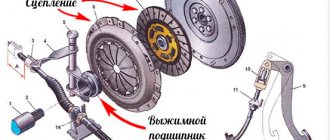

Most cars use a clutch consisting of 2 discs. To separate them when changing gears, a release clutch is created. When the car is moving, it is at rest and starts working after pressing the clutch pedal. Failure of this part makes it impossible to operate the car. If there are clear signs of a faulty release bearing, it must be replaced.

Defects that appeared after replacing the clutch

What does it mean to replace the clutch? This action means changing the driven or driven clutch disc; often both parts are changed at once. In this case, the release bearing must also be replaced. After such an operation, side defects are suddenly revealed that were not there before the repair.

If we think logically, then there are few reasons for the appearance of new malfunctions. Typically this is:

- Unqualified repairs;

- Defect of new spare parts;

- Erroneous diagnostics, as a result of which not all or the wrong parts were replaced, and previously hidden problems manifested themselves in full.

In general, the issue of the appearance of new unpleasant signs is very difficult and is individual in each specific case, but these signs have common characteristic features.

Review of Manufacturer Prices

| Manufacturer | Price, rub.) | Resource (Thousand km) |

| LADA 21901-1602210 original | From 634 | 100 |

| ASPCC260210 | From 465 | 75 – 80 |

| BRAND 219011602210 | From 300 | 75 — 80 |

| Plastic cable lead 21901-1602266-00 | From 150 | 40 |

| 21901-1602210-00 clutch cable assembly | From 550 – 600 | 75 |

| 21901-1602210-00 clutch cable assembly | —/— | 75 |

| JSC "ProSport" 26594516 | From 500 | 80 – 85 |

| JSC Vortex 5465465 | From 550 | 80 — 85 |

Related link:

Lada Kalina: changing the engine oil and oil filter

*prices are current as of October 29, 2018.

Recommendations for the selection of parts and components

The vast majority of spare parts for the Lada Granta are domestically produced. Foreign analogues are not in demand due to their high cost. Compared to “our” products, imports are 10–15% more expensive. The workmanship is at the same level.

When purchasing spare parts and components, always give preference to high-quality, original parts. Check the correspondence of catalog items with the actual data specified in the operating instructions for the technical device.

If you have no experience in car maintenance, seek qualified assistance from service station specialists.

If after replacing the clutch the car jerks

For example, before the repair, the car did not pick up speed well, it was slipping, and the clutch pedal was activated at the very top. All the signs of a worn driven disc were present. After replacing the disk, the car began to jerk. What could happen after the repairs were carried out?

- The issue may be a defective part. This is not so rare when it comes to non-original spare parts. In Russian-made cars (VAZ, GAZ, AZLK, IZH), defects also occur in factory parts. That is, the driven disk is simply curved. On the clutch basket (drive disc), the pressure petals may be at different levels, then the release occurs unevenly and the car jerks.

- The car may jerk due to clutch adjustment. More precisely, it was not performed after replacing the disk. The linings of the new part are much thicker; in this case, the clutch pedal “takes at the very end”. When starting off, the car moves jerkily, and the gear shifts into gear with a crunch.

- The car jerks due to the replacement of not all the parts that needed it. In particular, the cause of jerking is the worn surface of the flywheel under the driven disk. If the flywheel has not been replaced, there may be jerking when driving, and the car may also slip.

Possible causes of failure

Loads on the release bearing occur when the clutch is disengaged. The higher the engine speed at the moment of gear shifting, the more intense its operating mode. The most common reasons for part failure are:

- Holding the clutch pedal down for a long time. High rotation speed and large axial forces from the diaphragm spring lead to rapid wear of the device elements.

- Abrupt engagement and disengagement of the clutch. Characteristic of aggressive driving style. Instant uneven loads occur on the bearing, which can lead to failure of not only the rotating part and the pressure fork, but also the clutch elements.

- Poor adjustment of pedal or cable travel. The bearing is in constant contact with the surface of the spring. Constant rotation causes heating of the rolling elements, which leads to rapid wear.

Part destruction may occur due to the installation of a low-quality product or lack of grease in the release clutch cavity.

If there is a noise or whistle after replacing the clutch

Many car owners often complain that after replacement, a noise or whistle appears that was not there before. What could be the reasons for the extraneous sound and why does this happen? » alt=»»>

- The new release bearing turned out to be of poor quality or does not contain enough factory lubricant. A whistling or noise appears when you press the clutch pedal. Many people mistakenly believe that the bearing makes noise when the clutch is disengaged. But this is even illogical, in this state the part does not bear the load, and accordingly the noise (whistle) in this state is minimal.

