The clutch is whistling, what are the reasons?

A slight whistle appeared in the area of the gearbox at the bottom of the engine. The whistle goes away when you press the clutch pedal. One option is a throwout bearing. What other options? It seems that some other bearing on the input shaft could also be whistling? In addition to the clutch and release plate, is it worth buying it in advance, or do they not whistle? Thanks in advance to the experts who responded.

I'm not eager to become an expert. The release button is missed, because it is inactive when the pedal is depressed. Although if the drive is a cable, then it (the cable) can be pulled. Is there any free play in the pedal? It would be nice to go to the pit with an assistant for localization. What kind of car, some have a hatch in the basket that reveals the clutch.

Apart from the clutch release there is nothing to whistle about. don't worry Moscow))))

yes lana!! The release button just whistles when the pedal is released. squeezed out - does not whistle. )))

It seems like there should be a gap between the release lever and the basket.

Last edited by dzintars; 02/25/2009 at 23:57.

100 poods of release. I had this on my Karina ED, when you start it it whistles, when you press the clutch pedal the whistle goes away. By the way, is the whistle constant or until it warms up?

I give up. Author, change the clutch release ASAP!)

How about pachimu sooner? what will happen if you don't change it?

It will jam and start eating the petals on the basket(

Yes, the bearing needs to be changed urgently, otherwise the clutch will suffer. ts

20-30 thousand ago (it is possible that the bearing was not original, I bought a non-original one again). The car is all-wheel drive and there are a lot of problems with removing the gearbox. It's a pity to repeat everything all over again.

One more thing, the creaking periodically disappears almost completely (20-30 km of city driving), then it appears again, sometimes stronger (audible in the cabin), sometimes weaker (barely audible in the engine compartment).

If you also buy a basket, is it possible to drive to the service center (30 km) with a jammed bearing? I mean, how quickly from the first symptoms of the wedge to the erasure of the petals? Or is it abrupt and straight to the rope?

Releaser. I would score if the whistle goes away when the clutch, engine and gearbox warm up.

You can forget it for now: a good sound will come out on its own)

You can prance for a long time with a rotten release. Even if he cleans the petals and falls through, it’s not a problem. With a little skill, you can drive without a clutch without any problems, you just need to turn it off/start it often.

I’m not an expert by any means, but I also had a whistling noise and skated for six months. It turned out to be the release bearing. The whistle was so loud that my ears were dull)

Releaser. Hana will really start squealing. And it's okay.

Well, that is, if the release switch rustles, you can still drive for now?

Don't drive, the release lever whistles when you press the clutch. And if the whistle, on the contrary, disappears, then it is the bearing in the box that is whistling. You can drive for a very long time, but you may not be lucky.

By the way, I recently visited the website of Nissan Note owners. They've had the same bullshit on their mechanics since birth.

How to extend the resource?

To increase the service life of the device, you must drive on smooth roads. In our country, it is problematic to comply with this condition. Keep in mind that uneven roads destroy not only the vehicle’s chassis, but also the clutch system. Therefore, regular off-road driving is also dangerous for bearings. Don't make mistakes when operating your car. When the car is stopped at a traffic light, there is no need to depress the clutch pedal and engage first gear if you do not plan to move. This should only be done at the beginning of movement, since the part operates under high load conditions. Regular lubrication will increase the service life of the device.

Loading …

What is a release bearing and its role?

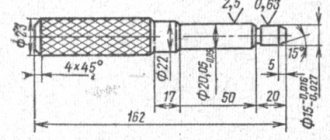

Layout of the release bearing in the clutch mechanism

The clutch release bearing comes into play when gears are changed, providing communication between the clutch discs, so when the first signs of a malfunction appear, you should immediately begin repairing it in your garage or by contacting a car repair shop.

