Wheel hub

- a part designed to install a car wheel on an axle called an axle.

Hub bearings, in such a connection, are a key element not only of the hub, but also of the entire chassis as a whole, since they are responsible for the controllability of the car and largely ensure the safety of the driver. photo gallery:

The purpose of the hub is to connect the shaft and the wheel rim to transmit torque. On one side, the car hub is mounted on the shaft, and on the other, it has a special seat for mating with the wheel rim. The hub transmits rotational motion from the crankshaft axis to the wheel. A brake disc is also attached to it, so it also participates in braking. The wheel rotates thanks to the hub bearings.

What is a hub in a car

This is a very significant element of any car, which connects two parts, a shaft with a wheel disk, responsible for torque. What does a car hub look like? One side of it is mounted directly on the shaft, and the other is connected to the wheel disk and has a special place for this.

The rotation of the crankshaft axis is transmitted directly to the car wheel through the hub. The brake disc is also attached to it, so it is an important component of the car’s braking system. The rotation of the machine wheel is carried out by bearings.

The design of the part allows it to perform the following functions and tasks:

- Torque transmission.

- Fixing a car disk.

- Keeping all components on the axle shaft.

- Ensuring normal wheel rotation.

- Reliable fixation of the brake disc and brake drum.

In some cars, the rear axle design does not require a wheel hub at all. On such vehicles, the axle is fixed to the base of the beam. The operating principle in this case is based on the use of two angular contact roller bearings. Thus, the inner race of both roller bearings is put on the axle, and the outer races are pressed into the drum.

With this design, the studs for fastening the wheel are mounted directly into the drum. The level of pressing of the cages to the rolling elements is regulated by the tightening torque of the bolt or nut.

Features of fastening the hub to the wheel

The hub is usually attached to the wheel using a variety of bearings. The fastening is carried out on the bridge beam or the axis of rotation, which is also called a trunnion. There is also a flange on the hub. The wheel brake disc is usually secured to the flange if the brakes are disc brakes. If the brakes are drum, the drum is mounted on a flange.

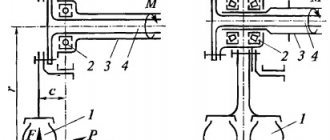

Drawing

The drawing of any hub is quite simple to understand. The wheel axle tube (4) and the shaft (5) are connected by welding. A pair of roller bearings (2) is well and reliably protected from sand and dust from the side of the axle (4) using a protective washer (3), and from the side of the nut (7) by means of a special cap (8), which is inserted into the housing with interference.

To remove the cap, use a bolt (9). The bearing play (2) is adjusted using a pressure washer (6) and a castle nut (7). The nut (7) is fixed with a cotter pin through the shaft hole (5). The housing (1) is well attached to the wooden wheel (10) using several screws (11). The space inside the hub is filled with a special lubricant.

What it looks like and how it works

When driving, the hub basically takes on a very significant load. So that she can cope with it, it is made in this way: a solid steel blank is taken and the required part is processed on a turning and milling machine.

The mechanism is simple: it is a round element with an outer rim where special holes are located.

Functions of its components:

- There are special holes on the outer rim to screw in the guide bolts and bushings that hold the wheel. Sometimes, instead of bolts, you can find studs that are screwed with nuts.

- In cars with ABS, there is a special place for the ABS sensor.

- The inner part of the mechanism is used to install roller bearings there.

- The slotted hole is used to install the CV joint axle shafts.

Roller bearings are used to rotate a car rim. They may vary depending on the specific design. As a rule, these are cone or roller mechanisms. Ball ones are rare because they have too small a contact area.

After diagnosing automobile roller bearings, it becomes clear that they are already quite worn out. You can change them right away, but most cars today have non-removable components. In this regard, when they wear out, you will have to change the entire mechanism, which, of course, is not profitable.

