Hi all. Today's article will be devoted to the clutch, or rather its malfunction. We'll talk about why the clutch pedal fails, the reasons why it happens, and how to fix it.

The trouble with a clutch failure is that shifting gears becomes impossible, which means driving such a car is out of the question. The first question that arises in your head is: “How to get to the service station when the clutch pedal has failed”?

Let's figure it out; naturally, we'll take domestic VAZs as an example, since our site is dedicated to cars of this particular brand.

First of all, let’s clarify something... If anyone doesn’t know, then VAZ from 2101 to 2107 has a hydraulic clutch, “, , and”, as well as “Kalin”, etc. have a “cable” clutch.

The clutch pedal of the VAZ 2106 fails

- Registration

- Entrance

- To the beginning of the forum

- Forum Rules

- Old design

- FAQ

- Search

- Users

- List of forums AUTOLADA.RU

- "Classic"

You will progress as far as you can travel - Kh.Z.

True, on older machines, faults take a long time to develop, so you’ll most likely make it to the base . But perhaps not.

The hydraulic clutch assembly (pipe + master and slave cylinders) costs around 1000 rubles (when I changed it on an old car, I couldn’t unscrew the tube, I had to cut it and replace both cylinders), and it can be changed in a couple of hours.

They are not sold “assembled” - the tube is placed “in place”. The working cylinder is assembled - with a rod and boot. And it happens without them. It’s better to take it with a stock - it’s actually a consumable. You also need a rubber hose and a clip to secure it.

You can drive like this for a year and you will die smoothly. But such driving is terribly infuriating, especially in the city

before it was much lighter and grabbed closer to the floor

bleed the pedal became tight and began to grab at the end

How much longer can you drive like this?

I started to grasp at the end, before it was much easier and grabbed closer to the floor, your verdict, why is this?

After pouring drinking water into a Movil flask, it turned dark after a few minutes of shaking. Question: why did it darken and is it safe to drink now? Is it possible to use a flask of dirty water as a pressure when making a herbarium album?

Let's get to the point: does the hydraulic drive work now or not? If you don’t like the color, change the brake until it clears up (which is unlikely) - but if you’re concerned about aesthetics, you can change the floor of the car

Almost the same problem. In the morning the clutch pedal is half empty. It started up, warmed up a little and that’s it, the clutch works fine. While driving, sometimes dips appear, but immediately disappear.

The symptoms appeared after standing in a traffic jam on an uphill highway. Looks like I set the disk on fire.

Methods for solving the problem

If the clutch pedal fails while driving a car, then there are not many ways to solve the problem. We recommend that you familiarize yourself with all the methods so that in the event of a corresponding breakdown you know how to behave.

Replacing the cable

To replace the cable, you will need the cable itself, as well as wrenches and pliers. It is advisable to use a spanner or open-end wrench, this will be much more convenient.

But if you don’t have a box and open-end wrench on hand, you can also use a regular wrench:

- Open the hood of your car. In the engine compartment you need to find the very place where the cable is attached to the tip. Since a break occurred, most likely the tip remained in the installation location, and the cable itself was dangling. You need to remove the tip using a wrench.

- Then get inside the car and disconnect the cable directly from the clutch pedal. Remove the cable.

- Take the new cable and install it in place of the old one, the entire assembly occurs in the reverse order.

- You need to measure the free code of the pedal, and then adjust the installed element. The free play should be no more than 3 cm, and the total should be no more than 14.7 cm. The accelerator travel is adjusted using the nuts on the end of the cable in the engine compartment.

1. Unscrew the fastening nuts

2. Remove the locking bracket

3. Adjust the new cable

We recommend: Replacing the low beam bulb on a Lada Priora: 3 best brands and step-by-step replacement technology

If the spring breaks

If the return spring bursts, the procedure will be different. To replace, you will need the spring itself; if you do not carry it with you, you will have to go to the nearest spare parts store.

How to change a spring:

- Open the hood and use a wrench (it’s more convenient to use a spanner) to unscrew the cable nut. You need to extract it.

- Carefully, so that the remains of the old return spring do not fall apart, remove them. Please follow all safety rules.

