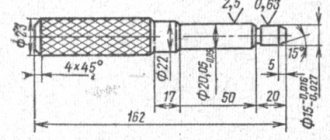

Correct and precise operation of the clutch on VAZ 2105, 2107 vehicles is ensured by certain adjustments to its drive. There are two of them: adjusting the gap between the pusher and the piston of the clutch master cylinder and adjusting the free play of the clutch pedal.

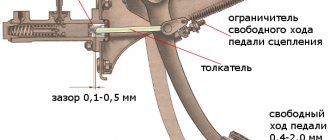

The gap between the pusher and the clutch master cylinder piston is 0.1 - 0.5 mm. It is regulated by rotating the clutch pedal free travel limiter. In this case, a certain free play of 0.4 - 2.0 mm is formed at the clutch pedal, which the driver selects when starting to press the pedal.

the gap between the pusher and the piston, free play of the clutch pedal of VAZ 2105, 2107 cars

It is measured with a ruler or tape measure, which is installed from the floor to the middle of the lower part of the pedal platform. We move the platform with our hand relative to the ruler scale by pressing the pedal. If there is a gap, at first the pedal moves very easily, and then with difficulty. If there is no gap, turn the pedal travel limiter out a little. We ensure that the free movement along the ruler fits within the required two millimeters.

This gap is necessary for the clutch to disengage completely. If it is missing, then the piston will not be able to fully return to the rear position when the pedal is released and in the working cavity of the master cylinder, and excess pressure will remain in the entire drive. As a result, the clutch will not disengage completely, since the release bearing will press on the leafs of the pressure spring, and the discs will slip (not be fully pressed against the flywheel). Increasing this gap will lead to the fact that the clutch will not disengage completely and will “drive” (the discs do not fully move away from the flywheel).

Adjusting the clutch pedal free play (the gap between the release bearing and the plane of the pressure flange of the clutch “basket” pressure spring)

It is adjusted by a nut on the clutch slave cylinder pusher. With proper adjustment, the free play of the clutch release fork is 4–5 mm (checked by hand: the fork is pulled away from the stop against the adjusting nut on the pusher), and the free play of the clutch pedal is 25–35 mm. It is necessary to unscrew the lock nut on the pusher and rotate the adjusting nut to set the required free play of the fork. The pedal free play of 25 - 35 mm (until the clutch is disengaged) can be checked using a ruler. It is this value that means there is a gap between the release bearing and the plane of the pressure flange of the clutch “basket” pressure spring.

free movement of the clutch slave cylinder pusher for VAZ 2105, 2107 cars

In the absence of this gap, the release bearing presses on the pressure spring of the “basket” - the clutch “slips”. With an increased gap, it “leads.”

The clutch pedal free play of 0.4 – 2.0 mm is included in the pedal free play of 25 – 35 mm. That is, 25 - 35 mm is the total required size.

Notes and additions

— The clutch on VAZ 2105, 2107 cars is of a constantly closed type, that is, constantly on: when the pedal is released, the driven disk is pressed by the drive disk to the flywheel and rotates with it, as well as the release bearing and the input shaft of the gearbox. There is a gap of 1.5 - 2.0 mm between the release bearing and the lining of the thrust flange of the clutch basket pressure leaf spring. This gap is selected when the driver begins to press the pedal.

— The full travel of the clutch pedal on VAZ 2105, 2107 cars is 140 mm.

— After adjusting the clutch drive, check for smooth gear shifting. Particular attention to reverse gear. The smoothness of its activation is an indicator of successful adjustment.

More articles on VAZ 2105, 2107 cars

How to adjust the clutch on a VAZ 2107?

Timely adjustment of the clutch on a VAZ 2107 will avoid wear of the release plate and other clutch parts. During vehicle operation, the travel of the clutch pedal may change, which leads to increased wear of the release plate. In this article we will tell you how to adjust the clutch on a VAZ 2107, which will help avoid car breakdowns.

Clutch device for VAZ 2107

Before we tell you about adjusting the clutch, let's talk about how this unit works on a VAZ 2107. This model uses a dry single-plate clutch, and the main drive from the clutch cylinder is located directly under the pedal. When you press the clutch pedal, the pusher begins to move, which fits into the corresponding socket in the master cylinder piston. Under pressure, a hydraulic mixture is squeezed out of the cylinder, which is directed through a pipeline to the working cylinder. Accordingly, such a working cylinder is connected via a pusher to the clutch fork. When you press the clutch pedal, such a fork moves the release bearing along the sleeve, connects and disconnects the clutch discs, which allows us to change gears. The presence of numerous moving elements invariably leads to frequent clutch breakdowns on the VAZ -2107. At the same time, timely adjustment and inspection of the condition of components will allow you to avoid serious breakdowns, which in turn will reduce the car owner’s expenses for servicing his car. That is why you should not neglect diagnostics of the clutch and its adjustment on the VAZ 2107. This work is not difficult, and its implementation does not require the use of any complex professional tools.

