Types of clutch drive

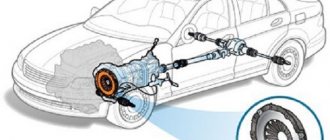

The clutch is not one part of the car, it consists of several parts. Among them: drive/driven discs, release bearing, release clutch, fork, drive, clutch basket. Due to the large number of components, the unit fails faster, but there is also a dependence on its type:

- Cable - is mechanical, the pedal and fork are connected by a cable, which is activated by pressing the foot. The fork presses on the bearing, which opens the discs.

- Hydraulic - bearing pressure is controlled by fluid. The pedal is connected to a hydraulic circuit; when pressed, pressure is created in it. It affects the hydraulics of the release bearing, which opens the discs.

The cable mechanism is simpler in design, but it also breaks more often due to its component parts. There the cable may fray or the bracket may break.

Attention! Even a slight breakdown of the cable assembly will lead to deterioration in pressing. If you do not pay attention to this, the problem will worsen and develop into a serious malfunction.

Adjustment instructions

The Lada Priora is equipped with a clutch cable with a ratcheting mechanism. The cable is backlash-free and does not require adjustment, but manufacturers recommend this be done during every maintenance.

Clutch cable

To adjust the cable on the Lada Priora, you need to prepare a screwdriver and a ruler. The procedure then consists of the following steps:

- To perform work, you must open the hood.

Engine compartment of Lada Priora First, you should disconnect the mass air flow sensor and remove the air filter.

Engine compartment without air filter

- After this, a cable will be visible, at the end of which there is a plastic clip.

- Before adjustment, it is necessary to set the cable to its original position: overcoming the resistance of the spring, push the cable clamp forward until it stops in the direction of movement of the car.

- This clamp should be pulled towards you and the distance between it and the plug should be measured, it should be 27 mm.

We measure the distance using a ruler - The distance is adjusted by turning the tip counterclockwise. In this way, an increase in distance can be achieved.

- Twist the clamp until the distance is 27 mm. Accuracy is very important here.

- Now you can release the cable and place it in the fork.

- After completing the steps, you need to get behind the wheel and press the pedal three times until it stops.

- Then again you need to measure the distance, it must be exactly 27 mm, otherwise we adjust until the desired distance is achieved.

- Next, you should insert the tip into the groove of the mechanism fork and release it. Thanks to the spring, the tip driver clamp is installed without any gap.

- After adjusting the cable, you need to return everything to its place, start the engine and check the operation of the mechanism.

After adjustment, the clicks disappear and the clutch release pedal operates softer.

Clutch pedals

When the clutch pedal travel is large, the clutch is not completely disengaged, so it still comes into contact with the flywheel of the power unit. When the stroke is low, the driven disk does not turn on completely, which leads to slipping and loss of torque.

You should measure your pedal stroke if the following symptoms occur:

jerks appear when starting to move; noise and shock when shifting gears; the pedal gets stuck.

The symptoms described indicate that the mechanism requires adjustment. You can diagnose its operation on Priora yourself. To do this, start the engine, slowly release the PS and start moving. If, when the PS is released, the car immediately begins to move, this means that there is no free play. If the car does not budge even with the pedal fully released, then its travel exceeds the norm. The brake pedal should be at the same level as the brake pedal. In this case, its full stroke will be in the range of 125-135 mm. Fluctuations up to 160 mm are possible.

We measure the free play of the pedal

When making adjustments, loosen the first cable adjusting locknut located in the engine compartment on the bracket.

Locknuts for adjusting free play

By tightening the second locknut, the distance and stroke of the PS are adjusted. Thus, the desired result is achieved. After completing the procedure, the first locknut is tightened.

If you adjust so that the brake pedal is located above the brake pedal, then the clutch will barely leave the floor. If it is lower, it will set almost at the very end. If the PS is located too high, the basket wears out faster. The ideal option is that the brake and clutch pedals should be at the same level.

In order to extend the life of any mechanism, you should use it carefully. You should not constantly keep your foot on the PS; it is better to place it on the left on the floor. During each technical inspection of the Lada Priora, it is recommended to monitor the free movement of the PS and the clarity of gear shifting and, if necessary, make adjustments.

Signs of a bad clutch

People who regularly drive a car immediately realize that something is wrong with it and the pedal has become tighter. In addition, problems can be determined by other factors:

- when you press the pedal, sharp grinding sounds appear that are uncharacteristic of normal operation of the system;

- the lever is pressed jerkily, there is no smooth movement;

- the free play of the pedal has to be adjusted frequently;

- when the pressure is released, the clutch engages jerkily;

- the clutch is slipping - this can be indicated by the smell of burning clutches and an increase in fuel consumption.

At the same time, for some cars a hard pedal is the norm, this applies to old domestic models - “classics”. But if tightness occurs in relatively new cars, both Russian-made and foreign, this is a reason to carry out diagnostics.

Why has the clutch pedal become stiff?

Since cable systems are the most prone to failure, let's first look at why the pedal might become stiff under these conditions:

- increased rigidity of the diaphragm spring petals - this leads to gradual wear of the part and its deformation;

- jamming of the release bearing, coupled with increased force to rotate the fork, subjects the clutch cable to increased loads;

- rupture of the cable wires - they adhere to the metal braid, increasing the resistance of the tight pedal.

