Some drivers joke that they can recognize from a crowd a person whose car has an old clutch - they clearly have a clubfoot on their left leg. But seriously, the problem of a tight clutch pedal and the associated double or even tripled load must be eliminated before problems with the knee joint of the leg appear.

Oddly enough, the problem of a hard clutch pedal exists on a variety of models and brands of cars with a manual transmission. An initially normal or slightly heavy clutch pedal can become stiff in both the cable and hydraulic clutch actuators. But in most cases, it is car models using a cable that suffer from this strange problem. In hydraulics, the percentage of such problems is lower. There are some peculiarities in the design of the basket, why the clutch pedal became tight without visible defects or breakdowns on the drive side.

In the overall picture, the main reasons for a tight drive pedal are the following:

- abnormal operation of the clutch basket diaphragm spring;

- the presence of local scuffing or local wedging of the release bearing, fork, friction disc on their supporting surfaces;

- a cable in a working braid that is partially torn and unraveled into wires.

The last point can be easily controlled independently, without the help or services of auto repairmen.

Lada Priora Sedan Pyrik › Logbook › Stiff clutch pedal. Part 1.

Hi all!

Of course, I understood that the pedal had become tight, but I tried not to pay attention to it, I sort of got used to it. But when I sat down behind my friend’s Shniva, I realized that my pedal was fucking tight. There were no jams, it returned well, but despite all this, it was necessary to press quite hard to squeeze it completely. Having climbed, as always, a huge number of sites and read a lot of articles on Drive, the symptoms look like a souring clutch fork. In order not to remove the box, it was decided to try applying grease through the boot and plug. The photo shows both the rubber boot of the fork (rectangular accordion) and the plastic plug (round). Liqui Moly LM 40 lubricant was purchased, price: 209 rubles.

I arrived in the village and, when I had some free time, decided to lubricate it. To make it easier to get to the plug, I removed the air filter from the mount and moved it towards the battery. The boot is easy to remove from its seat and move aside, but with the plug I had to work hard with two fingers, as in the first photo you can’t remove it. Firstly, it didn’t want to come out, and secondly, the hat began to break off, either because of my crooked hands, or it was sitting tight, or it was old... I didn’t know, but I continued to shred it. After the cap was all broken off, I took a screwdriver and began to hammer the remains inside, before putting a rag through the hole in the boot so that the pieces wouldn’t fall through. I broke the remains in half and, thanks to a rag, took out the main part successfully, but one piece did not want to come out, and thanks to “my luck” I still dropped the last piece... The plug is broken, let's pour grease on everything... I poured a fair amount, but did not achieve the effect, the pedal became softer, but still heavy. I got home without a plug. I parked the car and bought a plug only two days later.

VAZ 2108 markings. I think they are the same for the whole family. At home I looked at some more material about lubrication of the clutch fork and realized that I poured the grease a little in the wrong place; there are protrusions on the fork, due to which probably not all of the grease got to the lower bushing, because... it is she who sours.

In order for the lubricant to get on it, you need to pour the lubricant under the fork, but I poured it from above. Well, to consolidate the result, I took the good old oil can and added more oil to the fork.

Then he scored

I

just in the plug, because it fits quite tightly, having previously coated it inside with lithol.

I left the car and didn’t bother checking the clutch... An hour later I had to go to training and I was stunned. The pedal became elastic, but quite soft, compared to what it was - heaven and earth. I'm completely satisfied.

I also decided to lubricate the throttle cable, because I don’t like the operation of the throttle, the pedal is pressed not smoothly, but jerkily, which is very annoying in traffic jams. The car jerks constantly. I spilled the cable and lubricated the throttle assembly. Last fall, I also disassembled the pedal assembly and lubricated it, but this does not give any effect, the throttle cable and the clutch are new. Now, of course, it’s better, but the gas pedal’s jerky operation is annoying. If you have any useful advice on this problem, I will be glad.