- The clutch basket has unevenness and roughness at the tips of the pressure petals. Typically, spare parts from Russian manufacturers have such a defect. It should be noted that as the parts are ground in, the whistle that appeared initially disappears. You can temporarily eliminate the noise by lubricating the petals with lithol. But this can be done without disassembly on GAZ cars; on front-wheel drive cars, to perform a similar procedure it is necessary to dismantle the gearbox.

- It is possible that before replacing parts, the car owner did not pay attention to extraneous noises such as whistling, as he was expecting repairs. But after replacing the clutch, extraneous sounds remained, which the owner of the car did not expect. Noises are often caused by the gearbox. If, when the clutch is depressed, the unpleasant sound disappears or noticeably subsides, then most likely this indicates wear on the gearbox input shaft bearing.

- The driven disc linings have roughness. A rustling noise occurs when changing gears. There is no need to worry too much ahead of time - the new parts will get used to it, and the defect will disappear during the operation of the car quite quickly.

- The input shaft bearing in the crankshaft may also make noise. When disassembling the car, you should do an external inspection of the bearing. If it is very dry, it must be lubricated with lithol or other suitable lubricant. It is better to replace a clearly worn part immediately.

The release bearing of the Priora is noisy

I start the car, squeeze the clutch, release it, and an unpleasant hum appears! What should I do, change or tighten the clutch? When accelerating, it starts to work like a tractor!

Comments 18

the same bullshit only when it's cold

Change the oil first, for some reason it seems to me that it’s the gearbox.

Most likely the bearing itself has the same garbage, and especially when the car warms up and everything is fine when it’s cold, I don’t worry about it, this is normal for a Prior

In short, it’s better to take it apart before the release valve falls apart; if it falls apart, a scribe will come to you. It’s easy to check (on front-wheel drive except for priors) there’s a humming sound - lift the clutch pedal up with the toe of your foot (there’s a 1-2 cm stroke there), if the humming stops - the release, if it doesn’t stop - the input shaft bearing.

If you are going to disassemble it, then buy a set of KraftTech couplings, but throw out the clutch release from it. Good Samara release (600 rubles). It’s better to change everything so that they don’t tell you at the station, otherwise in six months you’ll change the disk and basket, and you’ll have to pay for disassembly again.

or releaser or secondary shaft bearing. If it hums at speed, check the oil, maybe it has run out and the fifth gear is humming, since the first place the oil flows from is the fifth.

Author: Alex May 26, 2022 Category: Car fault diagnosis

A car is a relatively complex structure; in the modern world it is impossible to do without this miracle of invention. It consists of a large number of interconnected mechanisms. One of them is the clutch system.

If the components of this mechanism break down, the engine will not stop working, but you will not be able to start moving. Car enthusiasts should have a good understanding of the car's structure in order to prevent damage to this mechanism. In this article we will talk about the clutch release bearing, signs of a malfunction of this part, and what to do if it breaks.

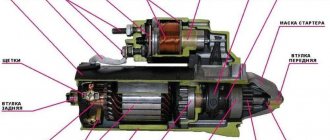

The process of shifting gears in a car occurs due to the separation of the clutch discs (clutch systems with two discs predominate in production); the release bearing is one of the components of this operation; it is the one that separates the drive disc from the driven disc. The release bearing creates pressure that separates the discs and stops the movement of the input shaft without stopping the engine.

If there is a knocking noise after replacing the clutch

As a rule, the cause of knocking after replacing parts is defective parts. In particular, there are dangling damper springs in the driven disk. Therefore, before installing such a spare part on a car, you need to carefully inspect it. Parts of the disk may also be poorly riveted. » alt=»»> Knocks in the clutch area can occur due to a crack in the release bearing bushing (the bushings are often made of plastic). Even at the site where the bushing fits on the flange of the gearbox input shaft, play may form, which also leads to a knocking sound.

The knocking noise occurs due to a broken clutch basket petal, but such a defect occurs infrequently. Another reason for the knocking is a broken starter housing in the Bendix area; it rattles when the car moves. A tooth on the flywheel crown may break off, and it will also knock when touching the rotating parts.

Signs of malfunctioning parts

The release clutch can fail not only due to improper use, but also due to natural wear and tear. Knowing the operating principle of the device, you can determine its technical condition based on its characteristic symptoms. Typical symptoms of a malfunction are:

- The occurrence of extraneous noise when pressing the clutch pedal. The destruction of the node is accompanied by a grinding or loud crunch.

