When gasoline comes into contact with air, vapors are released, which, when released into the atmosphere, worsen the environment. To catch them, an adsorber is installed in the ventilation system of the gas tank. In a number of European countries, the use of this device in a car is mandatory at the legislative level and is determined by environmental standards Euro-2 and higher. Knowing the adsorber device and why it is needed, you can easily identify malfunctions, as well as better understand its benefits.

Purpose and principle of operation of the adsorber purge valve

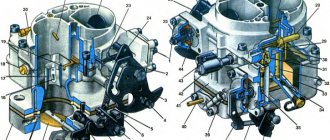

Absorber valve diagram

The EVAP system is installed on gasoline internal combustion engines to prevent fuel vapors from entering the atmosphere. The canister purge solenoid valve is an element of this system. Therefore, to find out what the canister valve is for and how it works, it is important to understand the operating principle of the entire system. The design of the adsorber is a container filled with an adsorbent, most often activated carbon. The device is connected to the fuel tank and the control valve of the vehicle using special tubes.

The canister valve is installed between the intake manifold and the canister and performs the function of ventilation.

Gasoline vapors formed in the fuel tank penetrate the separator, where they condense and are discharged back into the tank. Some of the vapor does not have time to condense in the separator and enters the adsorber through the steam line. In the filter system, they are absorbed by activated carbon, accumulated and then supplied to the intake manifold when the engine starts. The process of absorption of fuel vapors takes place only when the engine is turned off. When the car is running, the electronic control unit opens the canister purge solenoid valve, through which air enters and thus ventilation occurs. In this case, the accumulated condensate along with air is sucked out of the adsorber and again enters the engine, where it is burned out. The canister valve provides ventilation to the entire mechanism and directs fuel condensate back to the engine.

What is a filter element and how does it work?

In simple terms, the absorber is a large can filled with activated carbon. In addition, the system contains:

- Separator with gravity valve. It is responsible for trapping fuel particles. The gravity valve, in turn, is used very rarely, but in an emergency (for example, if the car overturned during an accident), it will prevent fuel from overflowing from the gas tank.

- Pressure meter. It is necessary to control the level of gasoline vapor in the tank. As soon as their level is exceeded, harmful components are released.

- Filter part. In fact, this is the same can of granular activated carbon.

- Solenoid valve. Used to switch between modes for capturing emitted gasoline vapors.

If we talk about the principle of operation of the system, it is very simple:

- First, gasoline vapors rise in the gas tank and are sent to a separator, where partial condensation of the fuel occurs, which is sent back to the gas tank in liquid form.

- That part of the vapor that could not settle in the form of liquid passes through a gravity sensor and is sent to the adsorber.

- When the car engine is turned off, gasoline vapors begin to accumulate in the filter element.

- As soon as the engine starts, the canister valve comes into play, which opens and connects the canister to the intake manifold.

- Gasoline vapors are combined with oxygen (which enters the system through the throttle assembly) and pass into the intake manifold and engine cylinders, where harmful fumes burn out along with air and fuel.

As a rule, it is the adsorber valve that fails. If it begins to open and close in the wrong mode or fails completely, this can negatively affect the operation of the entire vehicle and cause breakdowns.

Checking the functionality of the adsorber

To make sure that the malfunction is related specifically to the valve of this element, you can send the car for a full diagnosis. But this is expensive, so let’s first try to identify possible problems ourselves.

First of all, you need to see if the controller is generating errors, for example, “open circuit control.” If everything is fine, then it will use a manual check. To do this, just prepare a multimeter, a screwdriver and several wires. After this you need to follow a few simple steps:

- Raise the hood of the car and find the valve you need.

- Disconnect the wiring harness from this element. To do this, you must first release the special lock that secures the pad.

- Check if there is voltage going to the valve. To do this, you need to turn on the multimeter and switch it to voltmeter mode. After this, the black probe of the device is connected to the ground of the car, and the red probe is connected to the connector marked “A”, which is located on the wiring harness. The next step is to start the engine and see what readings the device gives. The voltage should be the same as the battery. If it is not there at all or is too small, then you will probably have to look for a more serious problem. If everything is fine with the voltage, then you can move on to the next step.