Source

Cleaning a motorcycle chain with a silicone brush

Cleaning should be approached calmly, preferably in your free time, immediately after driving. The engine should be raised using a winch or center stand to allow easy access to the chain. Since the motorcycle is constantly exposed to dirt and you ride on different types of surfaces and in different weather conditions, the task will not be so easy. Don't forget to change into work clothes because it would be a shame to get your clothes dirty.

It's a good idea to purchase a motorcycle chain cleaning kit - for a small price you get the necessary prep, lube and a special brush that allows you to reach every corner of the chain. Of course, each of these elements can be ordered separately. It is also worth having a dry, clean cotton cloth on hand.

Adjustment instructions

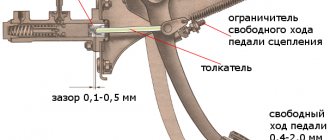

The Lada Priora is equipped with a clutch cable with a ratcheting mechanism. The cable is backlash-free and does not require adjustment, but manufacturers recommend this be done during every maintenance.

Clutch cable

To adjust the cable on the Lada Priora, you need to prepare a screwdriver and a ruler. The procedure then consists of the following steps:

Engine compartment of Lada Priora First, you should disconnect the mass air flow sensor and remove the air filter. Engine compartment without air filter

After this, a cable will be visible, at the end of which there is a plastic clip. Before adjustment, it is necessary to set the cable to its original position: overcoming the resistance of the spring, push the cable clamp forward until it stops in the direction of movement of the car. This clamp should be pulled towards you and the distance between it and the plug should be measured, it should be 27 mm.

We measure the distance using a ruler

The distance is adjusted by turning the tip counterclockwise. In this way, an increase in distance can be achieved. Twist the clamp until the distance is 27 mm. Accuracy is very important here. Now you can release the cable and place it in the fork. After completing the steps, you need to get behind the wheel and press the pedal three times until it stops. Then again you need to measure the distance, it must be exactly 27 mm, otherwise we adjust until the desired distance is achieved. Next, you should insert the tip into the groove of the mechanism fork and release it. Thanks to the spring, the tip driver clamp is installed without any gap. After adjusting the cable, you need to return everything to its place, start the engine and check the operation of the mechanism.

After adjustment, the clicks disappear and the clutch release pedal operates softer.

Clutch pedals

When the clutch pedal travel is large, the clutch is not completely disengaged, so it still comes into contact with the flywheel of the power unit. When the stroke is low, the driven disk does not turn on completely, which leads to slipping and loss of torque.

You should measure your pedal stroke if the following symptoms occur:

The symptoms described indicate that the mechanism requires adjustment. You can diagnose its operation on Priora yourself. To do this, start the engine, slowly release the PS and start moving. If, when the PS is released, the car immediately begins to move, this means that there is no free play. If the car does not budge even with the pedal fully released, then its travel exceeds the norm. The brake pedal should be at the same level as the brake pedal. In this case, its full stroke will be in the range of 125-135 mm. Fluctuations up to 160 mm are possible.

It wouldn't hurt to know

What do most owners of new Lada Priora do? Naturally, they treat the body with Movil or something similar against corrosion; they don’t have any more problems at the initial level. However, there were complaints about squeaking when pressing the clutch pedal; sometimes it was present when the engine was warm, sometimes only when it was cold - the essence is that there is a problem.

Of course, everyone immediately starts reading the “primer book” on how to correctly adjust the clutch on their Priora, which sometimes helps, but the fact of the matter is that sometimes. After this, owners can try several more methods, after which the squeak may disappear:

- Replace the drive cable, some drivers praise the “tenth”.

- Check the presence of a spring in the automatic tension mechanism; sometimes the effect can be achieved after replacing the standard part with a spring with greater elasticity.

- A certain percentage of car enthusiasts get rid of the crackling noise by lubricating the fork and the plastic cable nut.

- Lubricate the installation site of the plastic bushing on the pedal bracket with lithol.

- Remove the boot from the fork lever and lubricate the gearbox input shaft with graphite grease from a can.