- Gear shift drive sticking. Sometimes it is impossible to turn on the desired speed.

- Excessively free play of the clutch pedal.

- Incomplete engagement or disengagement of the clutch. The situation may be accompanied by an unpleasant burning smell.

Additional signs of a breakdown are: increased fuel consumption, engine overheating, and jerky movement of the vehicle. The service life of the part is reduced due to dust and dirt getting into the bearing, increased temperature and lack of lubrication.

Signs of a defect cannot be ignored, because... This can lead to serious consequences when driving with a faulty transmission.

Control check

You can diagnose the condition of the squeezing device in the following way:

- Start the car engine. Listen to your work for any extraneous noise. If available, determine the location.

- Depress the clutch pedal. If an extraneous sound appears, the part will need to be replaced.

The bearing cannot be repaired. The problem is solved by replacing the defective part.

Consequences of malfunction

The element has sufficient strength, so it cannot fall apart instantly. However, there is no point in delaying the elimination of the defect, since failure leads to misalignment of the disks and uneven wear. As a result, problems will arise with the transmission, which will negatively affect the technical condition of the vehicle.

If the part falls apart, the driver will not be able to engage the desired gear and move away. If such a defect occurs while the vehicle is moving in the city, the services of a tow truck will be required.

Clutch slipping after replacing all its parts

After replacing all elements, adjustment is required, but many car owners ignore this point. The cause is slipping, the car accelerates slowly, the engine speed does not correspond to the speed of the car. The engine just roars, and the car is driving quite slowly, as they say, slipping.

In cars with a mechanical clutch cable, adjustment is made by the cable itself. In hydraulically driven machines, this process is carried out using a clutch rod. In modern cars, you often come across rods that do not have adjustments. But this does not mean at all that it cannot be produced. In such cases, adjustment of the clutch pedal itself is provided, but not everyone knows about this possibility. » alt=»»>

Resource extension

Warranty obligations do not apply to parts that fail early, because its wear and tear depends entirely on the actions of the driver. However, there are several recommendations that, if followed, will extend the life of the unit.

To extend the life of a part you need:

- avoid abruptly moving the car;

- do not allow the pedal to be slowly released at high engine speeds;

- drive with the clutch pedal fully released and do not press it while braking;

- Avoid situations in which the car may slip.

But the main recommendation is to minimize holding the pedal down for a long time. The release mechanism will last longer if the clutch pedal is used only to change speed.

Vibration that occurs after replacing clutch elements

There are few reasons why vibration occurs after replacing a clutch. Vibration usually appears in two forms:

- The pressure plate (clutch basket) is not balanced;

- During assembly, the driveshaft was installed in a different position from the original installation (but this only applies to rear-wheel drive or all-wheel drive vehicles).

By and large, on cars with front-wheel drive, you can inaccurately secure the wheel drive (CV joint), and the movement of the car will be accompanied by vibration and knocking, but this does not happen often.

If the clutch basket creates vibration, you can try moving it to a different position. As a rule, the pressure plate mounts are symmetrical. On many models, the basket is attached to the flywheel with six bolts, and the basket can be placed in three positions. In one position the vibration may disappear completely or be minimal. But it is better to exchange the warranty part immediately for another one. This will be less hassle for the car owner.

The clutch system is the main mechanism of the car, through which torque is transmitted from the power unit to the transmission. The smooth operation of the gearbox and, accordingly, the proper functioning of the gearbox depend on the correct, proper operation of the system. It consists of: a pressure plate, a clutch basket, a drive mechanism and a release bearing. When you press the clutch pedal, a mechanical (using rods) or hydraulic (using liquid) drive acts on the release bearing, which presses with the help of a damper spring, in common parlance: the clutch basket, the friction disc to the flywheel.

A bearing made of high-alloy steel is a fairly reliable part, but frequent connection of the clutch (driving a car in a big city), improper operation of the mechanism: holding the car for a long time with the clutch pedal depressed (a mistake by inexperienced drivers) leads to overheating and destruction of the bearing race. Replacing the clutch release bearing is described in the step-by-step instructions below.

Where does noise come from when a car's clutch operates?

Using the example of the clutch of VAZ 2108, 2109, 21099 cars, we will try to figure out where the noise came from when the clutch was operating and what ways there are to solve this problem.

Clutch noise when engine is idling

If you listen, from the clutch and gearbox side, while the car engine is idling, you can hear a continuous, distinct noise. When you depress the clutch pedal, the noise disappears or noticeably decreases.