Inspection of the hub and further actions

After removing the part, you must immediately check the condition of the trunnion. If it is seriously damaged, you will have to replace it too. For minor scratches and dirt, it is enough to remove everything with sandpaper. The front hub itself undergoes the same inspection. The presence of cracks and deep potholes indicates the impossibility of its further use. Minor scratches allow the part to be reused.

To remove the bearings, first remove the O-rings on both sides. Then there are the bearings themselves. A special mandrel, hammer and drift will help here. The main thing is not to distort the outer ring to avoid damage to the inner surface. Bearings are removed in a similar way when repairing the rear hub. When both bearings are removed, you need to clean and inspect the inner surface of the part.

If necessary, we purchase a new hub into which we press both bearings. This is done using the same mandrel

Next, we reassemble the entire assembly in the reverse order, paying attention to the wear and performance of the remaining elements of the front suspension. You need to know that the procedure for removing and installing the rear hub is significantly different from the one suggested

If you have ABS, it is important not to forget to check the performance of the gear and install the sensor. https://www.youtube.com/embed/QnMIXT-QgZE

Kinds

- For all driven wheels. For driven ones: the system is mounted on the front discs for rear-wheel drive vehicles. For non-drivers: the element is mounted on the rear wheels of the vehicle, but with front-wheel drive.

- For all driving wheels. For non-drivers: part of the car is mounted on the drive axles of rear-wheel drive vehicles. For those driven: an important unit is mounted on the front axle of cars with front-wheel drive and all-wheel drive.

These mechanisms are made dismountable and monolithic, which affects the possibility of their repair.

- Monolithic design. If a roller bearing breaks, you will need to buy the entire part as an assembly, since replacing its individual components will simply be impossible.

- Collapsible design. In this case, it will be possible to remove the roller bearing or other components of the mechanism and then replace them.

Part device

The front wheel hub, which has various functions, is called a component of the vehicle's chassis system. When a part is taken out of working order, the vehicle cannot be moved. To fully understand the purpose and functions, you do not need to have special knowledge.

It is only enough for me to know that it transmits torque to the wheel in order to make forward motion. At the same time, the fastening to the axle shaft should be as reliable as possible, because a disk with internal rotating bearings is connected to it. There is no point in specifying all possible functions; the basic ones will suffice:

- The basis of the basics is to qualitatively connect the disk that is located on the steering knuckle.

- Due to the location of the brake disc on the hub, it ensures good braking and the general condition of the braking system.

- The presence of a hole with splines and the end of the axle shaft allows the vehicle to safely drive on sections of the highway (for front-wheel drive vehicles).

All modern cars are equipped with information sensors that collect data from the hub. A sophisticated electronic system will protect the driver on the road.

Malfunctions

The breakdown of this element of the car is a fairly serious defect, when further use of the car can lead to wheel jamming and other extremely dangerous situations.

At the first sign of damage, contact the service for professional repair or, if you are well versed in this, carry out the repair.

All the causes of the problems boil down to the following:

- Incorrect installation of subassembly. During installation, tapered bearings can be clamped with a strictly defined torque. If the nut is not tightened enough, the bearing will gradually break while driving on uneven roads. If the nut is pinched, the roller bearing will heat up from constant friction, and this will soon result in rapid wear of the installed bearing.

- Poor quality. Most modern assemblies, even cheap ones, are of normal quality. But you can still stumble upon various fakes, which after some time actually fall apart.

- Frequent driving on broken and uneven surfaces. Dynamic loads from this are the main cause of rapid wear.

- Lack of or contamination of the lubricant used. The assembly unit must be well lubricated. If there is too little lubrication, the working surfaces will very quickly become unusable.

Increased wheel bearing wear

The part is often faulty when a strange hum is heard in the car. Its source can be determined very simply. On a straight, level and empty road section, you need to accelerate to the speed when the hum starts to appear. After this, you need to slightly turn the steering wheel in different directions. If the noise increases when you turn the steering wheel to the right, then the right assembly is broken, and vice versa.

