In a car, the adsorber absorbs fuel vapor from the gas tank ventilation system and supplies it to the intake, because according to environmental standards, the gas tank must be isolated from the atmosphere.

From Wikipedia ;

Adsorber (from Latin ad - on, with and sorbeo - absorb) is a device for absorbing (thickening) a surface layer of a solid, called an adsorbent (absorber), of dissolved or gaseous substances, not accompanied by a chemical reaction. The adsorber is used in chemical, oil refining and other industries. The process occurring inside this apparatus is called adsorption.

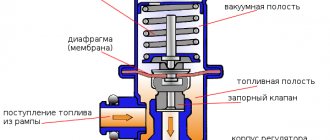

Gasoline vapor filtration system. The diagram is quite conventional, but it reflects the essence. Gasoline vapor from the tank passes through a carbon filter, is cleaned and supplied to the inlet through a solenoid valve controlled by the ECU.

Now the first question is - why filter gasoline vapors if they still go into the intake? The answer is simple - adjusting the internal combustion engine control program by adding the nth number of clean air at the inlet is much easier than making adjustments based on the fuel-air mixture (gasoline vapor from the tank) of an unknown proportion.

And now the answer to the main question - why delete it? So, although some manufacturers claim that this device will have enough resources for the entire life of the car, we know that they are lying)

In general, over time, the adsorber becomes clogged and stops passing air. As a result, we get excess pressure in the tank, which interferes with the normal operation of the fuel pump. In the cabin (sometimes under the hood) we get a periodic smell of gasoline, the vapors of which are squeezed out of the ventilation tube. And the engine starts running on a rich mixture due to lack of air.

Now guess how our country solves this problem? That's right, most people simply throw out the adsorber and turn off the system as shown in the diagram:

A fuel filter from a carburetor classic is usually placed on the tube from the gas tank, and the solenoid valve, through which clean air should flow into the engine, is simply shut off with a bolt.

In the picture I already wrote that this is wrong and here’s why. This method of removing the adsorber only partially solves the problem. Yes, the smell of gasoline disappears, the tank is ventilated, but no air is supplied to the intake and the engine continues to run on a rich mixture.

And now the following diagram:

And now it already shows how it SHOULD be done. The same filter from the classics is put on the hose from the valve to the adsorber, which now serves as an air filter and prevents dirt from getting into the receiver. This is how the fuel-air mixture is brought to normal parameters.

Well, now a couple of visual photos of what it all really looks like:

Everything is clear here, one tube goes to the gas tank, the second through the valve to the engine.

Bottom part of the adsorber. There is a fitting for supplying air from the atmosphere so that a vacuum is not created in the adsorber.

So this is all done on my machine. I didn’t take a photo of the tube from the tank, it’s hard to get to it even without a phone

After reinstalling the ECU, which was discussed in the previous post, 4 errors popped up and here are two of them: P0300 - multiple misfires detected; P0301 - cylinder 1 misfire detected; Moreover, these errors only popped up during intensive driving, and another noteworthy point was that on the old ECU there were no errors due to omissions, really, what can I say, either the block is nonsense, or the firmware from the Icebreaker... but I’m honestly inclined to the second. The check first blinked, then came on constantly, the car jerked and began to run on three cylinders, which had a very bad effect on traction and consumption increased. Having moved the IKZ to the second cylinder, the leak jumped to the second cylinder, as they say there are no options left, change the coil. A reel made by ELKAR was purchased at the store - 800 rubles.

What is an adsorber, what is it used for and how does it work? Replacing the VAZ 2110 adsorber with your own hands

According to the Euro-3 European environmental standard, the release into the atmosphere of hydrocarbon vapors that arise during the evaporation of gasoline is prohibited. Taking this into account, scientists have come up with a device that allows them to capture and neutralize the vapors described above.

This “saving” device was the so-called adsorber or, as some call it, “absorber” (from the word absorbent - capable of absorbing, in part, this name can also be considered correct), it is installed in the fuel system of a car in order to eliminate harmful vapors that result from the evaporation of gasoline.

Today, we will try to answer the most popular questions related to the adsorber, so that you can find out what it is, what it is for, and how the fuel system adsorber works. As an example, we will take the VAZ 2110.

The absorbent that absorbs hydrocarbon vapors is coal, which is used to fill the adsorber tank. Where do the pairs come from? Vapors, as mentioned above, are released by gasoline due to heating of the fuel and constant agitation during movement; the vapors rise upward, then through the hole in the neck of the tank they enter the separator. In the separator, the vapors condense and flow back into the tank, and part of the gases that did not have time to go from a gaseous state to a liquid state or, simply put, to become a condensate, flows through the steam line into the gravity valve and directly into the adsorber, which it neutralizes with activated carbon. This process occurs when the motor is not running.

