You can leave your wife, your job, your homeland, but don’t you dare leave the clutch!

The clutch system is a fairly simple mechanism that not only serves as a transmission link between the engine and gearbox, but also removes excess load from both of these units. Of course, such work is not in vain for the clutch system itself, but that’s why it contains consumables, so that you can spend money on replacing them, and not on a global car repair.

The clutch system's job is to mechanically connect the engine to the manual transmission when needed, and disconnect them when it is necessary to change gears. In essence, the task of the clutch does not change, whether it is a clutch on a VAZ 2107 or a Lexus, only the technical details differ.

Product location

The master cylinder on a VAZ 2107 is located under the hood, directly on the wall separating the interior from the hood, near the driver’s feet. Directly above it is the expansion tank, and next to it are the vacuum booster and the brake master cylinder. Usually, simply looking at the product is enough to determine the problem. The presence of a leak indicates that the part is faulty and requires repair or replacement.

Purpose of the device

Cars are equipped with clutch master and slave cylinders, without which the operation of the mechanism is impossible. The VAZ 2107 clutch master cylinder is designed to push out brake fluid. Below is a diagram from which you can visually find out the operating features of the unit.

When you press the clutch pedal, the piston moves in the device in question, thereby pushing out the brake fluid. This liquid enters the working cylinder through a tube, where the reverse process is observed (the liquid pushes out the piston). Brake fluid drives a piston, which is connected by a fork to the clutch disc. As a result, the clutch disc and flywheel are separated, allowing you to change gear. The GCS is also called the main one, since it is with its help that force is supplied from the pedal when it is pressed.

The need to replace the device: when required

Like all parts of any car, the GVC tends to wear out, resulting in the need for repair or replacement. The simplest breakdown of a product is wear of the boot, which can be determined by the characteristic signs of a fluid leak.

To identify a cylinder malfunction, an initial visual inspection is required. It is possible to repair a failed main circulation system on a VAZ 2107; for this you can look for repair kits, but this is not always rational due to the quality of modern spare parts, so it is easier and faster to replace it entirely. The malfunction can also be determined by the characteristic loss of pressure in the system, which is determined by pressing the pedal. Let’s take a closer look at how to change a faulty VAZ 2107 mechanism.

We change it ourselves

Replacing the VAZ 2107 clutch master cylinder begins with the need to pump out the brake fluid from the hydraulic reservoir. This can be done using a syringe or a rubber bulb. Together with this socket or a 10mm wrench, unscrew the bracket securing the expansion tank and move it to the side to gain access to the cylinder.

The next step involves removing the clutch expansion tank hose. To do this, you need to loosen the hose clamp, then disconnect the hose and position it so that it does not interfere with further work. If you want to remove the tank completely, this is done very simply.

Further actions are performed in the following sequence:

- Using a “10” wrench, you need to unscrew the pipeline securing nut to the device. Once the nut is unscrewed, the tube can be moved to the side.

- There is a hose nearby near the steel pipeline, which also needs to be disconnected from the main device. This can be done by loosening the fixing clamp.

- The GCS is fixed to the body using two fastening nuts. To unscrew them, you will need to use a wrench with an extension and a “13” socket. After unscrewing the two nuts, you can remove the product and drain the remaining brake fluid from it. If it is not possible to dismantle the unit, you can press the clutch pedal, as a result of which it will move.

- But repairs are usually not rational, so after removing the old one, a new unit is installed in its place. Installation is carried out in the reverse order of removal. After installation, it is necessary to carry out the process of pumping the hydraulic drive, first pouring fuel fluid into the tank. You can find out how the system is pumped from the relevant material on the website.

After the work is completed, you can test the operating features of the new GVC. If necessary, the RCS (working cylinder) should also be replaced, but you can find out more about this in the corresponding material.

Cars of the Volzhsky plant models 01-07 have a hydraulic clutch drive. The main actuator of this mechanism of the VAZ 2107 is replaced in the event of its breakdown or failure. The cylinder is secured to the engine compartment shield on the driver's side with two studs and nuts, and a reservoir with brake fluid is installed in the upper part. A pipeline is laid from it to the working unit.

