the box, the second you can do without it.

The second method is less labor-intensive, so it will be discussed in more detail below. First you need to prepare a lift or inspection hole.

4. Unclench the ends of the connecting spring and remove it from the coupling. If necessary, replace the spring. 5. Install a new clutch release bearing assembled with the clutch on the VAZ 2106 vehicle (making sure it works) in the reverse order of removal. 6. Lubricate the splines of the input shaft with a thin layer of lubricant Lsts-15 or Litol-24. 7. Install the gearbox and removed parts in the reverse order of removal.

The clutch, like any other component of the car, needs to be replaced or repaired if a malfunction occurs in its operation. The time, number of off-on cycles of the unit or vehicle mileage, after which the VAZ 2106 clutch needs to be replaced, has not been established. Yes, this cannot be done due to the influence of individual factors on its service life. Here you need to take into account the manufacturer of the installed clutch, the mileage of the car, the operating conditions of the unit and the driving style of the car.

Replacing the VAZ 2106 clutch with your own hands

It is quite difficult to imagine a car engine without a clutch. The main task of a car clutch is to ensure a smooth engagement of speeds by briefly disconnecting the engine from the transmission. Thanks to the clutch, the car can move off smoothly without overloading the engine and preventing premature wear of all its parts, as well as gearbox parts. Overloads are caused by inertial moment, which is formed due to the rotation of engine parts during a sudden sharp slowdown in crankshaft speed.

Replacing the VAZ 2106 clutch disc, as well as the clutch basket, is usually done at the same time. This process is not simple and requires certain skills and dexterity, so if you have only recently learned how to change spark plugs yourself, it is better not to take risks and entrust the work to specialists. Replacing the clutch can be done in two ways, with or without removing the gearbox; it is this less labor-intensive and convenient method that we will use today. This work is carried out on a lift or inspection pit.

Replacing the VAZ 2106 clutch with your own hands

- Secure the vehicle with wheel chocks.

- Disconnect the cardan shaft from the gearbox, as well as the clutch slave cylinder.

- Remove the reverse light switch wires from the contacts.

- Disconnect the clutch cover from the side of the cylinder block, unscrew the yoke from the bottom side.

- Using a socket on “13”, unscrew the two fastening nuts that secure the gearbox mount, then remove it.

- Move the gearbox as far as possible from the engine until the shift lever rests against the rear of the bottom hole.

- The transmission will hang from the downpipe of the muffler as a safety net, install an additional support under the rear of the box.

- Grasp the flywheel with a mounting tool and unscrew the 6 bolts securing the clutch basket using a 13mm wrench. Continuously turn the crankshaft to ensure you have access to the bolts.

9. Move the clutch basket towards the box, using the resulting opening, remove the clutch disc.

10. After this, move the basket towards the engine and remove the clutch basket.

11. After pulling it out of the clutch housing, remove the clutch fork and remove the release bearing from the transmission input shaft.

Installation of clutch parts is carried out in reverse order. Before installing them, you need to wipe the working surface of the basket, flywheel, and clutch disc with a clean rag soaked in gasoline. Center the clutch disc in relation to the bearing at the end of the crankshaft, using a special mandrel that imitates the splined part of the transmission input shaft. When you are finished tightening the basket mounting bolts to the flywheel, pull out the mandrel; it should come out easily by hand.

Apply a thin layer of CV joint-4 lubricant to the splines of the input shaft, then install the box in place. After replacing the VAZ 2106 clutch disc is completed, it is necessary to adjust the stroke of the clutch working cylinder rod; it should be free.

Watch also the video on how to replace the clutch on a VAZ “Classic”

Home

Source

Also check out

- Move the gearbox away from the engine as much as possible (the shift lever should rest against the rear cavity of the bottom hole).

- For insurance, install an additional support under the back of the box.

- While holding the flywheel with a mounting tool, use a 13 key to unscrew the 6 bolts that secure the clutch basket. To provide access to the bolts, you need to constantly turn the crankshaft.

- As soon as you manage to pull the basket out of the clutch housing, remove the clutch fork. The release bearing must be removed from the transmission input shaft.

