Setting the ignition timing with advance

This setup is quite easy to do.

Even a beginner can cope with this task. To do this, prepare a 13 mm wrench and a special 38 mm crankshaft wrench in advance. If your car starts, be sure to turn off the engine, as the ignition can only be turned on when the engine is off. First, the piston of the first cylinder is installed at the top dead center of the compression stroke, that is, in the ignition position. Before doing this, remove the candles and plug the hole from them with cotton wool.

It is necessary to align the mark on the crankshaft and the front engine cover. To do this, start turning the crankshaft clockwise using a wrench. During this action, the compressed air should push the cotton ball, marking the compression stroke. Continue to rotate the shaft slowly until the marks on the pulley and timing cover align.

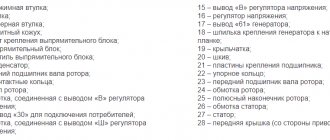

Pay attention to the 3 marks on the cover:

- the second – by 5 º;

- the third is zero.

- The first indicates ignition advance by 10;

Since a VAZ 2107 with a carburetor engine runs on 92 or 95 gasoline, we need to set the ignition to these types of fuel. Therefore, you should select the second sign, which will indicate an ignition advance of 5.

After the required parameters match, put the spark plugs in place and remove the wires. The system is ready for use.

Operating principle of the ignition system

We replace the VAZ 2114 heater radiator with our own hands, instructions and nuances. The process of burning the mixture in the cylinder takes some time. If the mixture ignites while the piston is at TDC, then it will burn after the piston passes TDC, catching up with it, that is, during the expansion stroke of the combustion chamber and exhaust gases. This will create insufficient pressure on the piston, as a result of which efficiency will be noticeably reduced and fuel consumption will increase (ignition is delayed).

When the mixture is ignited long before the piston passes TDC, a significant part of the energy will be spent on overcoming the pressure by the piston during the process of explosive combustion of the mixture. In this case, detonation occurs (early ignition). In addition, if the VAZ ignition is set incorrectly, the engine will overheat due to the increased absorption by the cylinder walls of the heat released during combustion of the mixture.

That is why the optimal ignition timing is considered to be one at which the mixture ignites shortly before the piston passes TDC, so that the combustion of the mixture coincides as much as possible in time with the piston passing TDC. In this case, the VAZ ignition timing provides the best operating mode.

In order to control the ignition of the VAZ 2109, divisions are applied in the clutch housing hatch shaft, and a mark is installed on the flywheel. When the point on the flywheel coincides with the central mark in the hatch, the pistons in the first and fourth cylinders are set to top dead center (TDC).

The way to control the VAZ ignition installation “on the move” is as follows: moving at a speed of 40-50 km/h on a flat section of the road with fourth gear engaged, you need to press the gas pedal to the floor. If, while accelerating, a slight detonation is heard, which disappears almost immediately, the ignition is set correctly. The absence of detonation manifestations indicates late ignition. Excessive detonation is a sign of early ignition of the combustible mixture.

What needs to be done before adjustment?

Adjustment is necessary for the “nine”, which has a carburetor installed. For those who have an injector, the good news is that the car has an automatic device that regulates the ignition itself. To make the adjustment you will need 2 devices: a strobe light and a speedometer. How to properly prepare everything for setup? Thus:

- Warm up the engine to normal operating temperature, which is approximately 85°C.

- The minimum engine idle speed must be set at 750-790 rpm. Turn the fuel mixture adjustment screw on the carburetor using a wrench to change the gauges. If the RPM meets the requirements, there is no need to change it.

Next you need to reach the marks on the flywheel. The algorithm of actions is as follows:

- Disconnect the silicone hose from the fitting on the carburetor vacuum regulator. It is worth checking for vacuum.

- Then turn off the engine.

- The silicone tube can be tied in a knot or closed.

- Take a 10mm wrench and remove 3 nuts on the distributor body.

- Let's inspect the crankcase. You need to find the marked hatch. This may take some time as it is often closed with a rubber stopper.

- Once you find the device, clean the scale inside it so you can see each mark clearly.

- Take a slotted screwdriver and turn the flywheel to the alignment mark. The stripe should be located opposite the triangle on the hatch scale (triangular notch). In this position, the ignition timing is 0 °, and the pistons of the 1st and 4th cylinders of the engine should be at the TDC point. This position is the starting point for further manipulations.