It is worth considering another effective method, shown in the video, which is used by experienced car enthusiasts. Its essence is as follows:

- Disconnect the mass air flow sensor and remove the air filter.

- Remove the clutch release rod plug.

- Release the cable from the clutch fork.

- Pour 30-40 ml of gear oil from a syringe.

- Move the fork back and forth 10-15 times.

- Reinstall the cable, plugs and filter.

Using the example of the second part of the article, it becomes clear that adjusting the clutch drive does not always bring the desired effect in the fight for acoustic comfort. Although, from a technical point of view, the procedure is necessary, since it ensures productive operation of the car.

Reviews from car owners

If you look at the opinions of car owners about this component of the car, many note that it quite often creates problems. For example, some have to deal with tight pedal movement or the appearance of unpleasant crunching and clicking noises.

However, few people have to buy a complete clutch kit. Often a specific detail is enough. Therefore, most often it is enough to install a new cable or lubricate the jacket. Accordingly, even if this unit fails, repairs will not be as expensive as it might seem.

In general, car owners are satisfied with this car. It is inexpensive and does not require special care. If you do not use it in extreme conditions, then there should be no problems. It also performs well on difficult roads. Many note that modern foreign cars at the same cost have much worse characteristics.

What does the resource depend on?

A faulty clutch assembly can be recognized by the following symptoms:

- After pressing, the pedal sinks and does not return to its original position. The probable cause of the breakdown is a malfunction of the drive mechanism, a broken cable, or failure of one of the cylinders.

- When you press the clutch, the clutch begins to creak or other kinds of extraneous sounds appear (squeaking or humming). After releasing the pedal, creaking or other noises disappear or their volume decreases. This problem is usually caused by a broken release bearing (more on that below).

- The pedal is depressed without problems, there is no grinding or other extraneous sounds. However, it is still not possible to engage any of the gears. One of the reasons is the breakage of the petals on the mechanism basket.

- The motor runs smoothly, the speed selector easily moves to any position, and there is no extraneous creaking. Despite the absence of visual problems, the car has difficulty picking up speed and there is clutch slipping.

Many Renault Logan owners are interested in how long the clutch lasts. It is difficult to give a definite answer, because a lot depends on the driving style, timeliness and quality of Renault service.

“If the car owner treats the unit with care, lubricates and adjusts the mechanism in a timely manner, then the first problems appear only after 100 thousand kilometers. But in practice, the clutch unit runs less - up to 60-70 thousand kilometers, after which it requires repair or other restoration work.”

Most often, car owners are faced not only with squeaking, but also with more serious problems, including clutch malfunction (slipping). In such a situation, the only way out is to replace the faulty element or one of the parts. On average, a clutch kit costs 4-5 thousand rubles.

Why is the clutch pedal stiff?

Personal experience of Opel Kadett E

In fact, the problem that caused the drive pedal to become hard and tight has a complex basis and connects all three factors:

The most common is the first reason. The cunning design of the basket petals leads to the fact that over time the central part with the release bearing protrudes like a hump above the plane of the spring. To overcome this hump, you have to spend extra effort.

Often, the manufacturer artificially increases the stiffness of the petals to increase the durability of the diaphragm spring. This is especially true for Chinese counterfeits of branded products, such as Kraft or Sachs. With the installation of such a piece of hardware, the tight clutch pedal will not become any easier.

In addition to the spring, the release bearing also adds problems as it wears out. After 150 thousand km it will hang on the spring petals and give any conceivable distortions. The design of the release fork is such that it is on it that the main efforts converge and concentrate. This leads to deformation of its rotation axis and jamming in extreme positions, characteristic of a worn basket mechanism.

Very often a situation arises when the owner replaces the clutch basket with a new one, but in order to save money, leaves the fork. The new basket creates a huge resistance force and, as a result, the worn fork breaks at the most inopportune moment. In this case, the driver gets a dropped clutch pedal instead of a tight pedal.