Clutch device VAZ 2107

The clutch is controlled by a pedal inside the cabin. When you press it, the clutch is disconnected from the gearbox, and when you press it, it engages. This ensures a smooth start of the car from a standstill and silent gear shifting. The node itself consists of a large number of elements interacting with each other. The VAZ 2107 is equipped with a single-disc clutch with a central spring .

Clutch basket

The clutch consists of two discs and a release bearing. The clutch used on the VAZ 2107 is simple and reliable. The pressure (drive disk) is installed on the flywheel. Inside the basket there is a driven disk connected to the gearbox input shaft with special splines.

The clutch can be single-disc or multi-disc. The first is considered more reliable. The clutch functions as follows. When you press the pedal, the release bearing mounted on the input shaft pulls the petals of the basket towards the engine block. As a result, the basket and driven disk are disengaged, and it becomes possible to change speeds.

For the VAZ 2107, wheels from the VAZ 2103 (for engines up to 1.5 liters) and VAZ 2121 (for engines up to 1.7 liters) are suitable. Externally they are very similar and have a diameter of 200 mm. These discs can be distinguished by the width of the linings (29 and 35 mm, respectively) and the presence of a 6 mm mark in one of the grooves of the VAZ 2121 damper.

Clutch disc

The driven disc is sometimes called a drum. There are pads glued to it on both sides. To increase elasticity, special slots are made on the disk during the manufacturing process. In addition, the drum is equipped with eight springs located in the plane of the disk. These springs reduce the frequency of torsional vibrations and reduce dynamic loads.

The drum is connected to the gearbox, and the basket is connected to the engine. During movement, they are pressed tightly against each other, rotating in the same direction.

The single-disk scheme used on the VAZ 2107 is distinguished by its reliability, comparative cheapness and ease of maintenance. This clutch is easy to remove and repair.

The driven disk for a 1.5 liter engine has dimensions of 200x140 mm. It can also be installed on a VAZ 2103, 2106. Sometimes a drum from a Niva (VAZ 2121) is installed on a VAZ 2107, differing in size (200x130 mm), a reinforced damper system and a large number of rivets.

Release bearing

The release bearing, being the most vulnerable element of the clutch, turns the rotation gear on and off. It is located in the middle of the disc and is rigidly connected to the pedal through a fork. Each press of the clutch pedal loads the bearing and shortens the bearing's life. Do not press the pedal unnecessarily. A bearing is installed on the gearbox drive shaft guide.

In the clutch kit, the release bearing is designated 2101. A bearing from a VAZ 2121, designed for high loads and having an increased service life, is also suitable. However, in this case, you will also need to replace the basket, since pressing the pedal will require great effort.

Clutch fork

The fork is designed to disengage the clutch when the clutch pedal is pressed. It moves the release bearing and, as a result, the inner edge of the spring.

Most often, if the fork is faulty, it becomes impossible to disengage the clutch. However, sometimes it continues to malfunction. If you do not replace the fork right away, you will have to replace the entire clutch assembly later.

Causes of VAZ 2107 clutch failure

Driven and driven discs are subject to the greatest wear.

Clutch failure can be caused by the following reasons:

To eliminate these problems, in each individual case you need to change worn parts; it is better to replace the clutch system assembly.

Visual inspection of the disk

Clutch mechanism of VAZ 2107

The VAZ 2107 clutch is a rather complex mechanism consisting of several dozen elements. The reasons for its malfunction can be very different. However, they can all be divided into two groups:

- Defects in the clutch mechanism itself. These include malfunctions of the driven part of the clutch, pressure device, basket, flywheel, and clutch fork.

- Defects in the hydraulic drive of the clutch mechanism. They can be caused by leakage of the working fluid, the formation of an air lock in it, as well as malfunctions of the main or working cylinders (MCC and RCC) and the pedal mechanism.

The clutch, like any other car part, has a limited service life. First of all, it depends on the skill of the driver, and therefore is not regulated by the manufacturer. To increase the service life of the clutch, it is necessary to adjust it in time, monitor the level of working fluid, avoid off-road driving, and learn the skills of using the clutch correctly.

