Print this article Font size 16

Owners of the domestic VAZ 2110 car often encounter a whistling noise in the clutch , which is caused by the release bearing of the unit. Moreover, this is a problem not only of the “tens”, but also of other cars from different manufacturers, the clutch design of which involves the use of this element. Therefore, replacing the release valve on a VAZ 2110 is not at all an exceptional problem. But it needs to be solved.

Release

What you need to know

The release bearing is not the weakest link in the clutch system, but for some reason it is the one that causes problems and troubles.

coupling

Some car owners have gotten used to the whistle and simply ignore it. But this cannot continue for long, since untimely solution to the problem can lead to even more complex and expensive repairs. If the situation gets worse, then a simple replacement will not be enough for you.

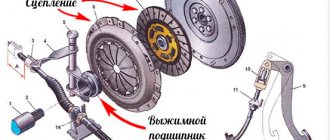

The clutch serves to act on the leaf spring of the clutch basket. It is also called diaphragm, so don't be confused if you hear this designation. Due to this impact, the driven disk is disconnected from the flywheel and the pressure plate of the basket. This disengages the clutch.

If the squeezer is faulty, this can lead to various consequences:

- The clutch fork will be damaged;

- The integrity of the clutch spring petals will be compromised;

- The guide bushings are deformed.

In order not to pay twice, or even three times, promptly react to the appearance of a whistle in the clutch and try to quickly take action.

Replacing the VAZ 2110 clutch step by step instructions

1. “Tear off” the left wheel mounting bolts, then jack up the front of the car and place it on the sawhorses.

2. Remove the wheel and unscrew the two lower ball joint bolts.

3. Remove the “-” terminal from the battery.

4. Remove the mass air flow sensor, then loosen the clamp securing the mass air flow sensor corrugation and remove the air filter.

5. Now you need to remove the clutch cable from the clutch fork. Loosen the two mounting nuts that secure the cable to the bracket on the gearbox.

6. Unscrew the bolt securing the starter to the box, then unscrew the first bolt securing the gearbox.

7. Head on “19” amplifier pipe. There is another gearbox mounting bolt nearby.

8. Loosen this nut and the upper starter mounting bolt.

9. Remove the connector from the speed sensor, then unscrew the speedometer cable.

10. Remove the longitudinal brace paired with the lever.

11. Now unscrew the lower starter mounting bolt.

12. Unscrew the 3rd gearbox mounting bolt; in the area of the right CV joint there is another nut that needs to be unscrewed.

13. Unscrew the two torque rod mounting bolts.

14. Loosen the nut located on the clamp of the gearbox control drive rod, then remove this rod from the box.

15. Place a support under the engine, then unscrew the two nuts securing the rear cushion. This is done just in case, so that if the engine lowers too much, your hoses do not break.

16. Carefully move the gearbox away from the engine and lower it to the floor, it will hang on the axle shafts.

17. I recommend replacing the clutch release bearing at the same time.

Assess the wear, replace the disc, and if necessary, the clutch basket, check whether the petals are normal.

Further assembly is carried out in reverse order. Thank you all for your attention, this is actually the simple way to replace a VAZ 2110 clutch without removing the box and draining the oil.

Is noise a sign that replacement is needed?

Not really. If noise occurs, this does not mean that you should immediately replace the element. But it is strongly not recommended to delay repairs. Let's just say this is a signal for certain actions, which you will have some time to complete before the consequences become catastrophic.

In some cases, the noise occurs when the engine is started, and it persists until the car warms up, after which it disappears. In other cases, the noise returns every time you try to disengage the clutch.

The worst option is a grinding sound. This sound indicates that the element is rubbing against the leaf spring, and wear will form on the petals. If you are “lucky enough” to encounter such a situation, there is no time. Replacement needs to be done quickly.

By the way, there is no point in repairing it. Release bearings cannot be repaired, so the only solution is replacement.