Determining the need for adjustment

The presence of even minimal play when pressing the clutch pedal is an indication for appropriate repairs. In case of any changes in the sensation of the clutch pedal, the car owner must make adjustments, which will help avoid increased wear of the corresponding components. Also, such service work must be carried out if, when you press the clutch pedal, the gearbox does not engage the gears well and the power does not release. You can clearly see how to adjust the clutch on a VAZ 2107 in the video that you can find at the end of this article. Indirect signs of problems with the clutch can be jerks when shifting gears, grinding and slipping. In this case, you should check the clutch play and diagnose the hydraulic drive.

Installation or replacement

Removing or replacing the clutch slave cylinder is carried out in the following order:

- Unscrewing the pair of bolts securing the cylinder body to the clutch housing.

- Disconnecting the pusher from the clutch fork.

- Disconnecting the hose connecting the clutch slave and master cylinders.

- Plug the hose with a suitable size plug to prevent liquid leakage.

Installing a new or repaired wheel cylinder is carried out in the reverse order, after which the system is pumped to fill it with brake fluid and remove air. During assembly, a special lubricant is applied to the pusher axis, usually CASMOLY L9508.

We adjust the clutch on a VAZ 2107, VAZ 2106.

Clutch adjustment for VAZ 2107, VAZ 2106 is usually required after replacing the clutch. Correct adjustment ensures longer operation of the clutch parts. Before you begin checking and adjusting the clutch drive, make sure and, if necessary, remove air from the clutch hydraulic drive. It is also advisable that the fluid in the hydraulic pipe be replaced with fresh one if it is used for a long time.

Adjusting the clutch drive comes down to ensuring clearance between the rod and the piston of the clutch master cylinder, as well as between the release bearing and the friction ring on the clutch basket.

The gap between the rod and the piston of the master cylinder is considered normal if it is 0.1–0.5 mm, which in turn provides free play of the clutch pedal to a value of 0.4–2 mm. This gap is adjusted using the pedal travel limiting screw.

The gap (2 mm) between the release bearing and the friction ring on the clutch basket can be determined by the amount of free play (4–5 mm) of the working cylinder rod.

It will be more convenient to check this gap on an inspection hole or a lift. To do this, we will do the following;

- Press the clutch fork, resting your finger on the clutch slave cylinder rod. The clutch fork should move freely relative to the rod by 4–5 mm.

- If the gap does not correspond to these values, the gap will need to be adjusted...

- ...to do this, use keys “13” and “17” to loosen the lock nut on the rod of the clutch working cylinder...

- ...and, holding the rod with a “8” wrench, we adjust its free play by rotating the adjusting nut with a wrench.

- After we complete all the adjustments, the free play of the clutch pedal should be 25–35 mm. Next, tighten the locknut.

When will we start repairing the clutch slave cylinder?

The clutch slave cylinder has a special location, and is traditionally located on the clutch housing. The design of the clutch slave cylinder does not differ fundamentally on different models and brands of cars. That is why the entire principle of repairing or replacing the clutch slave cylinder is the same, both on new foreign cars and on ancient domestic cars.

In order to make it possible to independently repair or replace the clutch slave cylinder, you need to know the device itself and the technology for disassembling it. This procedure (disassembly) of this mechanism is quite simple if you observe certain aspects when trying to penetrate inside the entire device.

How to adjust the clutch pedals on a VAZ 2107 car: instructions and

Instructions for adjusting the clutch on a VAZ 2107

Content:

The clutch system in every car is one of the key components of the control system, in the event of which failure it is impossible to continue driving. The clutch is controlled using a pedal. It’s probably not worth saying that this is a complex system that requires systematic care and attention, and any driver should be able to adjust the VAZ 2107 clutch.

Thanks to a correctly adjusted clutch, the risk of premature wear of clutch parts, for example the release plate, is significantly reduced.

Signs of a bad clutch

Let's try to understand in general terms the process of debugging the clutch. Why is adjustment necessary? If the adjustment is not carried out in a timely manner, this will subsequently lead to complex repair work or a complete replacement of the entire system. If the pedal stroke is increased, this will subsequently lead to incomplete shutdown; the disk will still be in contact with the motor flywheel.

If on the contrary, that is, the pedal travel is small, then the driven disk will not be fully engaged, as drivers say, slipping will occur, or loss of torque will occur.