- Connect the strobe pins according to the instructions to the device. They are usually connected to the battery with correct polarity.

Return to contents

Adjusting the ignition timing

For the following steps, loosen the nut securing the distributor (ignition distributor) with a 13mm wrench. Connect the harness from the light bulb (it will act as a voltmeter, that is, it will indicate the presence of voltage) to the low-voltage terminal which has a coil, and the second one on the ground.”

Now turn on the ignition. Slowly and carefully rotate the dispenser body clockwise, stopping immediately when the light goes out. The sparks that appear will indicate the moment of fire. Move the distributor counterclockwise until the contacts break and the lamp lights up again. Everything is in order, you can safely turn over the distributor, the installation is complete.

Adjusting the ignition by light bulb

There are ways to adjust without strobing. To make adjustments using a light bulb, you will need a crankshaft wrench and a standard 12-volt light bulb.

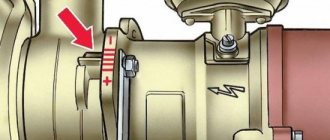

Setting the ignition timing by weakening the spark torque sensor.

The procedure for adjusting the ignition by light bulb

- Turn the crankshaft with a special wrench until the marks match. If there is no key for the crankshaft, engage 4th gear and push the car until the marks match.

- Connect a 12-volt light bulb to the wire connecting the distributor and ignition coil.

- Connect the light bulb to ground using the second wire.

- We connect the central cable to ground Lada 2109.

- Loosen the bolts on the toggle switch housing and turn on the ignition - the light should light up.

- Turn the lid to the right until the light goes out.

- After the light goes off, carefully turn the dispenser to the left.

- Stop when the light comes on.

- Tighten the housing bolts.

The lamp ignition control circuit is ideal for home surgery without the additional cost of instruments.

Third adjustment option

Setting the ignition in this way requires the participation of two people, one of whom must be inside the car. In more detail it looks like this:

The controller in the cabin turns on the ignition and controls the speed using the tachometer.

In the engine compartment, loosen the mounting bolts of the distributor housing and begin to rotate it (the housing).

The ignition timing (target setting) is determined by a sharp fluctuation and return to the zero mark of the tachometer needle.

The distributor body is fixed in a position that initiates the beginning of the tachometer needle deflection. Due to the complexity of its (position) determination, the operation will most likely have to be performed repeatedly.

Installation of electronic ignition

Electronic ignition makes the engine smoother and softer, makes it easier to start in winter and reduces fuel consumption. If you, having a carburetor engine, decided to switch to contactless (electronic) ignition, we will tell you how to install it correctly on a VAZ 2107 car.

An electronic system for a carburetor car does not have to be too expensive or cheap. It’s better to opt for a product in the mid-price category so that you don’t have to change anything after a while.

Before work, prepare a drill and a set of wrenches.

For a general overview, first carefully read the included instructions and open the carburetor engine kit. Includes:

- 4 candles;

- connecting and high-voltage cables.

- distributor;

- switch;

- ignition coil;

The system is easy to install. First of all, remove the negative terminal from the battery and let the crankshaft run until marks 3 and 4 coincide, that is, the highest dead center.

Now you can begin the main steps. The coil must be disconnected from all wires, removed and installed a new one. The coil can now be connected to the central high voltage wire. Connect 2 brown wires to pin "K" and 2 blue wires to pin "B".

Now remove the dispenser cap. Please note that the slider must be set exactly as shown in the figure. Mark this point with a marker on the block to ensure the new dispenser is installed correctly. You can now unscrew this part and set it aside.

After opening the cover of the new distributor, install the slide perpendicular to the engine and insert it into the hole in the cylinder block. Align it with the mark on the block. Next, put the cover on and connect the wires.

Decide where the switch will be located, since there is no room for it in the VAZ 2107. It is recommended to install it next to the washer reservoir. Secure with self-tapping screws and install the connector.

Don't forget the candles. To replace them on a VAZ 2107 car, you will need a spark plug wrench, which should be used to unscrew the old spark plugs from the cylinders and install new ones.

Their color can tell a lot about the engine's performance, so if the spark plugs have soot deposits on them, the air filter should be replaced. Normally, candles should be light brown in color.

Replacing the starter relay

Another common problem encountered on a VAZ 2107 with a carburetor is a malfunction of the starter relay. When you turn the key in the lock, the system clicks, but the retractor relay does not operate. Replacing the relay is very simple.