If the engine is running, the control system purges the adsorber by opening the solenoid valve, after which harmful vapors along with air are emitted into the intake pipe, where they are burned.

The benefit of such a system is double, because first of all, there is no pollution of the atmosphere with harmful fumes, in addition, fuel savings occur, since gasoline does not evaporate, but is returned through the separator to the tank.

And now in more detail

How can I check the functionality of this device? The fundamental element in the absorber is the valve. To understand the function, let’s look at how the adsorber works. When a car is parked, a huge amount of gasoline vapor can accumulate in its tank. Some of the vapor is caught by the recuperator, and the rest settles back into the tank. The part that was caught goes into the adsorber. When the engine is running, the absorber valve closes and interrupts the access of vapors, now they are sent to the combustion chamber. What is it for? When you start the car, our device prevents vapors from entering the exhaust manifold, thereby reducing the amount of harmful substances in the gas.

Where is the adsorber located on the VAZ 2110?

In order to find the adsorber, you need to lift the hood and look in the near left corner, there you will see a small black cylindrical jar.

Replacing the VAZ 2110 adsorber is a simple procedure; it consists of buying a new adsorber, removing the old one and connecting all the hoses in accordance with how they were connected.

That's all for me, the article about the adsorber has come to an end, whoever liked it, comment and share the article on social networks using the special buttons at the bottom of the article. Thank you for your attention, see you again at VAZ Repair.

Source

How to check the adsorber

Many car owners may be interested in the question of how to check the adsorber and its purge valve when the diagnostics showed it to be faulty (an absorber error popped up). It is quite possible to make such a diagnosis in a garage, however, for this it will be necessary to dismantle either the entire adsorber or just its valve. And to carry out such a test, you will need metalworking tools, a multifunctional multimeter (to measure the insulation value and the “continuity” of the wires), a pump, and a 12 V power source (or a similar battery).

What is an adsorber for?

Before moving on to the question of how to check the operation of the adsorber, let us briefly describe the operation of the gasoline vapor recovery system (in English called Evaporative Emission Control - EVAP). This will give a clearer picture of the functions of both the adsorber and its valve. So, as the name implies, the EVAP system is designed to capture gasoline vapors and prevent them from entering the surrounding air unburned. Vapors are formed in the fuel tank when gasoline is heated (most often during long-term parking under the scorching sun in the warm season) or when atmospheric pressure decreases (very rarely).

The task of the fuel vapor recovery system is to return these same vapors to the engine intake manifold and burn them along with the air-fuel mixture. As a rule, such a system is installed on all modern gasoline engines in accordance with the Euro-3 environmental standard (adopted by the European Union in 1999).

The EVAP system consists of the following elements:

- carbon adsorber;

- adsorber purge solenoid valve;

- connecting pipelines.

Change or remove, everything you need to know about the adsorber in a car

Hello, dear friends!

Almost everyone has heard the word “adsorber”, but not everyone understands what it is and why it is needed in a car.

Basically, people know that this is some kind of filter that does not affect the operation of the car's systems. But it is not so.

How the adsorber system works and why it is needed:

There is a special container installed under the hood or on the bottom that contains coal! Because it copes well with gasoline vapors.

Also, the system includes pipes that connect everything and an important element: the Solenoid valve. Additionally there is a pressure sensor and a separator.

So, this is the essence of how the system works. I will try in my own words to make it as clear as possible.

Gasoline vapors generated in the gas tank enter the adsorber. This relieves the pressure in the tank.

The accumulation of vapors and their transformation occurs on a cold engine.

External signs of malfunction

Before checking the adsorber purge valve, as well as the adsorber itself, it will certainly be useful to find out what external signs accompany this fact. There are a number of indirect signs, which, however, can be caused by other reasons. However, when identifying them, it makes sense to also check the operation of the EVAP system, as well as its constituent elements.

- Unstable engine operation at idle speed (the speed “floats” to the point where the car starts and stalls, because it runs on a lean air-fuel mixture).

- A slight increase in fuel consumption, especially when the engine is running “hot”, that is, in a warm state and/or in hot summer weather.

- It is difficult to start a car engine when it is hot; it is usually impossible to start it the first time. And at the same time, the starter and other elements associated with starting are in working condition.