System diagnostics

- Let's start with the simplest. We will need a regular ruler. However, measuring the pedal stroke will be required when problems occur during gear shifting or at start.

- If you start moving and at this time there are jerks or impacts, a crackling sound when changing speed, or the pedal sinks, these are clear symptoms that the system needs adjustment.

- Apart from this, you can personally carry out the diagnosis. You need to start the engine, slowly release the pedal and move away.

- If the car starts immediately when you release the pedal, this means insufficient free play. And otherwise, if the car does not move, even if the pedal is released, then this means that its speed exceeds the norm.

- Using a ruler or tape measure, measure the distance between the floor and the pedal - it should be 160 millimeters, otherwise it needs to be adjusted.

DIY master cylinder repair

To carry out the work, the entire assembly will have to be completely dismantled, having first disconnected all the pipes and drained the liquid from the system. You should also prepare in advance a repair kit for the clutch master cylinder, which includes all parts subject to wear. Despite the fact that the “composition” of the clutch master cylinder is not complicated, it is advisable to carry out the work by persons who have at least minimal experience in plumbing work. If the question of how to remove the clutch master cylinder is completely unclear, it is better to abandon repairs yourself and simply replace the cylinder with a new one.

Troubleshooting clutch problems on a VAZ 2107

The clutch of a car is an important, one of the most important components in a car. If the clutch fails, it will simply stop and stop driving.

Device

Everyone is accustomed to the fact that the clutch is a simple pedal located under the left foot. In fact, this is a complex system that requires constant attention and care. Let's understand the principle of its operation, it is not at all difficult. First of all, we need to understand that modern cars have a hydraulic clutch, like brakes. The incompressibility property is also used here. By pressing the pedal, the driver transfers force to the piston, which pushes the working fluid from the master cylinder through the tubes. Then the liquid flows through the tubes, after which it transfers equal force to the piston of the working cylinder. A rod is attached to the piston, which is adjustable in length. We'll talk about adjustments later.

So, then the force is transmitted through the rod to the clutch fork, which is made according to the principle of a rocker arm. Thus, the fork presses on the release bearing (that’s what it’s called), after which, under its influence, the brake disc moves away from the flywheel. This is necessary in order to disconnect the drive wheels from the crankshaft at the time of gear shifting.

Basic faults

Now let's talk about what can break in such a system. First of all, the rubber seals that are located in the working cylinder suffer. As a rule, their service life is approximately equal to the service life of similar seals in the main cylinder. To eliminate this type of malfunction it is necessary to replace them. Here all the work comes down to simply removing the indicated components, disassembling them and simply replacing the parts, namely small rubber rings, with new ones. It is not difficult. Particular attention should be paid to the working cylinder. The fact is that it is located in a very inconvenient place. All problems can be solved with a lift or inspection hole.

So, we must not forget that there is brake fluid in the system, so you need to take care to drain it in a timely manner, because the strong flow that will break through after you pull out the piston cannot simply be plugged with your finger. It is advisable not to touch the flare nut, because then you will have to adjust the free play of the pedal. In principle, craftsmen can cope with replacing the clutch slave cylinder repair kit without removing the cylinder itself. But this requires skill.

Another problem that can cause clutch failure is wear of the release bearing. To replace it, no matter how you look at it, you will have to remove the gearbox. There shouldn't be any further problems. The friction linings of the brake disc can also wear out; this procedure is described in one of our articles. This type of wear is not at all difficult to detect. The fact is that then the clutch will begin to make noise, and at first the noise will not be constant, but only at the moment when you release the pedal. Then it will begin to develop into a constant hum.

And finally, the most typical problem is air that has entered the system. It should not be there, because in this case the efficiency of work is seriously reduced. Let's look at how to remove it.

Bleeding the clutch on a VAZ 2107

First of all, you need to stock up on brake fluid so that the fluid does not leave the system. You also need to take care of the container that will be used for draining. It should be accompanied by a transparent hose with a diameter of 4-5 mm in order to put it on the fitting. An assistant should also become an integral tool. So let's get started. The clutch pedal does not have a return mechanism or spring: it returns to its place using a spring that is installed on the fork. But this effort alone is not enough, so at first the assistant will have to return it with his foot.

Clutch master cylinder - design, repair and replacement

If we simplify the formulation of the actions performed by the clutch drive, it will sound like this - the transmission of torque from the motor to the corresponding gearbox shaft with the ability to disable and then softly engage after switching to the desired gear. Nowadays, designers have not yet come up with anything more effective for achieving this goal than a hydraulic clutch drive. The diagram and principle of operation of the described device is simple: a depressed pedal acts on the clutch cylinder rod, which, accordingly, using hydraulic fluid located in the tank through tubes, activates, through the working cylinder, the fork and the release bearing.