First, remove the starter from the relay. Unscrew the 2 screws that hold it in place. Slide it to the right and remove it by turning it backwards. Unscrew the nuts securing the starter and relay.

Unscrew the terminal.

Turn to the side.

Remove the 2 bolts securing the relay to the starter.

We remove the relay.

Install the new one upside down.

comments provided by HyperComments

Probably every motorist who owns a car of the VAZ 2108-09 family has encountered malfunctions in the ignition system. Most often, the cause of these malfunctions is a trivial reason - an incorrectly configured ignition. We are talking about how to set the ignition on the carburetor and injector of the VAZ 2109, and we will talk below.

System design

Before we begin to consider the setup process, we consider it necessary to understand the scheme and principle of operation of the system. Vehicles of the VAZ 2109 model range are equipped with a non-contact ignition system. The connection diagram for all elements is as follows:

There is nothing complicated about how the system works. For the spark to start, the crankshaft must turn. Simultaneously with the rotation, the camshaft will also turn. As a result, the sensor generates a signal that will be sent to the switch. The “K” terminal of the coil will be connected to the common wire (with “ground”), as a result of which a spark will appear on the main wire. At the moment when the working distributor slider connects the main wire with one or another high-voltage wire on the corresponding spark plug, a spark will appear and the car engine will start.

If the settings are incorrect, the spark plugs operate in the wrong timing modes. As a result, such a violation causes unstable operation of the entire power unit.

How to check high-voltage wires of a VAZ 2110

how to check the high-voltage wires of the ignition system.

Diagnosis of misfires on VAZ cars.

High-voltage wires of engine 2112 (1.5i 16v) - check and replacement.

Ignition coil with wires VAZ 2110 BU.

High voltage wires 8kl. injector VAZ 2111 SLON.

procedure for connecting high-voltage wires VAZ 2110 injector Do it yourself.

AT 320N Wiring for VAZ 2110 (1.5i 16V).

Removal, installation and repair of Lada Granta ignition coils

How to install high-voltage wires correctly.

Checking and replacing spark plugs of the VAZ 2110 Lada.

High-voltage wire VAZ-2111 dv.1.5 SLON set.

ignition module 2112-3705010-02 -2110.

2111-3707080 SLON High-voltage wire VAZ-2110 SLON kit (packed)…

Spark plugs for VAZ 2110 8 valves.

How to check the high-voltage wires of a car?

VAZ 2110 (VAZ 2110) – Replacement of I/O ignition wires.

Diagram, procedure for connecting VAZ high-voltage wires.

The numbering of the wires is marked on white rings, and the qi numbers are cast on the module...

VAZ 2110 (VAZ 2110) – Replacement of I/O ignition wires.

Replacement of high-voltage wires and installation of the left rear view mirror, i.e...

Comment on Removing and disassembling the ignition sensor-distributor of the VAZ-2110.

High-voltage wire VAZ-2112 V16 silicone set, RF.

Preparatory activities and necessary tools

Installation of the VAZ 2109 ignition carburetor begins with preparatory activities. In particular, you need:

- Warm up the car engine;

- Set the parking brake on the vehicle and place the anti-roll bars under the rear wheels.

Remember that you cannot ignore safety rules because a car is a more dangerous vehicle and failure to follow safety rules while driving, maintaining and repairing can cost you dearly.

An important point: before starting work, you need to make sure that the carburetor is correctly configured on the car. It would be a good idea to conduct a visual inspection of all elements of the system. If we are talking about a carburetor car, then special attention should be paid to inspecting the condition of the distributor.

If you have a car with an injection engine, it is worth checking the ignition module for maintenance. The fact is that, as practice shows, it is this module that most often fails and is the reason for the inoperability of the entire system.

To complete the work we will need:

- a set of keys.

- strobe;

Adjustment by tachometer

In the event that you do not have a strobe light or a control light, then, in principle, even without this it will be possible to solve the problem of setting up the OZ. To perform this task, you will need a regular car tachometer, which is designed to read crankshaft revolutions. In this case, to complete the task you will need the help of a partner, since one of you will be driving the car, and the second will be rotating the distributor housing at the same time.