- Remove the purge valve. To remove it you need to use a screwdriver to slightly loosen the clamps. After this, you can easily move the valve slightly up and smoothly pull it out along a small bracket. After this, the device must be connected directly to the battery terminals. One wire goes to the purge valve (to “+”), and the second is connected to “minus”. After this, both conductors are connected to the corresponding battery terminals. If there is no click, then the valve is completely out of order and it is best to replace it.

We recommend: Xtronic CVT

Absorber valve: what is it for and what does it affect?

The valves in the absorber are a technically simple device that operate differently depending on whether the engine is running or not. Like all valves, it must open and close.

When the absorber cavity is clogged or some other malfunction occurs, the valve malfunctions. With a faulty adsorber valve, serious vehicle damage can occur because pressure is not released from the fuel tank and the cavity is not purged.

Symptoms of Absorber Valve Problems

There are several signs and symptoms that can help identify the technical condition of the valve:

- The fuel gauge shows either a full tank or an empty one.

- After starting the engine, after 5-10 minutes the revolutions begin to fluctuate.

- At idle speed, when you press the pedal, the car begins to stall.

- The engine does not gain speed when driving. It takes a long time to accelerate.

- When opening the gas tank cap, a vacuum is felt and a whistle is heard.

- Increased fuel consumption.

- When it’s cold (when the engine is running but not yet warmed up), knocking noises from the absorber are heard, as if valves are knocking.

The cause of absorber failure is not always the valve. This may be severe contamination of the absorbent element, in this case coal. Gases should easily pass through the coal granules and condense there.

The valve is very cheap. Therefore, it is possible to change if signs of improper engine operation are detected. You can also replace the adsorber filter element with your own hands: disassemble it, pour out the old coal, pour in new coal in large granules.

Where is the adsorber located?

Logically, since the adsorber prevents direct contact of gasoline vapors from the tank with clean air, then it should be located either in the gas tank itself or near it. In fact, the automaker itself decides where to install the key element of the system in the car. Thus, domestic car models (Lada) are equipped with an adsorber, which in almost all versions is located under the hood near the right headlight.

In other brands, this element may be located in a niche along with the spare tire, on the fuel tank itself, under the fender liners, etc. Take, for example, Audi, models A4 and B5. In them, depending on the year of manufacture, the adsorber was installed in completely different departments of the car. In the Chevrolet Lacetti it is generally located under the trunk near the right rear wheel. To clarify where this element is located in a particular case, you must refer to the vehicle’s operating manual.

What is an adsorber and what is it for?

What does the adsorber look like?

The adsorption process is the absorption of gaseous media by bodies of solid or liquid consistency. Accordingly, the main task of the adsorber is to absorb gases, preventing them from entering the environment. However, these are not exhaust gases, but gasoline vapors emanating from the cavity of the fuel tank. When the car engine is running, the trapped vapors are transferred to the intake manifold; while parked, gasoline vapors are neutralized inside the adsorber.

Thus, the adsorber does not allow gasoline vapors to penetrate into the environment, which is required by modern environmental standards, and also does not allow them to enter the cabin. In addition, delaying, condensing vapors and returning gasoline back to the fuel system provides additional savings.

We recommend: Table of signs and causes of automatic transmission malfunction

It should also be noted that the function performed by the adsorber is complex ventilation of the fuel tank. When fuel is consumed, the freed space is filled with air, which is supplied through the adsorber. Here the air is filtered and dried, which has a positive effect on the operation of the engine as a whole.

The key basis for dividing adsorbers into separate classes is its filling. Currently the following options are used:

- granular adsorbent in a stationary state;

- granular adsorbent capable of moving in the cavity of the device;

- fine-grained filling with a boiling bottom layer.

Adsorbers with static coarse-grain filling show maximum efficiency. Its main advantage is protection from partial or complete loss of the active substance along with fuel vapors.

