The source of powerful low-frequency sound in sound systems is the subwoofer. This also applies to car acoustics, which is why most car enthusiasts equip their cars with such devices.

You can purchase a ready-made unit, but many people prefer to buy speakers and make a box for the subwoofer with their own hands. This is not as difficult a job as it might seem, but it will require tools and certain skills.

How to make a subwoofer box correctly

Before you start making a subwoofer box, you need to choose a loudspeaker. The volume of the future structure will depend on its parameters. Most often, specialized imported loudspeakers with a diameter of 10-12 inches are used to reproduce powerful bass. Structurally, the subwoofer box can be made in three options:

- Closed box

- Bass reflex

- Bandpass

The quality of the loudspeaker and the design of the box ultimately determine the sound quality of the low-frequency sound system.

How to make a housing for a subwoofer

The easiest to make is a buried box or box. This is a completely closed structure, the manufacture of which will require a minimum of simple wooden parts. How to make a housing for a sub becomes clear when you see such a device. Essentially, this is a rectangular box with a hole cut out in the front wall for a dynamic head. The box consists of six walls, which are easy to cut out of the appropriate material. A terminal block is mounted on the side or rear wall to connect wires from the amplifier. The closed box (CB) is distinguished by dense and not vague bass, smooth amplitude-frequency response, but has the lowest efficiency among all designs.

The box can be in the shape of a parallelepiped or trapezoid with beveled walls. Due to its characteristics, the closed design is suitable for many musical styles. The sealed, closed design conveys bass well in pop and rock music, classical, jazz and instrumental works. But fans of rap and dubstep will be disappointed, as the closed box is not suitable for playing music that has a lot of heavy bass and where the low frequencies are the basis of the music.

Where to begin?

Once the tasks for the sub are determined, consider the device that is responsible for the amplification in your system. If it is a receiver, such devices already have a dedicated subwoofer output. It is most often indicated by a corresponding inscription near the connector.

If your system uses a stereo amplifier, most likely it does not have a separate output for a subwoofer. In this case, the selected subwoofer model must have a so-called “high-level input”. This input allows the subwoofer to process and correct the outgoing full-range signal from the stereo amplifier.

With this option, the subwoofer is connected to the speaker terminals. It is preferable to use the “-” terminal from one channel and the “+” terminal from the other. But there have been cases when experimenters connected a subwoofer to the terminals of one of the speakers - this option is quite acceptable, but remains at your discretion.

There are also subwoofer models that are equipped with two pairs of terminals for your acoustics. In this option, both channels from the stereo amplifier are connected to the corresponding inputs on the subwoofer, then the signal from the subwoofer is supplied to the stereo pair.

This allows the sub, using the built-in crossover, to unload your speakers from low frequencies. But in this way one more link is introduced into the sound path, and I don’t think that fans of “direct drive” and similar buttons will prefer this option.

How to properly assemble a subwoofer enclosure

It is not difficult to make a housing for a subwoofer with your own hands if you strictly follow all the recommendations. The most important thing that a closed case requires is tightness and lack of vibration. The optimal material for a low-frequency speaker is multilayer plywood or MDF. The thickness of the material must be at least 18-20 mm. Thin walls will resonate and these vibration waves entering the car interior will greatly degrade the quality of low frequency reproduction. The most important parameter of any subwoofer is its volume. This parameter takes into account the internal space of the box without the volume occupied by the speaker. The relationship between the volume of the housing and the diameter of the loudspeaker is as follows:

- 10 inches (25 cm) – 15-20 liters

- 12 inches (30 cm) – 25-35 liters

- 15 inches (35 cm) – 40-60 liters

- 18 inches (46 cm) – 70-110 liters

In order to increase efficiency and improve sound quality, all seams between wooden walls must be sealed. It is best to use silicone sealant for this purpose. A closed box for a subwoofer, made with your own hands, has its undoubted advantages:

- Easy to calculate volume

- Ease of production

- Small sizes

- Distinct and clean bass

There are only two main disadvantages: low efficiency, not suitable for listening to “heavy” bass. The internal volume of a closed subwoofer can be filled with padding polyester or cotton wool. If the volume is calculated correctly, then this is not necessary. It is recommended to listen to the work of the subwoofer, both with and without filler, and choose the best option. At different air temperatures, the pressure inside a closed volume changes and to equalize it, a small hole of no more than 1.5-2.0 mm is sometimes left in the subwoofer housing.

