01/26/2022 20,644 VAZ 2109

Author: Ivan Baranov

Many VAZ 2109 owners carry out repairs and maintenance of their “iron horses” on their own. People who at least once in their lives are faced with the sudden need to repair a “nine” will be able to independently replace the release bearing of a VAZ 2109. Of course, you should use our instructions and follow simple instructions. In addition, at the end of the article, our readers will be provided with a video that will help them perform the replacement work themselves.

Car VAZ 2109 [Hide]

Signs and causes of clutch failure

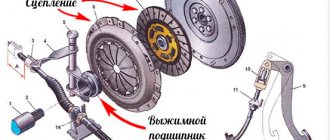

The VAZ 2108, 2109, 21099 clutch consists of a basket, a pressure bearing, a drive and driven disk. The main signs of a clutch malfunction are clutch slipping and incomplete disengagement:

- When switching off is incomplete (the pedal is pressed), there is difficulty shifting gears with the engine running, noise and crackling noises when changing gears, and large free play of the clutch pedal.

- When the clutch “slips” (the pedal is released), a burning smell may be felt in the cabin from the burning of the clutch disc linings, the car’s dynamics will deteriorate, the engine may overheat, and fuel consumption will increase.

Most often, the cause of a breakdown of the VAZ 2109 clutch is improper operation of the car. For example, if the car “sits down” in the snow and you continue to accelerate hard, or really like to start with slipping, all this shortens the life of the clutch.

In addition to the clutch disc itself, the release bearing can also fail - it serves to smoothly engage and disengage the clutch. When the release bearing wears out to the limit, you can hear a characteristic squealing sound - this is a sure sign that the bearing needs to be replaced. The cause of clutch failure may also be a breakdown in its drive mechanism, for example, a break or jamming of the clutch drive cable, a breakdown of the lever system, a fluid leak from the hydraulic drive if the clutch is hydraulic, or other similar breakdowns in the drive.

By the way, when replacing the release bearing at a service station, they may advise you to also replace the clutch disc. Usually, if problems begin with the clutch, it is better to replace all these parts, because replacing the clutch is very difficult: you need to remove the gearbox. But if someone wants to save on this, then all clutch parts can be purchased separately.

To work you will need the following:

- wrenches 8, 10, 13, 17 mm;

- torque wrench, 8 mm socket;

- jack;

- container for draining oil;

- inspection hole or lift.

- flat screwdriver, hammer.

When removing or installing the gearbox, do not rest the input shaft of the gearbox on the clutch pressure spring petals, so as not to damage them.

Worn clutch release bearing

Clutch VAZ 2109

Typically, those who like to drive fast are more likely to encounter the problem of bearing wear. At the same time, people who are supporters of quiet driving have often never even heard of this problem. If it is noticeable that the bearing is failing, it urgently needs to be replaced, otherwise:

- The very next trip can be fatal for the car.

- The disc will overheat, causing the pads to crumble.

- It will be necessary to change not only the bearing, but also the clutch disc.

- In addition, the clutch itself can become “covered.” A sign of this may be an incomprehensible noise coming from it.

To change the release bearing, you will need to completely disassemble the entire assembly, and this is a rather labor-intensive process.

How to replace

Clutch for VAZ 2109

To ensure that replacing the clutch bearing does not cause inconvenience, it is advisable to drive the car onto a lift or place it over an inspection hole.

Note: bearing replacement can also be carried out in “field” conditions, that is, with a jack. However, it is very important to ensure that the car does not roll down.

Replacement occurs as follows:

- Remove the negative battery terminal.

- Disconnect the flashlight connector.

- Disconnect the driveshaft.

- Remove the slave cylinder.

- Remove the gearbox, which is secured by several large bolts.

Note: to make this easier, you can bend the gear knob all the way. At the same time, the handle must not be allowed to “hang” freely. It is advisable to provide it with reliable support.