Unexpected breakdowns along the way

You all know that the road is a real test for the driver. And if, in addition to all this, some kind of car breakdown occurs, then the person experiences even more stress. In this article I would like to talk about the car’s clutch, which may not withstand city travel. Sometimes it happens that the pedal fails. Of course, you can start to worry. But you need to find out the real reasons for this behavior, and then conclude that this breakdown is not very serious, you can fix it on the way, get to the nearest service center or to your home. If the clutch pedal suddenly gets stuck, don’t despair; it’s not difficult to solve this problem.

Let's sum it up

Taking into account the above information, it becomes clear that there are many reasons why the clutch pedal is tight or the clutch is hard. In the process of troubleshooting, you should step by step check the pedal mechanism itself, and then move on to the clutch elements, cables, rods, etc.

Ignoring this rule often leads to the fact that a tight or hard clutch pedal can come as a surprise to the driver while on the road. The clutch pedal also fails, the clutch may not “grab”, etc. To avoid such unforeseen breakdowns, the quality of the clutch must be checked at every scheduled maintenance.

KBM with unlimited insurance

KBM, or bonus-malus coefficient, is used to calculate compulsory motor liability insurance

By taking out a policy in any option, the driver can count on his discount for accident-free driving being taken into account. In accordance with the law, recalculation of the KBM is allowed in the event of a transition to an open form of the MTPL insurance policy.

When applying for compulsory motor liability insurance with a limited number of drivers, the CBM of the motorist with the highest indicator is applied. With unlimited insurance, the car owner's coefficient is taken into account.

For each year of accident-free driving, a discount of 5% or 0.05 KBM is awarded. With the occurrence of each insured event, the coefficient worsens by 0.15 or 15%.

This means that the cost of the policy will increase by 15% if an accident occurs due to the fault of the policyholder.

When an OSAGO policy is issued for the first time, the driver will have a basic 3rd class of insurance. This will be used to determine whether insurance prices will become cheaper or more expensive.

The KBM for open insurance is checked using the following data:

- last name, first name, patronymic of the owner;

- passport series and number;

- VIN number of the car.

How to deal with a tight clutch pedal

Most drivers do not want to put up with this state of affairs and try in every possible way to improve the performance of the clutch.

Among the most common recipes for dealing with a tight pedal are the following:

Important! All of the above methods, to one degree or another, can effectively deal with a tight clutch pedal. The first recipe will be the best and most effective.

In addition to cable drives, hydraulic systems also suffer from similar problems. But, unlike the cable, due to the high force on the clutch release fork, the cylinder cuffs are destroyed first, and brake fluid leaks.

The video shows what a stiff clutch pedal is and how to fix the problem:

When pressing the clutch pedal we definitely have to apply some kind of force, but there are situations when it is pressed too hard. In such a situation, we are dealing with the problem of a tight clutch pedal. There may be several reasons for such a breakdown. The most common of them are sticking of the lever or cable, wear of the fork bearing. So, in order to restore the correct functioning of the pedal, you first of all have to deal with the so-called symptom of the breakdown (or what led to the breakdown).

So, if the clutch pedal becomes stiff as a result of wear on the fork bearing, then when you press the pedal, you will hear some rumbling, which indicates that the release bearing has already served its purpose and needs to be replaced with a new one.

The mechanisms developed in our time are designed to cover long distances (more than 1,300 thousand km), if the driver regularly diagnoses them and the necessary replacement of worn parts.

But if the system is treated carelessly, then it will serve you no more than 50 thousand km. In large trucks, problems can also arise with new, not yet ground-in elements.

You also need to check if everything is in order with the release bearing; it may be damaged and this may cause problems with pressing the pedal. It is also worth checking the diaphragm spring, which is located on the pressure plate, for damage. If you are well versed in your car, then you can perform this type of check yourself, but for a better result, you should still contact the service station workers.

Causes of wear

The main reason for the breakdown of this element is long-term operation of the VAZ 2110 car in poor conditions. For example, a car is stuck in a snowdrift, the driver has to accelerate frequently, which affects the condition of the part.