Wipe the basket, clutch disc, and flywheel with a clean rag moistened with gasoline. Reinstall the clutch parts in reverse order. Using a special mandrel that imitates the splined element of the transmission input shaft, center the clutch disc in relation to the bearing of the end part of the crankshaft. After tightening the bolts that secure the basket to the flywheel, you need to pull out the mandrel.

It is worth applying CV joint-4 lubricant to the splines of the first shaft. After completing the clutch replacement, it is necessary to adjust the stroke of the clutch slave cylinder rod (this element must be free).

Replacing the VAZ 2106 clutch with your own hands

It is quite difficult to imagine a car engine without a clutch. The main task of a car clutch is to ensure a smooth engagement of speeds by briefly disconnecting the engine from the transmission. Thanks to the clutch, the car can move off smoothly without overloading the engine and preventing premature wear of all its parts, as well as gearbox parts. Overloads are caused by inertial moment, which is formed due to the rotation of engine parts during a sudden sharp slowdown in crankshaft speed. Replacing the VAZ 2106 clutch disc, as well as the clutch basket, is usually done at the same time. This process is not simple and requires certain skills and dexterity, so if you have only recently learned how to change spark plugs yourself, it is better not to take risks and entrust the work to specialists. Replacing the clutch can be done in two ways, with or without removing the gearbox; it is this less labor-intensive and convenient method that we will use today. This work is carried out on a lift or inspection pit.

- Replacing the driveshaft crosspiece on a VAZ 2101 with your own hands

- Replacing the VAZ 2106 driveshaft with your own hands

- Replacing the VAZ 2108-2109 gearbox rod seal

Replacing the VAZ 2106 clutch with your own hands

- Secure the vehicle with wheel chocks.

- Disconnect the cardan shaft from the gearbox, as well as the clutch slave cylinder.

- Remove the reverse light switch wires from the contacts.

- Disconnect the clutch cover from the side of the cylinder block, unscrew the yoke from the bottom side.

- Using a socket on “13”, unscrew the two fastening nuts that secure the gearbox mount, then remove it.

- Move the gearbox as far as possible from the engine until the shift lever rests against the rear of the bottom hole.

- The transmission will hang from the downpipe of the muffler as a safety net, install an additional support under the rear of the box.

- Grasp the flywheel with a mounting tool and unscrew the 6 bolts securing the clutch basket using a 13mm wrench. Continuously turn the crankshaft to ensure you have access to the bolts.

Replacing the clutch hose VAZ 2101-2107

A torn clutch hose always leads to fluid leakage from the system, which in turn leads to difficulty shifting gears and, of course, to a bad mood for the driver. Replacing the clutch hose can be done even by a novice driver, therefore, if you just recently got behind the wheel of a VAZ classic and have already encountered this problem, going to a service station is not at all necessary.

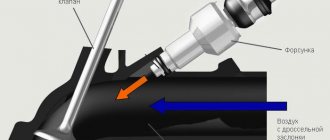

The work of replacing the clutch hose begins with disconnecting the rubber hose and the metal tube leading the fluid from

clutch master cylinder to the rubber hose. In order to disconnect the rubber hose, hold it with a 17-gauge wrench under the metal plate (see photo), and use a 13-gauge wrench to unscrew the metal tube from its fastening point. After the metal tube is unscrewed, you should pull out the metal bracket and push the rubber hose down through the metal plate. Already at this first stage, you may encounter a difficulty in the form of a broken metal tube. If it breaks when unscrewing, the old hose still sticks out,

but now you need to unscrew the broken metal tube from the clutch master cylinder - this is most conveniently done with a special 13-size wrench; a regular spanner wrench can lick the edges, but no one likes unscrewing a bolt, nut, or fitting with licked edges. Also, if you still need to unscrew the metal hose, you will have to remove the expansion tank from its mounts and move it to the side, because it prevents you from getting to the clutch master cylinder.

Once the old hose on top is no longer holding anything, the metal tube is either not damaged or is disconnected from the master cylinder after damage, you can begin to unscrew the old hose from the clutch slave cylinder. It is more convenient to carry out this operation in a pit or on an overpass, but if necessary, you can drive the front wheels onto bricks or boards to increase ground clearance - the main thing is to securely fix the car, because you will need to climb under it. The hose is unscrewed from the cylinder with a 17-size wrench, but it is screwed into the cylinder quite deeply - this leads to the fact that in some cases it is impossible to unscrew the hose even in a pit and even with a wrench with a long arm.

