Adsorber or absorber, which is correct? Any internal combustion engine is a source of emissions of harmful substances into the environment. New methods are being invented and old ones are being improved to reduce harmful emissions. Today, environmental friendliness is the reputation of a car manufacturer. For example, in order to comply with the environmental friendliness of Euro 3 engines, a capture device must be installed in the vehicle design, which will ensure lower CO2 emissions.

What is an adsorber in a car, why is it needed and where is it located?

Today, the European environmental standard “Euro-6” is in force, according to which the emission into the atmosphere of hydrocarbon vapors resulting from the combustion of fuel is prohibited. To implement this task, a special device was developed - an adsorber.

The name of the device comes from the word adsorbent (absorbent composition). The unit is mounted in the fuel system of a vehicle in order to absorb harmful vapors arising during the evaporation of fuel.

The absorbent is activated carbon, which fills the tank. It is this that absorbs harmful substances when the engine is not running. Otherwise, the vapors are sucked into the intake pipe and burned in the engine along with the combustible mixture.

This feature helps to increase the efficiency of the car. The result is a double effect: fewer harmful vapors enter the atmosphere and the combustible mixture is saved. Over time, the filter element becomes dirty and its effectiveness decreases.

The main sign of a malfunction is a “hissing” sound when the fuel tank cap is unscrewed. This happens due to the fact that fuel vapors have nowhere to go, and they “rush” out with all their might.

The location of the adsorber varies depending on the make and model of the car. So, in VAZ cars the device takes the form of a black can with a cylindrical shape. The device is often located on the right side in the direction of travel, in the near corner (near the headlight).

But for each model, the manufacturer determines the location of the device individually.

For example, in the VAZ 21099 the absorbent injector is located like this.

Problems with the purge valve

The most common problem with the purge valve is when it sticks or doesn't close completely. This may cause the Check Engine to come on.

In some vehicles, a stuck purge valve can cause difficulty starting immediately after refueling: the engine may run rough and jerk for the first few seconds.

CPA problems are common in many cars. Some early 2000s Hyundai models (Elantra, Santa Fe, Tucson, Tiburon) often have a stuck purge valve, causing trouble code P0441.

Similar problems are quite common in many European cars, including Audi and Volkswagen. In some Mazda vehicles, a faulty valve can cause code P0446 and other EVAP codes.

The purge valve is not very expensive and is easy to replace.

From what Euro standards is it established?

According to international requirements, the installation of an adsorber is mandatory on cars with Euro-2 standards and higher. As for the standard known in Russia (Russia-83), there is no installation of an adsorber here.

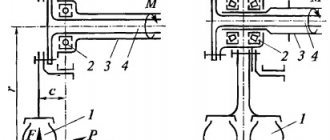

So, in VAZ-2108 cars there is no adsorber. Here the separator and the fuel tank are connected to each other using a drain tube.

During operation, condensation occurs and returns to the fuel tank.

In addition, the separator interacts with the atmosphere using a 2-way valve, which does not allow the pressure in the tank to increase or decrease.

The connection between the tank and the neck occurs using a gasoline-resistant tube, fixed with clamps. It turns out that when the pressure in the tank decreases (increases), fuel vapors escape into the atmosphere.

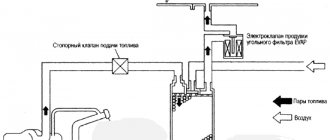

The system is organized differently in VAZ Priora cars. Here, the fuel vapors that entered the separator from the fuel container condense. The condensate then accumulates and returns to the tank.

A gravity valve is mounted in the upper part of the separator, which prevents the fuel mixture from leaking out of the tank if the machine overturns.

If the engine is started, the vapors of the fuel mixture are mixed with air masses and discharged through the throttle assembly into the intake pipe - to the cylinders of the power unit.

It turns out that fuel vapors in a stationary position of the car accumulate in the adsorber, and if the car is moving, they are purged by the valve and sent to the receiver and to the engine for afterburning.

According to Euro-2 requirements, the fuel tank ventilation must not come into contact with ambient air, and vapors must be collected and directed to the engine (or adsorbed by the device in question).

As for the Russia-83 standards, contact between the atmosphere and ventilation of the fuel bank is not prohibited.

Why do you need an adsorber?

The first development of a car adsorber appeared as an additional system that increased the environmental friendliness of the car. Thanks to this device and the modernization of the power unit, the car could comply with the Euro2 eco-standard. This system itself is not needed for better engine performance. If you correctly adjust the gasoline injection , set the ignition and equip the car with a catalyst , the vehicle will comply with more stringent environmental standards.

This system was not used in carburetor engines. For this reason, there is always the smell of gasoline near an old car. If the vehicle is stored outside, it is hardly noticeable. But it is no longer possible to stay in a garage next to such a car for a long time without signs of gasoline vapor poisoning.

With the advent of injection internal combustion engines, the adsorber is an integral element of any car. The fact is that the environment is polluted not only by the removal of exhaust gases through the exhaust pipe. Gasoline vapors also enter the air, and even the highest quality engine with a modern exhaust gas purification system without this system for purifying vapors generated in the gas tank will not meet the high requirements of environmental protocols.

On the one hand, it would be possible to close the gas tank hermetically, and the problem is solved - the fumes do not enter the environment. However, this would not mean that gasoline would stop evaporating. As a result, the pressure in a sealed tank (especially during the hot season) will increase. This process is undesirable for the fuel system. For this reason, the tank must have ventilation.

It turns out to be a vicious circle: the tank cannot be closed hermetically so that gasoline vapors do not increase the pressure in it, but if ventilation is provided in it, these same vapors inevitably enter the atmosphere. The very purpose of the adsorber is to maintain the pressure in the tank at atmospheric level, but at the same time the environment is not polluted with harmful fumes.

In addition to environmental concerns, automakers have improved the safety of the vehicles themselves. The fact is that when the car is stored in a garage, without an adsorber, the air near it will be saturated with toxic fumes. Inevitably, this air enters the vehicle interior. Even with the windows open while driving, it will take time for these volatile substances to dissipate. Because of this, the driver, as well as all passengers, partially inhale polluted air and are poisoned.