The release bearing comes into play when gears are changed, providing communication between the clutch discs/

There are two types of this part: roller (ball) and hydraulic. How do they work? Everything is quite simple: the chain of action of the mechanism begins at the moment when the driver presses the clutch pedal, then the fork acts on the slave cylinder, after which the two clutch discs are disconnected, and for them to come together again, this spare part exists. We figured out why a release bearing is needed. Why do problems sometimes occur in the clutch system? Malfunctions arise due to excessive loads, usually experienced by novice motorists when they hold the clutch pedal . This is a very small round part, but when driving it bears a great responsibility; if a breakdown occurs, it is not possible to drive the car. The price of a new spare part ranges from 400 rubles to 4,500 thousand rubles, depending on the country of origin. Where is the clutch release bearing located? It is located in the part where the gearbox is connected to the clutch, that is, on the input shaft of the box.

If after replacing the clutch the car jerks

For example, before the repair, the car did not pick up speed well, it was slipping, and the clutch pedal was activated at the very top. All the signs of a worn driven disc were present. After replacing the disk, the car began to jerk. What could happen after the repairs were carried out?

- The issue may be a defective part. This is not so rare when it comes to non-original spare parts. In Russian-made cars (VAZ, GAZ, AZLK, IZH), defects also occur in factory parts. That is, the driven disk is simply curved. On the clutch basket (drive disc), the pressure petals may be at different levels, then the release occurs unevenly and the car jerks.

- The car may jerk due to clutch adjustment. More precisely, it was not performed after replacing the disk. The linings of the new part are much thicker; in this case, the clutch pedal “takes at the very end”. When starting off, the car moves jerkily, and the gear shifts into gear with a crunch.

- The car jerks due to the replacement of not all the parts that needed it. In particular, the cause of jerking is the worn surface of the flywheel under the driven disk. If the flywheel has not been replaced, there may be jerking when driving, and the car may also slip.

Signs of a faulty release bearing

To be confident in your car, rule out the following signs of trouble:

- when squeezing the clutch, a repeated knock or noise appears (the release bearing is humming), but with uniform movement without changing gears, these sounds do not exist;

- changing gears becomes impossible.

There are difficulties with shifting gears, most often this applies to reverse gear;

All of the above factors require diagnostics for malfunction. The question arises: how to check the release bearing? It's not difficult at all. You need to listen to the sounds made when squeezing the pedal; extraneous noise in the area of the box will indicate a breakdown. The characteristic “death” squeal in the car is the main sign that the part needs to be changed urgently, otherwise a situation will arise when the release bearing jams at the most inopportune moment. If you feel that the release bearing is noisy or whistling when it is cold, then evaluate all the risks, and when deciding whether it is possible to drive with noise, it is better to answer - no. On average, it operates without breakdowns for about 150 thousand km; this part is highly durable and reliable.

How to remove and replace a release bearing

Removing the release bearing

An important rule for the release bearing: it should not “play” or move unevenly or spasmodically.

If repairs are necessary, you will have to disassemble the entire gearbox, because... the required part is inside it. Next, the spring clamp is released from tension, and the bearing itself is removed. To do this, you will need a tool, because you will have to remove it from the spring “legs” of the holder. Remove from the bushing, removing the retaining springs, and disconnect from the coupling. The removed part is inspected for cracks and other external signs of failure. It is more reliable to install a new spare part, since it is relatively inexpensive. After all actions, lubricate. How to lubricate the release bearing? Some people prefer molybdenum grease, others prefer graphite; parts are usually supplied with it when purchased in a store. An important rule for a bearing: it should not “play” or move unevenly or spasmodically. How to lubricate the release bearing without removing the box? You will have to contrive, it is almost impossible to provide good thorough lubrication without removing the gearbox. In any case, if the bearing hums, it is best to replace this part with a new one! Beginning motorists may have difficulties with how to change the clutch release bearing; this is quite a troublesome undertaking if there are no basic repair skills. That's why some people turn to a car service center for help. How much does it cost to replace a throwout bearing? This procedure will cost approximately from 2000 to 5000 thousand rubles.

Which release bearing to choose

Release bearing with fork from Valeo

It is better not to purchase only a release bearing. If clutch elements are from different manufacturers, an imbalance may occur during operation. It’s not difficult to select the entire clutch system kit: focus on popularity among customers, reviews, the name of the manufacturer and the established reputation of the store. A one-piece set of excellent quality is produced by Valeo.