Hub failure

Problems with the assembly unit can be identified by the strong heating of the part. If you have any suspicions, then after the trip you need to carefully touch all the discs with your hand. If in the end you find an element that is really hotter than others, then there are definitely problems with it.

Bearing failure

A breakdown of the front assembly can be determined by greater play in the steering wheel. The latter will tremble when driving at high speed on an uneven road.

Possible defects, reasons for their occurrence

The failure of the hub assembly does not occur instantly. Usually defects appear gradually. They are accompanied by an increase in the clearance in the bearing, which leads to play and runout of the wheel. Main types of hub malfunction:

- Destruction of the cage or rolling elements. This usually occurs due to poor quality materials or a violation of the bearing assembly technology. In addition, destruction is possible due to improper installation of the unit.

- Development of contact surfaces. Bearing parts inevitably wear out, however, the intensity of the process depends on the hardness of the material from which they are made.

- Loosening of fastenings. The design of the mechanism includes locking rings and nuts. If they become loose, the bearing assembly may become loose.

- Dry or lack of lubrication. Without a lubricant, the wear rate will increase several times, which will lead to premature failure of the elements.

- Ingress of dirt or abrasive materials. If the seal is broken, foreign substances contribute to the rapid destruction of parts.

It is difficult to predict what exactly will break. It all depends on the car model, the design features of the hub unit, and the components used. You should not operate the car if there is a suspicion that the chassis components are damaged. Increased clearances in the wheel support lead to increased dynamic loads on suspension components (balls, ends, struts, shock absorbers and other less significant parts). In addition, hub failure while driving can cause loss of control and an accident.

Replacing the hub step by step

The hub is a very durable element. There may be a malfunction or bending due to a significant impact at the time of the accident. Under normal operating conditions, this part must be replaced only if the roller bearing cannot be removed for some reason or its seat is loose.

In addition, it is worth replacing when the threads of the wheel bolts are worn. If the system has removable roller bearings, then its service life is almost unlimited.

It is difficult to find information about after what mileage this part should be replaced. The decision is made separately for each machine.

To replace the mechanism on a car, just do the following:

- Unscrewing the brake caliper and tying it to the spring.

- Removing the chip from the ABS sensor.

- Unscrew it with a 21 ball wrench, tap it on the side with a hammer so that the ball comes out.

- Unscrewing the steering tip.

- Unscrew the bolt securing the steering knuckle to the strut and remove the steering knuckle itself.

- Watering the structure with VD 40, and then removing the old mechanism and installing a new one.

Wheel bearing

To know how a hub works, it is also important to understand what a wheel bearing is. In fact, this is the most loaded element of the vehicle, which can withstand the pressure of its entire mass. This unit also bears additional loads of various directions that arise during sudden braking or when the vehicle moves on an uneven road.

Driving safety directly depends on the reliability and quality of this part. In this regard, it is extremely important that this component of the machine is of high quality, allowing it to remain constantly in good working order.

The mechanism consists of:

- Rolling bodies;

- Inner and outer rings;

- Separator.

Rings are special supporting surfaces that secure the system in the hub bore and in the axle area.

The separator is necessary so that the rolling elements are distributed around the circumference of the cage in the structure as evenly as possible. In addition, this component does not allow contact between rolling elements that are located nearby. Some models also have dust collectors that protect against dust and dirt getting into the unit.

Hub maintenance and repair issues

When operating a vehicle, the hubs and associated parts - mainly bearings - are subject to wear, and various defects and breakdowns may also occur. Therefore, it is periodically necessary to replace wheel bearings, seals, and sometimes the hubs themselves. The need to do this is indicated by increased play (checked with the wheel raised) and knocking noises while the car is moving.

Roller wheel bearings require periodic adjustment, which is done using nuts. In passenger cars with double angular contact bearings, such adjustment is not necessary; these bearings are maintenance-free. If replacement of bearings is required, it can only be done using special tools for removal and pressing.

