Print this article Font size 16

Owners of the domestic VAZ 2110 car often encounter a whistling noise in the clutch , which is caused by the release bearing of the unit. Moreover, this is a problem not only of the “tens”, but also of other cars from different manufacturers, the clutch design of which involves the use of this element. Therefore, replacing the release valve on a VAZ 2110 is not at all an exceptional problem. But it needs to be solved.

Release

What you need to know

The release bearing is not the weakest link in the clutch system, but for some reason it is the one that causes problems and troubles.

coupling

Some car owners have gotten used to the whistle and simply ignore it. But this cannot continue for long, since untimely solution to the problem can lead to even more complex and expensive repairs. If the situation gets worse, then a simple replacement will not be enough for you.

The clutch serves to act on the leaf spring of the clutch basket. It is also called diaphragm, so don't be confused if you hear this designation. Due to this impact, the driven disk is disconnected from the flywheel and the pressure plate of the basket. This disengages the clutch.

If the squeezer is faulty, this can lead to various consequences:

- The clutch fork will be damaged;

- The integrity of the clutch spring petals will be compromised;

- The guide bushings are deformed.

In order not to pay twice, or even three times, promptly react to the appearance of a whistle in the clutch and try to quickly take action.

Incomplete inclusion

A characteristic symptom is that the transmission is difficult to engage or does not engage at all. May be accompanied by a strong crunch even with the pedal fully depressed. There are several reasons for this failure:

- Deformation or damage to the driven disk.

- Worn clutch fork.

- Incorrectly adjusted cable drive.

- Worn diaphragm springs on the clutch disc.

- Insufficient pedal travel.

- Lack of lubrication in the bearing guide sleeve.

- Different adjustment of pressure plate levers.

Is noise a sign that replacement is needed?

Not really. If noise occurs, this does not mean that you should immediately replace the element. But it is strongly not recommended to delay repairs. Let's just say this is a signal for certain actions, which you will have some time to complete before the consequences become catastrophic.

In some cases, the noise occurs when the engine is started, and it persists until the car warms up, after which it disappears. In other cases, the noise returns every time you try to disengage the clutch.

The worst option is a grinding sound. This sound indicates that the element is rubbing against the leaf spring, and wear will form on the petals. If you are “lucky enough” to encounter such a situation, there is no time. Replacement needs to be done quickly.

By the way, there is no point in repairing it. Release bearings cannot be repaired, so the only solution is replacement.

Clutch selection

When purchasing a new clutch kit for the VAZ 2107, experts recommend being guided by the following criteria. When assessing the driven disk:

- the surface of the linings must be smooth and uniform, without scoring, cracks or chips;

- all rivets on the disk must be the same size and located at an equal distance from each other;

- there should be no oil stains on the disc;

- there should be no play in the places where the linings and springs are attached;

- The manufacturer's logo must be applied to the product in one way or another.

When choosing a basket, you should pay attention to the following points:

- the casing must be stamped, without cuts or scratches;

- the surface of the disk must be smooth and uniform, without cracks or chips;

- the rivets must be identical and strong.

The most popular brands are the following.

- Valeo (France), specializing in the production of excellent quality brake system elements. The characteristic features of the Valeo clutch are soft operation with a clear engagement moment, reliability, and long service life (more than 150 thousand kilometers). However, such a clutch is not cheap.

The Valeo clutch is characterized by soft operation with a clear engagement moment - Luk (Germany). The quality of the Luk clutch is close to Valeo, but costs a little less. The good damping properties of Luk products are noted.

- Kraft (Germany). However, production is concentrated in Turkey. The Craft clutch features soft operation without overheating and reliable flywheel protection.

- Sachs (Germany). The company specializes in the production of transmission parts. The use of asbestos-free linings in the manufacture of clutch discs made Sachs very popular in Russia.

The choice of clutch should be approached comprehensively and the choice should be made after examining the product and receiving expert advice.

Bearing removal

Broken

To remove this device, you will have to perform a series of sequential actions.

- Raise the car or drive it into a hole to gain access to the underbody of the car.

- Use appropriate tools to remove the gearbox.

- Squeeze the special clamps from the release bearing.

- Remove the element from the gearbox shaft.

- Press the locking tabs to remove the spring holder.

- After this, it will not be difficult for you to remove the damaged release bearing from the clutch.

The complexity of the process lies in the fact that in preparation for removing the release bearing it will be necessary to dismantle several components and mechanisms, such as:

- Accumulator battery;

- Clutch cable;

- Air filter box together with air flow sensor;

- Upper gearbox fixing bolts;

- The nut responsible for fixing the starter.