- Take the new part and install it in place of the old one. This also needs to be done carefully, since in this case it is very easy to damage your hand or fingers.

- Then reinstall the cable. Tighten the nut. After this, adjust the free and overall travel of the pedal. Start the engine and try to drive it.

1. Unscrew the fastening nut.

2. Remove the spring and replace it with a new one

How to get to the service station on your own?

Of course, it will be better for the driver if this breakdown occurs near his home, then you can consider yourself lucky. But if this happened on the road, and the nearest service station is not so close that you could push the car to it, then this is already a problem. But there is a way out of every situation, so if the clutch pedal fails, you can still get to the nearest service station, and now we’ll tell you how.

To drive in first gear - if you need to restore the pedal's functionality, you can do the following:

- The gearshift lever must be moved from neutral to first gear. In this case, the gas must be released.

- Start turning the key in the ignition. When the engine tries to start, apply gas, but do it so that the car does not stall.

- When the car starts to move, do not try to change to the next gear. This is fraught with breakdown of the gearbox, and its repair, believe me, will cost more than calling a tow truck.

In general, the same method allows you to start moving at second speed.

But before you do this, check out some important points:

- When the pedal fails, do your best to stop the car on a downhill slope or on a straight road without the car rolling backwards.

- Warm up the engine before driving.

- Before you start moving, carefully consider your entire route, because you need to take into account all the nuances. This includes the number of intersections, traffic lights, where you should turn from and where, and so on. It will be more convenient to drive only on the main road, so that you don’t have to stop to let other cars pass.

- Turn on the warning lights (hazard warning lights).

- Avoid unnecessary maneuvers and remember that no one knows about this problem except you. It’s better to stop once again and repeat the procedure than to create more serious problems for yourself.

- If you are not sure that you can cope with such a task on your own, then maybe it makes sense to call a tow truck or tow the car to a service station?

The clutch pedal falls all the way when pumping on a VAZ

- How to nap the chipping cylinder on a VAZ 2101? – 5 answers

- The clutch doesn't work well! – 4 answers

- It is difficult to change gears on a VAZ 2101 - 3 answers

- I can’t bleed the VAZ clutch – 3 answers

- Clutch disappears - 2 answers

How to bleed the clutch is described below or provided in this article; if the clutch does not bleed or does not engage, then the problem may be in the clutch master cylinder (MCC), in the clutch slave cylinder.

If anything, then repair - replacement of hoses, replacement of cuffs

The pedal falls, but the clutch does not release, then this means there is air in the hydraulic system. Or the cuffs in the clutch master cylinder have worn out and are leaking brake fluid.

Previously, when there was a shortage of spare parts. parts, bought cuffs, removed and sorted out the main clutch and clutch slave cylinder. But this did not always help, because the cylinder mirror also wears out, and the seal could not be obtained even with new cuffs. Time was wasted on rearranging the cuffs in vain and we had to look in stores for a new clutch master cylinder or clutch slave cylinder.

With the clutch slave cylinder it is easier, or rather faster, it was clear if it does not work, the cuffs are leaking, then it is wet, the fluid decreases in the reservoir. If you still go through it and install new cuffs, then after filling the brake fluid you will also see whether the new cuffs are holding or not (meaning, if they don’t hold, then there will be leaks from the cylinder, it will get wet again and not work).

But with the master cylinder it may be different. Let’s say the working cylinder is working properly, that means there is “trouble” in the main circulation system. If the cuff that is closer to the passenger compartment is worn out and the brake fluid leaves the reservoir, then dampness will appear in the passenger compartment, where the rod enters the clutch from the pedal, through the engine shield. If the interior is dry, in the sense that fluid does not come out near the rod, and there is no decrease in the reservoir, and there is no pedal pressure, the clutch does not disengage, then the second cuff is worn out, it bypasses the brake fluid, the fluid is driven through the cylinder itself and is not pressed into the system. You can, of course, buy cuffs and sort out the main fluid circulation system, it may help, but maybe not if there is a large hole in the walls of the cylinder (sometimes an oval hole is packed). Now they make it simpler, buy a new cylinder and install it.