The first reason is more common, and this is due to the arrangement of the petals of the basket. The central part, which has a release bearing, becomes higher than the plane of the spring; additional pressure is required to overcome this elevation.

To make the diaphragm spring more durable, manufacturers artificially increase the rigidity of the petals. This happens especially often with Chinese counterfeits of well-known companies. Despite expectations, the tight pedal will not change with the installation of such an element.

How to fix the problem

Knowing that the system is faulty, you need to take measures to repair it. First you need to determine the breakdown, because it is likely that only one part has broken.

Additionally!

It is better to change the “clutch” completely; although this will cost more, the entire system will work effectively.

Without wanting to spend money, you can solve minor problems yourself:

- lubricating or replacing the release clutch bearing;

- replacing fluid in the hydraulic drive with subsequent pumping;

- changing the driven disc pads or springs if the elements are worn out, weakened or deformed;

- replacing the basket and all parts with a new assembly recommended by the vehicle manufacturer.

Even if these steps are taken, the tightness may still remain. Then you need to try to replace the cable, clean its jacket from dirt and corrosion, and also lubricate it with machine oil. Hydraulic systems can also have cylinder failures, which is also quite serious.

Broken clutch cable

In any case, the most accurate diagnostics can be carried out in services where the nodes are disassembled and their suitability for use is determined. There, the car will be put in order and the stiffness of the lever, which interferes with comfortable driving, will be corrected.

Types

The clutch varies:

by type of drive (models with hydraulic, mechanical or electrical control);

- by type of friction (the mechanism can operate in an oil bath or without it);

- by the number of driven disks;

- by type of spring arrangement;

- by switching mode.

The most common today are models with one or more friction discs, that is, those that operate due to friction (without additional lubrication). Depending on the number of driven elements, they can be single-disk, double-disk or multi-disk (three or more).

The material used to make clutches is similar to that used in brake pads. If earlier in both cases asbestos was added to the composition (there were asbestos linings on the metal disks), now it is non-asbestos options that are used.

In Europe, the production of friction discs containing asbestos is prohibited. During operation of the mechanism, the asbestos lining wears off, forming dust that is hazardous to health.

Modern passenger cars are often equipped with single-plate clutches. They are optimal for low and medium power engines.

Dry double-disc clutch

Double-disc models are suitable for trucks and passenger cars with a powerful engine. Due to their design features, they are more durable than single-disc ones, but they are also more expensive, so using them on low-power cars is simply impractical.

Multi-disc clutches are used in construction and heavy trucks, powerful sports and tuned cars, including all-wheel drive.

Smooth operation of the clutch is ensured by slipping of the discs as the compressive force decreases. Accurate transmission of torque - tight connection between the driving and driven surfaces.

Under heavy loads and prolonged use, the working surfaces wear out and the clutch begins to “slip.” If the clutch is faulty, the discs do not disengage completely, and normal gear shifting is disrupted.

Basic mistakes when repairing clutches

The most effective repairs are possible in a service station, where technicians will perform diagnostics, repair broken components and configure the system to factory settings. Self-repair, like tuning, is undesirable, because it leads to a number of mistakes:

- Pouring brake fluid or WD-40 into the cable jacket will not soften the movement, but will serve as destructive factors for the protective sheath.

- Replacing the entire basket except the fork - the new basket will create too much resistance, causing the tired fork to break. The tight lever will simply stop working.

- Using cheap analogue parts - wanting to reduce the cost of clutch repairs, drivers often choose Chinese alternatives.

Interesting! In fact, counterfeits either do not have an effect or break down quickly enough, which requires new injections of money.

If the clutch pedal on a car becomes difficult to press, this means problems with the corresponding system. It is necessary to check the clutch basket, cables and forks, or cuffs, if we are talking about the hydraulic version, and replace all problematic components.

To do this, it is best to contact professional technicians; they will carry out diagnostics and repairs. If you try to fix it yourself, you may not take into account the nuances and provoke even bigger breakdowns that require significant expenses.

Let's sum it up

Taking into account the above information, it becomes clear that there are quite a lot of circumstances why the clutch pedal is tight or the clutch is hard. In the process of troubleshooting, you should inspect the pedal mechanism itself step by step, and then move on to the clutch elements, cables, rods, etc.

Ignoring this rule often leads to the fact that a tight or hard clutch pedal can become a surprise for the driver right on the road. The clutch pedal also fails, the clutch may not “grab”, etc. To avoid such unexpected breakdowns, the performance of the clutch must be inspected at any scheduled maintenance.

How to adjust the clutch pedal, why adjustment is needed: clutch functions, clutch pedal adjustment (free play and total travel).

How to bleed the clutch, why do you need to do the function. When it is necessary to bleed the clutch: signs. How to bleed the clutch yourself.

Car clutch: purpose, types, device, mechanism of operation. Frequent clutch malfunctions in the car gearbox, signs of problems.

Car clutch and design overview: clutch pressure plate, driven disc, release bearing. Types of clutch drives on manual transmissions and manual transmissions.

The clutch pedal has fallen off: why does this happen? The main reasons why the clutch pedal fails is what the driver should do if the clutch is lost.

Types of clutch drive. If the clutch pedal falls, the clutch has become soft, problems with the clutch have appeared: the causes and repair of the main defects.

Source: krutimotor.ru