Also check out

- Remove the 3rd transmission mounting bolt. Unscrew another nut located near the right CV joint.

- Remove the torque rod mounting bolts. There are 2 of them.

- Loosen the nut located on the box control drive rod clamp and remove the rod from the box.

- Place the support under the engine, unscrew the 2 nuts that secure the rear cushion (the purpose of this is to avoid a possible breakthrough of the hoses).

Installing a new element

When you have completed the entire range of dismantling work, you can move on to the final stage - installing a new component.

- The first thing to do is check the condition of the new clutch release bearing. For some reason, many car owners forget to make sure that the bearing that replaced the old one is actually in good working order. This is easy to check. Rotate the bearing, pull it in different directions. If there is no jamming during rotation, and there is also no play, then you bought a really serviceable, good release bearing.

- Insert the new part into the coupling. This must be done so that the protruding part of the inner ring is directed towards the coupling.

- After inserting the element, secure it using the holders.

- Before inserting the new release bearing onto the bushing (guide), do not forget to lubricate it with a grease. The layer of lubricant should be thin, do not overdo it.

- Secure the coupling and bearing using a spring lock.

- Place the gearbox and other dismantled elements in their rightful places.

- The entire repair process is completed by adjusting the clutch.

Replacing the release bearing yourself is not very difficult. The main problem is removing the gearbox. All other events cannot be called difficult. However, you will need to be careful, consistent and careful.

Do not ignore the most useful thing that you can need when repairing your favorite VAZ 2110 - the instruction manual. Literally everything a car owner needs to know is described in detail there. With its help, you can even perform complex repairs, the cost of which at a specialized service station would be prohibitive.

How to renew?

The main factor influencing clutch life is driving style. To save the disk, you need to avoid high loads. Do not start driving at high speeds (with slipping) and do not overload the vehicle itself. The last factor also applies to those who like to drive with a trailer. Remember that every kilogram from the trailer loads the gearbox and clutch components. Do not tow vehicles that exceed your curb weight. These factors directly affect the life of the clutch disc. Using a careful driving style, you can increase the capabilities of this element to 150 thousand kilometers or more. In sports driving mode and other loads, even the highest quality VAZ 2110 clutch, the price of which is quite high, will not last even 40 thousand kilometers.

Owners of the domestic VAZ 2110 car often encounter a whistling noise in the clutch , which is caused by the release bearing of the unit. Moreover, this is a problem not only of the “tens”, but also of other cars from different manufacturers, the clutch design of which involves the use of this element. Therefore, replacing the release valve on a VAZ 2110 is not at all an exceptional problem. But it needs to be solved.

Release

Operating principle and components

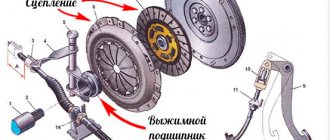

The clutch is single-plate, with a central pressure spring. Drive – cable. The housing is attached to the flywheel and pressure plate. There is also a driven disk.

For dozens, the “native” clutch system is VIS, and although many reviews criticize it, there are also many who believe that there is no better VIS (VAZINTERSERVICE) for VAZ.

The main components are:

- casing;

- Pressure and driven disks;

- Carter with bottom cover. It also has support planes with which the crankcase is attached to the frame;

- Release bearing for disengaging the clutch;

- Flywheel;

- Power plug;

- The cable lead that goes directly to the clutch pedal (far left).

This, in brief, is the clutch device of the VAZ 2110.

How to replace the release bearing on a VAZ-2110 with your own hands

Owners of a VAZ-2110 car are well acquainted with such a problem as whistling in the clutch.

The reason for this sound is the release bearing, which often fails during operation. That is why replacing the release bearing on a VAZ-2110 is considered a very pressing issue that is worth finding an answer to. The release bearing is not the weakest link in the entire clutch system, but for some reason it causes trouble for vehicle owners. Some drivers, ignoring extraneous sounds, have already gotten used to it, so they do not take any action. But you cannot turn a blind eye to this problem for long, because it can lead to serious breakdowns in the car, the elimination of which will require a lot of money. If you let the situation take its course, then replacing the bearing alone will no longer be enough.

Consequences of a malfunction of the release device:

- Damage to the clutch fork.

- Violation of the integrity of the clutch spring petals.

- Deformation of guide bushings.

In order not to spend large sums of money, you need to quickly respond to the appearance of whistles or knocks in the clutch. Appropriate measures must be taken immediately.