A small hint (but important): in order not to have to suffer for a long time with pumping the clutch, before installing the clutch, you need to pump it by hand, that is, pour the brake fluid into the reservoir and pump the piston several times with the piston pusher. As soon as the liquid flows out of the outlet, plug it and install the GCS in place. Then, when the cylinder is in place, remove the plug and connect the tube. A little brake fluid will leak out, but it’s not a big deal, you’ll need to add more to the reservoir, the main thing is that it doesn’t completely leak out of the reservoir, because if additional air gets through the reservoir, then again you’ll have to pump the air for a long time and persistently with the pedal.

And if the clutch is pumped and there is already brake fluid in it, then after installing it in place, the clutch starts working almost immediately; there is little need to pump. This is if the worker is in good working order and there is liquid in it.

If you only checked the working cylinder, then you don’t have to push it with the pedal for a long time either, just open the bleeder fitting and wait a few minutes. Monitor the brake fluid level in the master cylinder reservoir and top it up on time.

Well, actually, if you don’t miss the start of fluid flowing out of the working cylinder, then a little of it will flow out. Close the fitting. Test the clutch pedal. If everything is done carefully, then sometimes there is no need to bleed, the clutch works immediately, there is a release. Even if the squeeze is not full, in the sense that there is some air in the system, then bleeding does not take much time, it will quickly pump and the pedal will work as it should and the clutch will disengage.

Yes, if you installed a new clutch, then adjustment is needed on the clutch slave cylinder rod.

The drive is working - we are looking for another reason

If the pedal fails, and you find out that the drive is in working order, then the reason is more serious - the clutch mechanism itself has broken down. There are several possible faults:

- the axis of the release fork gets stuck - the most “successful” type of breakdown;

- damage to the release bearing (clutch release);

- Damage to the diaphragm spring of the drive disc.

To accurately identify the cause of the malfunction, you need to completely disassemble the clutch mechanism and inspect it. To do this you will need a pit or overpass. Repairs are carried out only by replacing worn parts.

The clutch pedal of the VAZ 2106 fails

Inveterate Zhigulist

Group: Zhigulists Messages: 715 Registration: 7/31/2008 From: Tomsk User No.: 4176 Car: Hyundai Accent Color: Blue Year of Issue: 2008 Thanks said: 4 times

Good day !

Something went wrong today. I was driving as usual, drove about 20 km from the start of the journey, and then before a turn I squeezed the clutch and the car almost stalled. The free play of the clutch pedal has increased by almost half of the entire travel. Somehow I got to work. When idling, you simply depress the clutch and the revolutions drop sharply from 2 thousand to 900. When you release, they return to place. I looked at the brake fluid and there are no drips, the level is normal. The working cylinder rod and fork move normally. I thought maybe it was bent or broken. I went to the service center for diagnostics. The serviceman looked and said that everything was ok with my clutch (like a fork, release and both cylinders). But I wasn’t there and I don’t know what he was watching. But I didn’t remove the box for sure. 1) Is it possible to determine whether the release valve is intact or not without removing the gearbox? I changed the fork boot, of course nothing changed.

We conduct an inspection and analyze the situation

Disassemble the joint in which the head cylinder rod is connected to the clutch pedal mechanism. If the pedal return spring is broken, the lever will freely rotate on the hinge to its previous position. A similar situation occurs with a spring that pushes back the clutch release tab and the working cylinder rod mounted on the engine crankcase. From time to time, the springs look intact, but their stiffness and elasticity are obviously not enough to return, due to poor hydraulic performance. Therefore, it would not be superfluous to remove and check their functionality.

Most of the symptoms indicate a recurring pattern of malfunction, due to which pedal turns poorly or does not turn at all. If the prerequisite for poor performance was a weak spring, the lack of pedal return would remain unchanged.

Diagnosis of clutch problems of a VAZ 2106 car without contacting a service station

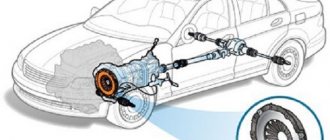

The clutch, as a separate hydromechanical unit in a vehicle, is responsible for the interaction of the power plant and transmission. The clutch of the VAZ 2106 and the entire range of VAZ models with rear-wheel drive are no exception.