Making a box for a subwoofer with your own hands

Making a do-it-yourself subwoofer housing is simple and takes a minimum of time. After the speaker has been selected and the internal volume of the closed box has been calculated, you need to prepare the material, fasteners and tools. With your own hands, the subwoofer body is usually made from the following materials:

- Plywood

- MDF

- Chipboard

Moisture-resistant multilayer plywood is considered the best material for making a subwoofer box. There are some difficulties with this. Plywood is the most expensive material and it is difficult to find plywood with a thickness of 18 mm or more. If the volume of the subwoofer is too large, then the plywood walls will emit a “ringing”, which can be eliminated by installing internal stiffeners. A good choice would be to use MDF. It is cheaper than plywood, easy to process and has good moisture resistance. Chipboard has become widespread. It can be found at any furniture company. There the slab will be cut to the specified dimensions. The disadvantages of chipboard structures include very low rigidity, when strong low-frequency vibration at the fastening points causes the material to collapse. In addition, it absorbs moisture well and if water gets into the trunk of a car, the box may simply crumble. This material can be used to make a housing for a home subwoofer. It will not be used in extreme conditions and will last a long time.

Why doesn't a subwoofer play without a box?

If we remove the speakers from the box of a working subwoofer, we will find that the bass that it reproduced efficiently will disappear. That is, a subwoofer without a box (acoustic design) does not play! Why is this happening? The subwoofer creates sound vibrations in both directions, i.e. forward and backward.

If there is no screen between these sides, the sound vibrations cancel each other out. But if we place the subwoofer speakers in a closed box, we can separate the front and back of the subwoofer and get good quality sound.

By the way, in a bass reflex box the box works on a slightly different principle; it reproduces sound in one direction, which increases the volume by about 2 times compared to Z/Y.

The principle of operation of subwoofer boxes

You say, why do we need this mess with frequencies, waves and boxes? The answer is simple, we want to clearly and simply demonstrate to you how the material from which the box is made affects the quality of the final result.

What happens if the box is made of poor quality material?

Now let's imagine that you made a box from your grandmother's closet, that is, you used chipboard material, which is only 15 mm thick. After that, a medium-power subwoofer was made from it. What will be the result?

Due to insufficient wall thickness, the rigidity of the box is reduced. When sound is reproduced, the walls of the box begin to vibrate, i.e. the entire box turns into an emitter; the sound waves that the box resonates, in turn, dampen the waves that the speaker emits from the front side.

Remember we said that a subwoofer speaker without a box simply cannot produce bass. Likewise, a low-rigid box will create only partial shielding, which will not be able to completely prevent the interpenetration of sound waves emitted by the subwoofer speakers. As a result, the output power level decreases and sound distortion occurs.

What should a subwoofer box be like?

The answer is simple. The main requirement that a subwoofer box must meet is its rigidity and strength. The stiffer the walls, the less vibration the subwoofer creates during operation.

Of course, in theory, a box made of a ceramic slab or cast of lead with 15 cm walls would be considered ideal, but of course, this can be considered nonsense, because...

such subwoofers will not only be expensive to manufacture, but also enormously heavy.

Types and comparison of materials for a subwoofer

Let's look at real options for materials for making a subwoofer and try to give a short conclusion on each of them.

Plywood

Better moisture resistant. In our opinion, this is one of the most worthy materials for the manufacture of acoustic equipment.