In this case, you will have to change the clutch slave cylinder.

Clutch cyl. bolted to the gearbox with two 13mm bolts

Before you start unscrewing them, you should use pliers to remove the spring from the working cylinder, and then you can unscrew the bolts - pay attention to the photo

It is better to immediately screw the new clutch hose into the new slave cylinder, climb under the car, insert the slave cylinder fitting through the gearbox fork, secure the cylinder itself with bolts and adjust the free play of the fork to 1 cm using the adjusting bolts on the fitting.

Afterwards, all that remains is to install a new metal tube, or screw the old one (if it remains undamaged) into a new hose. After that, the hose will be pushed through the metal plate - it must be secured with a bracket. Now all that remains is to install the expansion tank in its old place, pour fluid into the tank and bleed the clutch.

The second time, replacing the clutch hose will take no more than an hour, even if disconnected and replaced

additional details.

Bleeding the clutch is carried out in the following way. Liquid is poured into the reservoir, and the assistant pumps it by sharply pressing the clutch pedal. After a series of sharp pumping of the pedal, the assistant holds the pedal in a clamped position, and you sharply open the fitting of the working cylinder and sharply close it. In this case, air will escape through the fitting of the working cylinder along with the liquid. The procedure should be carried out until the pedal becomes as hard as possible.

Start the car and warm up the engine to operating temperature, try to move off without gas; on a flat road, a properly adjusted clutch should allow you to slowly move off without gas, but in the second car the car should not drive with the gas pedal not pressed. If the car does not move, or you hear small extraneous sounds when the clutch pedal is not pressed, you should tighten the clutch a little.

Other articles on autobelyavcev.ru

Kraz 6510

Kraz 255

Below you can leave your feedback on replacing the VAZ 2101-VAZ 2107 clutch hose.

How to check the clutch basket on a VAZ 2106

Replacing the clutch disc on a VAZ-2104-2107

Clutch kit The clutch is the most important component of a car, without which it is impossible to imagine the operation of the gearbox mechanism, as well as the car’s performance of such operations as starting and braking to a final stop. In other words, the clutch is a necessary mechanism of any car, which is a kind of transfer point between the engine and the drive axles.

This unit includes:

- driven clutch disc;

- clutch basket and release bearing with clutch.

So what is this component of the clutch mechanism? This is a disc with spring plates and friction linings that are not connected to each other and are made of a material comparable to the material of the brake pads, i.e. abrasion resistant. In the center of the disk there is a hub with a splined connection.

Replacing the VAZ 2106 clutch

Today we will talk about a common problem - the clutch of a VAZ 2106 car. The replacement must be done correctly and it is advisable to have straight hands with you. Theory.

The main task of a car clutch is to ensure a smooth engagement of speeds by briefly disconnecting the engine from the transmission. Thanks to the clutch, the car can move off smoothly without overloading the engine and preventing premature wear of all its parts, as well as gearbox parts. Overloads are caused by inertial moment, which is formed due to the rotation of engine parts during a sudden sharp slowdown in crankshaft speed.

Replacing the VAZ 2106 clutch disc, as well as the clutch basket, is usually done at the same time. This process is not simple and requires certain skills and dexterity, so if you have only recently learned how to change the oil in a VAZ 2106 engine yourself, it is better not to take risks and entrust the work to specialists. Replacing the clutch can be done in two ways, with or without removing the gearbox; it is this less labor-intensive and convenient method that we will use today. This work is carried out on a lift or inspection pit.

Replacing the VAZ 2106 clutch with your own hands

1. Secure the vehicle with wheel chocks.

2. Disconnect the cardan from the gearbox, as well as the clutch slave cylinder.

3. Remove the reverse light switch wire contacts.

4. Disconnect the clutch cover from the side of the cylinder block, unscrew the yoke from the bottom side.

5. Using a socket on “13”, unscrew the two fastening nuts that secure the gearbox mount and then remove it.

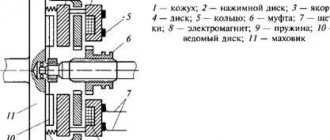

Clutch basket

The clutch consists of two discs and a release bearing. The clutch used on the VAZ 2107 is simple and reliable. The pressure (drive disk) is installed on the flywheel. Inside the basket there is a driven disk connected to the gearbox input shaft with special splines.