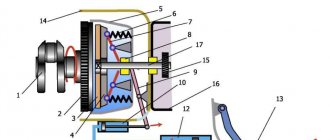

Clutch device

The “six” is equipped with a dry clutch with 1 disc, operating in a permanent closed mode. It is equipped with a spring pressure element located in the center and a vibration damping device located on the driven clutch disc. The mechanical section of the unit is a non-separable part, which includes a protective housing, a push-action clutch disc and a diaphragm-type spring. The protection housing is attached to the flywheel with special mounting-type bolts and pins. This disc is mated to the safety housing with 3 pairs of steel plates that connect the clutch disc and the protective housing part.

With the help of locking fasteners, the VAZ 2106 clutch basket (also known as a pressure disk) is articulated with the outer segment of a diaphragm-type spring. The spring itself is directly held on 2 rings of the protective housing part with rivets. The 12-sector standard clutch disc with driven slots is made of steel. Friction linings are connected to the sector elements of the product separately from each other. To attenuate passive torsion pulses, the VAZ 2106 clutch mechanism contains a damper located between the hub and the driven disc.

The hydraulic part of the mechanism consists of the GCC and RCS (clutch master and slave cylinders), as well as a clutch fork, a release bearing, a fluid reservoir and a clutch foot pedal with a spring. The reliability of the clutch mechanism, the price of which is quite high, depends not only on the length traveled during the period of operation, but also on the conditions of its functioning and the degree of load. If the clutch fails in a VAZ 2106, this means that, most likely, you will need to adjust the size of the free movement of the foot drive.

Sometimes it happens that the clutch pedal fails due to a break in the cable of this mechanism. If the VAZ 2106 clutch slips, then an accelerated wear process occurs, the so-called. "ferrado", i.e. friction linings of the disc, clutch basket diaphragm and flywheel interacting with the engine. The lack of free movement of the foot drive also indicates wear of the clutch basket. The dismantling and repair of this important unit can be seen in the film “VAZ 2106 clutch”, video instructions for which are presented in the next viewing frames on our Internet portal.

Clutch faults

There is a list of VAZ 2106 clutch malfunctions, which are presented in the table in this article. If the clutch is lost, you should look for a defect in the unit here:

Clutch faults

How to fix

The table shows the most common clutch malfunctions in practice.

Preparing to adjust the clutch

Some car owners are wondering how a VAZ 2106 can cost less and be better without hiring expensive professionals. Therefore, our article outlines how to carry out the entire complex of technological operations for adjusting the clutch of a VAZ “classic” with your own hands in a garage or inspection pit.

It should be understood that if deficiencies appear in this mechanical assembly, then adjustment of the clutch is required to allow correct functioning. Adjustment, a video about which is located on the Internet, is needed when pressing the foot pedal for turning on this mechanism unit reveals shortcomings in the operation of the unit. Such malfunctions include:

- dips when pressed;

- there is no complete integration of the mechanism in the working joint with the box with loss of elasticity;

- other possible shortcomings.

The clutch on a VAZ 2106 is lost. The clutch pedal on a VAZ 2106 has failed

Help me please. The clutch pedal on a VAZ 2106 fell through, I looked into the fluid reservoir. It's empty. Can I just add liquid or what should I do? Is this fluid reservoir also used for the brakes? Maybe I braked and the fluid flew out somewhere through a pipe and because of this the clutch was lost? The clutch on the VAZ 2106 was lost.

Similar articles

32 comments on “The clutch on the VAZ 2106 is lost. The clutch pedal on the VAZ 2106 has fallen out”

First of all, you need to find the leak, fix it, then add fluid, bleed the clutch, and you’re good to go.

If my memory serves me right, there should be a separate tank there

Did you even understand what you wrote?

How can you drive like this and not look under the hood before leaving? You need to know basic things. And if there is no liquid in the reservoir, then what did you use to brake it? Handbrake? Or, before the trip, I decided to look under the hood, and oh my God, what do I see: there is no fluid in the brake reservoir.