- When the engine operates at low speeds, the loss of power is very noticeable. And at higher speeds there is also a decrease in torque.

How to check the adsorber

Now let’s move directly to the algorithm for checking the adsorber (its other name is the fuel vapor accumulator). The main task in this case is to determine how sealed its body is and whether it allows fuel vapors to escape into the atmosphere. So, the check must be performed according to the following algorithm:

- Disconnect the negative terminal from the vehicle battery.

- First, disconnect all hoses and contacts going to it from the adsorber, and then remove the fuel vapor accumulator directly. This procedure will look different for different machines, depending on the location of the assembly, as well as the mounting means with which it was secured.

- It is necessary to plug (seal) the two fittings tightly. The first one goes directly to atmospheric air, the second one goes to the solenoid purge valve.

- After this, use a compressor or pump to apply a slight air pressure to the fitting going to the fuel tank. Don't overdo it with pressure! A working adsorber should not leak from the housing, that is, be sealed. If such leaks are detected, then most likely the unit needs to be replaced, since it is not always possible to repair it. In particular, this is especially true if the adsorber is made of plastic.

It is also necessary to perform a visual inspection of the adsorber. This is especially true for its body, in particular, for rust spots on it. If they occur, then it is advisable to dismantle the adsorber, get rid of the mentioned spots and paint the body. It is imperative to check whether coal from the fuel evaporation accumulator is leaking into the EVAP system pipelines. This can be done by inspecting the condition of the adsorber valve. If it contains the mentioned carbon, then you need to change the foam separator in the adsorber. However, as practice shows, it is still better to replace the adsorber completely than to engage in amateur repairs that do not lead to success in the long term.

Pinout DS 2109, 2110, 2112, 2114, 2115

If you understand how to connect the speed sensor, then there is the following pinout that you should follow

At the same time, it is important to understand the essence of the operation of the DS to study the circuit diagram of the sensor, which is attached to this article

The factory speed sensor of VAZ cars is manufactured with some differences in connections to the block connector. The square-shaped connector is used in Bosh electronics systems. The circle-shaped connector is used in electronic systems such as January 4 and GM.

When connecting a sensor, you should choose devices with contact group digitization such as “-”, “A”, “+” (internal designation on the block contacts) instead of digital designations such as “1”, “2”, “3”. In addition, preference should be given to devices with a metal-type rod, since plastic rods are very short-lived.

How to check the adsorber valve

If after checking it turns out that the adsorber is in more or less working condition, then it makes sense to check its purge solenoid valve. It’s worth mentioning right away that for some machines, due to their design, some actions will differ, some of them will be present or absent, but in general the verification logic will always remain the same. So, to check the adsorber valve, you must perform the following steps:

- Visually check the integrity of the rubber hoses included in the fuel vapor recovery system, in particular those directly approaching the valve. They must be intact and ensure the tightness of the system.

- Disconnect the negative terminal from the battery. This is done to prevent false alarms of the system diagnostics and to enter information about the corresponding errors into the electronic control unit.

- Remove the absorber (usually it is located on the right side of the engine, in the area where the air system elements are installed, in particular the air filter).

- Turn off the electrical power to the valve itself. This is done by removing the electrical connector (the so-called “chip”) from it.

- Disconnect the inlet and outlet air hoses from the valve.

- Using a pump or medical bulb, you must try to blow air into the system through the valve (into the holes for the hoses). It is important to ensure the tightness of the air supply. To do this, you can use clamps or a thick rubber tube.

- If everything is in order with the valve, it will be closed and air will not be blown through. Otherwise, its mechanical part will fail. You can try to restore it, but this is not always possible.

- It is necessary to supply electric current from the power supply or battery using wires to the valve contacts. At the moment the circuit closes, you should hear a characteristic click, which signals that the valve has actuated and opened. If this does not happen, then perhaps instead of a mechanical failure there is an electrical failure, in particular, its electromagnetic coil has burned out.

- With the valve connected to an electric current source, you must try to blow air into it in the manner described above. If it is working properly, and therefore open, then this should work without problems. If it is not possible to pump through air, then the valve has failed.

- Next, you need to reset the power from the valve, and there will be a click again, indicating that the valve has closed. If this happens, it means the valve is working.

How can I do it without having to deal with dirty gaskets?

The largest absorbers seem to be found in Epson printers.

It was for them that clever users first came up with the idea of storing “spit” in a separate container outside the printer.

This requires partial disassembly of the printer.

The tube through which the waste is discharged into the absorber is extended using a tube from a medical dropper and an adapter from the refill of a ballpoint pen.