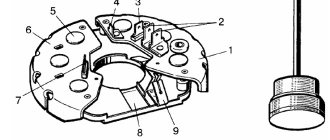

- Once you have access to the clutch basket, you can begin removing it. To do this, unscrew the bolts that secure it to the flywheel (it must be completely motionless).

Note: You can use a large screwdriver for this.

- Pull out the clutch release fork.

- Remove the bearing.

- Change it.

- Press in properly using a key.

- Wipe the surface of all parts with a degreaser to remove dirt and foreign objects. This may cause the car to slip.

- Reassemble everything in reverse order.

Note: Before you begin assembling the gearbox, it is advisable to apply a little lubricant to the sprockets of the input shaft.

- When all the parts are assembled, the clutch should be adjusted.

- The length of the working cylinder should be slightly reduced.

Replacing the clutch bearing can be done at home and with your own hands. Usually in car services the price of this procedure is quite high. Therefore, if you want to save your money, you need to give preference to home repairs. Any instructions will also help you quickly and begin to review many photos and videos on this topic. perform quality work.

Replacing the clutch on a VAZ 2109/21099 without removing the gearbox

Replacing the VAZ 2109/21099 clutch without removing the gearbox is quite difficult. You will not find instructions or recommendations on this topic in the car's owner's manual. These recommendations are based on the experience of car enthusiasts who share their experience of replacing the clutch.

The main problem when replacing a clutch is that not every motorist has an overpass, a pit, and especially a lift, and it is necessary to make sure that the massive gearbox does not fall to the ground. But lifting it is problematic, since it is impossible to crawl under the car with it. All steps for removing the gearbox are almost the same as the instructions above, with the exception of some nuances:

- Purchase two bolts from the upper arm of the classic front suspension from the store. Their threads are exactly the same as those on the bolts that secure the box and the engine block together.

- Screw them in from above, only after that, with a small crowbar or screwdriver, we begin to disconnect the nodes. After moving away, the rear part of the box will rest on the transverse rod, and a gap of about 15 centimeters will form between the clutch housing and the flywheel.

- The release bearing is removed through the resulting gap and the bolts on the basket are unscrewed.

But the installation is slightly different from the process shown in the instructions:

- Place the new release valve in its place. Then a disk is installed on the flywheel and a basket on top of it.

- Just tighten the bolts a couple of turns, but do not overtighten!

- Carefully begin to slide the input shaft onto the splines in the disc.

- Then we move the box back and tighten the bolts on the basket. The basket fastening bolts are tightened only after the box is installed in its place.

- After this, you can install the gearbox and tighten the bolts on it.

When replacing the clutch without removing the gearbox on a VAZ 2109/21099 car, there is no need to center the disc!

General information about the bearing

The release bearing of the VAZ 2109 car (hereinafter referred to as VP) is an important part in the operation of the vehicle. If it breaks down, movement by car is impossible, so the driver will immediately know about the failure of this element.

If this component breaks down, then the optimal functioning of the car's clutch is already impaired. In particular, if the release bearing breaks down, the clutch stops disengaging, which means the vehicle cannot move. If this element fails, then there is no way to do without replacing it.

How to choose a release bearing

Its quality determines how long you drive your car without taking it in for clutch repair. There is quite a large assortment of parts on the market, so below is a selection of bearings depending on some of the most popular car brands in the Russian Federation:

- Domestic Lada. These machines are equipped with a cable-driven part. This may seem surprising, but the competition here is very small: the number of participants does not exceed a dozen. Most often they buy AvtoVAZ products. In second place is Sachs from Germany, followed by Valeo. You can also mention Coram from Italy and TSN. Among the manufacturers in the Russian Federation - TZA (Tolyatti).

- Ford Focus (2nd generation). It has a hydraulic type bearing connected to the working clutch, so everything is replaced as an assembly. Removing and installing the entire system is quite problematic. There are approximately 15 manufacturers on the market. Of these, it is worth highlighting Sachs, which is the leader, Ford OEM, INA. Lucas, Valeo, FTE, Pilenga are also popular.

