Hi all! Clutch failure does not bode well for the car and its owner. The sooner signs of problems can be detected, the better. A fairly common question on this topic is why the clutch slips or slips. Different terminology is used, but the essence remains the same.

It is important to understand that modern cars use dry and wet, also known as oil, clutches. In the first case, we are talking about simple friction, while in the second, the procedure is carried out in a special oil, which additionally cools the clutch discs and other elements. Most often we encounter the dry type. Wet is used on cars with dual clutch and robotic gearboxes. It is difficult to adjust and repair a wet clutch with your own hands. This requires the help of specialists.

The most common sign of unit malfunction is slipping. Moreover, for some it happens constantly, while for others it sometimes stalls, sometimes not. This can happen both hot and cold, that is, before and after the unit warms up.

How the problem manifests itself

Most often, the cause of clutch slipping is normal mechanical wear of the assembly elements. This allows you to diagnose an impending problem even before serious consequences appear. This is done by simply observing changes in the behavior of the machine.

If you notice one of the following signs on your Niva, passenger car or scooter, be sure to diagnose the clutch or contact a service center.

- Extraneous sounds occur during system operation. They appear in the form of knocking noises when the pedal is depressed or released;

- If the noise disappears when the clutch pedal is depressed, the problem is most likely in the release bearing;

- There are signs of vibration on the pedal;

- In this case, the pedal may sink too much or be pressed too hard;

- A characteristic burning smell emanates from the clutch. The clutch usually burns if the driver operates it incorrectly.

The manufacturer provides each vehicle with instructions that indicate all recommendations for routine maintenance and replacement of clutch assembly elements. Most often, the driven disk needs to be replaced.

Before you try to adjust the system yourself, be sure to familiarize yourself with the principle of operation of the clutch. In our previous article we discussed this issue.

Causes of clutch slipping

Clutch wear occurs directly at the moments of closing and opening the discs, when there is their mutual slipping, that is, it is always associated with starting off and changing gears.

If the car continuously moves along a country road without interference, populated areas and traffic lights, then the clutch will turn from a consumable into an eternal unit that will last longer than the engine or car body.

On topic: How to bleed a car’s clutch yourself

Slipping can be considered normal when it stops when the pedal or rod is completely released, and also a sign of complete wear if the discs continue to slip when engine torque increases, despite the complete removal of force from the release bearing.

Abuse of incomplete squeezing

In addition to its main function, that is, breaking the connection between the engine flywheel and the gearbox input shaft, the clutch is capable of transforming the gear ratio within certain limits.

For example, when starting off, the wheels, and therefore the input shaft of the box, are motionless. It is impossible to apply engine torque to them without slipping, since an internal combustion engine is not an electric motor, and its torque at zero speed is also zero.

The crankshaft must be untwisted until an acceptable torque value is obtained, it must be applied to the clutch driven disc, after which the clutch will slip until a certain speed is reached.

This mode is completely normal, but it can be abused, that is, it can unreasonably prolong the slipping time:

- when trying to start as smoothly as possible and lacking experience;

- when starting from second or higher gear instead of the intended first;

- compensating for the lack of traction capabilities of the car by incomplete engagement of the clutch;

- just keeping your foot on the pedal without thinking about the consequences.

In this case, the clutch overheats, wears out quickly and begins to slip during normal driving, especially in higher gears, when the torque on it is maximum.

Contamination of friction discs

Dirt on the driven disk linings can appear for various reasons:

- burning of the linings after a long slip;

- driving with deep immersion in water and mud;

- ingress of lubricant during replacement of parts due to negligence;

- leaking engine and gearbox seals.

The clutch is rarely made with a large margin of force of the working spring, so the slightest contamination of the discs and flywheel, which leads to a drop in the coefficient of friction, will certainly lead to a slippage when trying to transmit the maximum engine torque.

Severe wear on the linings

The driven disc linings are made of a special material that has a high coefficient of friction against steel, but is also quite soft.

It wears out due to slipping, the thickness of the disk decreases, and the working stroke of the pressure disk is no longer enough for reliable pressure. As a result, slipping occurs, causing the linings to wear out even faster.

Weakening the pressure plate spring

The drive disc in the clutch is made in the form of a housing with a central diaphragm spring. The preload of this leaf spring is created during the installation process, when the housing (basket) is tightened around the circumference with screws to the flywheel.

You need to know this: How the release bearing works, malfunctions and methods of checking

Over time, this force weakens due to metal fatigue and temperature loads. The discs are pressed with reduced force, and the coupling can no longer transmit the calculated torque without slipping.

Flywheel surface wear

The flywheel has a groove for the driven disk, which works together with the drive disk, clamping the linings. If the car has a significant total mileage, during which the clutch has been changed several times, then wear accumulates on the flywheel.

Its thickness decreases, signs of uneven wear, depressions and protrusions appear. All this reduces the clamping force and efficiency of the clutch, leading to slippage.

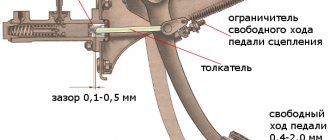

Incorrect adjustment

The design of the clutch drive can be different, including requiring periodic adjustments. Neglect of the regulations can lead to constant loading of the release bearing, which reduces the force applied to the discs.

