All modern cars with internal combustion engines of any type (carburetor, injection, diesel) have an idle system.

This system ensures stable engine operation at idle speed (idling speed) when the accelerator throttle valve is fully closed.

One of the main elements of this system is the idle air solenoid valve, also called “electro-pneumatic valve”, “solenoid valve”, “idle air regulator”.

Why is KXX used?

The purpose of the device is to ensure the flow of the fuel-air mixture inside the inlet manifold. The supply occurs bypassing the throttle valve, which is controlled by the gas pedal, through an additional channel XX.

The electromagnetic unit is responsible for controlling the IAC. Opening/closing involves changing the cross-sectional diameter of the passage channel.

Depending on the type of power unit, the idle air valve functions differently:

- Carburetor engine. The IAC is installed directly in the carburetor body, which makes it part of the forced IAC economizer system of the fuel system. The control unit is located in the engine compartment of the vehicle. The ignition timing is a signal for the unit that supplies power to the valve, which opens and gasoline is supplied to the intake manifold through the XX channel. When the ignition is turned off, the IAC is de-energized and the fuel supply stops. Adjusting the idle air valve is necessary to regulate the amount of gasoline supplied and is carried out by manipulating a special valve.

- Injection motor. The idle speed control is located in the throttle body as part of the electronic control system. The control electronic unit is usually mounted in the car interior under the front panel. Recording signals from sensors monitoring engine operating parameters, it analyzes them and transmits a control signal to the regulator. The device regulates the volume of air supplied to the manifold, ensuring the required idle speed.

- Diesel engine. The IAC is installed inside the high pressure fuel pump. The engine control unit located in the engine compartment is responsible for the controls. Commands to the valve are transmitted as a result of the reaction to the supply of fuel to the cylinders of the power unit.

Operating principle of the XX valve

At its core, the idle air valve is an electromechanical actuator operating under the control of an electronic unit that supplies electrical signals to open or close it.

In this case, the diameter of the flow section of the XX channel changes, supplying the required amount of fuel or air to the engine intake manifold.

Carburetor engines.

In gasoline carburetor engines, the XX solenoid valve is installed directly in the carburetor body and is part of the forced idle economizer system (ISP) of the fuel system.

The operation of the XX valve is controlled by the EPHH control unit installed in the engine compartment of the vehicle.

When the ignition is turned on, power is supplied from the control unit to the solenoid valve, which opens and supplies gasoline through the XX channel into the engine intake manifold.

When the ignition is turned off, the idle air valve is de-energized and cuts off the fuel supply.

To adjust the amount of fuel supplied through the idle passage, an adjusting screw called the “idle screw” is installed in it.

Injection engines.

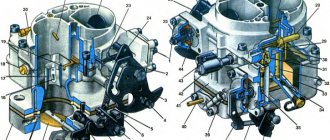

In gasoline injection engines, the idle air valve, more often called the “idle control valve,” is mounted in the throttle body and is part of the electronic engine control system (ECM).

Its operation is controlled by an electronic ECU (controller), located, as a rule, in the car interior under the front panel.

The control unit records signals from sensors that monitor individual engine operating parameters, processes the received information and issues a control signal to the idle speed controller.

Upon command from the ECU, the XX regulator increases or decreases the volume of air supplied through it to the engine inlet manifold, ensuring the specified XX speed.

Diesel engines.

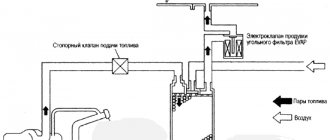

In diesel engines, the idle air valve is installed in the housing of the high pressure fuel pump (HPF) and, just like in the injector, is connected to the engine ECU control unit located in the engine compartment.

But at the same time, it regulates the supply of fuel, not air, to the cylinders, providing the necessary idle speed.

Device diagnostics

Motorists are interested in how to check the idle air valve themselves and its current condition.

For many car enthusiasts, independently checking this valve, a component of the idle air system, is a completely doable task. There are several methods for diagnosing the condition of the regulator.