Which bearing is better

Many car owners try to replace it with a “original” part from the car manufacturer. But, for example, domestic spare parts from Lada cannot be characterized as the most durable and durable. Popular models are from the German company Sachs or the official supplier for our AvtoVAZ - the Italian bearing Coram. The price leader is Sachs; this is an inexpensive and acceptable quality alternative to replacing a faulty part. You can also choose EXEDY and SASSONE from more inexpensive models.

Adjusting the clutch system and release bearing

If the clutch mechanism is not working properly, the car moves jerkily, jumpily, the lever sinks, and various sounds are emitted from the box.

Good performance properties of a car depend on the quality of operation of three motion systems: gas, brake and clutch mechanisms. To adjust the clutch, sometimes it is enough to adjust the drive; in other cases, repair and replacement will be required. Adjustments must be made on time to avoid breakdowns that require large financial costs. The main signs of a malfunctioning clutch mechanism: the car moves jerkily, jumpily, the lever sinks, various sounds the gearbox Ideally, after depressing the pedal, the car should move slowly and smoothly. Sometimes a lot depends on the little things, and it would seem that such a small part of a large machine, like a release bearing, is a drop in the bucket. But in practice, everything is not so; even the smallest particle that has become unusable requires attention. An experienced driver will be able to repair or replace the release bearing; a beginner will most likely go to the nearest service station or try to solve the problem on his own by reading this article. Good luck on the roads!

If there is a knocking noise after replacing the clutch

As a rule, the cause of knocking after replacing parts is defective parts. In particular, there are dangling damper springs in the driven disk. Therefore, before installing such a spare part on a car, you need to carefully inspect it. Parts of the disk may also be poorly riveted. » alt=»»> Knocks in the clutch area can occur due to a crack in the release bearing bushing (the bushings are often made of plastic). Even at the site where the bushing fits on the flange of the gearbox input shaft, play may form, which also leads to a knocking sound.

The knocking noise occurs due to a broken clutch basket petal, but such a defect occurs infrequently. Another reason for the knocking is a broken starter housing in the Bendix area; it rattles when the car moves. A tooth on the flywheel crown may break off, and it will also knock when touching the rotating parts.

The release bearing is whistling, what should I do?

Getz Driver

Messages: 30 Registration: 16.3.2007 From: Peter, Kolomyagi - Citizen

Good afternoon everyone!

The release bearing was noisy, and it’s about time it ran for 100,000 thousand, so I decided to change the basket and clutch disc to catch up. It so happened that the release tool and basket were purchased in one place, and the disc in another. The same place where the disk was purchased and repair work was carried out. I dropped off the car in the morning and came to pick it up at 6:00 pm.

I start it up and immediately hear the car making some kind of high-frequency whistling or ringing sound. And apparently it’s cyclical (the cycles are very short). I press the clutch pedal - the whistle disappears, I release it - and there it is again. I am absolutely sure that before I handed over the car this did not happen, only the release bearing made noise when I pressed the clutch pedal.

When asked by the master, what kind of nonsense is this, the master said: “What do you want, the clutch is new, it should get used to it.” Drive around and the sound will go away, perhaps you can point at the hole right now and everything will fall into place!” I confess it was my mistake, I believed it, I left in peace! Loch! True, I agreed with the master that if the symptoms did not go away, I would come for an examination.

And as you probably guessed, after a certain amount of time, or to be more precise, 2 weeks have already passed, this sound. hasn’t gone away, it’s hard to say whether he has begun to progress, if so, it’s completely unnoticeable.

And here I have a question. What could be causing this sound? Help me figure it out, and in the next post (so as not to clutter up the first one, there are so many letters) I’ll write how the return visit to the service ended!

Getz Driver

Messages: 30 Registration: 16.3.2007 From: Peter, Kolomyagi - Citizen

I arrived at the service, waited 15-20 minutes until the lift was free, as it turned out later the wait was in vain, we never used the lift.

