You are sitting behind the wheel of your car. To start it, press the brake pedal all the way with your right foot, press the clutch pedal with your left foot and turn the key in the ignition, and to get moving, engage first gear and begin to smoothly release the clutch pedal, and then just as smoothly release the brake pedal and smoothly press the gas pedal. There are no questions about the brake and gas; even those who got behind the wheel for the first time understand the processes that are started by pressing these pedals. But why do we need to depress the clutch pedal every time we start or stop the car, or change gears? What is the main task of the clutch and why it is impossible to do without it in the design of a car, we will tell you in this article.

What is clutch

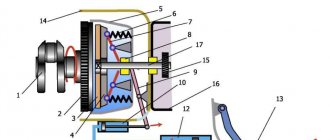

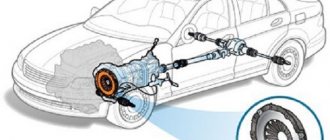

The reason a car moves is its engine, or more precisely, the torque it produces. The clutch is a transmission mechanism that is responsible for transmitting this torque from the car’s engine to its wheels through the gearbox. The clutch is built into the structure of the machine between the gearbox and the engine. It consists of such parts as:

- two drive disks - flywheel and clutch basket;

- one driven disc – a clutch disc with spokes;

- input shaft with toothed gear;

- secondary shaft with toothed gear;

- release bearing;

- clutch pedal.

Clutch pedal on “mechanics”: purpose and use

Everyone understands perfectly well that driving a vehicle is associated with enormous responsibility; therefore, the driver who gets behind the wheel of a car must have the appropriate skills and abilities. And this especially applies to cars that are equipped with manual transmissions. Unlike an automatic transmission, driving a manual car is much more difficult. It’s not for nothing that before obtaining a driver’s license, future motorists have to listen to many hours of lectures that teach them how to drive independently. And most importantly, even after completing the course, graduates do not always understand all the intricacies of driving a car, and especially working with the clutch pedal. Meanwhile, if you clearly understand these nuances, you can not only improve the start and acceleration of the car, but also significantly increase the service life of the element itself. This material provides more details about the operation of the clutch and the intricacies of its operation.

Brief historical background

While working on the creation of the first cars, engineers discovered the need for a device that would transmit torque from the engine to the wheels, but with different amplitudes of rotation, so that the car would move smoothly.

Without such a device, every time you wanted to slow down or increase the speed, you would have to completely turn off the engine. And this device was invented by the German engineer Karl Benz in 1885. The clutch then consisted of two pulleys connected by a leather belt. The driver moved the pulleys apart with a lever, which made it possible to open and close the clutch. The next stage in improving the device was the invention of the cone clutch by German engineers Gottlieb Daimler and Wilhelm Maybach in 1889. In the cone clutch design, the leather belt is replaced by a spring. This design was replaced by another - a multi-disc one, which worked in a liquid medium (kerosene or oil). Then Ferodo linings began to be put on the discs, and the automotive industry switched to dry single-plate clutches. The prototype of the modern diaphragm clutch was developed by auto mechanics of the American corporation General Motors in 1936, but due to the war, their mass production began only in 1965 and continues today.

Clutch operating principle

The drive disk - the flywheel - is rigidly mounted into the engine crankshaft.

The clutch basket, in turn, is bolted to the flywheel. The clutch driven disc is pressed against the flywheel surface thanks to a diaphragm spring equipped with the clutch basket. When the car is started, the engine provokes rotational movements of the crankshaft and, accordingly, the flywheel. The gearbox input shaft is inserted through the bearing into the clutch basket, flywheel and driven disk. Rotations are not transmitted directly from the flywheel to the input shaft. To do this, the clutch design has a driven disk that rotates with the shaft at the same speed and moves back and forth along it.

The position in which the gears of the primary and secondary shafts do not engage with each other is called neutral. In this position, the car can only roll if the road has a slope, but not drive. How to transfer rotation to the secondary shaft, which indirectly drives the wheels? This can be done using the clutch pedal and gearbox. Using the pedal, the driver changes the position of the disk on the shaft. It works like this: when the driver presses the clutch pedal, the release bearing presses on the diaphragm and the clutch discs release. In this case, the input shaft stops. After this, the driver moves the lever on the gearbox and turns on the gear. At this point, the input shaft gears mesh with the secondary shaft gears. Now the driver begins to smoothly release the clutch pedal, pressing the driven disk against the flywheel. And since the input shaft is connected to the driven disk, it also begins to rotate. Thanks to the meshing between the gears of the shafts, rotation is transmitted to the wheels. In this way, the engine is connected to the wheels, and the car begins to move. When the car is already at full speed, you can completely release the clutch. If you add gas in this position, the engine speed will increase, and with it the speed of the car.