Dmitry, what should I look there? Everything worked great, the liquid just flew out

Pavel, yes, exactly, there are 2 tanks there

Pull back the carpet under the steering column and check for signs of leakage from the master cylinder. Then dive down

Svyatoslav, where to go down? What should you watch?

As far as I remember, there are two barrels on the classic...

Dmitry, yes, that’s right, 2 tanks, I’ve already figured it out. What should I do with the clutch, where did the fluid go, what should I do now?

Pour the fluid into the reservoir, park the car in a clean place and press the clutch pedal... and you will see where it leaks...

Dmitry, Got it, thank you

Dmitry, do you put regular brake fluid in there?

Vyacheslav, working cylinder, oil seal leak

On the box, look at the clutch slave cylinder in the classic, this disease is starting to leak

Vyacheslav, it's too slow

Vyacheslav, of course I don’t know, I have a ten, but preferably the same one should be poured in...

Off-topic question, sorry, it's already frozen... the horn is constantly screaming, if you remove the relay, will it stop?

Clutch fails: causes and repairs

The manual transmission is simple, reliable and has a long service life. At the same time, the clutch in a manual transmission is considered a “consumable material” with a rather limited service life. In addition, if the car is actively loaded, errors are made when servicing the clutch, and the car is operated in difficult conditions, some clutch components may fail after 60-80 thousand kilometers. km on a new car.

As a rule, quite often owners of cars with manual transmission encounter a breakdown when the clutch pedal fails. The reasons for such a breakdown may be different, since a manual transmission is an assembly consisting of a large number of parts and mechanisms. Next, we will look at why the clutch pedal failed, as well as what needs to be done if the clutch fails.

The clutch has fallen: why does the clutch pedal fail?

Firstly, such a breakdown in the absence of clutch can occur completely unexpectedly. To accurately determine the malfunction, it is important to know why the clutch fails and what needs to be done in such a situation.

In short, the clutch is needed to "disconnect" the engine from the transmission so that gears can be engaged and disengaged and the car can idle.

The driver independently controls the clutch using the pedal. When the pedal is depressed, force is transmitted to the clutch basket through a series of mechanisms. This allows the clutch disc to retract and interrupt the transmission of torque from the engine to the transmission.

Firstly, a sticking clutch pedal usually occurs for the following reasons:

- The return spring has failed. The clutch return spring provides the resistance that forces the pedal to retract after the driver stops applying pressure to it. If you simply remove your foot from the clutch, the pedal itself should return to its original position. If the spring is broken, twisted, or severely worn, the clutch pedal may not return or may drop. To solve this problem, it is necessary to disassemble the return mechanism and replace the spring; Another problem on the list is clutch fork damage. As a rule, these forks need to be replaced, as they actively wear out and then become damaged during use; The clutch cable is damaged (the clutch cable is broken/broken), the clutch cable fastening is damaged. In this case, the clutch cable must be replaced; Air in the hydraulic clutch. In some cases, you can fix the problem yourself, although this is not always possible. You will actually have to bleed the clutch. The most important thing is to have the correct keys and a supply of brake fluid. The master cylinder (MCC) is damaged. This element can be damaged for many reasons (damage to the actuator mirror, crack or damage to the clutch master cylinder flange, etc.). In some cases, repairing the master cylinder by replacing the seals with new ones from the master cylinder repair kit helps. . If the master cylinder mirror is damaged, it is better to replace the entire part immediately.

- The return spring is broken. A suitable clutch return spring creates resistance that pushes the pedal back after the driver has stopped pressing. If you simply remove your foot from the clutch, the pedal itself should return to its original position. If the spring is broken, twisted, or severely worn, the clutch pedal may not return or may drop. To solve the problem, it is necessary to disassemble the return mechanism and replace the spring;

- Another problem on the list is clutch fork damage. As a rule, this fork needs to be changed, since it actively wears out and then becomes damaged during operation;

- Broken clutch cable (broken/broken clutch cable), the fastening of the end of the clutch cable is damaged. In this case, the clutch cable must be replaced; Air is trapped in the hydraulic clutch actuator. In some cases, you can fix the problem yourself, although this is not always possible. You will actually have to bleed the clutch. The most important thing is to have the correct keys and a supply of brake fluid.