Separately, it should be said about the correct operation of the machine. With a sharp start at high speeds or with regular movement, when your foot is on the clutch pedal, which causes slipping, this is also a wear factor. Operational reasons are not the only ones. Cable wear may occur earlier than expected due to the following factors:

- low quality cable installation;

- Carrying out repair work with many mistakes;

- ignoring the first signs indicating a breakdown.

Every factor must be taken into account to avoid unexpected damage and expense.

What to pay attention to

There are certain signs that the clutch on the Lada Grant has failed and action needs to be taken. It is worth paying attention that if the car has just been purchased, the pedal will be pressed quite easily. If this requires great effort, then this is the first evidence that the clutch needs to be adjusted or replaced.

It is also worth paying attention to the appearance of extraneous squeaks at the moment when the driver presses the pedal. In addition, it should not twitch when the car owner does not touch it.

Most often, car enthusiasts are faced with the fact that the pedal travel becomes too tight. It is worth considering in more detail the reasons for this problem.

Drive system design and symptoms of malfunction

The pressure mechanism is controlled by the leftmost pedal. A well-designed lever ensures easy movement of the release disc petals. In this model of machine, commands to move the fork are supplied by a cable. He “walks around” in a matching shirt. It is worth noting that an automatic cable length adjustment system is implemented here.

Symptoms of a problem

On a new car, the important pedal assembly moves easily. Violation of the factory condition requires stopping operation and identifying the reasons. Usually, along with tight movement, related symptoms occur that indicate a malfunction of the assembly module:

- Extraneous squeaks during pedal movement.

- Jerky movement of the pedal.

- The need for frequent adjustment of the idle speed of the lever.

- The machine jerks when connecting the box to the motor.

Bleeding the clutch

When bleeding the clutch system, it is necessary to control the pedal. When inflated and the outlet fitting is open, it is necessary that it drops to the floor when pressing on it. It is better to perform these manipulations with a partner. When it collapses under the pressure of the assistant’s foot, a characteristic noise of gurgling air bubbles is created. This procedure must be repeated several times.

With a fully functional clutch system, the pedal returns every time it is released, but if it fails again, it means that something is wrong and it is necessary to re-diagnosis and repair.

Everything you wanted to know about the Ford Fusion but didn't know where to ask

Required Tools

Before starting work, it is important to prepare all the necessary tools. Here's what you'll need:. Welding machine - is a heating element with nozzles for different pipe diameters

Some models have a thermostat to maintain a set temperature; working with these devices is much easier

Welding machine is a heating element with nozzles for different pipe diameters. Some models have a thermostat to maintain a set temperature; working with these devices is much easier.

If you do not plan to use this device in the future, then there are many services where you can rent a welding machine for the duration of the repair. So you don't have to buy it.

Scissors. You can cut the pipe with a hacksaw, saw or even a grinder, but the quality of the resulting surface will be unsatisfactory. It is much more convenient and practical to purchase special scissors for these purposes.

Gloves to protect your hands - choose thick ones that do not conduct heat well. This will protect you from getting burned.

Shaver. The device removes the outer aluminum layer when working with reinforced pipes. The tool may not be useful, depending on the type of material

Trimmer. The device is designed to remove part of the internal reinforcement. This is necessary to avoid water getting between the layers of the pipe.

Degreasing agent. Necessary for cleaning the pipe from dirt and grease. You can use ethyl or isopropyl alcohol. It is not recommended to use acetone; it can soften polyvinyl chloride.

Hydraulic failure

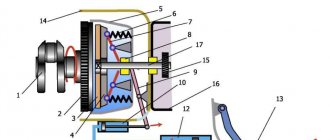

Some VAZ models have a hydraulically driven clutch. This system involves:

Here the base of the pedal is fixed to the piston rod of the latter. Pressing it squeezes out the liquid, and it goes into the working cylinder, which acts on the fork. Thus, the pedal on a VAZ can fail if the system loses its tightness. First of all, you need to see whether there is enough liquid left in the tank located in the engine compartment. Proceed like this:

Types of connection of polypropylene pipes

When polypropylene is heated, mutual diffusion occurs - mixing of particles. What’s characteristic is that when it cools, the reverse reaction does not occur; the part becomes monolithic. This quality is used when connecting two pipes. Let's consider how the result is achieved.