Failure of the clutch drive occurs for several reasons, one of which may be a faulty clutch master cylinder; in order to repair it, it is advisable to understand its structure, signs indicating the inoperability of the mechanism, methods of repair, and if repair is not possible, then how to make it replacement.

Device

Possible malfunctions and their diagnosis

Repair work

If the pedal fails, in order to avoid unreasonable disassembly of the cylinder, it is worth initially pumping the system and expelling air from there that could get in when the liquid in the tank drops below the minimum permissible level. If this does not help in principle, it is worth starting repairs. For this case, there is a repair kit for the clutch master cylinder on sale, which, depending on the make of the car, contains the main wearing parts: cuffs, return spring, rod, retaining ring, etc.

The master cylinder is located under the clutch pedal. Depending on the car model, dismantling will have to be done either from the engine compartment or from the car interior, having previously dismantled the floor covering in the driver’s area. Having removed the clutch master cylinder, we begin disassembling it, after which we need to wash all the parts. During the subsequent inspection, after disassembly, it is worth paying special attention to the body and the condition of the rod and mirror; if there are visible scuffs, this may indicate the appearance of wear in the cylinder or wear of the rod. In general, experienced craftsmen recommend changing all the parts in the repair kit, especially the cuffs.

Clutch diagnostics

So, before you start repairing, check to see if the part needs to be adjusted enough. For example, frequent problems arise with the clutch, or more precisely with the release plate. Owners first of all blame the “basket”, they say, it has burned out, when you often keep the pedal in the active position in traffic jams.

In fact, it turns out that this is not at all the case, you need to tighten the clutch cable a little and everything will work out. At the same time, the need to replace the unit as a whole simply disappeared. Proper operating conditions for the clutch will ensure a service life of at least 70 – 90 thousand km.

Facts of a maximum mileage of 390,000 km have been recorded, however, this happened on the “famous” troika manufactured in those days. Some manage to “kill” the basket and disc within 50–60 thousand runs.

The cylinder repair is complete, what next?

After replacing the clutch master cylinder or repairing and reinstalling the old one, it is almost always necessary to bleed the clutch system. This is a necessary measure to eliminate accumulated air bubbles, the presence of which is not allowed in the hydraulic drive system. During repairs, air inevitably enters the system, and if it is not removed, clutch problems will soon arise. The whole pumping procedure is not so complicated and does not require much time. If the replacement was carried out at a service center, its mechanics use heavy vacuum pumps to remove air from the cylinder, and bleeding of the system is not required.

For bleeding, it is necessary to provide free access to the master cylinder, and for this it will be more convenient to drive some vehicle models into a pit or lift them on a hydraulic lift. New brake fluid is poured into the reservoir, a transparent tube is put on the fitting, the end of which is lowered into a container with the same working fluid. By rhythmically operating the clutch pedal, the hydraulic drive is pumped until the release of air through the fitting stops completely. After this, the fitting is tightened and the car is ready for use.

Despite the apparent “insignificance” of this procedure, the operating principle of the clutch master cylinder does not allow the hydraulic drive to function normally in the presence of air. If bleeding is not performed, even after replacing the unit with a new one, all the characteristic signs of a malfunction of the clutch master cylinder will very quickly begin to appear, negating all previously applied efforts.

How to adjust the clutch on a VAZ 2107

First, we need to make sure that such a procedure is necessary.

What tools will be needed for repairs?

We check in advance the availability of automotive tools needed for repairs, such as:

» data-medium-file=»https://i0.wp.com/avtoivan.ru/wp-content/uploads/2018/10/instrumenty.jpg?fit=300%2C201″ data-large-file=»https ://i0.wp.com/avtoivan.ru/wp-content/uploads/2018/10/instrumenty.jpg?fit=700%2C468″ data-lazy-src=”https://i0.wp.com/ avtoivan.ru/wp-content/uploads/2018/10/instrumenty.jpg?fit=700%2C468″ data-lazy-srcset=”https://i0.wp.com/avtoivan.ru/wp-content/uploads /2018/10/instrumenty.jpg?w=700 700w, https://i0.wp.com/avtoivan.ru/wp-content/uploads/2018/10/instrumenty.jpg?resize=300%2C201 300w, https ://i0.wp.com/avtoivan.ru/wp-content/uploads/2018/10/instrumenty.jpg?resize=90%2C60 90w" data-lazy-sizes="(max-width: 700px) 100vw, 700px" />