It must be remembered that in addition, the clutch is a safety device that protects the transmission from serious damage when the rear wheels are blocked by various obstacles. The car is stuck in a quagmire, the drive wheels are stuck, the engine power is enough to turn the stuck tires. In this case, the clutch will begin to slip, protecting the gearbox, cardan and rear axle from damage. Yes, the driven disc linings will burn out. Yes, the clutch will overheat, which can cause the steel flats to warp or weaken the spring plates. But more expensive units will be protected from breakdowns.

Classic VAZ models have a dry, permanently closed single-plate clutch . It includes two main elements:

- Leading part. It consists of a driven disk, the splined part of which transmits rotation to the gearbox due to friction between the friction linings and the surfaces of the flywheel and pressure plate.

- Non-removable drive unit (basket). The basket is attached to the flywheel and consists of a pressure plate and a diaphragm pressure spring.

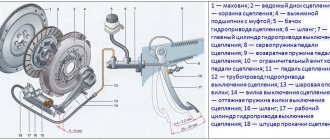

Classic VAZ models use a single-disc dry, permanently closed clutch: 1 - flywheel; 2 — clutch driven disc; 3 — clutch basket; 4 — release bearing with clutch; 5 — hydraulic clutch reservoir; 6 - hose; 7 — master cylinder of the hydraulic clutch release; 8 — servo spring of the clutch pedal; 9 — clutch pedal return spring; 10 — clutch pedal travel limit screw; 11 — clutch pedal; 12 — hydraulic clutch release pipeline; 13 — ball joint fork; 14 — clutch release fork; 15 — release spring for clutch release fork; 16 - hose; 17 — working cylinder of the hydraulic clutch release; 18 — clutch bleeder fitting

The clutch mechanism must be reliable, durable, and capable of dampening fluctuations in engine torque. The clutch has a hydraulic drive consisting of:

- clutch master cylinder;

- clutch slave cylinder;

- clutch on/off forks;

- release bearing;

- foot pedal.

Dismantling the hydraulic drive

To perform the operation we will need:

- container for operating fluid and a large-volume syringe.

- set of wrenches and sockets;

- screwdriver and pliers.

The order of work is as follows:

- Brake fluid is pumped out from the expansion tank of the master cylinder of a VAZ 2107 car using a syringe. A rubber tube is disconnected from the drive, from which the remains are also poured into the prepared container. If liquid gets on paint surfaces, they must be wiped with a damp cloth.

- Using an open-end wrench set to “10”, unscrew the fitting of the pipeline connecting the main and working hydraulic drives.

- Using a “13” socket and an extension adapter, unscrew the nuts holding the assembly to the engine compartment panel.

- To remove the master cylinder from the studs, simply press the clutch pedal, this will move it out of place, after which you can pull it out by hand.

The work on removing the unit is completed, and you can begin installing the spare part.

Clutch slave cylinder spring 2107

Today we will look at how to replace a faulty clutch slave cylinder. They change it if a brake fluid leak is detected and, as a result, problems arise with gear shifting.

In our case, the brake fluid was periodically pushed outwards, the rubber cap was torn, dirt and moisture got under it - the clutch was not fully depressed, and jerks were observed when shifting.

To replace it we will need: - A set of wrenches for 7(8),10,13,17,22 - Pliers - Metal brush - VD-shka or other “liquid wrench” - New working cylinder - Copper O-ring D12 - Brake fluid — Tube and container for bleeding the clutch

To begin, remove the release spring and cotter pin from the hole in the pusher, and loosen the hydraulic hose. We unscrew the two bolts securing the cylinder to the clutch housing.

Hydraulic drive installation

Replacing a mechanism involves purchasing it in a retail network or via the Internet. Installation work is performed in the following sequence:

- The clutch master cylinder of the VAZ 2107 is put on the studs and pushed all the way to the base.

- The nuts are screwed onto the fasteners and tightened with a wrench to “13”.

- The union nut of the pipeline laid to the working hydraulic drive is screwed into the main cylinder.

- The rubber tube is connected to a plastic connecting element and secured with a clamp.

- The expansion tank is filled with brake fluid, which enters the main and slave cylinders of the clutch through tubes. Replacing the fluid in the system is mandatory due to wear products.

What reasons will indicate a malfunction?