- Visual inspection. First a visual inspection is carried out. This allows you to determine the presence of defects on the body, signs of needle wear, and signs of carbon deposits on surfaces. If there are deposits, they can be removed using carburetor cleaner. Surely, if the IAC is dirty, the entire throttle assembly will be dirty. Therefore, it will not be superfluous to clean it too.

- Diagnostic software. Some car enthusiasts are switching to using special diagnostic programs. In addition to the software, an adapter is also required to connect to the system. Through the software menu, the position of the controller is selected and its operation is observed.

- Wiring condition. It would not be superfluous to carefully check the wiring connected to the IAC. Here you need to use a multimeter. The engine is turned off, the sensor connector is removed. On the multimeter, select the voltage test mode with a limit from 0 to 20 V. When working properly, the device should show about 12 V.

- Resistance. The resistance of this regulator is also checked. To do this, using the same multimeter, the resistance between the terminals is checked by disconnecting the sensor terminals. The multimeter is turned on in resistance mode, and the limits are set from 0 to 200 Ohms. The terminals are conventionally designated as A, B, C and D. When measuring resistance at A and C, as well as at B and C, the device should display infinity. In other cases, 50-55 Ohms is considered the norm.

- Check with throttle. Checking with the throttle assembly is also quite common among motorists. The complexity of the method is that you will have to completely dismantle the entire throttle assembly directly along with the sensor itself. After connecting the IAC connector, turning the ignition on and off, visually observe the operation of the suspected regulator. Make sure that the needle moves normally, the stroke is uniform, and there are no extraneous sounds.

Types of valves

The set of actions and their sequence during an operation such as adjusting the idle air valve depends on the type of device:

- Solenoid. The electromagnet is a retractor coil with a core. Installed at the entrance to channel XX. Applying power causes the core to retract, opening the passage hole. De-energizing returns the core to its initial position, closing the channel.

- Rotary. The operating principle of the device is identical. The role of the core is played by a rotor that rotates in different directions, which changes the cross-section of the passage channel.

- Stepper. A ring magnet and four windings are the main elements of the device. Control signals are applied to one of the windings in turn, causing the rotor to rotate and smoothly adjust the channel cross-section.

Main types and design of XX valves

Depending on the engine type, three main types of solenoid valves are used:

- Solenoid;

- Rotary;

- Stepper.

The solenoid version is an electromagnet in the form of a retractor coil with a core installed at the entrance to the idle channel.

When power is applied to the coil, the core retracts, opening the channel through the hole.

When the coil is de-energized, the core returns to its initial position, locking the channel.

The rotary valve type works on the same principle as the solenoid valve. But instead of a core, a rotor is used, which rotates in different directions, smoothly changing the cross-section of the idle passage channel.

In this case, pulse-width modulation (PWM) is used, which provides a high frequency of control signals for opening or closing the valve.

A stepper idle valve is essentially an electric motor made in the form of a ring magnet and four windings.

Control signals from the ECU unit are applied alternately to one of the windings, as a result of which the rotor rotates, smoothly changing the cross-section of the passage channel from its full opening to its complete closing.

Types of IAC

Externally, the regulator somewhat resembles an electric motor with a conical needle in its design.

There are 3 types of such controllers.

- Solenoid. The regulators are the simplest in design. When voltage is applied, the internal core on the winding is triggered and placed in a specially provided slot, which makes it possible to reduce the diameter of the passage channel. This reduces the volume of air or fuel supplied. The simple design helps reduce the cost of the product. Such a regulator can only operate in the fully open and closed position.

- Stepper. These IACs consist of a winding and a special ring magnet. There are four windings in total. Control signals from the computer are supplied to one of the windings, which contributes to the rotation of the rotor. Because of this, the cross-section of the passage channel smoothly changes from the state of complete opening to complete closure, and vice versa.

- Rotary. Their operating principle is similar to solenoid IACs. But here the tasks of the core are performed by the rotor. The latter is capable of rotating in different directions, thereby changing the dimensions of the channel cross-section.

Depending on the type of motor and its technical factory characteristics, different types of regulators are used.

Purpose of the XX valve

The idle air valve ensures that the fuel-air mixture enters the engine inlet manifold through a separate additional channel XX, bypassing the throttle valve controlled by the accelerator pedal.