How to set the OZ using a tachometer:

Photo gallery “Adjusting the OZ using the tachometer”

How to regulate

Practice shows that very often problems with the ignition system are observed in older models with a carburetor-type power plant. To complete the setup you will need the following tools:

- key for 10 (suitable for both the bell and the terminal);

- tachometer (available in almost all car multimeters).

- strobe light (in principle, you can do without it, but with its help you can set the angle more accurately);

- Screwdriver Set;

On to the road. Ignition installation (VAZ 2109)

In this video, Nail Poroshin once again shows and explains exactly how to install the ignition

on the…

2109. Ignition in minus, do it as it should, and not according to the strobe

Carburetors on the map – – near you! – Purchasing from Nail...

Method without strobe

In this case, adjust the ignition system with the help of a friend, since adjustment using the method in question cannot be performed alone.

You must act in this order:

- a person directly in the car starts the engine and monitors the number of revolutions using a tachometer;

- the second one in the engine compartment unlocks the distributor and begins to turn it;

- at the moment the ignition is triggered, the tachometer needle jerks sharply and returns to zero;

- the distributor is clamped in the position in which the above-described event occurred.

It should be warned that this method, unlike those previously described, is not very accurate. To achieve the expected result, you will have to repeat the procedure several times.

How to correctly set the ignition on a VAZ 2109 carburetor - detailed instructions

The installation process looks like this:

1. Start the car engine and make sure that the engine speed is about 800 rpm. To set the idle speed within these limits, simply adjust the carburetor fuel mixture screw using a slotted screwdriver.

2. After setting the idle speed to the above value, turn off the vehicle engine.

3. Disconnect the rubber tube from the vacuum corrector. Gently bend the tube approximately in the center or close it with a screw of the appropriate diameter.

4. Connect the positive terminal of the strobe light to the “+” terminal of the battery;

5. Connect the negative wire of the strobe to the “-” terminal of the battery;

6. Disconnect the spark plug wire from the cylinder 1 socket as shown in the figure:

Disconnect the spark plug wire

7. Install the strobe sensor into the socket and connect the high-voltage cable to it;

8. Remove the cover from the clutch housing hatch:

Removing a stub

9. Turn on the ignition and start the engine. The actively changing luminous flux created by the strobe is directed into the hatch of the clutch housing:

We direct the strobe towards the clutch housing hatch

10. When the indicator flashes, the mark on the flywheel appears to have stopped. When setting the ignition correctly, the first mark should be between the technological notch and the previous mark on the scale.

Label

11. If after the described operations it turns out that the ignition adjustment of the VAZ 2109 is incorrect, we continue to work.

12. Using a wrench, slightly loosen the nuts securing the ignition distributor:

Mounting nuts

13. Having loosened the fastening nuts, turn the distributor body to the right if it is necessary to increase the firing angle, and to the left if it is necessary to decrease the angle.

14. Connect the rubber tube to the vacuum corrector and check that the ignition settings are correct. If it was not possible to achieve a normal result, we make repeated adjustments. The following describes how to check that the system is working correctly.

Setting the ignition using a strobe

Checking and subsequent adjustment of the VAZ-2109 ignition (carburetor) can be considered correct only if the engine is warmed up to its operating temperature (in the range from 80 to 90 degrees). All further actions must be performed according to the following instructions:

- Start the engine and set the crankshaft speed to 800-900 rpm.

- Remove the vacuum tube from the fitting of the vacuum ignition timing corrector and, turning off the engine, close the gap in the tube.

- Using a “10” wrench, unscrew the three nuts on which the distributor-switch is secured.

- The gearbox has an inspection window, closed with a cap, after removing which the flywheel gear ring is revealed to the eye. Rotate the flywheel until you see the alignment mark, placing it in front of the center scale graduation located on the edge of the sight glass, you will place the first and fourth pistons at top dead center. It would be a good idea to check the correct position of this mark - to do this, find the same mark on the crankshaft pulley and make sure that it is aligned with the mark on the timing cover.

Make sure the marks match

Using this method will allow you to adjust the ignition as accurately as possible with your own hands without the participation of a specialist.

- Direct the stroboscopic beam into the viewing window: the pulses of the device correspond to the moment the flywheel mark appears.

- Now you need to turn the distributor until the desired advance angle is set. According to the passport data, for A-92 gasoline this angle is 1 ± 1 degree, and for A-95 gasoline – 4 ± 1 degree. Make sure that the mark is placed opposite the desired danger, and the installation of the VAZ-2109 ignition (carburetor) can be considered complete.