The following signs will help you understand that the clutch master cylinder is malfunctioning:

- a sharp decrease in the level of working fluid in the tank;

- traces of leaks in the area where the working and main cylinders are located;

- a kind of “failure” when pressing the clutch pedal;

- inability to fully press the clutch pedal.

Among the main types of malfunctions noted by experts, it is worth highlighting the following:

- malfunction of the cylinder itself;

- worn cuffs or piston;

- filling the system with low-quality brake fluid, which may contain both numerous dust particles and an excess of moisture.

To eliminate the causes of the malfunction of the main element, it is time to use two methods - replace the one that has become unusable with a new one or eliminate a minor breakdown by repairing it yourself. However, it is worth understanding that only rubber cuffs and the body can be repaired, and besides, repairing components will not always give the expected result. It should also be noted that as for the boot, it also needs to be inspected for the presence of large contaminations. According to experts, it is best to completely replace the cylinder, especially since its cost does not exceed 550 rubles.

Replacement

The cost of this type of work in a car service starts from 550 rubles. But for most car enthusiasts, this operation is not so difficult to perform on their own.

- new GVC;

- brake fluid;

- set of wrenches with extension;

- syringe or rubber bulb.

- Pump out the fluid from the hydraulic drive reservoir using a syringe or rubber bulb.

- Remove the expansion tank and move it to the side so that it does not interfere with work.

- Unscrew the tube with a 13mm wrench. Move it a little.

- Loosen the clamp and disconnect the rubber hose that goes from the tank to the cylinder.

Unscrew the two nuts with a 13mm socket wrench and an extension. - Remove the master cylinder from the studs.

- Replace the GCS with a new one.

- Reassemble everything in reverse order.

Bleeding the clutch

The replacement has been made, but you should not hit the road without bleeding the clutch system. The process is similar to bleeding the brakes and is carried out in the following sequence:

- Brake fluid is poured into the reservoir.

- A hose is put on the master cylinder fitting, the other end is lowered into a bottle filled with liquid. This will show how air leaves the system during the pumping process.

- The operation requires an assistant. One sits in the car and presses the clutch pedal 5-6 times on command, after which he leaves it pressed. The second one opens the fitting until the release of air stops. This is done several times until all air is removed from the clutch system.

Conclusion

After replacing the clutch master cylinder and bleeding the entire system, you can safely hit the road without fear that the clutch will fail and the car will lose control because of it.

And again we are repairing the VAZ 2107

Clutch problems? Does it not engage completely, is the clutch pedal “soft” or does it fail altogether? All this will tell us that the time has come to repair the clutch - the master and slave cylinders! How this is done will be discussed in this article. Here you will find: instructions for repairing the clutch on a VAZ 2107 car, a useful video, tips and features of this type of work. Here you will find information on how to change cylinders, repair and bleed them.

How to bleed the clutch of a VAZ 2107

To remove air locks from the system, after any repair you need to bleed the system. To do this correctly, you will have to work in the pit and with an assistant. The video below shows in detail how you can pump the clutch in several ways.

- Add fluid to the main cylinder expansion tank to the top (to the top edge) and close the plug;

- Place a small hose at one end onto the working cylinder fitting;

- Press the clutch pedal sharply 5 times at intervals of 3 seconds. After the last press, do not remove your foot from the pedal, do not release the pedal;

- Lower the second end of the hose into an empty container;

- Use a wrench to loosen the fitting so that liquid begins to drain through the hose;

- So much liquid should drain so that the expansion tank becomes almost empty.

- Tighten the fitting, release the clutch pedal;

- Add liquid to the top of the tank, tighten the cap and repeat pumping.

The task of pumping is to ensure that the liquid that drains from the fitting is without a single bubble. Then add fluid to the reservoir up to the mark.

Not all manipulations for servicing and repairing the VAZ 2107 clutch can be performed by the car owner with his own hands. However, for a skilled craftsman this work is quite possible when he has the equipment and the right tools. In the end, “classics” are not particularly difficult to repair.

When replacing a clutch, you need to pay attention to the quality of the parts. Now there are many brands that make spare parts suitable for VAZ, and it is better to choose initially high-quality brands. Then you won’t have to listen to what’s happening under the pedal every time.

Video.