When to replace the clutch

Replacing the clutch on a VAZ-2110 is not just desirable, but necessary if you note the following nuances:

- when you start the car and feel completely wrong engine power;

- you feel that the clutch does not engage completely, but only works partially;

- any tapping, clicking and, in principle, extraneous sounds should alert you and lead you to believe that the clutch may be acting up;

- if the clutch stalls on its own and “does not obey”;

- When you depress the clutch pedal, you feel a vibration.

Bearing removal

Broken

To remove this device, you will have to perform a series of sequential actions.

- Raise the car or drive it into a hole to gain access to the underbody of the car.

- Use appropriate tools to remove the gearbox.

- Squeeze the special clamps from the release bearing.

- Remove the element from the gearbox shaft.

- Press the locking tabs to remove the spring holder.

- After this, it will not be difficult for you to remove the damaged release bearing from the clutch.

The complexity of the process lies in the fact that in preparation for removing the release bearing it will be necessary to dismantle several components and mechanisms, such as:

- Accumulator battery;

- Clutch cable;

- Air filter box together with air flow sensor;

- Upper gearbox fixing bolts;

- The nut responsible for fixing the starter.

Results

If there is an overpass or lift, the operation is carried out quickly and efficiently, and when there is a reliable assistant, it is also fun. However, not everyone has such capabilities, and this is where engineering ingenuity comes into play.

Some car enthusiasts practice repairing the clutch without removing the gearbox; for this purpose, instead of the upper standard mounting bolts, they screw in longer bolts. For this, for example, two bolts from the upper arm of the front suspension of the “VAZ classic” are suitable. By screwing them into the upper holes, the box can be moved back by 14-15 cm with a pry bar. In this case, the transverse rod should not be unscrewed, because the rear part of the gearbox will lie on it. These conditions are quite enough to replace faulty parts.

If repairs are necessary, experts recommend doing a complete replacement of the entire assembly along with the release bearing, especially since the choice of clutch kits is quite wide. This position is explained simply - an old part left behind threatens to fail at any moment. The procedure, as you yourself saw in the video, is quite labor-intensive, and repeating it over and over again is not a pleasant pleasure, except for real “homemade people.”

Installing a new element

When you have completed the entire range of dismantling work, you can move on to the final stage - installing a new component.

- The first thing to do is check the condition of the new clutch release bearing. For some reason, many car owners forget to make sure that the bearing that replaced the old one is actually in good working order. This is easy to check. Rotate the bearing, pull it in different directions. If there is no jamming during rotation, and there is also no play, then you bought a really serviceable, good release bearing.

- Insert the new part into the coupling. This must be done so that the protruding part of the inner ring is directed towards the coupling.

- After inserting the element, secure it using the holders.

- Before inserting the new release bearing onto the bushing (guide), do not forget to lubricate it with a grease. The layer of lubricant should be thin, do not overdo it.

- Secure the coupling and bearing using a spring lock.

- Place the gearbox and other dismantled elements in their rightful places.

- The entire repair process is completed by adjusting the clutch.

Replacing the release bearing yourself is not very difficult. The main problem is removing the gearbox. All other events cannot be called difficult. However, you will need to be careful, consistent and careful.

Do not ignore the most useful thing that you can need when repairing your favorite VAZ 2110 - the instruction manual. Literally everything a car owner needs to know is described in detail there. With its help, you can even perform complex repairs, the cost of which at a specialized service station would be prohibitive.

Clutch replacement is necessary in the following cases:

- If the clutch begins to “lead”, that is, when engine power decreases.

- If the clutch is not fully engaged, that is, it “slips.”

- If you hear extraneous sounds when turning on - clicks, jerking, etc.

- In case of unauthorized disengagement of the clutch.

- In case of vibration when pressing the clutch pedal.

In this article I will tell you how to replace the VAZ 2110 clutch at home without removing the box and draining the oil.

To work you will need:

- Jack;

- Inspection pit or lift;

- Set of socket and open-end wrenches: “19”, “17”;

- Mount or amplifier pipe.