- VW Polo. There is also a hydraulic clutch here. But the bearing is simpler compared to the Ford Focus. There are approximately 14 suppliers on the Russian market, among which the leader is the little-known company SKF. Next comes JP Group (also unfamiliar), then Sachs. You can also note Luk, Dello, Automega, Vag, Febi and others.

Robotic gearboxes require special attention. If an experienced car owner can drive all 150 thousand km without problems with a conventional clutch and manual transmission, then for a robotic gearbox the service life is approximately half, and this does not depend on the driver’s experience. In order for the service life to be maximum, during the next maintenance (10-15 thousand km) it is necessary to adapt the robot to the level of wear of the clutch disc.

Tools required for repairs

To replace the VAZ 2109 clutch basket you need to prepare the following tools:

- standard set of keys;

- jack.

Do-it-yourself repairs are quite advisable, since the price for replacing a VAZ 2109 clutch as of March 3, 2022, on average in car services is 3.2 thousand rubles.

On a note! At a car service center, the work will be completed in one and a half to two hours, since the service station has lifts and overpasses. The most difficult part of the work is disassembly and assembly; replacing parts and the unit itself takes no more than half an hour. When working in the garage yourself, you can spend one or several days on dismantling and installation.

But self-repair is quite accessible even without an assistant, and without completely removing the gearbox. The principle of repair and the sequence of work are identical for models 2108-2115, so we suggest you see how such dismantling is performed on a VAZ 2114:

How does a release bearing work?

It is part of a structure that consists of a couple of elements:

- drive (pressure) disk (some call it a “basket”) with movable petals and springs, fixed on the crankshaft flywheel;

- driven disk connected through splines to the gearbox input shaft.

The bearing operation is controlled when the clutch pedal is activated. The whole node works like this:

- in the normal position, the drive disk presses the flywheel against the driven disk;

- when you press the pedal, the release bearing, thanks to the clutch fork, begins to move, affecting the petals;

- as a result of this effort, the two disks are separated and the engine is “disconnected” from the transmission;

- when the pedal is released, the paddles return to their previous position, which is why the discs connect again and the car moves on.

It is worth noting that the clutch can be mechanical or hydraulic. In the first case, the operation of the VP requires exclusively the physical effort of the driver. In the second, the bearing operates through hydraulic fluid. Its use makes pressing the pedal easier, but makes the clutch system more complex.

Symptoms of malfunction

The clutch release bearing itself will tell you that its life is already at its limit or it has completely failed. Therefore, your task is to monitor the behavior of the car and promptly respond to emerging problems.

Sign of breakdown

Peculiarities

The clutch pedal becomes hard to press

Initially, this only causes a certain discomfort, since you have to apply more force to change gears. But this phenomenon should not be ignored. Bearing needs to be replaced

Difficulty engaging first and reverse gears

This indicates that the bearing's life is gradually ending, and you urgently need to take action. If you don't do this, you will soon be unable to engage any of the gears in your transmission.

The car doesn't pull

There is a loss of efficiency and performance of the box. Consequently, it is not possible to change gears correctly and quickly. This makes maneuvers, overtaking and a banal increase in speed more difficult.

This happens occasionally at first, and therefore almost every time you change gears. This symptom clearly indicates that it is time to send the car to a service station or garage for repairs.

Old and new VP

If the release bearing is not replaced in a timely manner, the gearbox will soon fail, the clutch will not work, and this will lead to dire consequences.

Consequences of wear

If you have encountered such a phenomenon as wear of the clutch release bearing, then you probably often drive your own VAZ 2109. It is time and the many kilometers traveled that lead to such breakdowns.

If the bearing is not replaced in time, this will result in the following consequences:

Why does a release bearing break?

This is mainly due to several reasons, among which the first place is the inexperience of the driver. If you constantly keep your foot on the clutch pedal, the VP will constantly spin, which shortens its service life. The second point is an aggressive driving style. Also, constant off-road driving does not contribute to the long service life of the part. It’s very simple: the less often you press the clutch pedal, the longer it will last, including the release bearing. Constant temperature changes or high humidity do not contribute to its long operation.