How to remove the adsorber

Some motorists completely remove the adsorber from their car. They remove it because the old filter gets clogged, and buying a new one is simply not affordable. However, when the adsorber is removed, it is necessary to install a fuel filter from AvtoVAZ carburetor engines on the hose coming from the separator. It will prevent dirt from entering the tank, but at the same time gasoline vapors will be able to escape into the atmosphere and there will not be much pressure in the tank.

The benefits of removing the carbon filter are as follows:

Engine operation returns to normal, the speed will stop fluctuating

No need to buy a new filter or valve

There will be free space under the hood

The disadvantages include environmental pollution and the appearance of the smell of gasoline in the car.

What is an adsorber and EVAP system

Many motorists call the device for absorbing fuel vapors an “absorber,” but this is incorrect, since the name “adsorber” comes from the Latin words “ad” (translated as “on”) and “sorbeo” (translated as “absorb”) , which together means “surface absorption” (accumulation on the surface). In turn, the absorber absorbs the entire volume and cannot be used in this case.

Diagram of the fuel vapor recovery system

Since the largest amount of vapor accumulates in the fuel tank, the adsorber is located not far from it. In fact, it is part of an entire gasoline vapor recovery system (EVAP). The latter consists of the following elements:

- Gasoline vapor separator.

- An adsorbent element is a container with an adsorbent substance.

- Ventilation valve.

- Canister purge solenoid valve (located between the canister and the intake manifold).

- Pipes and hoses for connection to the fuel tank, intake manifold and atmosphere.

In addition to the main elements, the EVAP system is part of the OBD-II on-board diagnostic system and includes a number of sensors (fuel evaporation, pressure) and an electronic control unit (ECU) that actuates the solenoid valve.

Let's get started

Let's start by dismantling the part.

First you need to free it from the fastening elements, then disconnect from it the hose that supplies gasoline vapor to the throttle, and the wires with the block. Next, the purge valve is dismantled. The fuel outlet hose from the separator is also disconnected. The bracket should be unscrewed and removed. This is not difficult to do, since it is secured with only three bolts.

Malfunctions of the adsorber valve and their elimination

Almost continuous operation of the fuel vapor absorption system canister can cause damage to the purge valve. A malfunction of the canister valve often leads to damage to the fuel pump. Due to poor ventilation of the adsorber, gasoline accumulates in the intake manifold, the engine loses power, and fuel consumption gradually increases. This may cause the engine to stop completely. The operation of the entire vehicle depends on how the adsorber valve works.

How to check the functionality of the canister purge valve?

Checking the absorber valve

In order to notice and correct problems in time, regular checks of the adsorber valve are necessary. In this case, a breakdown can be identified by certain indirect signs. When the engine is idling or in cold weather, the vapor absorption system makes characteristic sounds, like the canister valve clicking. Some people confuse this sound with a faulty timing belt, rollers or other parts. You can check this by sharply pressing the gas pedal. If the sound has not changed, it means the canister valve is clicking. Experts can explain what to do if the canister valve knocks too loudly. To do this, you need to tighten the adjusting screw, and first it is cleared of epoxy resin.

The absorber valve can be adjusted.

The screw turns approximately half a turn. If you tighten it too much, the controller will generate an error. This adjustment of the adsorber valve will make its operation softer and the knocking noise quieter. However, how to check the adsorber valve for damage? Valve failure can be determined using an error diagnostic system or mechanical testing. Electronic error codes are stored in the controller's memory and indicate electrical damage. To check the valve, it is recommended to pay attention to errors generated by the controller, such as “open circuit of the canister purge valve control circuit.” Signs by which a malfunction of the adsorber valve can be mechanically determined:

- The appearance of dips at idle speed of the engine.

- Very low engine thrust.

- There is no sound of valve operation when the engine is running.

- A hissing sound when the gas tank cap is opened indicates a vacuum in the system. This is a sure sign of a malfunction in the adsorber ventilation.

- The appearance of a fuel smell in the car interior. However, its appearance can also be caused by other reasons.

