The clutch is one of the most important systems of any car. This means that you need to understand how it works and how the clutch release bearing functions - the signs of malfunction of which any car enthusiast should know. It plays a big role - transmitting pressure to the drive disk.

Clutch malfunctions are one of the main and very common problems that can happen on the road. As a rule, the car simply stops and the engine continues to operate as normal. Such breakdowns do not happen overnight; they are often accompanied by certain signs of an imminent breakdown.

Signs

The main signs of an impending breakdown are its slipping and incomplete shutdown.

Clutch system

During incomplete shutdown (the pedal is depressed), it is difficult to change gears with the engine on. The appearance of noises and crackles when shifting gears, increased free play of the pedal. When the clutch slips when the pedal is released, a burning smell is felt, the vehicle's movement is deteriorated, the engine overheats, and fuel consumption increases.

If you notice such signs of a malfunction, if you cannot fix the problem yourself, immediately go to the nearest service station. If you get there on your own, then move slowly, don’t accelerate too much and be very careful when changing gears. It would be a good idea to use a double squeeze when switching.

Clutch pedal

You can also resort to a special technique. When shifting to a higher gear, the clutch must be depressed and the gear lever must be held in neutral for a while. Next you need to release, then squeeze again, then turn on the gear you need.

When switching to a lower gear, the gear lever, as in the previous case, must be held in neutral. Next, we release the clutch and lightly press the gas, then squeeze it again and go to the required gear. If you can master this kind of gear shifting, you will significantly reduce the load on the clutch and extend the life of the gearbox.

What makes the gearbox on the Kalina noisy, what to do if the gearbox lever on the Lada Kalina 1 and 2 rings

The noise of the Kalina gearbox usually starts from the factory. This problem is caused by insufficiently precise machining of the gears - with a tolerance of 0.2 mm. In this case, noise or howling is heard only in a certain gear. Therefore, it is impossible to completely make the box silent; you can only reduce sound vibrations.

Lada Kalina of the 1st and 2nd generations has both manual and automatic transmissions. The box model depends on the engine size and the number of its valves. A common problem is that the gearbox on the Kalina (as well as on many other VAZ cars) is noisy.

Solving the problem

There are many reasons for clutch failure, but in this article we will describe one of the most common, namely the failure of the release bearing.

Release bearing

The release bearing is an important part, and any car owner should know how to prevent it from breaking and malfunctions, and if this happens, how to replace it correctly.

Causes of failure

The release bearing is influenced only when the pedal is depressed, at which point it is pulled back, as if it were moving the driven disc. As a result, if you hold the clutch for a long time at the engaged speed, there is a load on the bearing, which can cause rapid wear or malfunction. However, if used correctly, no repairs will be needed.

Has your release bearing failed?

- No (100%, 1 Vote)

Total votes: 1

Signs of release bearing failure

Symptoms of wear on the release bearing are typical knocking noises when pressing the clutch while the engine is running. But if this knocking noise mainly increases at low temperatures, then there is no need to worry. Because this part is made of very strong steel, which has relatively low expansion. The glass in which the bearing itself is located, on the contrary, is very sensitive to temperature changes.

Changing the release bearing

To make a replacement you must:

- Remove the gearbox (removing the gearbox will be described below).

- The ends of the clamp disengage from the coupling.

Disconnect the retainer from the coupling. Remove the bearing from the sleeve along with the coupling.

Repair, features and technical specifications

Inside a VAZ 21118 car, like any other, there is always a gearbox. For a model such as Kalina 1118, this device is a mechanical type design, which is equipped with one reverse stage, as well as 5 forward stages.

Gearbox from Lada Kalina.

In Lada Kalina, the gearbox is structurally combined with a differential, the main gear. Transmission differential repair should also take this into account.

The mechanism body of the VAZ Kalina car is presented in the form of three aluminum copper crankcases:

Special sealants are applied between them when assembling and repairing the gearbox.

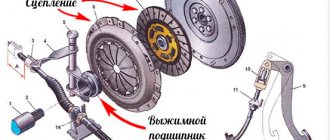

What is a release bearing and its role?

Layout of the release bearing in the clutch mechanism

The clutch release bearing comes into play when gears are changed, providing communication between the clutch discs, so when the first signs of a malfunction appear, you should immediately begin repairing it in your garage or by contacting a car repair shop.

The release bearing comes into play when gears are changed, providing communication between the clutch discs/

There are two types of this part: roller (ball) and hydraulic. How do they work? Everything is quite simple: the chain of action of the mechanism begins at the moment when the driver presses the clutch pedal, then the fork acts on the slave cylinder, after which the two clutch discs are disconnected, and for them to come together again, this spare part exists. We figured out why a release bearing is needed. Why do problems sometimes occur in the clutch system? Malfunctions arise due to excessive loads, usually experienced by novice motorists when they hold the clutch pedal . This is a very small round part, but when driving it bears a great responsibility; if a breakdown occurs, it is not possible to drive the car. The price of a new spare part ranges from 400 rubles to 4,500 thousand rubles, depending on the country of origin. Where is the clutch release bearing located? It is located in the part where the gearbox is connected to the clutch, that is, on the input shaft of the box.