The driven disk is located inside the basket

The clutch can be single-disc or multi-disc. The first is considered more reliable. The clutch functions as follows. When you press the pedal, the release bearing mounted on the input shaft pulls the petals of the basket towards the engine block. As a result, the basket and driven disk are disengaged, and it becomes possible to change speeds.

For the VAZ 2107, wheels from the VAZ 2103 (for engines up to 1.5 liters) and VAZ 2121 (for engines up to 1.7 liters) are suitable. Externally they are very similar and have a diameter of 200 mm. These discs can be distinguished by the width of the linings (29 and 35 mm, respectively) and the presence of a 6 mm mark in one of the grooves of the VAZ 2121 damper.

Video: Replacing the clutch disc of a VAZ 2106

Clutch kit price

Now, in the era of the development of the Internet, there is no need to run to stores and look for the necessary spare part. It is enough to have access to the World Wide Web and you will have any detail in a couple of clicks. Prices for clutch discs for the VAZ-2107 vary from 470 to 2000 rubles. The cost of replacement work in Moscow and the Moscow region is 2–2.5 thousand rubles.

What advice can you give when choosing a disk? First, rummage through the forums and read reviews. Secondly, when purchasing a disc, do not be lazy to inspect it. Examine the splines especially carefully - there should be no nicks or burrs there, otherwise there is a risk that the disk simply will not fit on the shaft or will not be removed during the next replacement.

Take a look at the friction linings: they should all be uniform in composition and free of cracks. Another point is the quality of the riveting. The key to quality here is the identical dimensions of the flange. Try to swing the damper springs; if there is play, then you should refuse the purchase. And the last thing worth paying attention to is the presence of markings on the damper plate.

Preparing for repairs

Before putting the car in a pit and removing the box to replace the clutch, you need to visit the store and buy all the necessary spare parts:

- Clutch disc.

- Basket (drive disk).

- Release bearing.

- If necessary, clutch fork.

- If there is significant wear, the crown on the flywheel will also need to be replaced.

- Bolts securing the basket to the flywheel.

It is also important to have a good set of tools on hand, WD-40 penetrating lubricant, sometimes even a gas torch is necessary (if the bolts and nuts are very rusty).

It is advisable to carry out all the work in an inspection pit or overpass (it is unlikely that the average driver of a six will have a lift in the garage, so we do not mention it). If everything goes smoothly and the nuts unscrew well, you will complete all the work very quickly.

VAZ 2106 clutch replacement

Clutch disc VAZ 2106

The clutch is necessary to disconnect the gearbox input shaft from the engine crankshaft. This operation is carried out using two disks - a master and a slave. The VAZ 2106 clutch is replaced when these elements are worn out.

Replacement

— remove the gearbox; — mark with a marker or paint the position of the clutch assembly in relation to the flywheel;

— using a special tool or a screwdriver, use the teeth of the flywheel gear to block it from turning;

— gradually loosen the bolts 1 of the clutch assembly mounting diagonally, turning each bolt half a turn until the spring action stops and the bolts can be unscrewed by hand;

— remove the pressure plate, while supporting the driven disk so that it does not fall out;

— clean the clutch release bearing from dirt, but do not use solvents;

- Wipe the flywheel with gasoline.

To install the clutch disc:

— lubricate the splines in the hub of the driven disk with a thin layer of special lubricant based on molybdenum disulfide;

— install the driven disk on the flywheel so that the spring of the shock-absorbing hub of the disk is directed outward, towards the gearbox;

— when reinstalling a previously removed clutch pressure plate, check that the marks made before removal are aligned;

- tighten the clutch mounting bolts so that the clutch driven disc is pressed, but at the same time can still move to the sides;

— using a special mandrel 0213/0214 or the old gearbox input shaft, center the clutch disc relative to the flywheel;

— after centering the driven disk, gradually tighten the clutch casing bolts diagonally to a torque of 20 Nm;

— remove the mandrel from the driven disk;

— lubricate the splined part of the gearbox input shaft, the guide sleeve of the clutch release bearing and the fork tips with a thin layer of special MOLYKOTE BR2 PLUS lubricant;

— install the clutch release bearing;

— install the gearbox.