We recommend: Fuel pressure regulator: diagnostics, repair, replacement

Why do some motorists remove it?

Many car enthusiasts decide to remove a functional adsorber, considering it an unnecessary element in the car. At the same time, not all motorists can justify their actions.

Some drivers are sure that the presence of an adsorber leads to a decrease in the dynamics of the car, others - to an increase in the “gluttony” of the vehicle, and to others such a device seems completely unnecessary.

There is also a category of car enthusiasts who remove the device if it breaks and do not return the new element to its place. The reason is the high cost of the adsorber, which was mentioned above.

The work of discarding the adsorber (if you know some aspects) takes no more than 5 minutes. All that is required is to put a fine filter on the separator tube.

In this case, fuel vapors are directed into the atmosphere. In this case, the tube from the valve is closed, and the ECU program is adjusted. If you do not perform the last action, an error appears.

Solenoid valve malfunctions

If the adsorber is in uninterrupted mode almost all the time, the purge valve can easily stop functioning. This will damage the fuel pump. If the adsorber does not ventilate properly, gasoline will gradually accumulate in the intake manifold.

This leads to some rather unpleasant “symptoms”:

- At idle, so-called dips appear.

- Traction is impaired (it seems that the vehicle is constantly losing power).

- When the engine is running, the sounds of the valve operating are not heard.

- Fuel consumption increases noticeably.

- When opening the gas tank cap, a hissing and whistling sound is heard.

- The fuel tank sensor literally lives its own life (it can show that the gas tank is full, and a second later - that there is nothing in it).

- An unpleasant gasoline “aroma” appears in the car interior.

Sometimes the filter element, on the contrary, makes too loud sounds, which are also not the norm. To make sure that the cause is a faulty valve and not a timing belt, just press the gas sharply. If the sound effect remains the same, then most likely the problem is in the canister valve.

In this case, it is recommended to slightly tighten the adjusting screw of the device. However, you need to tighten it no more than half a turn. Holding too tightly will result in a controller error. If such manipulations do not help, then you need to conduct a more detailed diagnosis.

Automotive absorber design

In simple words, the absorber design is a plastic jar with a filled filter catching element. The best substance for trapping and neutralizing fuel vapors is activated carbon.

The adsorber consists of:

- Separator. The separator captures gasoline vapors and sends them back to the fuel tank.

- Gravity valve. The gravity valve protects against fuel overflow if the car overturns. The valve blocks the movement of fuel.

- Pressure meter. The pressure sensor performs an important function - it monitors the vapor pressure in the fuel tank. When the maximum permissible pressure in the tank is reached, the sensor opens and releases the pressure.

- Filter element (activated carbon). The filter element in a car absorber is carbon in large granules. Large granules allow vapor to pass through the layer of carbon powder and condense.

- Connecting tubes. Connecting tubes serve to connect all structural elements.

- Solenoid valve. The solenoid valve changes the fuel vapor recovery modes.

Changing the device yourself

To change the adsorber, it is enough to perform a number of simple manipulations. In this case, there are two solutions - do the work yourself or go to a service station and entrust the problem to specialists.

The advantages of the first option are cost savings and high speed of work. The sequence of actions is as follows:

- Dismantle the old part, freeing it from the fixing elements and discarding the tube through which fuel vapors enter the throttle.

- Discard the block and wires.

- Connect the fuel outlet pipe from the separator and the purge valve.

- Remove the bracket by unscrewing the three bolts.

The work time is 15-20 minutes.

As soon as the faulty unit is dismantled, proceed with the installation of a new device.

Here the sequence is as follows:

- Connect a long piece of rubber tube to the hose through which fuel vapors flow into the purge channel.

- Connect the short part of the tube to the intake tube from the separator.

- Put the adsorber in place.

- Connect the vapor supply pipe to the purge channel, which is installed on the motor cover.

- Connect the block with wires.

- Install a tube between the purge channel and the adsorber. Make sure that the material from which the pipe is made is resistant to oil and gasoline.