Such signs may indicate a failure of the gearbox input shaft bearing on which the clutch basket and driven disc are “mounted”. The shaft begins to “dangle” together with the broken bearing, making noise, and when the clutch is disengaged, the load on it is reduced and the noise disappears. This malfunction is often accompanied by oil leakage from the gearbox under the input shaft oil seal. In the early stages, the malfunction is practically unnoticeable, but as the bearing deteriorates, it makes itself known.

The release bearing can also make noise and even howl at idle, since its working surface is always pressed against the leaf pressure spring of the basket and rotates with it (the clutch on the VAZ 2108, 2109, 21099 is backlash-free). A bearing malfunction may be a consequence of lubricant leaking out of it, after which a play appears and it will begin to make sounds when its moving part rotates. See photo at the beginning of the article.

To determine what exactly is noisy at idle - the releaser or the shaft bearing, we will do the following.

Disconnect the cable from the clutch release fork. We start the engine and leave it idling. Then turn the fork slightly clockwise. The release bearing will come out of contact with the clutch pressure diaphragm spring and the sound should disappear. The howling has disappeared - the release valve is faulty and needs to be replaced. If it does not disappear, you will have to remove the box and replace the input shaft bearing, or replace the oil in it with a better or thicker one.

Noise when disengaging the clutch

If a howling sound is heard from the clutch housing when you press the pedal, then the release bearing has most likely failed. We release the pedal, the noise disappears or decreases. If the bearing jams or is completely jammed, then it will not be possible to press (disengage) the clutch normally. The engine will stall, and it will become almost impossible to “stick” the gear.

Also, when you press the pedal, the clutch may make noise if its drive is not adjusted correctly. It “drives” - the driven disk does not completely move away from the flywheel when turned off, it rubs against it and makes noise. The malfunction can be eliminated by adjusting the drive.

Noise when engaging clutch

When the driver releases the clutch pedal, turning it on, a distinct noise or even rattling, metallic ringing and knocking is heard from the gearbox and clutch.

This indicates wear or breakage of the driven disk (wear, deformation, loosening of its linings, breakage of damper springs) or loosening of the gearbox to the engine.

Notes and additions

— On VAZ 2108, 2109, 21099 cars, the clutch is constantly engaged, that is, the input shaft of the gearbox rotates together with the clutch basket and driven disk. See “Design and principle of operation of the clutch of VAZ 2108, 2109, 21099 cars.” When you press the pedal, the release bearing comes into operation, which presses on the pressure spring of the basket, forcing its drive disk to move away from the driven one.

— The operation and serviceability of the clutch can be fully assessed by carrying out a comprehensive check. See “Checking the clutch on VAZ 2108, 2109, 21099”.

Signs of a faulty mechanism

The only sign of a faulty release bearing is an unusual sound (noise, whistling, knocking) when the clutch pedal is depressed, which disappears when the pedal is returned to its place. In winter, in severe frosts, noise is often heard when the clutch is engaged, but you should not pay much attention to this, since the materials from which the mechanism parts are made react differently to temperature changes, and the sounds disappear during the warming up process. There are no external, visible malfunctions of the unit, since the bearing is located in the clutch housing. The regular appearance of noise with each press of the clutch pedal indicates an imminent replacement of the release bearing. Unusual sounds occurring when the clutch is depressed indicate a malfunction in the gearbox.

Types and design features

In the design of a car clutch, two types of release bearings are used:

- Mechanical.

- Hydraulic.

The main elements of release bearings are closed ball or roller bearings. They are used on both mechanical and hydraulic types of products. Their design also includes a housing.

In mechanical elements, this housing is designed to interact with the clutch drive fork. Such units can have a very different design (the housing is presented in the form of a bushing inserted into the inner race, or it is installed on the outer ring), but all housings have special protrusions on which the fork acts. In general, in mechanical bearings, housings are designed for just this.

Clutch diagram of a VAZ car - 2107 1 - flywheel; 2 — clutch driven disc; 3 — clutch basket; 4 — release bearing with clutch; 5 — hydraulic clutch reservoir; 6 - hose; 7 — master cylinder of the hydraulic clutch release; 8 — servo spring of the clutch pedal; 9 — clutch pedal return spring; 10 — clutch pedal travel limit screw; 11 — clutch pedal; 12 — hydraulic clutch release pipeline; 13 — ball joint fork; 14 — clutch release fork; 15 — release spring for clutch release fork; 16 - hose; 17 — working cylinder of the hydraulic clutch release; 18 — clutch bleeder fitting

In hydraulic release bearings, the housing design is more complex because it acts as a hydraulic cylinder. The essence of his work is this: the driver, by pressing the pedal, creates fluid pressure in the clutch drive. This fluid enters the housing and squeezes out the hydraulic cylinder piston with the bearing attached to it. The housing itself in this design does not move along with the thrust element, which makes it possible to rigidly fix it with bolts to the clutch housing.