Depending on the type of engine, the idle air valve regulates the flow of either fuel or air.

In carburetor and diesel engines, it controls the supply of fuel to the inlet manifold, necessary for stable engine idle speed.

In gasoline injection engines, it supplies the required amount of air.

Signs of malfunction of the XX valve and its elimination

A faulty idle air valve can cause:

- problems with starting the engine, it may start and immediately stall;

- unstable engine idle speed;

- turning off the engine when the gearbox is in neutral;

- decrease in idle speed when turning on the load (stove, headlights, etc.).

The functionality of the idle speed solenoid valve on carburetor engines can be checked independently by the slight click of the solenoid when the ignition is turned on.

For injection and diesel engines operating under the control of an ECU, its malfunction can be detected using diagnostic equipment.

Principle of operation

Next up is the question of how the idle air system valve, that is, the idle air regulator, works on car engines.

The KXX itself is an electromechanical actuator, which is controlled and controlled by the engine ECU. The latter supplies electrical signals, due to which the valve opens or closes. In this case, the diameter of the flow section of the idle channels changes, through which the required volume of air or fuel for the internal combustion engine enters the intake manifold.

To understand the operating principle on which the operation of the idle air control valve is based, it is worth considering the unit on different types of engines.

Carburetor

Carburetors running on gasoline must have such a solenoid valve. It is located in the carburetor body itself and is an integral part of the forced XX economizer.

This valve is controlled through the economizer control unit, which is located in the engine compartment. When you turn on the ignition, power is supplied from the unit to the regulator, it opens and supplies fuel to the manifold through the idle channel. By turning off the ignition, the power supply to the valve is stopped, and therefore the fuel supply is cut off.

To select the optimal volume of fuel for supply to the XX channel, the carburetor design provides a special adjustment screw.

This screw received a completely logical name and is referred to as the idle screw.

Injector

For gasoline injectors, the operating principle of the XX regulator is somewhat different. Structurally, it is located in the throttle body and is part of the electronic control system of the internal combustion engine.

The ECU is responsible for the operation of the valve. It records signals coming from monitoring installed sensors, processes the data and transmits control signals directly to the regulator itself. Due to commands from the ECU, the IAC can increase or decrease the volume of air entering the engine manifold, thereby maintaining the set speed.

What is it for?

To begin with, you should understand what CXX is and why it is used in a car.

IAC, that is, the idle air valve, is responsible for the flow of the air-fuel mixture into the ICE manifold. In this case, a separate idle channel is used, which bypasses the main damper of the throttle itself. The latter is controlled by the gas pedal.

Depending on what type of engine we are talking about, the valve can regulate the supply of the required volume of air or the fuel component. If it is a carburetor or a diesel internal combustion engine, then the fuel supply is regulated. If it is a gasoline injector, then air is supplied in the required volume using the IAC.

But it’s not enough just to know about the purpose of this idle air system valve. It is also worth understanding the features of its work.

How to identify a malfunction

Malfunction of the IAC is expressed in the following problems:

- The turnover is unstable.

- There were problems starting the engine: it does not start immediately, it stalls.

- Idle speed decreases with additional load (headlights, heater).

- The engine automatically stops working when the gearshift lever is moved to the neutral position.

Special diagnostic equipment will help determine the exact cause of engine malfunctions and determine the malfunction of the IAC. Depending on the complexity of the problem, adjustment, repair, or replacement of a spare part may be necessary.

How does the idle air control valve work?

Idle air valve operation

Much depends on the amount of air entering the fuel-air mixture injection system. An incorrect air to fuel ratio can lead to various consequences:

- excessive consumption of gasoline,

- insufficient degree of combustion of the mixture,

- premature wear of engine parts,

- reduction in engine power.

At idle speed, the throttle valve does not regulate the air flow into the intake manifold. To solve this problem and maintain the speed at the proper level, an idle speed valve is provided, which many mistakenly call a sensor.

On the one hand, this unit indirectly performs the functions of a sensor, but it also does another job, namely, it regulates the air supply for preparing the air-fuel mixture. Depending on the engine speed and operating mode, this unit regulates the amount of air entering the fuel system.