Welcome! Clutch slave cylinder - not all people know what it is, but still from time to time you have to replace it, but how can you replace it if not everyone knows what it is? In short. In the car we are currently considering a classic, there are two clutch cylinders, one of which is the main one and the other is the worker. They perform almost the same function; when you press the clutch pedal, the piston (Indicated by a green arrow) which is located inside the clutch master cylinder moves and thereby pushes the brake fluid further.

At this time, the brake fluid continues its path and thereby rests against the same piston (Indicated by a blue arrow), only which is already located in the clutch working cylinder, and after the brake fluid rests, it begins to push the piston and therefore it moves to the front and there, by pressing the fork, the clutch in the car disengages.

In general, we understand that there must always be brake fluid in both cylinders, but why is it needed, some of you may ask? The thing is that brake fluid is not compressible, and therefore it is used both in the brake system and in the clutch drive, in general, let's get back closer to the topic.

Note! To replace the clutch slave cylinder with a new one, you will need to stock up on: A basic set of wrenches, as well as pliers, and you may also need about 1 or 2 liters of new brake fluid!

Summary:

Where is the clutch slave cylinder located? It is located next to the box, and to be more precise, it is secured with two bolts on the clutch housing itself, so you will only be able to see it unobstructed if you are under the bottom of the car, or if you look deep into the engine compartment, For more details on its location, see the photo below, it is indicated by an arrow:

When should you replace the clutch slave cylinder? As we already understood, inside the working cylinder there is brake fluid due to which the clutch is disengaged in the car, but it happens that over time this cylinder becomes unusable and cracks begin to appear in its body and thereby the liquid that is in it gradually begins to come out of it be, it is very easy to understand if you visually look at it, and it can also be understood without looking at it at all, but how to do this you ask?

The thing is that if the cylinder becomes unusable and brake fluid begins to come out of it, then the first thing that will happen to the clutch pedal is that it will become very easy to press, that is, the system will not be airtight, so to speak, and if the system is not is sealed, then the clutch will practically not work, that is, you press the pedal, it is pressed very lightly and the clutch does not engage, this is perhaps one of the most common problems that happens when the clutch slave cylinder fails.

Note! But we must not forget that light engagement of the clutch pedal can also be caused due to other reasons, for example, a leaking clutch master cylinder, which in this case will also need to be replaced! (For information on how to replace the master cylinder and find out what malfunctions require it to be replaced, see the article entitled: “Replacing the clutch master cylinder”)

Clutch adjustment in an injection VAZ 2107

The clutch adjustment carried out on the VAZ 2107 injector is somewhat different from the similar operation on the “Seven” with a carburetor engine. The fact is that on vehicles with an injection power plant, an additional shield is installed to protect against mud deposits formed from road dirt. In the frontal projection, the protective casing is secured with bolted connections, and in the rear projection - with 2 self-tapping screws.

To dismantle this protective casing, use an 8-type socket wrench to unscrew the 4 fastening bolts. We also dismantle 2 self-tapping stern fastening screws. To carry out such a technological operation as adjusting the clutch pedal of a VAZ 2107, the following work cycle is required:

- Using a scale ruler, measure the distance from the pedal to the surface of the driver's mat. Using the force of your palm, press the pedal until the resistance force of the reverse action of the pedal begins to act and measure the length of free movement of the pedal. It should be 1-3 mm.

- If the measured value does not fall within the required dimensions, then: loosen the lock nut, give the bolt a rotational movement, carry out an adjustment followed by tightening the lock nut.

After carrying out the adjustment work, tighten the fasteners, after which you need to tighten the locking nut. We turn the pusher until the desired stroke value is determined, and finally tighten the locking nut. Care must be taken to maintain the position of the pusher in relation to the main center coupling.

Upon completion of the adjustment of the VAZ 2107 clutch pedal, it is necessary to clarify that the desired length of free movement is normal. Data for control: the stroke of free movement of the pedal is 1-3 mm. The length from the driver's floor to the pedal is 90 mm.

Preparing for clutch repair

What you need to prepare in order to repair the clutch yourself:

- A set of keys

- Screwdriver (preferably thin)

- Special pliers-pullers

- WD-40 or similar rust remover

- Knife

- Brake fluid

- Bleeding hose

- Bleeding container

- Syringe

That's probably all that is needed.