This tube must be taken out through a slot in the back wall of the printer or through a specially made hole and inserted into any suitable container (for example, an ink bottle).

Now there is no need to wash the absorber, you just need to remove waste from the external container in a timely manner.

Therefore, it must be honestly washed (or changed). But, if a service station needs to be serviced, then most likely the interior of the printer and the encoder strip are dirty, the grease on the carriage guide has dried out, etc.

In other words, the printer needs full maintenance.

How to repair the adsorber and valve

It’s worth noting right away that in most cases both the adsorber and the valve cannot be repaired; accordingly, they need to be replaced with similar new components. However, as for the adsorber, in some cases, over time, the foam in its body rots, which is why the carbon contained in it clogs the pipelines and the solenoid valve of the EVAP system.

Rotting of foam rubber occurs for banal reasons - from old age, constant temperature changes, exposure to moisture. You can try to replace the foam separator of the adsorber. However, this cannot be done with all units; some of them are non-separable.

If the adsorber body is rusted or rotten (usually also due to old age, temperature changes, constant exposure to moisture), then you can try to restore it, but it is better not to tempt fate and replace it with a new one.

Checking the valve using a homemade tester

Similar reasoning is valid for the solenoid valve of the gasoline vapor recovery system. Most of these units are non-separable. That is, the electromagnetic coil is sealed into its body, and if it fails (insulation breakdown or winding break), it will not be possible to replace it with a new one.

This is exactly the situation with the return spring. If it has weakened over time, you can try to replace it with a new one, but this is not always possible. But despite this, it is still better to perform a detailed diagnosis of the adsorber and its valve in order to avoid expensive purchases and repairs.

Some car owners do not want to pay attention to the repair and restoration of the gasoline vapor recovery system, and simply “turn off” it. However, this approach is not rational. Firstly, this really affects the environment, and this is especially noticeable in large cities, which are not known for their clean environment anyway. Secondly, if the EVAP system does not work correctly or does not function at all, then under pressure gasoline vapors will periodically escape from under the gas tank cap. And this will happen as often as the temperature in the gas tank increases. This situation is dangerous for several reasons.

Firstly, the tightness of the tank cap is broken, the seal of which is broken over time, and the car owner will probably have to periodically buy a new cap. Secondly, gasoline vapors not only have an unpleasant odor, but are also harmful to the human body. And this is dangerous provided that the car is parked in an enclosed area with poor ventilation. And thirdly, fuel vapors are simply explosive, and if they come out of the gas tank while there is a source of open fire next to the car, a fire hazard will arise with very dire consequences. Therefore, there is no need to “turn off” the fuel vapor recovery system; instead, it is better to keep it in working order and monitor the adsorber and its valve.

Conclusion

Checking the adsorber, as well as its electromagnetic purge valve, is not very difficult even for novice car owners. The main thing is to know where these components are located in a particular car, as well as how they are connected. As practice shows, if one or the other unit fails, they cannot be repaired, so they need to be replaced with new ones.

As for the opinion that the fuel vapor recovery system needs to be turned off, it can be attributed to misconceptions. The EVAP system must work normally and ensure not only environmental friendliness, but also safe operation of the vehicle in various conditions.

Source

Working with EVAP elements

To repair the EMS, you will need a file, a set of wrenches and a screwdriver. It is very easy to get to the adsorber itself - it is located under the hood. Sometimes it is fixed with special fasteners, sometimes not

Pull the part out and carefully unscrew the cap. This is where the work begins

Carefully start sawing the part from the bottom. You can make several cuts of 10 millimeters each from the wide part of the body

These cuts are sealed with tape. Next, after the bottom has been sawed off, the adsorber needs to be turned over and the tape removed. Now it is enough to disassemble the lower part of the part, pull out the filters and springs inside. The coal inside spills out. You are interested in filters: they should not be damaged. If the filters are foam rubber, it is better to replace them with felt pads, since this material is more durable. Such gaskets are applied to the walls of the automobile adsorber and treated with high-quality sealant. It is better to replace the spilled coal with new one and dispose of the old one.

Spare parts for Renault 10

Steering rack/mechanism oil seal (see standard sizes) Now the adsorber remains to be assembled. To connect the two parts of the adsorber, the upper part is lubricated with epoxy resin and applied to the lower one. Some car enthusiasts recommend wrapping the device with tape for better fixation.

Of course, the above method is very crude. However, it will allow the car enthusiast to save a lot. The best option would be to buy a new device, since no repair or replacement of filler will allow the adsorber to be brought to marketable condition.