A car subwoofer capacitor is becoming increasingly popular among car owners. Now the installation can be found not only in expensive audio systems, but also in simple sets of audio equipment that use external sound amplifiers.

Do you need a capacitor for a subwoofer? Drivers who understand the meaning and functionality of the device answer unequivocally: of course it is needed. Since this device significantly improves the performance of the amplifier, as well as the quality of the sounds produced.

Basic Concepts

First, you need to understand what a container is and why it is needed, and what types it comes in. Anyone who has connected a capacitor has encountered this problem. If you decide to connect the container without certain knowledge, then your system will not work correctly, and, accordingly, proper high-quality power will not be provided.

This electrical element consists of two metal plates that are rolled into a tube. A dielectric is laid between them. Externally, it looks like a cylindrical element with two terminals.

Let us list the tasks that are assigned to a capacitor in an electrical circuit:

- Retaining charge for normal voltage.

- Retention of potential charge for a long time.

- In order to eliminate voltage surges, the current value must be within normal limits.

Procedure for starting a car engine in cold weather

To ensure trouble-free starting of the engine, the car must be prepared for winter use before the onset of cold weather. It is necessary to fill the engine and gearbox with oil designed to operate at low temperatures. It is imperative to replace spark plugs and filters, oil, air and gasoline. And of course the most important thing is the technical condition of the battery. Even if the battery is new, it must be charged from an external charger. If all these requirements are met in advance, then there will be no problems starting the engine in the cold season.

It is recommended to start the car engine in the following order: ☞ It is necessary to insert the key into the ignition switch, turn it clockwise one sector and make sure that all electrical appliances are turned off. Although they should turn off automatically when the starter is running, it is nevertheless better to turn them off so as not to create additional load on the engine at the first moment after starting it. ☞ To bring a cold battery into working condition, you need to warm it up by turning on the headlights or side lights for 20-30 seconds. ☞ If the transmission is not automatic, be sure to depress the clutch pedal all the way. In this case, the gearbox will be disconnected from the engine, which will significantly reduce the load on the starter. Turn on the ignition for half a second so that the engine shaft moves from a dead center and the oil lubricates the rubbing surfaces of the engine. ☞ Turn on the ignition again for no more than 3 seconds. If the engine does not start, you must wait at least 15 seconds before restarting. During this time, the battery, warmed up due to an unsuccessful engine start, will gain strength. If after 5-6 attempts with pauses it was not possible to start the engine and the battery did not die, it means that either the water that got into the mechanisms froze and it is necessary to warm up the car by placing it in a warm garage. Or a malfunction has occurred and you need to contact service. ☞ If the car engine starts, you need to smoothly release the clutch pedal. After warming up, the car is ready to go.

Processes that take place in a capacitor

It is known from the laws of physics that oppositely charged particles attract. If they are connected to each other, a discharge will occur. However, if they are not connected, but only brought as close to each other as possible, a greater force of attraction will arise. The capacitor uses this principle. Oppositely charged particles accumulate on the plates, which are separated by a dielectric, but due to the high resistance of the material, an instantaneous discharge does not occur.

Due to the fact that the dielectric allows them to discharge, it is possible to maximize the time during which the plates will remain at a given required voltage.

Each element is manufactured to operate within a specific voltage range. It all depends on the materials of manufacture, as well as on the design of the product. If the potential difference exceeds the maximum permissible, the dielectric will cease to perform its function and the capacitor will fail. Capacity is one of the most important parameters, since the entire design of the device depends on it. It directly depends on how the plates are located, as well as on their sizes.

How to choose a capacitor

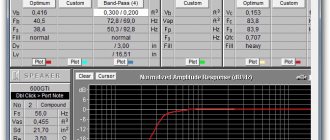

When choosing a capacitor for a car electrical system, you should take into account 2 important parameters: capacitance and equivalent series resistance (ESR, Equivalent Serial Resistance), which determines the speed of release of the accumulated charge. The capacity required is large, compared to ordinary electrolytic storage devices (in jargon - “electrolytes”).

For modern automotive devices, drives are offered with capacities ranging from tenths of a farad to several tens of farads, with internal resistance from several hundredths to thousandths of an ohm. The lower the internal resistance, the more efficiently the electrolyte releases its charge.

The higher the power of the audio amplifier, the greater the electrolyte capacity required. It is estimated as follows: per 1 kW of amplifier power, a minimum of 1 farad is required. If the capacity is larger, it will not harm the system. You should buy drives of proven models from reliable suppliers.

Popular brands range in price from $40 to $400 or more.

Expensive models are equipped with a protection system against overvoltage and switching on in the wrong polarity (i.e. when plus is supplied to minus, and minus to plus).