Socket welding

This principle is most popular due to its simplicity and accessibility. To connect pipes of the same diameter, a special part is used - a coupling. Its internal diameter is slightly smaller than the external diameter of the pipes being welded.

Welding occurs due to heating and melting of the outer surface of the pipe and the inner surface of the coupling. Then the pipe is inserted into the coupling, the operation is repeated with the other part, and the connection is complete.

Butt welding

This principle is applied in production. To connect pipes of the same diameter, their sides are melted and then joined into a joint. The method is complicated in that it is necessary to ensure perfect, precise alignment, which is impossible at home.

Cold welding

Cold welding (using glue) is another type of connection. A special glue containing a strong solvent is applied to the pipe. It softens the surfaces of the pipes and they can be inserted into each other.

The big disadvantage of this method is the low strength and tightness of the resulting connection. Another disadvantage is the drying time – a day or more. This is where cold welding loses to thermal welding.

At home, it is advisable to use connections using couplings. We will consider this method in more detail.

Features of the Lada Priora clutch

Any motorist interested in how to adjust the clutch on a Priora should know about the presence of the drive cable auto-adjustment function. That is, VAZ designers took care of the owner and saved him from the need to constantly adjust the clutch drive mechanism during operation. The same ratchet-type system is installed on Kalina , but both there and on Priora it is impossible to do without periodic adjustments. This factor has been proven by practice and forum discussion pages.

How does an automatic cable tensioner work?

In the release drive on the VAZ 2170, there are no gaps as a concept, hence the name - backlash-free clutch. The ratchet mechanism serves to compensate for the working length of the cable as the driven disk linings wear out. To understand the process, it is important to accept the following data:

- During operation, the driven disk wears out and its linings become thinner - as a result, the release bearing and basket springs shift towards the gearbox.

- Accordingly, the fork at the place where the cable is attached moves towards the radiator.

- The spring located on the bushing of the adjusting mechanism is compressed at this time and tightens the clamps of the cable tip.

- As a result, the tip is pulled out of the driver, due to which the wear of the disc linings is compensated.

For those who don’t yet know how to adjust the clutch on a Priora themselves, it is important to take into account the moment when the linings are new. In this case, when releasing the pedal, the ratchet bushing will only lightly touch the bracket without releasing the clamps. Therefore, the toothed tip of the cable will not move relative to the housing. Only as the linings wear out does the spacer sleeve release the spring-loaded clamps and the cable tip extends to the amount necessary to balance the worn parts.

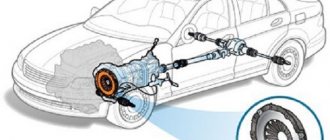

Mechanics

Mechanically, the clutch operation process is extremely simple. Let's analyze it from the moment the movement begins. After starting the engine, the car is in neutral gear (starting the engine in gear is bad manners). The clutch is depressed all the way - this means that it is turned off, the driven and pressure plates have separated, that is, a moment is created to change gear. The gearshift lever is moved to position 1, and first gear is engaged.

The pedal is smoothly released (the clutch is engaged), at this moment the most important thing happens: the distance between the pressure plate and the driven one is constantly decreasing, and the force transmitted by the engine has already set one disk in motion, which makes the moment of “collision” of the two disks become difficult. If the pedal is released abruptly, they will quickly touch, which means that the disc will pause (imagine walking and tripping over a stone - much the same thing happens with an engine).

The engine may stall, or in the best case, the car will simply “bite.” At such moments, the “petals” on the driven disk suffer greatly - the more “flattened” they become, the closer the time for replacing the “hitch” is. If the discs come into contact smoothly and the driven disc is slowly set in motion, the car starts from a standstill.