The foreman stopped by the repair shop, wondering what I didn’t like. I advised to release the clutch pedal, and lo and behold. Still the same whistle! (I would be very surprised if there was no sound, because it ALWAYS appears, and not periodically)

The master called the locksmith boy, they began to listen, periodically asking me to press the pedal and then release it. But no one came to a 100% conclusion, the mechanic guy said that you can find out only by disassembling the clutch again, the master agreed with him, but suggested that the culprit could be a “defective release bearing.” After calling some Auto-GURU, a theory has emerged that the clutch is not to blame at all, but that this is the beginning of the end of the manual transmission input shaft! Which could result in complete failure or breakage of the box.

I, as a person who has not even studied the basics of car manufacturing, and who did not have various connections with our automobile industry in the past, but what is there to hide - Goetz is my first car, it was bought used, and I drove about 27 on it in 1.5 years -28 thousand km., at the moment I am in a complete standstill and lack of understanding, however, there is a strong feeling that this whole story will end with additional injections.

In general, the position of the parties is as follows:

THEY: They claim that the mechanic could not have “messed up” and the problem is either in a defective “releaser” or in the pre-transmission box.

Me: in turn, I don’t understand how something could happen to the gearbox if there were no symptoms with the old clutch. And I do not rule out the possibility of incorrect or poor-quality clutch installation (I wonder if this could happen if desired?)

What we have now agreed on: I’m going to the service center tomorrow, and they remove the clutch in front of me and look for the cause of the sound, if it’s their fault, then they apologize and fix the problem, if it’s the fault of the spare parts or other units I brought, then I pay for everything in full completed work! .

Does anyone have any thoughts on this matter? I have no one to turn to, so I am writing to you! How should I behave in this situation, and what could ultimately cause this sound?

I would be grateful for any advice, any feedback!

P.S. Thanks in advance for your answers.

P.P.S. Today I promise to post a voice recording of the sound.

Defects that appeared after replacing the clutch

What does it mean to replace the clutch? This action means changing the driven or driven clutch disc; often both parts are changed at once. In this case, the release bearing must also be replaced. After such an operation, side defects are suddenly revealed that were not there before the repair.

If we think logically, then there are few reasons for the appearance of new malfunctions. Typically this is:

- Unqualified repairs;

- Defect of new spare parts;

- Erroneous diagnostics, as a result of which not all or the wrong parts were replaced, and previously hidden problems manifested themselves in full.

In general, the issue of the appearance of new unpleasant signs is very difficult and is individual in each specific case, but these signs have common characteristic features.

The release bearing is whistling, what should I do?

The clutch costs less than a week, and immediately the next day after installation, when the engine temperature rose to 90 degrees, the bearing began to whistle.

and now: the clutch kit was installed LUK 624 3097 00 as I found on the Internet in this clutch kit there is a LUK bearing number 500 1041 11

I'm interested in what analogues of the LUK release bearing are there. motor 406 box 5 knock

PS. I read on the Internet that you can install a native GAZ bearing on a LUK clutch (of course it’s dumb, but if so, which option is better to look for) is this true?

Posts 1 page 12 of 12

Share117.12.2011 20:23

- Author: Krasnoarmeyets

- Beginner neon guide

- Registered: 01/13/2010

- Invitations: 0

- Posts: 78

- Respect: 0

- Positive: 0

- Spent on the forum: 5 days 21 hours

- Last visit: 01/02/2014 22:23

Good day everyone. The essence of the problem is that I installed a new clutch assembly and release bearing.. An extraneous sound appeared - whistling. I lightly press the clutch pedal and the whistle disappears. Please note that the whistle sometimes disappears and appears randomly, regardless of whether the engine is warmed up or not, Sometimes When pressed, you can hear a clicking sound in the pedal area when you press it. The clutch is Sachs, the bearing is Luke. I thought it would break in, but I drove 400 km and the whistle did not go away.. It feels like the release lever is slightly touching the basket. How can I fix it?