Why does noise appear in the gearbox on a Lada Kalina - when you squeeze the clutch, the noise disappears

Car : Lada Kalina. Asks : Makar. The essence of the question : the problem is noise in the clutch, what should I do?

When starting the car when it is cold, a noise is noticeable. As it warms up the noise disappears. But if you immediately depress the clutch pedal, the noise disappears. What is this? I'm afraid that I might get in the way. They told me it was a release.

This is especially noticeable on a cold engine.

The problem is relevant not only for Kalin, but also for the tenth family, Prior, Grant.

How to remove and replace a release bearing

Removing the release bearing

An important rule for the release bearing: it should not “play” or move unevenly or spasmodically.

If repairs are necessary, you will have to disassemble the entire gearbox, because... the required part is inside it. Next, the spring clamp is released from tension, and the bearing itself is removed. To do this, you will need a tool, because you will have to remove it from the spring “legs” of the holder. Remove from the bushing, removing the retaining springs, and disconnect from the coupling. The removed part is inspected for cracks and other external signs of failure. It is more reliable to install a new spare part, since it is relatively inexpensive. After all actions, lubricate. How to lubricate the release bearing? Some people prefer molybdenum grease, others prefer graphite; parts are usually supplied with it when purchased in a store. An important rule for a bearing: it should not “play” or move unevenly or spasmodically. How to lubricate the release bearing without removing the box? You will have to contrive, it is almost impossible to provide good thorough lubrication without removing the gearbox. In any case, if the bearing hums, it is best to replace this part with a new one! Beginning motorists may have difficulties with how to change the clutch release bearing; this is quite a troublesome undertaking if there are no basic repair skills. That's why some people turn to a car service center for help. How much does it cost to replace a throwout bearing? This procedure will cost approximately from 2000 to 5000 thousand rubles.

Traditional first aid methods

If suddenly during a trip you discover that the pedal has treacherously failed and there is no longer any hope that the car will last until the planned trip to the car service center, you need to know 3 possible options for further action.

The first is to ask a friend to hold out the frozen car in tow, the second is to call a tow truck. But what to do if your friends are far away and there is no tow truck? In this case, there is a 3rd option: try to restore the clutch yourself so that it works until you get to the service station.

The driver is required to do the following:

- turn off the engine;

- use the lever to set first gear;

- simultaneously with turning the ignition key and starting the engine, press the pedal.

Here we go. Slowly? Of course, but don't even count on 2nd gear. If you try to switch, the gearbox will instantly fail, and its repair will cost a lot.

Which release bearing to choose

Release bearing with fork from Valeo

It is better not to purchase only a release bearing. If clutch elements are from different manufacturers, an imbalance may occur during operation. It’s not difficult to select the entire clutch system kit: focus on popularity among customers, reviews, the name of the manufacturer and the established reputation of the store. A one-piece set of excellent quality is produced by Valeo.

Oil leak at the junction of the gearbox and the front part of the driveshaft

Found on cars with a spline connection located in the box or transfer case.

Causes of leakage:

- Oil leakage occurs due to a defective oil seal in the box. The O-ring hardens over time, forming a gap between the movable cardan rod and the oil seal. Eliminated by replacing the oil seal in the box or transfer case.

- Damage to the mirror on the movable rod (spline connection) of the propeller shaft. The appearance of burrs or roughness on the splines. Treated by replacing the splines. As a temporary option, burrs can be cleaned off with sandpaper, which reduces leakage.

Which bearing is better

Many car owners try to replace it with a “original” part from the car manufacturer. But, for example, domestic spare parts from Lada cannot be characterized as the most durable and durable. Popular models are from the German company Sachs or the official supplier for our AvtoVAZ - the Italian bearing Coram. The price leader is Sachs; this is an inexpensive and acceptable quality alternative to replacing a faulty part. You can also choose EXEDY and SASSONE from more inexpensive models.

Preparing for work

When buying a new crosspiece for a VAZ 2107, you don’t need to try to save money.

Everyone knows that “the miser pays twice,” so it’s better to buy an original part right away than to change a couple of crosses in six months. The body of the crosspiece is made of heat-treated steel. This is necessary to ensure the special hardness of the studs. Thus, the quality of the material plays a big role in the service life of the part. How long can a car run without replacing crosspieces? It is believed that approximately 500 thousand km!

The retaining rings and bearing also need replacement.

Please note that the rubber of the bearing itself must be sufficiently elastic

AMT Robot

Priora with a robotic transmission was installed only on restyled versions (2013-2018), and the choice of car enthusiasts was not always in favor of the “robot”. But the robotic automatic transmission was developed based on the design of the new manual transmission, so there is nothing to be afraid of - everything is reliable. The computer or, in this case, the “robot” itself controls the engagement and disengagement of the clutch and changes gears itself (except in cases where the driver takes responsibility for manual gear shifting).

A Priora with a “robot” can also bite when starting and changing gears. The reason for this may be either an electronic error or wear of the “clutch” mechanism - if it’s time to change some part, then no matter how much the “robot” wants to smooth out the next peck, it will not be able to do so.