But there are a couple of downsides;

- This is the most expensive material.

- It is difficult to find plywood with a thickness of more than 18 mm.

- If the wall area is large, it begins to “ring” (additional stiffeners or spacers are needed)

MDF

Now it is gaining great popularity. It is a kind of gap between plywood and chipboard. Its main advantage is its lower price than plywood (about the same as chipboard) and good rigidity (but not as good as plywood). Easy to saw. Moisture resistance is higher than that of chipboard.

- It is problematic, but possible to find, a thickness of more than 18 mm.

Chipboard

Cheap, common material. Every furniture company has it, and you can order cutting from the same companies. This box will cost you 2-3 times less than one made from plywood. Flaws:

- Very little rigidity of the material (example about grandma’s closet above).

- Not moisture resistant. Absorbs moisture well and crumbles. It is especially dangerous if water gets into your trunk.

How to increase the rigidity of the box?

- The first, the simplest and most obvious.

This is the thickness of the material, the thicker the material, the greater the rigidity. When making a subwoofer, we recommend using materials of at least 18 mm, this is the golden mean. If your subwoofer has a power of more than 1500w RMS, then it would not be superfluous to choose a material thickness of 20 mm or more. If you have difficulty finding thick-walled materials, you can use the following recommendations. - An option that will add rigidity to your box is to make a double front wall. That is, the front part in which the speaker is installed. This part of the subwoofer is most subject to stress during operation.

Therefore, having a material width of 18 mm, making the front wall double we get 36 mm. This step will significantly add rigidity to the box. You should also do this provided that your subwoofer has an RMS (rated power) of more than 1500w. If you have a subwoofer with a lower power, for example, 700w, the front wall can also be made double.This makes sense, although the effect will not be very large.

- Another tip is to use spacers inside the subwoofer to add extra rigidity. This works especially well when the subwoofer has a large volume. Let's say you have two 12-inch subwoofers (speakers) in a box. In the middle, the rigidity of the box will be the smallest due to the large area. In this case, it would not hurt you to strengthen the structure and install a spacer in this place.

That's all we wanted to tell you about materials for the subwoofer. If this article helped you, please rate it out of five below.

Do you want to try to calculate the box yourself? Our article “Learning to count a subwoofer box” will help you with this.

What material is best to use for making a subwoofer Link to main publication

The right subwoofer box

The correct body means a more complex, but also higher quality design. This could be a body with a bass reflex or an even more complex system called a bandpass. Assembling a subwoofer enclosure with your own hands will take more time, but the result is worth it. The bass reflex can be slotted or in the form of a pipe. This design is a small “tunnel”. It rotates or inverts the phase of the signal with its further radiation into space, as a result of which the efficiency of the subwoofer doubles. A bass-reflex subwoofer is distinguished by strong and rich bass, and on its amplitude-frequency characteristic, at the tuning point, there is a large protrusion and At this frequency the volume increases. The tuning peak is regulated by changing the size of the port and the ratio of the working volume of the subwoofer to the size of the bass reflex. This subwoofer design is well suited for playing music with fast and powerful lows. How to assemble a subwoofer box largely depends on its design.

conclusions

We have long gotten used to the idea that a subwoofer is an integral part of a cinema system. The debate about its role in the Hi-Fi system has not subsided for quite some time. The lucky ones who have a properly configured triphonic or “2+2” system tirelessly try to convince others that “life has become better, life has become more fun.” Unfortunately, very often it is to no avail.

For my part, I can add: after I once heard a well-tuned triphonic, most speakers for me became not so attractive in the low-frequency range. Many of them need subwoofer support - and this is audible to the naked ear. But the choice, as always, is yours.

Making a housing for a subwoofer with a bass reflex

As with making a closed box, work on a more complex design begins with choosing a loudspeaker. How to make a box for a subwoofer depends on the type of material and fasteners. Multi-layer plywood is the strongest recommended material. To assemble the subwoofer housing with your own hands, you can use any self-tapping screws. When connecting elements from MDF, and especially from chipboard, you need to use only white self-tapping screws. Black ones do not provide such a strong connection. Sometimes the caps break off when screwed in.