Share217.12.2011 20:50

- Author: Andrew69

- Neon Guru

- From: Kimry

- Registered: 06/07/2011

- Invitations: 0

- Posts: 1737

- Respect: +36

- Positive: +157

- Gender: Male

- Age: 38 [1983-04-03]

- Time spent on the forum: 27 days 3 hours

- Last visit: 02/13/2020 15:47

More likely just a replacement. It can also be a squealing noise, but the clicks sound like the springs are falling off on the disk, or the gearbox, the input shaft, which is the last thing to blame in this case

Edited by Andrew69 (12/17/2011 21:54)

Share317.12.2011 21:43

- Author: masiy

- Neomaniac

- From: Krasnodar

- Registered: 12/02/2009

- Invitations: 0

- Posts: 3647

- Respect: +174

- Positive: 0

- Gender: Male

- Age: 63 [1958-02-15]

- Spent on the forum: 1 month 16 days

- Last seen: Yesterday 20:54

If you have a cable, the release lever always turns. And when pressed, the whistle disappears, the load increases and the clutch unlocks and the input shaft does not spin.

Share417.12.2011 22:06

- Author: leo just leo

- Club member

- From: Moscow Leninsky Prospect

- Registered: 05/07/2009

- Invitations: 0

- Posts: 3221

- Respect: +212

- Positive: +239

- Gender: Male

- Age: 32 [1989-04-28]

- Time spent on the forum: 4 months 27 days

- Last visit: 07/10/2021 22:43

If you have a cable, the release lever always turns.

all neons from 1995 to 2000 inclusive were with a cable drive, from 2001 to 2005 with a hydraulic drive, so here it is 100% cable.

Share517.12.2011 22:14

- Author: Andrew69

- Neon Guru

- From: Kimry

- Registered: 06/07/2011

- Invitations: 0

- Posts: 1737

- Respect: +36

- Positive: +157

- Gender: Male

- Age: 38 [1983-04-03]

- Time spent on the forum: 27 days 3 hours

- Last visit: 02/13/2020 15:47

What is the difference? Is the vizhimnoy not spinning all the time?

Share617.12.2011 22:20

- Author: masiy

- Neomaniac

- From: Krasnodar

- Registered: 12/02/2009

- Invitations: 0

- Posts: 3647

- Respect: +174

- Positive: 0

- Gender: Male

- Age: 63 [1958-02-15]

- Spent on the forum: 1 month 16 days

- Last seen: Yesterday 20:54

leo just leo I'm getting dusty, not my pen, I threw the thought away and let the owner have a headache. On old hydraulic systems it was always necessary not to tighten, but to release the rod, remove it, tighten it, because If you don't release the clutch will be half depressed. The thinner the clutch disc, the higher the basket's lobes rise (PLATES THAT GO TO THE RELEASE). I didn’t find any adjustment on the new models; it’s clear that a non-adjustable system was installed from the factory. But I'm not God, I could be wrong.

Share717.12.2011 22:37

- Author: masiy

- Neomaniac

- From: Krasnodar

- Registered: 12/02/2009

- Invitations: 0

- Posts: 3647

- Respect: +174

- Positive: 0

- Gender: Male

- Age: 63 [1958-02-15]

- Spent on the forum: 1 month 16 days

- Last seen: Yesterday 20:54

Andrew69 If the release cable is spinning constantly, but without load, i.e. with slipping and rubbing of the breakers. It happens that you remove the gearbox (only on imported models, not ours), the working surfaces of the flywheel and basket with a visible hone (honing, scratches) from the factory, and the scrapers are erased to zero.

Share817.12.2011 22:49

- Author: Andrew69

- Neon Guru

- From: Kimry

- Registered: 06/07/2011

- Invitations: 0

- Posts: 1737

- Respect: +36

- Positive: +157

- Gender: Male

- Age: 38 [1983-04-03]

- Time spent on the forum: 27 days 3 hours

- Last visit: 02/13/2020 15:47

It’s clear, I just have some kind of ringing, but when it’s cold and when it’s cold outside, when it’s squeezed out it’s silent, when it’s heated it’s also quiet, it doesn’t sound like it’s being squeezed out, I think if it was the input shaft, then it would constantly misbehave, I’m blaming the damper springs , what else could be the reason?

Share917.12.2011 23:39

- Author: masiy

- Neomaniac

- From: Krasnodar

- Registered: 12/02/2009

- Invitations: 0

- Posts: 3647

- Respect: +174

- Positive: 0

- Gender: Male

- Age: 63 [1958-02-15]

- Spent on the forum: 1 month 16 days

- Last seen: Yesterday 20:54

Removing and installing the Lada Priora clutch

Replacing the clutch.