When the car is idling, the throttle valve is not engaged and cannot change its position. Accordingly, there is a need for a device that will provide air access to the injection system. This is where the XX (idle) valve comes to the rescue.

What is the idle air solenoid valve and how does it work?

Warming up the engine is a procedure that allows you to increase its service life and reduce fuel consumption during the first time of its operation. The air supply mechanism at idle speed does not work due to its design, namely the throttle valve design. In order to solve this problem, an idle air valve is installed in the car, which regulates the operation of the throttle valve when the engine is idling.

How does the idle air control valve work?

Much depends on the amount of air entering the fuel-air mixture injection system. An incorrect air to fuel ratio can lead to various consequences:

- excessive consumption of gasoline,

- insufficient degree of combustion of the mixture,

- premature wear of engine parts,

- reduction in engine power.

At idle speed, the throttle valve does not regulate the air flow into the intake manifold. To solve this problem and maintain the speed at the proper level, an idle speed valve is provided, which many mistakenly call a sensor.

On the one hand, this unit indirectly performs the functions of a sensor, but it also does another job, namely, it regulates the air supply for preparing the air-fuel mixture. Depending on the engine speed and operating mode, this unit regulates the amount of air entering the fuel system.

When the car is idling, the throttle valve is not engaged and cannot change its position. Accordingly, there is a need for a device that will provide air access to the injection system. This is where the XX (idle) valve comes to the rescue.

Where is the idle air valve and its control unit located?

The valve is located directly in front of the damper and forces it into action. Its operation is regulated by a solenoid valve control unit, which is located in the engine compartment. If the placement of the valve depends solely on the design of the air intake system, then the location of the block varies depending on the car model.

The valve control unit can be installed:

- near the XX valve directly;

- under the windshield;

- in the generator area;

- anywhere in the engine compartment that is protected from water and high temperatures

The valve control unit is a sensitive device. It can be damaged due to mechanical stress, sudden temperature changes or moisture. In order to secure the unit, the designers suggest its location in the most protected areas of the engine compartment. The installation location directly depends on the design of the engines and other equipment located under the hood.

What kind of idle air valve can it be?

On older cars with carburetor engines, mechanically actuated valves were installed. Their operation was regulated depending on the operating mode of the engine, but such a system did not justify itself, but was used for lack of a better one. The mechanism was set to a certain mode and did not have time to react in time to changes in the amount of fuel supplied to the engine and changes in the number of revolutions.

Subsequently, electronically controlled XX valves appeared, which began to be installed on injection cars. The control unit receives information from several sensors, processes it and accordingly regulates the valve capacity and its operating mode.

As a result, optimal fuel consumption and gentle engine operation are achieved. Thanks to such a control system, it is possible to reduce gasoline consumption and increase engine life. The idle air solenoid valve has taken root, although it has a rather complex device, but its operational characteristics offset this drawback.

The idle air valve is a device that allows you to increase the life of the engine and prevent its wear. If it fails or does not work correctly for some reason, the engine begins to start poorly, and its parts are subject to increased wear. This is caused by incorrect valve settings, which may result from unqualified replacement or repair. Therefore, it is important that all work with it is carried out by a good specialist. It would be useful to periodically check the quality of its work.

Where is the idle air valve and its control unit located?

Operating principle of the idle air valve

The valve is located directly in front of the damper and forces it into action. Its operation is regulated by a solenoid valve control unit, which is located in the engine compartment. If the placement of the valve depends solely on the design of the air intake system, then the location of the block varies depending on the car model.

The valve control unit can be installed:

- near the XX valve directly;

- under the windshield;

- in the generator area;

- anywhere in the engine compartment that is protected from water and high temperatures

The valve control unit is a sensitive device. It can be damaged due to mechanical stress, sudden temperature changes or moisture. In order to secure the unit, the designers suggest its location in the most protected areas of the engine compartment. The installation location directly depends on the design of the engines and other equipment located under the hood.

Where is the idle speed sensor located and how to replace it

KXX on the throttle valve

This device on Toyota cars is installed on the throttle body using several screws. In some cases, these screws may have specially drilled heads to make removal difficult. Then experts recommend completely dismantling the damper to avoid damage to the valve fasteners.