- The master cylinder (MCC) is damaged. This element can be damaged for many reasons (damage to the actuator mirror, crack or damage to the clutch master cylinder flange, etc.). In some cases, repairing the master cylinder by replacing the seals with new ones from the master cylinder repair kit helps. . If the master cylinder mirror is damaged, it is better to replace the entire part immediately.

- The return spring is broken. A suitable clutch return spring creates resistance that pushes the pedal back after the driver has stopped pressing. If you simply remove your foot from the clutch, the pedal itself should return to its original position. If the spring is broken, twisted, or severely worn, the clutch pedal may not return or may drop. To fix the problem, it is necessary to disassemble the return mechanism and replace the spring;

- Another problem on the list is clutch fork damage. As a rule, this fork needs to be changed, since it actively wears out and then becomes damaged during operation;

- Broken clutch cable (broken/broken clutch cable) or broken clutch cable end fastening. In this case, the clutch cable must be replaced; Air in the hydraulic clutch. In some cases, you can fix the problem yourself, although this is not always possible. You will actually have to bleed the clutch. The most important thing is to have the correct keys and a supply of brake fluid.

- The master cylinder (MCC) is damaged. This element can be damaged for many reasons (damage to the actuator mirror, crack or damage to the clutch master cylinder flange, etc.). In some cases, repairing the master cylinder by replacing the seals with new ones from the master cylinder repair kit helps. . If the master cylinder mirror is damaged, it is better to replace the entire part immediately.

Diagnosis of clutch faults VAZ 2106 Zhiguli

Oiling of the flywheel, pressure plate, friction linings of the driven disk

Thoroughly wash oily surfaces with white spirit or gasoline and wipe them dry. Replace the heavily oiled driven disk. Eliminate the cause of oiling (oil leakage through the cuffs of the engine and/or gearbox)

Severe wear or burning of the friction linings of the driven disk

Replace the driven disk assembly

Reduced diaphragm spring force

Replace the pressure plate assembly with the clutch housing (“basket”)

The piston of the clutch master cylinder slowly returns to its original position due to swelling of the rubber cuffs

Replace the cuffs or cylinder assembly. If you suspect gasoline or other solvents have gotten into the clutch fluid, replace it

Incorrect clutch drive adjustment (full pedal travel is too small)

Adjust the drive. Replace the deformed clutch fork

Air has entered the hydraulic drive system (the pedal is “soft”)

Bleed the system, tighten connections

Loosening of rivets or breakage of friction linings, warping of the driven disk (end runout more than 0.5 mm)

Severe and uneven wear, scoring on the working surfaces of the flywheel or pressure plate

Grind or replace the flywheel. If the surface of the pressure plate is damaged, replace the housing with the pressure plate assembly (“clutch basket”)

Distortion or warping of the pressure plate

Replace the housing with the pressure plate assembly (“clutch basket”)

Jamming of the driven disk hub on the splines of the input shaft of the gearbox

Clean the splines from dirt, remove minor damage with a file. If the splines are significantly worn or damaged, replace the transmission disc and/or input shaft. Before assembly, apply CV joint grease to the splines

Release bearing jammed

Severe wear of the diaphragm spring blades at the point of contact with the release bearing

Replace the housing with the pressure plate assembly (“clutch basket”)

The clutch release fork is severely deformed or broken

Air in the hydraulic drive system

Bleed the system, tighten connections

Heavy wear and defects in the master cylinder mirror; dirt in the cylinder

Clean or replace the cylinder. During any maintenance, its cuffs should also be replaced.