However, the clutch is necessary not only for the car to start and accelerate. You can’t do without it when braking. To stop, you need to depress the clutch and gently press the brake pedal. After stopping, switch off the gear and release the clutch. At the same time, in the operation of the clutch, processes occur that are opposite to those that occurred at the beginning of the movement. The working surface of the flywheel and clutch basket is made of metal, and that of the clutch driven disc is made of a special friction material. It is this material that ensures the disc slips and allows it to slide between the flywheel and clutch basket when the driver holds the clutch at the start of movement. It is thanks to the slipping of the discs that the car moves smoothly.

When the driver abruptly releases the clutch, the basket instantly compresses the driven disc, and the engine does not have time to start the car and start moving so quickly. Therefore the engine stalls. This often happens to novice drivers who have not yet felt the position of the clutch pedal. And it has three main provisions:

- top - when the driver does not press it;

- lower - when the driver squeezes it completely and it rests on the floor;

- medium – working – when the driver smoothly releases the pedal and the driven clutch disc comes into contact with the flywheel.

If you release the clutch at high speeds, the car will start to move with slipping. And if you hold it in a half-pressed position when the car is just starting to move, and gradually add gas, then the friction of the driven disk on the metal surface of the flywheel will be too intense. In this case, the car’s movements are accompanied by an unpleasant odor, and then they say that the clutch is “burning.” This can lead to rapid wear of the working surfaces.

What to remember when starting out

When the vehicle is started, the gear lever must be in neutral. To prevent damage to the clutch, the pedal must be depressed and then set to first gear. It is important that the crankshaft and gearbox connect as smoothly as possible, without jerking.

To competently move from neutral to first speed, you must follow the following points:

- squeeze the medal a little. If the flywheel connects smoothly to the disk, the machine will begin to move at minimum speed;

- pause for a few seconds. As a result, a balance will be established between the rotation of the flywheel and the disk. This will result in a slight increase in speed;

- then release the pedal. Do not overexert the clutch, otherwise the disc will wear out prematurely.

Types of clutches

According to the clutch actuator system, clutches can be divided into:

- friction (mechanical);

- electromagnetic;

- hydraulic.

The most common type of clutch is a friction clutch, which uses friction in its operation.

Electromagnetic, on the other hand, uses an electric motor with current to operate, which starts when the pedal is pressed. And the hydraulic clutch works by flowing oil fluid from a special reservoir into the master cylinder. Fluid fills the cylinder and, under pressure, the master cylinder piston pushes the slave cylinder rod, propelling the vehicle. Depending on the number of driven discs, the clutch can be single-disc or multi-disc. And according to the type of friction - dry and wet.

Automotive single-plate clutch device

Diagram of a double-disc clutch device

General design of a double-disc clutch

- Engine flywheel friction surface - blue color on the left

- Two driven discs - brown

- Intermediate drive disc - blue

- Pressure drive disk - green color

- Compression Springs - Gray

- Housing - blue color on the right

Not shown in the picture

- Forks

- Clutch release levers

- Release bearing

- Clutch release fork

- Release springs

Clutch: why is it needed and how does it work?

Understanding the purpose of the clutch pedal, you first need to understand the operating principle of this important unit. Since the unit is considered one of the fundamental elements of the car’s chassis, it makes it possible to disconnect the crankshaft from the gearbox. It is the ability to perform this action in a short period of time that allows motorists to change gears while driving. Most modern car models have a single-plate friction clutch. That is, such a clutch device requires the presence of a main element and a drive. The clutch assembly, for a clearer understanding, consists of the following elements:

Do cars with automatic transmissions and electric cars need a clutch?

There is no clutch in the classical sense in cars with an automatic transmission (automatic transmission). That is, the driver has neither a clutch pedal nor discs that operate on friction. The clutch functions in cars with automatic transmission are performed by a special torque converter that converts torque. In electric cars, the motion control is carried out by a control system that shifts the car, which is why they do not need a gearbox or clutch.

Some tips on when to use the clutch

Quite often you can hear that the lightest pedal is the clutch, because it is not directly responsible for either braking or acceleration. It is worth noting that such a statement is erroneous.

It is the clutch that allows experienced drivers to control the vehicle as efficiently as possible.

With its help, you can achieve maximum performance and durability of the vehicle. On the other hand, improper use of an element often leads to premature wear of several machine components (including the engine). Thus, there is a need to learn how to use the clutch at the right moment. Now we will talk about how and when to use the clutch. But first you need to make sure that the clutch has been adjusted correctly.

conclusions

So, in this article we introduced you to the principle of operation of the clutch and explained what functions it performs in the design of the car. Like any part, the clutch tends to wear out. It is impossible to determine the exact shelf life of this mechanism, since it directly depends on the dexterity and accuracy of the driver. Grip also suffers from uneven road surfaces with deep holes and from traffic jams, since the driver often has to slow down, or even brake completely, and then move off again. Therefore, if you hear an unpleasant smell in the cabin, there is a reason to stop by the service station and have a technical inspection.