How to remove the rear axle shaft follow the link.

Installation

After which you can remove the basket, since nothing else holds it, as well as the clutch disc itself:

New parts are installed on the car in reverse order. But before installation, it is necessary to center the disk. To do this, during installation it is necessary to insert a rod into the central hole, almost equal in diameter to this very hole. And only after that tighten it.

Prices for these parts are:

Clutch disc - about 450 rubles Cart - about 550 rubles

Video: REPLACING THE CLUTCH ON A VAZ 2109-2115, STEP-BY-STEP INSTRUCTIONS!

Video: Replacing the clutch of a VAZ classic 2101-2107, how to remove the gearbox (gearbox) of a VAZ classic

Features of clutch functioning

In the general case, although approximately, the service life of the VAZ 2106 clutch before its replacement is about 150 thousand km for the basket, and about 70-90 thousand vehicle kilometers for the driven disk.

Prerequisites for repair are:

Clutch slipping is characterized by a loose fit of the driven disk to the surfaces of the flywheel and pressure plate of the basket when the clutch pedal is fully released in the passenger compartment. In this case, the engine speed, as the load on it increases, increases, but in some cases the car is not able to move at all when starting to move or weakly, uncharacteristically slowly increases its speed while driving. This malfunction is clearly visible when driving uphill, overtaking, or trying to move away abruptly. It occurs when the friction linings of the driven disc are worn out or the clutch drive is incorrectly adjusted.

Incomplete disengagement of the clutch, on the contrary, is manifested by the inability to engage a gear or increased force on the shift lever during engagement. Usually, switching is accompanied by an uncharacteristic crackling sound from the gearbox gears. The clutch pedal is fully depressed. This suggests that the force transmitted by the clutch pedal to the leaf spring of the basket is not enough to completely release the driven disk, that is, disengage the clutch.

Extraneous noise in the area where the clutch assembly is located indicates a mechanical malfunction or wear of one of the constituent elements of this mechanism. Misadjustment or malfunction in the hydraulic clutch system can be determined by the following symptoms:

- too weak or excessive resistance to the force on the pedal when pressing it (the pedal sinks to the floor or the impossibility of pressing it);

- lack of free play of the pedal, its failure to return to its original position after removing the pressing force;

- leakage of fluid from the hydraulic clutch system.

Do-it-yourself replacement and adjustment of the VAZ 2106 clutch

Today, the article will talk about procedures such as replacing and adjusting the 2106 clutch with your own hands. As we like to repeat, everything can be done without the help of car service specialists; there are no difficulties in repairing VAZ cars and there cannot be any. Often, drivers try to solve all the problems with the car on their own, because the cost of maintenance is absurdly high.

Even despite the fact that the VAZ 2106 has not been produced for ten years. And we will try to help as much as possible with the repair. If you have any questions, leave comments, share your experience, and describe unusual situations. After all, the topic is quite interesting and rich.

- Clutch mechanism of a VAZ 2106 car

- Description of design

- Clutch failure

- Symptoms of malfunctions

- How does the clutch drive work?

- Preparing for repairs

- Work on top of the car

- Work under the car

- Clutch replacement

- Bleeding the system

Clutch mechanism of a VAZ 2106 car

Description of design

You all know that the driver's feet have a clutch pedal. For some, this is enough and they don’t go any further. But if you’ve already decided to take on the repair, you’ll have to study the entire rest of the chain. On the VAZ 2106, like on all other classics, the clutch drive is hydraulic. The pedal drives the master cylinder rod, which moves a small piston inside it.

Clutch drive system

There are only two main components in the VAZ-2106 clutch system. The clutch master cylinder allows pressure to be created in the pipes using the driver's muscular strength. The worker acts on the fork, which drives the release bearing. Briefly, the operation of the entire system can be described as follows:

- When you press the pedal, the rod in the master cylinder moves. Since the system is closed, the pressure rises sharply.

- Under the influence of this pressure, the piston is extruded in the working cylinder, which is installed on the clutch housing.

After releasing the pedal, the reverse process occurs:

- When the pedal is released, the master cylinder rod returns to its initial position, as a result of which the volume inside the system increases and the pressure decreases.

- A return spring acts on the working cylinder, which allows the rod to move to its initial position.