- Restart the engine and re-check that the crankshaft rotates at the required minimum.

- Now you need to connect the strobe light by connecting one wire to the camshaft instead of the center high voltage wire and the other to the negative terminal of the battery.

Adjustment with strobe light

How to configure and adjust the OZ on a VAZ 2109 or 21099 using a strobe? Anyone can cope with this task, but you need to take into account that if there are malfunctions in the operation of the module, then most likely the adjustment will not solve the problem. When adjusting, engine speed should be in the region of 820-900 rpm. The method of adjusting the SOP using a strobe is considered one of the most accurate.

How to perform this procedure:

- First you need to start the power unit and set the appropriate number of revolutions for its operation. If this value on a carburetor engine is outside the limits, then you need to adjust the air-fuel ratio to form a combustible mixture.

- Next, you need to disconnect the vacuum line from the fitting. Having done this, the car engine should be turned off, after which the gap in the vacuum hose will need to be removed. If there is no clearance, you will need to unscrew the three nuts that secure the distributor or switchgear housing.

- Once these steps are completed, you will need to remove the rubberized plug from the transmission housing; directly behind it is the flywheel inspection hole. In addition, you will need to disconnect the high-voltage wire from cylinder number 1 from the distribution unit cover.

- After this, you should activate the strobe itself. This device is connected instead of the disconnected wire, as well as to the battery. After starting the power unit, the device will transmit impulses in time with the flywheel. In this case, the distributor body will rotate until the mark on it coincides with the one marked on the flywheel itself. Once the marking is complete, you will need to secure it in place. For diagnostics, make sure that the marks on the flywheel and crankshaft match; if this is the case, then the installation of the OZ was carried out correctly (the author of the video is Nail Poroshin).

Incandescent lamp instead of strobe light

Many car owners will ask a completely correct question - how to set the ignition of a VAZ 2109 in the absence of a strobe light. Of course, it is even more correct to work with a strobe, especially since in this case you can carry out the setup and adjustment work as accurately as possible. However, there is another method that will be useful for those who, for one reason or another, do not want to buy a strobe light.

To work, we need a regular incandescent lamp, designed for an operating voltage of 12 V. The entire algorithm of actions is as follows:

- Disconnect the wire going to the ignition coil from the distributor

- We connect one terminal of the incandescent lamp to the wire. Connect the second wire from the lamp to ground.”

- As in the case when the ignition of a VAZ 2109 is set using a strobe light, we loosen the nuts securing the distributor using a wrench.

- Turn on the ignition. The incandescent lamp should light up.

- Gradually turn the dispenser until the lamp stops burning. Next, turn the distributor slightly in the other direction. Once the lamp lights up again, you can tighten the mounting nuts.

Of course, the method described above cannot provide the highest possible control accuracy. However, with its help it is quite possible to achieve more or less correct and stable operation of the power unit.

Checking the ignition

To check the functionality of the ignition in a car with an eight-valve injection engine, you will need:

So, if you decide to check the entire system, you should not rush and test the ignition module before a comprehensive check. The point is that the system must function properly with all connected devices. Turn the key in the ignition and connect to ground. After turning on the ignition, fuel should begin to flow into the system. At this moment, carefully monitor the indicators: if the red signal lights up, determine the nature of the problem using a special program.

When everything is ready, you can check the operation of the throttle valve. To do this, you need to turn on the ignition again, take a tester and use it to find out what voltage is coming to the on-board computer sensor. Everything is normal if, according to the readings, you get the following values: on-board system voltage is greater than or equal to 12 V, sensor - 0.5 V, damper opening degree - up to 1%.

Next, press the accelerator. At this point, the readings should change between 4.5 V and 90%. If you want to achieve the best result, increase the throttle reading to 100%. Finally, stop supplying additional air and open the system to 50%. The final step in adjusting the throttle valve is to close it completely.

Checking with a light bulb

This will make it easier when using a strobe light. Requires a 12 volt lamp. The procedure is as follows:

- start the engine and loosen the bolts on the distributor;

- then slowly turn to the left - when the light flashes, the dispenser is stable.

- a central closing wire is installed there (high voltage;

- the body must be turned to the right until the lamp goes out;

- the second is applied to the mass;

- a contact from a light bulb is connected to the wire from the coil to the distributor;

To better understand how the moment is established, we suggest you watch this video:

How to check the malfunction of the VAZ 2114 ignition module on your own?