The result is still the same - slipping and accelerated wear.

Possible consequences

A slipping clutch is a fairly common occurrence. This is especially true for domestic cars, motorcycles and cars with high mileage.

Practice and experience clearly show that slipping is usually associated with wear and damage to elements. This can happen on any car or other vehicle. Judging by the requests of fans of self-repair, most often the problem of a slipping clutch is solved on the following vehicles:

- VAZ 2107;

- VAZ 2114;

- IZ Planet;

- UAZ Bukhanka;

- Jupiter;

- KAMAZ;

- Minsk;

- VAZ 2110;

- Renault Logan;

- Kia Rio;

- Lada Priora;

- GAZelle, etc.

Despite the obvious cause of such problems, many car owners stubbornly continue to ignore all recommendations for maintenance and timely repair of the unit.

If you feel characteristic signs of problems, you should take prompt action.

When buying a used car or getting behind the wheel for the first time, some people think that they are simply driving the vehicle incorrectly, are not yet fluent in manual shifting techniques and are making some mistakes. In reality, it may turn out that the clutch is failing.

It is important to pay attention to the characteristic signs. Namely:

How to check if the clutch is slipping

Depending on the transmission design, there are different options for testing clutches for slippage.

On the flywheel

When installing a basket with a driven disk embedded in it, a very certain tension must be created, determined by measuring the gaps or thread stroke of the screws securing the basket.

This stroke is reduced due to flywheel wear. If it is too large, or significant wear of the working groove for the linings is visually determined, then the flywheel should be machined to the nominal size or replaced with a new one.

On mechanics

A manual transmission with manual shifting is designed in such a way that the beginning of clutch slippage at a threshold level of wear will be noted in the highest gear and maximum engine torque.

To check, just engage fifth or sixth gear at a speed of about 60-70 km/h and fully press the accelerator. If the car begins to pick up speed in the usual mode, and the engine speed on the tachometer increases slowly and in proportion to the speedometer needle, then the clutch will not slip yet.

Otherwise, the speed will increase sharply, but the speed of the car will remain almost unchanged. This means that the clutch has slipped, you must immediately release the gas and carefully go to the repair site.

On a variator

The presence of a clutch at the input of a variator is rare, but it does happen. It is difficult to determine the presence of slippage by sensation, since the very principle of operation of the variator implies a stepless nature of changing the gear ratio, exactly the same as with a slipping clutch.

But if a deterioration in acceleration is noticed, the engine switches to unusually high speeds, then the gearbox should be diagnosed, where the scanner, among other things, will allow you to assess the condition of the clutch.

Automatically

In the place where a manual clutch has a clutch, a classic hydromechanical automatic transmission has a torque converter. For him, slipping is a completely normal mode of operation, which is what it was created for.

But there are clutches, or rather friction clutches, in the box, they are controlled hydraulically and serve to make gear shifting smoother. When they wear out, acceleration deteriorates and the oil in the automatic transmission begins to burn, which is determined by the smell from the dipstick.

The cause of friction clutch slipping can be various problems, most often it is failures in the valve body due to dirty oil. The automatic transmission will need major repairs.

At work

The operation of one or two clutches on robotic gearboxes is not fundamentally different from conventional mechanics. Adjusted for the sign, for boxes with two clutches they turn on when pressed, and do not turn off.

But since they are controlled here by a computer through servos, this entire system requires regular checking with a scanner and, if necessary, adaptation. You should not wait for the symptoms of slippage described above to appear; clutches on robots, especially preselective ones, are much more expensive.

The scanner will allow you not only to assess the condition, but even approximately predict the remaining resource.

What kind of vehicle can a trailer be used with?

- the car loses dynamics;

- cravings drop;

- the car is difficult to climb;

- speed is gained slowly;

- the pedal vibrates;

- there is a smell of burning in the cabin;

- the pedal is too tight;

- the pedal fails;

- gear shifts with a crunch;

- Extraneous uncharacteristic sounds appear when switching.

If you do not pay attention to this in time, the engine flywheel is highly likely to be damaged, not only the coupling unit, but also the gearbox will suffer. The problem mainly affects the gearbox input shaft.

Is it possible to drive like this?

It is highly undesirable to continue operation with a slipping clutch. It is not always possible to accurately control the moment when sliding begins, and this will release significant power.

So much so that the linings can burn completely in a matter of seconds. After which the car will be completely immobilized, possibly in a dangerous place on the road, and during repairs it will also be necessary to replace the flywheel, which is covered with cracks from overheating.

After the first signs of slipping, you must, without sudden acceleration and at low speed, proceed to the repair site, where you can replace the complete clutch. Attempts to save money on individual parts usually lead to unnecessary work on removing and installing the gearbox.

Source

Independent and quick diagnostics

If this is just the beginning of the emergence and development of a problem associated with clutch slipping, inexperienced drivers may not notice it.

There is a fairly simple diagnostic method that is almost error-free. You can do it yourself after replacing the clutch, when adjustments have been made, or simply when you suspect that the system is not working correctly.