Expanding pliers (circlip pliers)

Clutch replacement

Often, car owners prefer to simply replace clutch parts, since the cost is low and time can be saved significantly. Therefore, you can first consider the process of replacing clutch parts.

Replacing the clutch master cylinder

- First you need to drain the fluid from the clutch reservoir. This can be done using a syringe - select the liquid and pour it into another container.

- You can also remove the hose from the master cylinder fitting and insert it into the same container. Slightly straighten the clamp on the fitting to make it easier to remove the hose. Do whatever is more convenient for you.

- After this, you need to unscrew the pipe fitting that fits the clutch slave cylinder.

- Then spray the two studs that secure the clutch master cylinder to the car body with WD-40 or an equivalent to prevent breaking them when unscrewing the nuts.

- Take a 13mm wrench or a socket with extensions (whichever is more convenient) and unscrew the two fastening nuts one by one.

Removing the nuts securing the main brake cylinder VAZ 2107

- Remove the clutch master cylinder.

Ready! Withdrawal completed. Now let's install the new cylinder:

Advice! Before installing a new master cylinder, pay attention to the condition of the clutch reservoir flexible hose. It often happens that it cracks at the end. There are two options - either replace the hose or cut it (if the length allows).

- First you need to get the drive rod from the clutch pedal into the hole in the new master cylinder. For convenience, ask a friend to press the clutch pedal a little.

- Then install the clutch master cylinder onto the mounting studs.

- Tighten the fastening nuts with a 13 mm wrench or a socket with extensions.

- Using a 10mm wrench, connect the pipeline from the clutch slave cylinder.

- Install the clutch reservoir flexible hose.

- Fill the reservoir with brake fluid to the filler neck.

Replacing the clutch slave cylinder

Clutch slave cylinder for VAZ 2107

Now we will change the clutch slave cylinder on a VAZ 2107:

Advice! When unscrewing and tightening the slave cylinder mounting bolts, be careful not to strip the threads in the gearbox housing.

- Remove the spring from the slave cylinder.

- Next, you need to unscrew the tube that connects the main and working cylinders using a 10mm wrench. Brake fluid will flow from it - put the cap on the end of the tube, which is located on the bleeder fitting of the working cylinder.

- Unscrew the two bolts securing the working cylinder using a 13mm wrench and remove them together with the plate.

- Remove the slave cylinder.

Removed. Now we will install a new clutch slave cylinder on the VAZ 2107:

- To begin, unscrew the adjusting nuts in approximately the same way as they were set on the old cylinder. This will help you either avoid clutch adjustments altogether or reduce them to a minimum.

Clutch adjustment VAZ 2107

- Then insert the slave cylinder push rod into the transmission fork.

- Screw the two bolts together with the plate. As practice shows, it is most convenient to tighten the upper bolt first, and then the lower one.

- Connect the fluid supply tube. Screw it into the cylinder with a 10mm wrench.

- Put the spring back on.

After replacing the working cylinder, it must be bled. If both the clutch master and slave cylinders were replaced at the same time, then read the bleeding method below:

- Unscrew the bleeder fitting 1 turn.

- Wait until liquid flows out along with air bubbles.

- When the air bubbles come out, tighten the fitting until it stops.

- Put on the cap.

- The pumping is over!

The design and principle of operation of the VAZ 2107 clutch

At its core, a clutch is a transmission link between the engine crankshaft and the input shaft of the gearbox. In this case, a simple press of the pedal separates these two units: the engine continues to operate without changing the optimal mode, and the driver can change gear to up, down or neutral.

Clutch device VAZ 2107: 1 - flywheel; 2 — clutch driven disc; 3 — clutch basket; 4 — release bearing with clutch; 5 — hydraulic clutch reservoir; 6 - hose; 7 — master cylinder of the hydraulic clutch release; 8 — servo spring of the clutch pedal; 9 — clutch pedal return spring; 10 — clutch pedal travel limit screw; 11 — clutch pedal; 12 - pipeline; 13 — ball joint fork; 14 — clutch release fork; 15 — release spring for clutch release fork; 16 - hose; 17 — working cylinder of the hydraulic clutch release; 18 — clutch bleeder fitting

What would happen if the crankshaft and gearbox were connected directly? At a minimum, when stopping the car, you would have to turn off the engine and then start it again. Nowadays there are cars on the roads with a “Start-Stop” system, when instead of idling the engine simply turns off, but on the VAZ 2107 neither the battery, nor the starter, nor the engine itself are designed for such “extreme”. Changing gears while driving is also not the best option; the load on the gearbox will be too strong. And such jerks do not add “health” to the engine itself.