The easiest way to check the device without removing it is to diagnose it at the moment the power unit is tripped. When the motor begins to operate unstably, it is necessary to disconnect the connector elements from each component of the module one by one. If the connector is disconnected from a functioning device, the operation of the engine will change. Dips will appear, and the unstable operation of the unit will increase. When the non-working element of the MH is disconnected, the motor will operate in the same way.

There is another simple diagnostic method, its principle is as follows:

- You will need an assistant to check. The spark plug is removed from the seat. The high-voltage cable is disconnected from the device.

- Then the disconnected wire is connected to a spark plug, which is applied to the body of the power unit.

- The machine motor is starting, you need to make sure that a spark hits the spark plug. If it passes, a blue light will appear between the device and the surface of the power unit, its formation is accompanied by a crackling sound. If there is no spark, then the spark plugs, high-voltage cable and module must be diagnosed.

In the absence of special equipment, diagnostics of the MH can be performed using a control light indicator designed for 12 volts. One conductor from the lamp is connected to the pin of connector A, and the second is connected to ground for grounding. An assistant must start the power unit or rotate the starter mechanism. If the light flickers when performing these steps, then the device is working. Similar actions must be done with another contact.

The channel “Diary of an Auto Electrician” spoke about self-diagnosis of ignition modules, as well as other elements of the system.

Checking the ignition unit with a multimeter

Diagnostics is carried out in the following order:

- The car engine is started.

- The tester switch must be set to DC measurement mode, the limit should be up to tens of volts.

- One of the contacts of the multimeter is connected to connector D on the coil, and the other goes to ground. You can use a car body or a cylinder block as a mass. If there is power, the diagnostic tool display will show 12 volts.

- Then the tester switches to the ohmmeter operating mode, the range of values is up to tens of ohms.

- One contact of the diagnostic tool is connected to output C, and the second goes to ground. If the device is operational, the test will show a value of less than 1 Ohm.

- At the next stage, the tester must be switched to voltmeter mode. The range of values is up to tens of volts.

- One of the contacts goes to the output marked B, and the second is connected to ground.

- If the diagnostics show that the voltage is less than 0.3 volts, then the device is working. This indicates a clear signal passage from the Hall controller. Finally, you can perform a similar test, only with connector A. The results should be identical.

How to adjust the ignition on a VAZ 2109 - an alternative method

In addition to the adjustment methods described above using a strobe and a light bulb, you should remember one more method - adjustment using a standard speedometer. We emphasize that this method, like the method using a light bulb, cannot provide high tuning accuracy. In addition, it has a significant drawback - it is impossible to carry out the adjustment yourself; an assistant will be required. Like:

- Your assistant is driving the car. Turns on the ignition and monitors the standard tachometer readings on the instrument cluster.

- Loosen the distributor nuts and twist a little.

- Your assistant turns the ignition key. The speedometer needle should quickly deflect and return to zero.

- It is necessary to ensure that the distributor remains in a position in which the tachometer needle deflects.

You may notice that this method requires patience and a lot of time. As practice shows, it is not possible to adjust the ignition quickly and the first time using this method. Therefore, it is recommended to use it only as a last resort.

Strobe light

To adjust the ignition using a strobe, you should:

- open the flywheel window in the gearbox;

- disconnect the high-voltage cable coming from the first cylinder from the camshaft and connect a strobe light to it;

- it, in turn, is powered directly from the battery;

- start the power unit of the car.

A working strobe light will begin to flash synchronously with the rotating flywheel. Once this has happened, you need to slightly loosen all three nuts holding the distributor. After this, slowly and very smoothly turn the distributor, monitoring the position of the flywheel. Stop doing this when the mark on it is halfway between the middle and the next scale divisions.

How to set the ignition on a VAZ 2109 injector

Above we described the process of adjusting carburetor engines. However, there are VAZ modifications equipped with injection power units. How to set the ignition on a VAZ 2109 with such an engine?

First of all, it should be noted that in the case of injection engines they do not have a distributor and a Hall sensor. In this case, the system simultaneously has two ignition coils and, accordingly, two switches. The main difference between the injection system and the classical one is that control signals are generated by a special electronic unit. The operating principle is as follows:

The principle of operation of the injection system

So there is simply no need for a distributor, because it is the electronic control unit that determines in which cylinder there should be a spark and at what moment. Signals from the control unit are sent to the inputs of the switches, and from them to the ignition coils. One switch is responsible for the spark in the first and third cylinders, the second - in the second and fourth.