Worn or defective cuff

Replace cuffs or cylinder assembly

Jamming of the driven disk hub on the splines of the input shaft of the gearbox

Clean the splines from dirt, remove minor damage with a file. If the splines are significantly worn or damaged, replace the transmission disc and/or input shaft. Before assembly, apply CV joint grease to the splines

Driven disk deformation

Replace the driven disk

Loose fastening of the friction linings of the driven disk, severe wear or cracks on the linings

Replace the driven disk

Loss of elasticity of the spring plates of the driven disk

Replace the driven disk

Significant settlement or breakage of torsional vibration damper springs, wear of windows for springs

Replace the driven disk

Seizures on the working surfaces of the flywheel or pressure plate

Replace the flywheel or clutch housing with pressure plate assembly (clutch basket)

Significant settlement or breakage of torsional vibration damper springs, wear of windows for springs

Replace the driven disk

Driven disk deformation

Replace the driven disk

Loose fastening of the friction linings of the driven disk, severe wear or cracks on the linings

Replace the driven disk

Worn, damaged release bearing or lack of lubrication

Plastic pedal bushings not lubricated

Lubricate the bushings with Litol-24 or CV joints-4

The plastic pedal bushings are severely worn

Replace the bushings; before installation, lubricate them with Litol-24 or CV joint-4

Air in the hydraulic drive system

Bleed the system, tighten connections

The pedal return spring has lost elasticity or is broken

Hydraulic clutch drive

More complex and similar in design to the brake system drive. Its valves also use low-compression brake fluid. The main elements of the hydraulic drive repeat the design of the brake system:

- pedal;

- master cylinder;

- working cylinder;

- container for liquid;

- connecting line;

- fittings for bleeding the system.

Structurally, hydraulic cylinders consist of pistons and pushers, which are located in the housing. The piston in the working cylinder moves, displacing the working incompressible fluid, which transmits pressure through the line into the working cylinder. The working piston and pusher move the clutch release fork, thereby separating the engine and gearbox. This type of clutch is installed on VAZ 2101, 2105-2107, VAZ 2106, Moskvich 412, GAZ 2410 Volga, Mercedes and many others. Now that we know in general terms the structure of the two main clutch drives, we can talk about the characteristic features and breakdowns. There are several other types of drives - pneumatic, hydroelectric, but they are used mainly on robotic gearboxes, and pneumatic can be used on trucks and buses; such systems are not used on passenger cars.

How to fix a stuck clutch on a VAZ 2106

guys, here’s the problem: the car has been in the garage for 8 years, it started driving under its own power, but the clutch got stuck over time and now I can’t push it (start it either) if I pull it with a truck, will the clutch come loose? and what can break from the jerking? (VAZ car 2108)

Life is full of surprises. And especially for motorists. Not only do you need to be constantly attentive on the road, but you also need to be able to notice and fix problems in your car in a timely manner. Especially when there are no populated areas nearby and the nearest service station is far away, or when you are stuck in a traffic jam and the clutch pedal is stuck or the brakes have disappeared.

This problem is a constant topic of discussion on many forums for car owners of almost all brands. Of course, a clutch can fail for many reasons. Let's look at the most common cases of problems with the clutch pedal of the VAZ 2106 and VAZ 2107.

Possible reasons for clutch pedal failure

The clutch pedal is depressed when depressed and does not return

This problem can be easily solved in stationary conditions either at a service station or with your own hands in the garage. To replace or repair the main clutch or control valve in the garage, you must have repair kits for the clutch slave and master cylinders.

Reasons for failure and non-return of the clutch pedal of VAZ2106 and VAZ2107:

- a break in the clutch cable where the tip touched. This problem is not easy to fix on your own. You can, of course, carry a spare cable with you just in case, but cases are different and it is not realistic to provide for everything;

- the spring that performs the function of returning the pedal to its original position may burst or fly off. If the spring has flown off, then it is enough to put it back in place, and if it has burst, then, as in the case of a cable break, you must either tow the car or try to get to the garage or service station under your own power.

How to drive a VAZ2106 or VAZ2107 without a clutch? We'll talk about this below:

What to do if the gear shift mechanism does not work?

If the clutch pedal fails on a road with heavy traffic, you should not be nervous, but act calmly with a “cool head” and get to the nearest parking spot, or even better, to a garage or service station. To do this, you can use a tug, tow truck, or drive yourself.