Some tips

- If you start having problems with the brakes, first of all you need to carry out an external inspection of the vehicle: check the fluid level in the reservoir, make sure that the front/rear cylinders are not leaking. There should not even be stains of brake fluid in the brake hydraulics.

- “Brake fluid” must be filled with the same brand; it is recommended to completely replace the brake fluid at least once every two years.

- If faults are identified in the gas turbine engine, and it has already served for at least a year, it is more advisable to replace it completely than to repair it. The same can be said about the rear working cylinders.

- Before changing the turbocharger, the brake fluid should be removed from it; this operation is usually done using a syringe.

- Usually a leak in the master cylinder is not visible, but if there is any suspicion that this part is faulty, you should remove the main cylinder - there will be traces of leaks at the rear, and this indicates its faulty condition.

- If, during an external inspection, cracks were found on the brake hoses, it is better not to take risks and immediately replace the defective parts.

Didn't find the information you are looking for? on our forum.

We recommend reading:

Which gasoline is better for VAZ 2114

Air leakage through injectors symptoms of VAZ 2114. Possible malfunctions, cleaning and adjustment

Vibration in the cabin when idling VAZ 2114 injector causes

Repair of the underbody of a VAZ 2107

VAZ 2114 injector boils, reasons

Error p1602 vaz 2114 how to fix

What is an ESD for a VAZ or an ECU for a VAZ 2114

Master cylinder, slave and clutch VAZ 2101. Replacement and repair, fluid pumping

DIY bearing installation

Upon completion of all preliminary work on bearing removal, you need to move on to the last stage of repair work - installing a new element. First you need to check the new release component. After all, car owners often forget that an old bearing can be replaced by a new one, which also failed for some reason. It is not difficult to do this check; you need to pick up the release element and twist it, pull it in different directions to make sure that there are no jams in it and it does not wobble.

Once you are sure that you have purchased a truly high-quality element, you can insert it into the coupling. The protruding part of the inner ring should be directed towards the coupling. Having inserted the release device into the required compartment, you need to secure it with holders so that it does not jump out while performing its functions. Before placing a new element on the bushing, the main thing is not to forget to lubricate it. The layer of grease should be thin so that nothing drips from the bearing. Next, the coupling and the bearing itself are fixed using a spring clamp. The final stages of installing this component are placing the gearbox and other dismantled elements in their places, as well as completely adjusting the clutch.

It is worth knowing that replacing a faulty bearing with a working one is not difficult. The most difficult part of the repair process is dismantling the gearbox. All other actions can be called easy

and which will not take much time to complete. To carry out such work, components such as patience, accuracy and caution are required.

Also, you should not ignore the simplest and very useful thing that can come in handy when repairing a VAZ-2110 car - the instruction manual. It describes in detail almost everything that a car owner needs to know. Based on the instructions in this document, you can perform not only simple repairs of any elements in the car, but also complex ones, the costs of which in maintenance would be incredibly high.

Source

Clutch adjustment on Lada Kalina. Subtleties and different points

- By systematically pressing the accelerator pedal, analyze its movement, the presence or absence of noise or squeaks, smoothness and freedom of movement. The presence of the above reasons will be the basis for carrying out repair work;

- Using a ruler, measure the distance from the pedal along the outer contour to the floor. If the distance is more than 14-14.6 cm, then the cable should be slightly tightened;

- The distance to the floor may be a little less, but not more, the free play of the pedal should be no more than 2.5-3.0 cm.

- Remove the air filter;

- Use your fingers to tighten the cable as freely as possible;

- Using a caliper, we take a measurement between the fork lever and the leash (rubber base);

- The distance should correspond to the figure 2.7 cm. Otherwise, tighten or loosen the tension nut using an open-end wrench;

- Take test measurements. If it does not match, repeat the procedure again;

- Reinstall the air filter.

AutoFlit.ru