When the clutch "leads"

When the clutch “leads”, unpleasant sounds appear from the gearbox, and it becomes more difficult to engage gears. In this case, there is a way to check the clutch:

- Turn on the engine and set the gear to neutral.

- Depress the clutch pedal.

- Turn on first speed.

If you have to exert force when activating the gear and there are strange sounds coming from the box, then this primarily indicates that the flywheel disc is not disengaging. Most often, this problem is solved by bleeding the hydraulics and adjusting the pedal.

Atlant bike rack: choosing a transportation option, owner reviews

- place the machine on a level surface;

- start the engine;

- turn on the handbrake;

- go into first gear;

- start trying to move away;

- gradually press on the gas;

- release the clutch at the same time;

- watch the result.

If the engine stalls during such manipulations, this is good. That is, the clutch does not slip. But when the engine does not stall, the car begins to move, the unit actually slips.

Appropriate measures should be taken immediately to correct the problem.

Slip check

This check is carried out if there are prerequisites for improper clutch operation. But depending on the nature of the breakdown, the method may differ. The most common situation is clutch slipping. In this case, its correct operation is checked as follows:

- We put the car on the handbrake.

- Let's start the engine.

- We activate third gear (fourth is possible).

- Depress the clutch and press the gas pedal.

If the engine stalls, then most likely the clutch disc is worn out and requires replacement. However, such a result is not always accurate.

Clutch pressure plate overheating

Overheated clutch disc

Causes:

- stable clutch slip;

- salting or oiling;

- a malfunction in the clutch release system or a small gap between the clutch release levers and the bearing.

Result: reduced lining friction. If the clutch compression force is too weak, clutch slipping will result in the heat absorption properties being exceeded. The result will be overheating.

Characteristic

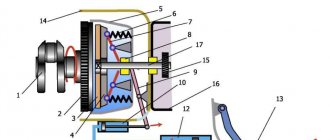

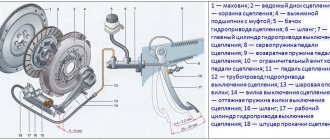

The clutch system is a separate design that allows the drive shaft of the motor to be disconnected from the mechanical drive to the drive wheels for a short period of time. This is done to switch to a higher or lower transmission gear. Also, with the help of the clutch, they achieve smoothness when turning on and off the load on the internal combustion engine. This helps prevent damage to the crankshaft of the power unit.

For all vehicles with a manual transmission, the clutch device is standard. So, it consists of a flywheel, a driven disk, a “basket” and a release bearing.

Operating principle of the clutch mechanism:

The car engine transfers its energy to the heavy flywheel. When controlling the accelerator, you can reduce or increase the speed. And in order for the car to move, such movement must be transferred to a “mechanical” gearbox - in our case, to the car’s gearbox. To prevent the car from stalling, the rotation must be transmitted as smoothly as possible. Similar requirements apply to stopping a vehicle. The clutch is precisely that auxiliary element without which this would be impossible to achieve.

The operation of the clutch is not difficult to explain!

The functioning of the car clutch mechanism.

Components of the clutch mechanism.

How to troubleshoot

Every car enthusiast must know what to do if the clutch slips. After all, this problem should be solved as soon as possible, so that during the movement the breakdown does not lead to failure of the motor.

Before removing the gearbox and checking how worn the clutch system components are, it is recommended to make sure that the pedal has sufficient free play. Each manufacturer has a different parameter.

For domestic cars, the free play size is from 20 to 30 millimeters. But it is better to find out exactly the parameter in the operating instructions. When the free play is abnormal, it should be adjusted by tightening or releasing the clutch cable.

If the free play is normal, but the clutch slips, the reason may be disc wear. This is the most common problem. In this case, it is necessary to dismantle the gearbox, unscrew the fastenings of the clutch basket, then remove it. Next you can see the driven friction disc. It must be removed and replaced with a new one suitable for the specific car model.

How to determine if there is slippage

When the clutch slips, it manifests itself primarily as a serious loss of power, which is especially noticeable on an incline. Acceleration dynamics also suffer. When driving in lower gears, the car may jerk.

While the problem has not yet become obvious, it may seem as if the power unit is not pulling. However, symptoms that directly indicate clutch gradually begin to appear. One of them is the smell that occurs due to intense friction of the friction layer of the clutch disc on the surface of the flywheel. The smell is reminiscent of burnt rubber and can be felt in the cabin.

A common sign of slipping is difficulty engaging gears and a crunching sound when shifting. It becomes increasingly difficult to move away.

In addition, knocking, grinding or other extraneous sounds indicate problems with the clutch, especially if they differ when the pedal is pressed and released. Sometimes vibration is observed, the pedal may be pressed tightly or, conversely, fail, and its free play may increase.

It also happens that when you press the clutch pedal, the discs do not separate completely, remaining in some contact. In this case, they speak of incomplete disengagement of the clutch. You can check this as follows. With the engine running at low speeds, press the pedal all the way and try to engage first gear. Difficulty turning on and extraneous sounds will indicate the presence of problems.