In general, the wheel hub is reliable and durable, and with regular maintenance and careful operation of the car it does not cause problems for the car owner.

Types of bearings

Depending on the rolling element, the part can be of three types:

- Ball. This is the most popular option. The rolling body here is a ball that rolls along a special track on rings. The balls are fixed in a separator, which can be synthetic, stamped, or machined. Due to its design, the friction moment of the ball type is minimal. This gives him the opportunity to develop a fairly high rotation speed.

- Roller. Here, a cylindrical roller is used as a rolling body, which is securely fixed in the cage. The latter can be made of steel, brass or polymers. In case of extreme need, cageless production of roller models also occurs. This technology is used today if it is necessary to significantly increase the load-carrying capacity of the machine. Multi-row roller models are also used for this.

- Angular contact or conical. An important feature of these elements is the ability to absorb both axial and radial loads. The level of the greatest load on such a model depends on the angle of contact of the mechanisms with the raceways on their rings.

What does a wheel consist of?

Bicycle wheels are the most conservative component. Of course, models with alloy wheels have appeared, and all-round wheels are installed on track models, but they are in the minority. Still, the majority of bicycles are equipped with spoked wheels.

The front wheel arrangement is as follows:

- normal bushing;

- rim;

- connecting needles;

- rim protective tape (flipper);

- tube and tire;

- disc (on models with disc brakes).

The hub is the axial part of the wheel and is an assembly unit consisting of a central axle, bearings and cone retainers. Cone bearing systems are most often installed on bushings with open bearings. They can also be equipped with sealed bearings or seals.

Bushing with open bearings

The rim is a supporting structure, a metal ring. The rims are made mainly of aluminum; expensive models have carbon rims. Based on rigidity and power, they are divided into three types:

- single-walled - the outer and inner surfaces have one line of contact (lintel);

- double - the inner surface is attached to the sides, separated from the outer;

- triple rims are the strongest and most durable option: the inner wall is also attached to the sidewalls, but, unlike the double rim, the triple rim has an additional wall in the middle.

Types of rims for bicycle wheels

Vertical jumpers form channels running in the direction of rotation. Based on the number of such channels, modern rims are divided into one, three and five-piece:

Spokes are elements connecting the hub to the rim. They perform the functions of securing, distributing loads along the rim and central axis and softening vibrations during movement. The rim is perforated, each hole is designed to secure one spoke. A bicycle wheel has a number of spokes that is a multiple of four. Depending on the model, their number varies - from 28 to 40 on average.

The number of spokes for the front wheel is usually less than the number for the rear wheel. This is due to the fact that the majority of the loads fall on the rear of the bike, and the wheel needs to be stronger there.

According to the type of cross-section, the spokes are divided into:

- standard (rolled) – constant circular cross-section along the entire length from the sleeve mount to the tip;

- aerodynamic (blade-shaped) - elliptical or rectangular profile;

- variable section (drawn) - standard section at the heads and narrowing towards the middle.

The tube is the inner part of the tire that holds air under pressure. The tire is the outer shell that contacts the road, absorbs bumps, and protects the tube. The tire is made of harder rubber than the tube.

Rim tape, or flipper, is a rubber lining under the camera to protect it from punctures on the tips of the spokes. Dynamic loads cause the chamber walls to bend, causing them to be pressed against the rim surface. Without a flipper, the camera may be pushed into the hole with the tip of the spoke. This problem is more pronounced on the rear wheel, where the loads are higher, but a flipper is also required on the front wheel. The torn tape must be replaced with a new one. A proven homemade option is to cover the rim with several layers of electrical tape, except for the hole for the nipple.

Replacing the front bearing step by step

When deciding how to properly replace a front roller bearing, it is important to always consider its location. After all, it is the front suspension that affects the car’s handling. Therefore, it is better to do this work with a puller.