The bass reflex subwoofer must be well sealed. To do this, a layer of sealant is applied to all seams on the inside. The cutting lines must be very even, so it is better to do the work on a special machine, if possible.

When making a slotted bass reflex, you need to ensure that all internal partitions do not have through holes. If the dimensions of the speaker and the box are large, then stagnant zones may appear in the turns of the slot port. To avoid this, all right angles of the bass reflex are smoothed out by installing additional wooden plates. Do-it-yourself subwoofer box assembly is completed by installing external contacts for connecting the amplifier. These places must also be sealed.

Where to put?

And so, here it is - a brand new, shiny, powerful sub. Successfully connected, but where is the bass? This happens often, don't panic. Most likely, the subwoofer is connected out of phase with your speakers, and they cancel out each other's low frequencies. Most modern subwoofers have a phase switch on the back side, most often marked “0–180”. We click the toggle switch and listen again.

If this was the reason, you will hear the difference immediately: the “correct” phase position is the one in which low frequencies are heard louder at the listening position. If the problem is out of phase, check that the subwoofer is connected correctly. And finally, look at the instructions. For some reason they put them in every box.

In addition, more advanced subwoofer models offer smooth phase adjustment. It can come in handy when you experiment with finding a place - two positions are not always enough.

So there's bass, but not quite what you expected? This is where the fun part begins - we send the subwoofer on a journey around the room.

There is an opinion that it is easier to put the sub in the listening position and go on a tour of the room yourself to find the position in which you like the low-frequency response the most. But this method does not always work - despite the flexibility of low-frequency radiation, it is also subject to reflections and depends on the proximity of the floor and walls to the emitter. And if the subwoofer is a bass-reflex type, this dependence doubles. Therefore, searching for such a place in the room and subsequent castling of the listener and subwoofer may not always give the desired result.

For a music system, the optimal location for the subwoofer is on the speaker line. In the center, to the left or to the right of the acoustics. The reference point is the quality of the bass, bordering on its optimal quantity.

For cinemas, the search for space should not be limited to the line of front speakers - here the field for experimentation can be expanded within the area where your system is located.

Small subwoofer box

Some motorists do not strive for powerful bass, but want to slightly improve the sound picture in the cabin. A small subwoofer is suitable for this. 8" speakers are suitable for this design. Some companies make 6-inch speakers, but they are hard to find. How to make a subwoofer box correctly. A subwoofer for a small loudspeaker has a small displacement, therefore, it will take up little space in the luggage compartment of the car. There is no need to reduce the size of the structure too much, but you also shouldn’t increase it. Increasing the size of the box will lead to the fact that low frequencies will “spread” and the bass will be unclear. If the volume is less than what is needed for a speaker of a certain diameter, then the lows will be too fast and will literally hit the eardrums.

Band pass loudspeaker

The third type of subwoofer, quite often used in car installations (although less often than the previous two) is a bandpass speaker. If a closed box and a bass reflex are acoustic high-pass filters, then a band-pass filter, as the name implies, combines high- and low-pass filters. The simplest bandpass loudspeaker is a single 4th order (single vented). It consists of a closed volume, the so-called. rear chamber and a second one, equipped with a tunnel, like a conventional bass reflex (front chamber). The speaker is installed in the partition between the chambers so that both sides of the diffuser operate in completely or partially closed volumes - hence the term “symmetrical load”.

Of the traditional designs, the bandpass loudspeaker, in any version, is the champion in efficiency. Moreover, efficiency is directly related to bandwidth. The frequency response of a bandpass loudspeaker has the shape of a bell. By choosing the appropriate volumes and frequency tuning of the front chamber, it is possible to build a subwoofer with a wide bandwidth, but limited output, that is, the bell will be low and wide, or it can be with a narrow bandwidth and very high efficiency. in this strip. At the same time, the bell will stretch in height.

