Every motorist expects an ideal response to his actions from his car while driving: pressing the gas should accelerate the car, turning the steering wheel should change its direction, and pressing the clutch pedal should disconnect the gearbox from the engine to change gears.

Any malfunction that slows down this reaction, or even blocks it, not only leads to discomfort, but also increases the likelihood of an accident. To eliminate unpleasant consequences, many mechanisms are equipped with adjustment.

Let's look at common issues related to clutch adjustment.

Clutch mechanism design

First, let’s briefly talk about how the mechanism works. How it works is discussed in a separate review . In the classic version, the clutch has one disc on which a friction lining is attached. He is called a follower. The leading role is played by the flywheel - a disk with a crown at the end, fastened with bolts to the flange of the spindle.

In a quiet position, both discs are pressed tightly against each other. When the engine is running, the friction disc rotates with the flywheel because it is pressed by the pressure plate. The drive shaft of the transmission is installed into the drive disk using a splined connection. This element receives torque from the power unit.

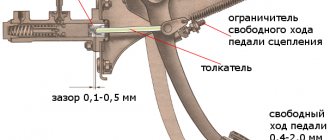

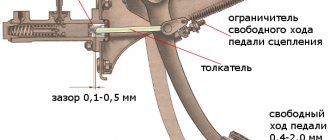

To change gear without having to turn off the engine, the driver presses the clutch pedal. The cable attached to it moves the lever to which the fork and release bearing are connected. The force is applied to the pressure plate. It disconnects the friction disc from the flywheel. Thanks to this, torque does not come from the engine, and the driver can easily change gear.

A conventional manual transmission (manual transmission) operates on this principle. As for automatic transmissions, there are several varieties. In them, torque transmission is provided by slightly different or fundamentally different mechanisms. More details about the types of such transmissions are described here .

Many manual transmissions have a power clutch pedal. It works on the same principle as its mechanical counterpart, only the force is increased thanks to hydraulics. In this case, there are two cylinders at the ends of the line. The main one perceives the effort from the pedal. When the pedal is depressed, increased force is transmitted to the working cylinder, which is connected to the clutch fork lever.