As in the case of engines with a carburetor fuel system, adjustment is carried out taking into account special technological risks. The ignition marks of the VAZ 2109 injector are shown in the photo below:

Ignition marks VAZ 2109 injector

Please note that it is impossible to adjust the engine injection system yourself. The fact is that this operation involves making changes to the software of the microcontroller of the electronic control unit. Of course, each specific microcontroller has its own specific firmware. In addition, there are non-standard firmwares, for example, with settings for a sporty driving style.

Only an experienced specialist with certain knowledge can make the electronic control unit blink. Therefore, if there is a malfunction in the ignition system of an injection engine, you must seek help from a trusted car service center.

Possible reasons for failure of the ignition module

Before repairing the main part in the car’s ignition system, you need to understand the nature of the problem. To do this, the consumer must be aware of the signs of a malfunction, as well as the causes of the breakdown.

The main reasons for device failure

Causes of problems:

- The ignition system uses spark plugs that do not match the vehicle parameters. They may not have the gap specified by the manufacturer. Also, the spark plugs themselves may not be working or dirty; this can be determined by visual diagnostics. If there are traces of carbon deposits on the devices, they must be removed.

- Malfunctions in the operation of the MH can arise as a result of frequent spark checks. At the time of diagnosis, a high load is placed on the device. If it appears frequently, it will lead to equipment failure or incorrect operation.

- The ignition module in the VAZ 2114 operates with the high-voltage cables disconnected. This also leads to device failure. The products themselves may be damaged, which affects the functioning of the engine as a whole.

- The device operates under severe vibration conditions. Their impact may be due to poor quality fixation of the module in the seat. As a result of vibrations, the factory soldering inside the equipment structure is damaged. This leads to its incorrect operation.

- The contact inside the plug with the low-voltage cables is broken.

- Initial use of a defective device or module with poor build quality. This factory defect can only be eliminated by replacing the mechanism; repairing the equipment is pointless.

- Moisture getting inside the case. This problem is unlikely, but exposure of the device to liquid may cause it to short out and break.

Signs of coil malfunction

The main symptoms of a malfunction in the VAZ 2114 ignition module:

- Difficulties arise when trying to start the engine. Starting the car engine may be difficult due to the fact that there is no spark on a spark plug or several.

- When idling or parking with the internal combustion engine running, the speed of the power unit floats. Their change is not associated with pressing the gas pedal and other third-party factors. This happens randomly.

- There are dips in the power of the car's engine. This is especially felt when driving uphill or sharp acceleration. Problems can also occur when driving on a flat road.

- Several cylinders stopped working. Usually these devices operate in pairs, so elements 1-4 or 2-3 could fail. Non-working cylinders may be indicated by “triple movement” of the engine.

- A “Check Engine” warning light appeared on the dashboard.

If the ignition module malfunctions, problems will appear not only in engine operation, but also when starting it.

The “Simple Opinion” channel, using the Lada Priora car as an example, spoke in detail about the symptoms that appear in the operation of the ignition modules.

How to check the correctness of the work performed?

If you set up POP yourself, you will also need to verify that the steps are correct.

To complete the verification you need to do the following:

- We start the engine, diagnostics are carried out while driving, for this you will have to drive on a flat road.

- To obtain more accurate test results, it will be necessary to accelerate the vehicle to approximately 50 km/h.

- After selecting this speed, you will need to engage fourth gear and then sharply press the accelerator pedal. When you press the pedal, an explosion is heard from under the hood of the car, that is, a metallic knock. In this case, the sounds themselves may not last long. If so, you have successfully completed all setup steps and the distributor has been installed correctly. If the sounds are long and prolonged, this will indicate that the SPD was installed too early, and the detonation will be quite loud. If there are no sounds from under the hood, we can conclude that the OZ was installed late.

Ignition check

How to check the correctness of the procedure?

There is no point in doing this in the garage - you should drive out onto a flat road to check.

If, after changing gear, you hear the engine begin to knock quietly, while the sounds are short, then this means that you did everything correctly. If the ignition is set too late, this will be indicated by the absence of sounds when accelerating. If the ignition is too early, the sounds will be quite loud.