The bandpass is a capricious thing to calculate and the most labor-intensive to manufacture. Since the speaker is buried inside the case, it is necessary to go to some lengths to assemble the box so that the presence of a removable panel does not violate the rigidity and tightness of the structure. The impulse characteristics are also not the best, especially with a wide bandwidth.

How is this compensated? First of all, as stated - the highest efficiency. Secondly, the fact that all sound is emitted through the tunnel, and the speaker is completely closed. When assembling such a subwoofer, considerable opportunities open up for installing it in a car. It is enough to find a small place at the junction of the trunk and the passenger compartment where the mouth of the tunnel can be placed - and the way is open to the most powerful bass. Especially for such installations, JLAudio, for example, produces flexible plastic tunnel sleeves with which it offers to connect the subwoofer output to the cabin. Like a vacuum cleaner hose, only thicker and stiffer.

Which box you choose for your speaker is of course up to you. And our auto studio will make this box for you.

As you know, a subwoofer in a car is an integral element for obtaining high-quality, rich and powerful sound. Moreover, in addition to the speaker for the subwoofer, the most important part is the box for the subwoofer.

The sound quality, volume, as well as the ability of the subwoofer to fully “open up”, etc. will depend on the box. In this article we will look at what to pay attention to when designing, as well as how to make a subwoofer box yourself.

How to make a housing for a subwoofer with your own hands

If you need to make a good box for a subwoofer, then it is best to focus on the most complex design. This system is called a bandpass. It comes in fourth order and sixth order. The fourth-order system is a two-chamber box, where one chamber is a closed box, and the other plays the role of a bass reflex.

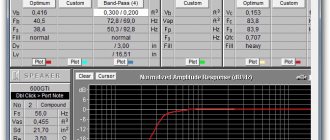

A sixth-order bandpass is a design with two bass reflexes. The most difficult thing here is the calculation of the second port and the relative relationship of the settings of each bass reflex. The two chambers have different sizes and are capable of limiting the frequencies reproduced by the loudspeaker. The box for two subwoofers is the most difficult to design, but it has the maximum efficiency. To determine all sizes of such sound systems, special utilities are used. The universal WinISD program is suitable for calculating any subwoofer design. It does not have a Russian-language interface, but it is not difficult to understand. To make a drawing of a box for a subwoofer, just load the parameters of the speaker you are using into your computer.

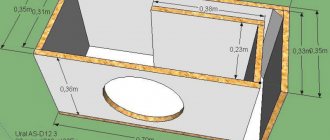

Subwoofer housing drawings

If you don’t have the time and desire to calculate the subwoofer box yourself, you can take ready-made calculations and drawings. If you need to make the bass very deep and powerful, you can make a subwoofer box for two speakers. In this case, the design can be in the form of a closed box or bass reflex. Both speakers must be of the same type and with the same resonance frequency, otherwise it will be difficult to adjust the bass reflex. If you have no experience working with car acoustics, then it is better to make your first subwoofer using a closed box design. A bass reflex subwoofer with one loudspeaker is also easy to make with your own hands. You should not, without experience, take on a system such as a bandpass. In any case, the result will not be satisfactory.

Bass reflex (FI) – vented box

A bass reflex is the next most common type of acoustic design. In a bass reflex, part of the energy that is “put against the wall” in a closed box is used for peaceful purposes. To do this, the internal volume of the box communicates with the surrounding space through a tunnel containing a certain mass of air. The size of this mass is chosen in such a way that, in combination with the elasticity of the air inside the box, it creates a second oscillatory system that receives energy from the back side of the diffuser and radiates it where needed and in phase with the radiation of the diffuser. This effect is achieved in a not very wide frequency range, from one to two octaves, but the efficiency is within its limits. increases significantly.