So, using the clutch you can:

- Transmit torque from the engine crankshaft to the transmission;

- Disconnect the engine and transmission, interrupting the transmission of rotation.

The clutch device on the VAZ 2107 is a classic clutch design, the simplest and most understandable:

- The engine crankshaft is rigidly connected to the flywheel, which rotates with it. The flywheel performs two functions: it maintains the moment of inertia so that the engine pistons do not freeze at a “dead point”, and serves as one of the elements of the clutch system;

- The driven (friction) disc is a transmission link between the flywheel and the pressure plate. It is installed on the input shaft of the gearbox and connects the clutch elements due to friction;

- The pressure (drive) disk is rigidly connected to the clutch basket. Its task is to tightly press the driven disk to the flywheel, then the torque will be transmitted to the driven disk and from it to the gearbox;

- The clutch basket consists of a casing and a system of leaf springs, which, when pressed, move the release plate back and separate it from the driven disk. When there is no pressure on the springs, they push the drive disc forward so that it presses the driven disc against the flywheel. The basket casing is rigidly connected to the flywheel and rotates with it;

- The release bearing is an essential element of the clutch system. When you press it, the leaf spring of the basket is pressed;

- The driver controls the clutch by pressing the pedal, from which the force is transmitted to the bearing through a system of rods and a hydraulic system.

As can be seen from the description, this is a “dry” (not in an oil bath) single-plate clutch, with a mechanical release bearing and a permanent connection (closed-loop system). Hydraulics are used to transmit the force that the driver applies to the pedal.

Clutch hydraulic drive device

Separately, it is necessary to say about the hydraulic drive. Thanks to it, it is possible to use the incompressibility of the liquid (maintaining a constant volume even under high pressure) and transmit force along a complex trajectory. There is no need to install complex rods and levers; hydraulics do their job perfectly.

Drive diagram VAZ 2107

The hydraulic drive system includes several elements:

- Clutch pedal;

- Master cylinder with expansion tank;

- Working cylinder with pusher;

- Pipeline and hose;

- Release fork.

Principle of operation:

- The force is transmitted from the pedal through the pusher to the master cylinder rod;

- The cylinder piston moves forward and pushes a portion of liquid into the pipeline leading to the working cylinder;

- The fluid presses on the piston of the working cylinder, combined with a pusher. The pusher comes forward and presses on the release fork;

- The fork moves the release bearing away from the clutch leaf spring.

Let's move on to removing the clutch

Let's move on to work “under” the car.

Disconnect the driveshaft from the box.

We unscrew the fastenings of the gearbox safety bracket, as well as the tube from the gearbox. There is no need to disconnect the cardan, since the box does not need to be removed.

Unscrew the nuts that secure the box to the bottom of the car.

Disconnect the wires from the reverse sensor.

Remove the fork spring, which is responsible for disengaging and engaging the clutch, and disconnect the two bolts from the clutch working cylinder.

Remove the clutch pan. Then remove the four clutch housing mounting bolts.

Using a pry bar, push the box as far back as possible. This way she won't get in the way.

Now you will see the flywheel, the basket is secured with six bolts.

Unscrew them and the clutch will be removed along with the release bearing.

Pull out the clutch basket and disc and look at them. If they are in order, then there is no need to change them, or replace them if necessary.

Before starting assembly, it is recommended to lubricate the splines of the gearbox input shaft and polish the clutch disc with a dry cloth.

It is necessary to adjust the location of the clutch disc to the crankshaft bearing. This must be done using a special mandrel. It can be purchased at any auto store. If everything is done correctly, the mandrel will come out freely from the bearing.

Read more: Characteristics of the generator for the VAZ 2101, its connection diagram, disassembly and assembly

That's all, you replaced the clutch yourself, now you can be confident in the reliable operation of your car's clutch.