This is a special tool with which you can easily remove such a bearing. To do this, you will need to secure the machine in a position convenient for operation. In addition, you will need to put it in first gear, tighten the handbrake and put some supports under the wheels.

This procedure requires special preparation of the work area. You will have to carefully inspect all the elements that you plan to deal with, prepare the necessary tools and think about how to remove the roller bearing more correctly.

The front drive wheels may have two roller bearings.

- Remove the bearing plug using a screwdriver, loosen the nut and hang the car wheel.

- Tie the caliper to the suspension part to prevent it from hanging on the front brake hose. Then you will need to press it out with a screwdriver and carefully remove it from the steering knuckle.

- Unscrew the brake disc bolts from and remove the required mechanism.

- Use a screwdriver to pry up the retaining ring and remove it.

- It is necessary to press out the roller bearing using a puller. Inspect the bearing area, clean it of dirt and corrosion, and then apply new grease. The new part must be pressed in without distortion using a puller.

- Place the snap ring in place and then secure the new part to the axle with a nut and thrust washer. Finally, tighten the nuts so as to correctly adjust the rotation of the disk to prevent backlash.

After completing all the work described above, you will need to make a test drive. It is needed to check for noise in the mechanism. Then you can check again for play in the steering wheel.

Signs of breakdown

To avoid premature damage, it is worth learning more about the types of people who are most likely to encounter this situation:

- racing driving enthusiasts should be the first to get ready;

- those who like to load their car beyond the permissible cargo limit;

- inexperienced amateurs who do not calculate the power of their car and get stuck in mud or snow.

A seized bearing or a cracked hub housing is guaranteed with these driving habits. Wheel play will be an alarm bell for replacement, and a ringing hum will already be a critical situation.

At the auto mechanic I saw the following tools:

- pliers;

- spanner;

- hammer;

- chisel;

- mount;

- block of wood;

- socket heads.

You should watch the thread, it can easily break off while tightening. The wheel bearings are immediately checked and replaced with a screwdriver and chisel. First, the first one is removed, then the oil seal, then the washer under the oil seal, then another bearing. The outer wheels are removed with a hammer and chisel. It is done!

However, there are other types of damage, such as wheel studs. To replace it, hammer it in and pull it out. Or they cut it with a grinder at the bend, since the pin is often bent.

Before installing the hub in place, you need to insert a new stud into the hole, screw on two nuts (the second wheel nut) and remove the car from the parking brake. For reliable fixation, it is worth checking the bolt for tightening force.

Replacing the rear bearing

Repair and complete replacement of the rear roller bearing consists of the following steps:

- Raising the vehicle on a jack and placing wooden blocks under it to make it impossible for the car to accidentally slide off the jack.

- Removing the disc.

- Unscrewing the bolts that hold the brake drum and removing the brake drum using a puller.

- Unscrewing the nut and separating the mechanism with a puller.

- Removing the retaining ring and preparing the new mechanism.

- Installing the new mechanism in the desired place, tightening and rolling the nut.

The hub is truly one of the most important parts of a modern car. Therefore, you need to take the prevention of its malfunctions seriously and responsibly. After all, your health or even life may depend on it. If this part of the car breaks down, it is important to understand how to quickly and correctly replace it with a new and functional one.

What to prepare for dismantling?

If you are sure that the part needs to be removed, then stock up on the following tools:

- a set of socket wrenches, and it is advisable that it be supplemented with a long pipe;

- passages, they are necessary in order to remove the locking rings;

- a spanner wrench, with its help the guide pins of the brake drum are unscrewed;

- a wooden block to soften the blow;

- hammer;

- pry bar and chisel.

It is worth considering that by contacting a service station you will not always receive guaranteed quality work. And an incorrectly replaced bearing will fail quite quickly, so it’s quite possible to dismantle this part yourself, and no one will worry about your “iron horse” better than you yourself. So that you don't feel shy, we offer detailed instructions.