Typical characteristics of drives from one trusted manufacturer for cars with a 12 V power supply are shown in Table 1.

| Models type 1, 2 and 3 | |

| Nominal capacity, farad | 1/1,5/2 |

| Permissible error of capacitance value, % | + / — 5 |

| Maximum operating voltage, V | 16 |

| Peak value of pulse voltage, V | 24 |

| Equivalent series resistance (ESR), Ohm | <0,0016 |

| Operating temperature, °C | -10 to +105 |

| Dimensions (diameter*height), mm | 76*245 |

| Weight, kg | 1,5 |

Installing a dubious inexpensive capacitor in the system will be useless due to the fact that its actual capacity, as established by practice and tests by independent experts, is 10 or more times less than the declared one, and the ESR value does not meet the standards. Since the electrolyte housing is sealed and cannot be opened by the buyer, unscrupulous manufacturers take advantage of this and save on materials for the linings; they put broken bricks and pieces of cement on the bottom for weight, and fill the remaining space with resin.

There are so many similar products on the market for storage devices for car audio systems that a myth has formed among car enthusiasts about the uselessness of installing a capacitor in a car.

The need for capacitors in car audio

Short-term voltage surges often occur in a car's audio system. This is due to the fact that the power system is not capable of delivering the required power in a given period of time. This happens when playing music with pronounced bass. This is due to the fact that the consumer resistance for the power supply decreases sharply, due to the long-term opening of the transistors.

Professional audio installers recommend using a capacitor capacitance of at least 60,000 - 65,000 microfarads. For versatility, the formula is often used: 1 Farad of power = 1000 Watts of load.

Additional benefits

Connecting a capacitor will bring a number of additional bonuses:

- filtering of high-frequency components of mains voltage, which has a positive effect on the operation of electrical systems and vehicle devices;

- preventing sudden voltage surges when the on-board electrical equipment is turned on reduces the overall load on the network and promotes smoother battery operation;

- assistance in starting the car using a starter, which is especially important in cold weather.

The main advantage of installing the device will be the normalization of low frequency reproduction, clear sound without interference or distortion.

Correctly setting up a subwoofer in a car

Connection

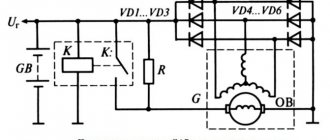

Connecting a capacitor to audio equipment is quite easy. It is connected next to the power consumer, the power polarity is straight. That is, the plus must be connected to the plus, and the minus to the minus. Remember that a car is a design solution with its own power supply system and wiring. It is necessary to exclude additional consumers from the circuit, except for audio equipment. To do this you need to install a diode. It is needed to limit the discharge from unnecessary consumers. This electrical element is installed on the positive wire between the power source and the consumer.

How to eliminate additional load on car wiring

Autocapacitors have one serious drawback: the ability to self-discharge. This type of electrical devices is bad for your car battery. Especially if there are a lot of them and it’s cold winter outside. To solve this problem, there are many devices on the market that are connected only when voltage appears at one terminal.

Capacitors from popular companies are equipped with a very convenient function, for example, installing a voltmeter. This is necessary for visual instrumental monitoring of voltage sags.

When connecting to the starting system, be sure to check that there is no voltage on the starting wire when parked. If there is no potential on it, then the car's network will be blocked from the capacitor. It is very easy to perform manual switching yourself. To implement this, you just need to use a relay. The switch can be placed in any place where it is convenient.

What types of automotive capacitors are there?

Today, many different capacitors for cars are already produced. From the simplest and cheapest models, to elite and expensive ones, with a large capacity of 20F. Such capacious installations are used in powerful equipment that has a distributor and has the ability to connect more than two amplifiers at the same time.

Automotive capacitor

The choice of device depends on several factors. Basically, you need to consider the power of the car's battery. Never buy equipment if it looks questionable. Capacitors have the “property” of exploding. And even the slightest violation of the integrity of the structure can lead to an explosion.

When inspecting the device in a store, you need to pay attention to the presence of protection on the terminals. They protect the system from accidental short circuits. It is also important to study the ease of connection and installation.

Automotive capacitor

Connection polarity

Another important point when connecting is maintaining polarity. Due to the characteristics of some models, the device only works with the correct polarity connected. If the polarity is violated, then such a capacitor will immediately fail. This is due to the fact that the dielectric instantly collapses, and the electrolyte boils inside the housing.

The capacitor charges instantly. This is directly related to the large current that passes through the electrical circuit in a short period of time. During normal operation, the device discharges slowly. Therefore, it is almost impossible to completely discharge the capacity.

Installing a capacitor for a subwoofer

Modern energy storage elements are not just an energy storage device, but a complex electronic device. The device body contains a chip that measures DC voltage at the terminals of an electrical device. Behind the transparent cover there is a four-digit LED indicator, by which this voltage can be controlled. How to connect the drive to an amplifier and subwoofer. In practice, nothing is connected to the woofer or speaker, and the storage device must be connected to the power terminals of the low-frequency amplifier, strictly observing the polarity. The terminals of the device are marked “+” and “-”, which must match the similar markings on the amplifier body.

The connection diagram for the subwoofer drive is very simple and can be implemented independently. The connecting wires can be clamped under the power terminal screw or an adapter block can be used for this purpose. In order to avoid the influence of connecting cables on the discharge of the device, it should be placed as close as possible to the low-frequency amplifier. The length of the connecting wires should not exceed 30-40 cm. All power wires running from the battery to the device and further to the amplifier must have a large cross-section to prevent energy loss. Copper-clad steel wires cannot be used for this purpose. The cables must be multi-core and made of pure copper.