Common signs of a bad idle air valve include extreme roughness when idling. In this case, there are jumps or dips when the number of revolutions increases, a decrease in speed when the load is on, when they should only increase, or a complete stop of the car engine.

The cause of sensor malfunction is usually its contamination due to the low quality of the fuel mixture. When the engine starts, the computer sets the valve to the factory-set value. This is a problem, since the machine is not able to determine the level of contamination of the valve and the amount of various foreign deposits on it that interfere with the normal operation of the sensor.

This type of problem can be resolved by simply cleaning or replacing the idle speed sensor. To do this, you need to disconnect the valve connector and unscrew the mounting bolts. Attention, all this work must be carried out strictly with the ignition off. After replacing or repairing the device, you must reinstall it. Correct installation is checked by measuring the distance between the cone needle and the flange. In normal condition, it should not exceed 23 millimeters. When installing the sensor, it is recommended to lubricate the O-ring with special high-quality motor oil.

What kind of idle air valve can it be?

On older cars with carburetor engines, mechanically actuated valves were installed. Their operation was regulated depending on the operating mode of the engine, but such a system did not justify itself, but was used for lack of a better one. The mechanism was set to a certain mode and did not have time to react in time to changes in the amount of fuel supplied to the engine and changes in the number of revolutions.

Subsequently, electronically controlled XX valves appeared, which began to be installed on injection cars. The control unit receives information from several sensors, processes it and accordingly regulates the valve capacity and its operating mode.

Removal, washing, installation

| This is what the idle air valve (IAC) looks like on a 1997 NISSAN CEFIRO. To remove it, you need to unscrew 2 bolts from the top and one from the bottom, naturally, having first removed all the connectors and the air duct tube from it. There is a metal gasket between the IAC and the intake manifold. Don't let her “go away”. It will be useful to us during assembly :-)). |

| After removal, we see a picture that is not at all pleasing to our eyes, especially the left one :-)… |

| The same thing, but disassembled. On the right are the valves themselves. The big one is the XX valve itself. The small ones are compensating valves for air conditioning and power steering. You need to remove them carefully, because they are spring-loaded, and searching throughout the garage for a small spring or valve is below average pleasure. They also have thin copper washers on them. Losing them is also undesirable :-). There is a rubber seal in the counter part of the IAC, which can also “slip away”. |

| This is what happened after washing with Unisma (domestic chemistry, a la WD-40). |

Everything is assembled without any frills, with one exception... I would strongly recommend sealing the junction of the valves and the body itself (coat the metal gasket on both sides) with sealant (just not too much, because the gaps there are very small), because any “left” leak air can cause problems with flow and starting. It is better to use a “black” or “gray” type of sealant. It is advisable to tighten the adjusting screw to approximately the same depth as it was originally. After installation, do not forget to connect all connectors! :-))

Who to entrust the adjustment to?

KXX is an important part in the power supply system of the power unit. The stable operation of any modern engine depends on its serviceability. You should not trust the adjustment of the idle air valve to unqualified performers.

At the MT-AVTO car service center, specialists with a high level of qualifications and extensive experience are at your service. Using high-tech equipment and modern tools, they will perform high-quality vehicle diagnostics and make the necessary repairs.

The thermal gap between the parts of the pusher and the valves is 0.15 mm for the normal functioning of the gas distribution mechanism. Idle air valves are checked on average every 20 thousand kilometers.

1500 RUR Cost of adjusting the idle air valve

Is it possible to save money by replacing this part?

Toyota idle air valve 22270-21011

If cleaning the idle air sensor does not bring any results, and all diagnostic operations show that the problem lies there, then you should think about purchasing a new device. You can buy a Toyota idle speed sensor either from the manufacturer or at many car flea markets. In addition, there are many websites of spare parts suppliers, equipped with a convenient search for the required part or device. Just enter the code in the search: for example, 22270-21011 (for engines 1NZ-FE, 2NZ-FE) and the site will not only give you the required original idle speed sensor, but also offer replacement options. But you should remember that branded models of spare parts for foreign car engines are quite expensive.