- The system has an expansion tank into which liquid is filled.

DOT-3 type brake fluid is used as the working fluid. It contains many additives, they contribute to the normal operation of the mechanism. These additives have a beneficial effect on the metal and allow the cylinders to cool better.

Try to fill the system only with those fluids recommended by the manufacturer. Effective operation depends directly on the quality of the liquid that is poured into the system. Never allow the level to drop to the minimum level. Add fluid if necessary.

Bleeding the system

Draining fluid from the clutch drive system is very simple:

- Using a blower, pump out the liquid from the expansion tank.

- Unscrew the fitting on the working cylinder and wait until all the fluid is gone.

- Press the clutch pedal several times to remove any remaining brake fluid.

- Change tubes if necessary.

- Tighten the fitting.

- Fill the reservoir with fresh brake fluid.

- Place a transparent tube onto the fitting.

- Have an assistant press the clutch pedal several times. With the last press, you need to hold it in the extreme position.

- Unscrew the fitting half a turn, allowing fluid and air to escape.

- Repeat the procedure until liquid begins to flow without air bubbles. Don't forget to monitor the level in the expansion tank.

In fact, two or three passes are enough to get rid of air in the system. As you understand, pumping the clutch on a VAZ 2106 is not difficult. The procedure is very similar to bleeding the brakes, only it is much faster - the line is very short.

After replacing the clutch, it will need to be adjusted. Pay attention to the working cylinder rod - it has a thread along which you can move the nut. It is by moving it that the clutch is adjusted on VAZ 2106 cars and the rest of the classic series. It is also possible to adjust the free play of the clutch pedal; for this purpose, a special bolt is provided directly above it.

AutoNews / Reviews / Tests

How to change the clutch disc on a VAZ 2106

Replacing the clutch in a VAZ 2106 with your own hands

The clutch, like any other automotive assembly, must be replaced or repaired if it malfunctions. The time, number of cycles of turning off/on the device or starting the car, after which the VAZ 2106 clutch needs to be replaced, is not set. Yes, and this cannot be done due to the influence of certain factors on his life. Here it is necessary to take into account the manufacturer of the installed clutch, the mileage of the vehicle, the operating conditions of the unit and the driving style of the vehicle.

Replacing a VAZ 2106 clutch without outside help

The value of the clutch in any car is obvious: it is thanks to the clutch and the ability to periodically disconnect the latter from the gearbox during engine operation, which reduces the level of wear of parts by blocking the inertial moment coming from the crankshaft when it sharply slows down its speed. However, to put it simply, without a clutch, a car works much less productively and wears out faster.

Replacing a clutch for a VAZ 2106 includes replacing the clutch basket and clutch disc. It should be noted right away: it is better to replace the clutch the first time under the supervision of an experienced mechanic. For novice motorists, such a task will most likely be overwhelming - a certain level of skill and dexterity is clearly required here. It is all the more important to choose the right replacement parts. If you cannot identify them by eye, you should resort to using catalog numbers. For example, some gearbox parts are numbered 16S2220.

The following tools are required for work:

- standard set of keys;

- wheel chocks;

- lift or inspection hole.

The work of replacing the VAZ 2106 clutch takes place in several stages:

- Open access to the clutch disc and basket. Before starting work, the car must be securely secured using wheel chocks. This will not only make the work easier, but will also prevent accidents, which are common when safety requirements are neglected. We disconnect the cardan from the transmission, the clutch cylinder, and the clutch casing on the side of the cylinder block. We remove the rear light switch wires from the contacts, unscrew the yoke (from the bottom side), as well as the fastening nuts of the gearbox mount that is to be removed. The transmission must be moved as far as possible from the engine - the gear shift lever should rest against the back of the hole in the bottom. The gearbox will thus be hung on the exhaust pipe of the muffler, and therefore, to be on the safe side, it is better to install an additional support under the rear of the transmission.

- Removing the clutch disc and basket.

Unscrew the bolts securing the clutch basket (a 13mm wrench is suitable for this). In order to gain access to these six bolts, we turn the crankshaft sequentially. We move the clutch basket box slightly to the side, remove the clutch disc, after which, moving the basket towards the engine, remove the clutch basket from the crankcase, and remove the release bearing from the transmission input shaft.

Source