Bearing replacement

Spare parts and tools

We recommend watching this video:

Without a pit, a lift and the help of a friend, it will be very difficult to complete the task. So if you decide to replace the release bearing yourself, you should provide as much space as possible under the bottom of the car for removing and installing the gearbox. The tool set is very simple: wrenches of various sizes, a container for draining oil, molybdenum high-consistency lubricant.

Algorithm for performing repair work on a unified unit

The work of dismantling the unit is labor-intensive, but does not require special mechanical skills; the main thing is to follow the sequence of actions:

- disconnect the battery;

- disconnect the cable or hydraulic clutch. On some cars, for example: Nissan, this requires removing the air filter and the battery mounting plate;

- disconnect the gear selector;

- dismantle the engine compartment protection;

- on cars with front-wheel drive or all-wheel drive, it is necessary to drain the oil from the gearbox, after which we disconnect and remove the front drives;

- on cars with rear-wheel drive and all-wheel drive, remove the driveshaft;

- disconnect all sensors and wires leading to the gearbox;

- Having installed the stops under the gearbox, unscrew the bolts connecting the gearbox to the power unit and mounting it to the car body, and carefully, without damaging the input shaft, remove the assembled mechanism;

- release the spring fastenings of the clutch release clutch and disconnect it from the drive;

- remove the clutch from the gear selection shaft;

- remove the bearing from the coupling;

- apply a thin layer of high-consistency lubricant to the surface of the gearbox input shaft (excess lubricant in the clutch mechanism leads to slipping of the clutches);

- install a new release bearing;

- install the transmission in the reverse order;

- connect all sensors, actuators and connectors;

- fill in the transmission fluid recommended by the manufacturer;

- pump the hydraulic clutch drive;

- adjust the mechanical drive of the system;

- install and connect the battery.

For proper use of fasteners, it is worth putting them, when dismantling, into labeled containers.

Features of the clutch system of some cars

Car manufacturers have taken different approaches to the design of the clutch mechanism; in cars of the French concern PEUGEOT, the release bearing, when you press the pedal, does not press, but pushes out the damper.

On some cars, for example: Volkswagen, equipped with a 020 gearbox, the release bearing is replaced without removing the gearbox. This part is located in the rear part of the gearbox. To replace it, you need to remove the left front wheel, disconnect the clutch drive, remove the box housing plug, move the pusher aside and replace the bearing.

Adjusting the clutch system and release bearing

If the clutch mechanism is not working properly, the car moves jerkily, jumpily, the lever sinks, and various sounds are emitted from the box.

Good performance properties of a car depend on the quality of operation of three motion systems: gas, brake and clutch mechanisms. To adjust the clutch, sometimes it is enough to adjust the drive; in other cases, repair and replacement will be required. Adjustments must be made on time to avoid breakdowns that require large financial costs. The main signs of a malfunctioning clutch mechanism: the car moves jerkily, jumpily, the lever sinks, various sounds the gearbox Ideally, after depressing the pedal, the car should move slowly and smoothly. Sometimes a lot depends on the little things, and it would seem that such a small part of a large machine, like a release bearing, is a drop in the bucket. But in practice, everything is not so; even the smallest particle that has become unusable requires attention. An experienced driver will be able to repair or replace the release bearing; a beginner will most likely go to the nearest service station or try to solve the problem on his own by reading this article. Good luck on the roads!

Main problems after replacing the clutch

What does the concept of replacing a clutch include? Clutch replacement means complete replacement of the clutch disc. Quite often, after such manipulations, previously non-existent side effects appear.

If you think about this problem, then there are not very many special prerequisites for the emergence of such negative aspects. As practice shows this:

- illiterate work of non-professional craftsmen;

- factory defect of a new spare part;

- incorrect diagnosis of the problem, due to which the wrong elements or not all components requiring repair were replaced. As a rule, after this, hidden defects reveal themselves fully.

In general, the problem of the emergence of new problems and defects in the operation of a car is very complex and individual in each specific case. But there are still common characteristics.