What caused the problem?

So, if the clutch pedal in your vehicle has fallen, then first you need to determine the cause of the breakdown.

There can be many reasons, so your task, as a motorist, is to reliably identify them:

- The first and one of the most common causes is a broken clutch cable. Usually the cable breaks near the tip, on the engine compartment side. It is quite possible to solve such a malfunction on your own and right on the spot, but for this you will need the cable itself. You will learn more about the replacement below.

- Failure of the return spring of the clutch system (hereinafter - CC), which could either burst from wear or simply fly off. If the spring bursts, then there is only one way out - only replacement, so you need to go to the nearest service station either in tow, or as we will describe below. If the spring just flew off, then you can try to find it and put it in place.

- Often the pedal fails when air gets into the hydraulic drive. Driving such a vehicle will also be impossible until air is removed from the system. By the way, instructions for bleeding the system are available on our website, you can find them here.

- Failure of the CC fork can also cause the clutch pedal to drop. It is unlikely that you will be able to solve the problem on the spot, unless you are a car repairman. There is only one way out - replacing the element.

- Incorrect operation of the master cylinder CC, in particular, defects in the mirror, wear or failure of the cuff. In this case, the clutch pedal has failed, but periodically it can be returned to its place by pressing sharply. For normal driving of the car, it is necessary to replace the main cylinder of the system itself.

- Driven disk failure. As a result of this, if the clutch pedal fails, it will be very soft, you will feel it. Failure of the driven disk may be due to the appearance of defects, mechanical damage or deformation of the element. In addition, the cause may be a fluid leak from the hydraulic system or a pipeline breakdown. In this case, the driven disk could fail as a result of the breakdown of the main and working cylinders, or one of them.

Let's sum it up

As you can see, problems associated with the clutch on a manual transmission in some cases can completely immobilize the car. If the problem is related to the clutch pedal, that is, the driver loses the ability to control the operation of the clutch, then repair is also necessary, however, if you have certain skills and abilities, you can drive to a service station or other place where the car is repaired under your own power.

If necessary, it is also recommended to adjust the clutch pedal, bleed the clutch, and also take into account even the slightest malfunction of this unit during vehicle operation.

Types of clutch drive. If the clutch pedal falls, the clutch has become soft, problems have arisen with the clutch: causes and repair of major faults.

How to adjust the clutch pedal, what adjustment is needed for: clutch functions, clutch pedal adjustment (free play and total travel).

Manual transmission gears (speeds) do not engage after replacing the clutch: main reasons, settings and adjustments. Diagnosis of problems, useful tips.

Clutch disc: purpose and device. How to replace a clutch disc, replace this element yourself. Recommendations.

Driving without a clutch: what you need to know

Taking into account the fact that most breakdowns that are associated with the clutch or clutch pedal (for example, the clutch pedal has failed) can take the driver by surprise, and it is often impossible to fix problems on the spot, the only option is to drive to the service station under your own power.

At the same time, we draw your attention once again to the fact that the methods described below should be used only in cases of extreme necessity, since the risk of damaging the box or getting into an accident increases significantly.

- So, first you need to turn off the car engine. If you lose traction on a hill, you should push the car onto a level road. Then it is recommended to think over the route in advance so that, if possible, you travel along a route with a minimum number of traffic lights, pedestrian crossings, not congested with traffic, so that you do not have to stop often, etc.;

- Next, with the engine turned off, you should engage first gear, and you also need to turn on the emergency lights, after which the engine can be started (note that the car will jerk forward sharply immediately after turning the key in the ignition switch to the “start” position);

Let us also add that beginners in such a situation should be prepared for the fact that the engine will stall when it comes to a complete stop or greatly reduces the speed without turning off first gear. This means that in this case you will have to start again on the first one.

This is possible if the driver feels when engaging a gear without a clutch with minimal effort can, without much risk, seriously damage the gearbox and transmission parts, taking into account engine speed and speed. However, if you try to do this without experience and skills, there is a high risk of damaging the gearbox, significantly reducing the life of the unit, or completely destroying the gearbox and other transmission elements.