Instructions for clutch repair, troubleshooting Lada Priora 2170, procedure for removing and installing the disc on Lada Priora cars. Maintenance and repair of transmission Lada 2170, 2172 Priora. Wheel drive. Replacing the VAZ 2171 clutch. You will need: an “8” wrench (a socket head is more convenient), a large screwdriver...

...a mandrel for centering the driven disk (can be made from the input shaft of the gearbox by removing the gears).

1. Remove the VAZ 2170 gearbox (see “Removing and installing the gearbox”).

2. If you are installing the previous VAZ 2171 pressure plate, mark in any way the relative position of the disc housing and the flywheel in order to install the pressure plate in the same position as before removal (to maintain balancing).

3. Install the mandrel into the pressure plate hole.

You can dismantle the clutch without a mandrel, but at the same time hold the driven disk: it may fall out of the clutch housing.

4. While holding the flywheel from turning with a screwdriver, remove the six bolts securing the clutch pressure plate housing to the flywheel. Loosen the tightening of the bolts evenly: each turn of the wrench, moving from bolt to bolt along the diameter.

5. Remove the clutch housing assembly with the pressure plate.

6. Pull out the driven disk along with the mandrel.

7. Cracks on the driven disk parts are not allowed. Check the wear of the friction linings 1. If the heads of the rivets 2 are recessed to a distance of less than 0.2 mm, the surface of the friction linings is oily or the rivet joints are loose, then the driven disk of the Priora fret must be replaced. Check the reliability of the damper springs 3 in the sockets of the driven disk hub; if the springs are broken, the disk must be replaced.

8. Check the runout of the driven disk if warping is detected during a visual inspection. If the runout exceeds 0.5 mm, replace the VAZ 2172 disk.

9

Inspect the working friction surfaces of the flywheel and pressure plate of the Lada Priora, paying attention to the absence of deep marks, scuffs, nicks, obvious signs of wear and overheating. Replace defective components

10. Using an external inspection, evaluate the condition of the disc spring 1 of the pressure plate. Cracks on the spring are not allowed. The contact points of the spring petals with the clutch release bearing must be in the same plane and have no obvious signs of wear (wear should not exceed 0.8 mm). Otherwise, replace the pressure plate assembly. If the rivet connections of 2 parts of the casing and the pressure plate of the Priora fret are loosened, replace the pressure plate assembly.

11. Assess the condition of the priora compression spring support rings. The rings should not have cracks or signs of wear. Otherwise, replace the pressure plate assembly.

12. Before installing the clutch, check the ease of movement of the driven disk along the splines of the input shaft of the Priora gearbox. If necessary, eliminate the causes of jamming or replace defective parts.

13

Please note that when installing the driven disk into the pressure disk housing of the VAZ 2170, the more protruding part of the hub should be directed towards the pressure spring

14. When installing the clutch, first install the priora driven disc using a mandrel...

15. ...then place the pressure plate casing on the three centering pins and screw in the bolts securing the casing to the flywheel.

- 16. While holding the flywheel from turning with a screwdriver, evenly tighten the clutch-to-flywheel bolts: each one turn of the wrench, moving from bolt to bolt along the diameter. The tightening torque of the bolts is indicated in Appendix 1.

- 17. Remove the mandrel and install the gearbox

- 18. Install the lower end of the clutch release cable on the Priora gearbox and restore the original adjustment of the clutch release cable (see “Replacing the clutch release cable on a Lada Priora”).

Before restoring the original cable adjustment, it is necessary to restore the wear compensation mechanism for the linings of the VAZ 2171 2172 clutch disc to its original state, since if the clutch disc is completely worn out, the wear compensator slider will remain in the lowest position. After installing a new, unworn driven disk, the length of the threaded part of the lower end of the cable may not be enough to restore the initial position of the cable.

To bring the wear compensation mechanism to its original position, by installing size L (see “Replacing the VAZ 2170 clutch release cable”) between the driver and the clutch release fork lever, move the clutch pedal up until it stops - the spring of the mechanism will automatically return the slider to its original position. Then check the L size again and adjust if necessary.

vazclub.com