Clutch repair

Now let's consider another option - using a repair kit for the clutch cylinders - main and working.

Master cylinder

So, we have removed the main cylinder and now we begin to disassemble it.

VAZ 2107 clutch master cylinder repair

- We start by removing the fitting. Use a screwdriver to remove the retaining ring.

- After which you can easily remove the fitting with the gasket.

- Now remove the rubber boot (protective cap) by simply prying it with a screwdriver or other convenient object.

- Now, using a 22 key on the other side, you need to unscrew the plug of the VAZ 2107 clutch master cylinder.

- You also need to remove the retaining ring from the boot side. This can be done using two screwdrivers, or special pliers. It is more convenient to use expansion pliers.

- Now you can easily remove all the insides of the cylinder.

Now about damaged parts and their replacement:

- All rubber seals should be replaced. 2 rubber rings - on the piston and pusher rod, one on the fitting, and we also replace the protective cap if necessary.

- If necessary, replace the spring. If it is deformed or damaged.

- Also pay attention to the internal mirror of the cylinder. It should not have burrs or chips.

- If the piston is damaged or the pusher is bent, then it is better to replace the cylinder with a new one.

- When assembling, all parts should be washed very thoroughly.

Note! Never wash parts in gasoline or oil and do not allow these liquids to get inside the cylinder. Lubrication is carried out only with brake fluid!

Then install the cylinder back on the car. This is how the clutch master cylinder is repaired on a VAZ 2107 car.

Working cylinder

VAZ 2107 clutch slave cylinder repair

- Clamp the VAZ 2107 clutch slave cylinder in a vice and unscrew the rear plug.

- Remove the protective rubber cap.

- Remove the retaining ring from the plug side and remove all internal parts of the working cylinder.

- Using a 10mm wrench, unscrew the bleeder fitting.

- Check the condition of the spring.

- Replace all rubber seals of the VAZ 2107 working cylinder.

- Check the condition of the working cylinder mirror.

- Wipe the inside with a clean cloth if necessary.

- Clean the bleeder fitting. If the edges on it are “licked”, replace it.

- Wash all parts in brake fluid.

- Lubricate each part with brake fluid during assembly.

- Reassemble all parts in reverse order.

- Install the retaining ring, protective cap and plug.

Install the VAZ 2107 clutch slave cylinder on the car (see above).

The design of the clutch mechanism on the VAZ 2107

Although the clutch performs a simple task, it consists of many component parts. All parts have a corresponding lifespan, so sooner or later the clutch needs repair and adjustment. Before setting up the clutch on the VAZ 2107, you need to understand its structural elements.

Classic cars of the VAZ family are equipped with a dry closed-type clutch mechanism. The device consists of the following elements:

- The driving part is a driven disk that has splines for transmitting the moment of movement to the gearbox shaft. This rotation is transmitted by friction that occurs between friction linings with the flywheel and the pressure plate.

- Non-separable mechanism - this unit is called a basket, which is fixed to the flywheel.

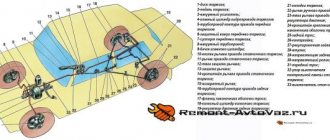

The clutch mechanism on the VAZ 2107 is activated by the leftmost pedal in the car's interior. The device is driven by a hydraulic drive. The basis of the hydraulic drive consists of the following components:

- Master and slave cylinders.

- On and off forks.

- Release bearing.

All classic VAZ models, as well as carburetor and injection VAZ 2107, are equipped with a similar clutch design. The only difference is the presence of an auxiliary shield on injection models, the purpose of which is to protect against dirt. To give you an idea of what we're talking about, below is a diagram of the device in question.

How to adjust the clutch on a classic

The clutch adjustment on the seven should be done after the work on installing the mechanism is completed. If the setup procedure is correctly completed, you can continue to operate the machine without worrying about premature failure of the unit. Before the adjustment process, you will need to check the hydraulic drive for the presence of air in it. The air must be removed by bleeding the system, and if necessary, replace all the fluid.

This is interesting! If, after replacing the clutch parts, the adjustment of the mechanism was carried out incorrectly, then continuing to further operate the machine with an unadjusted device is not only inconvenient and dangerous, but may risk repeated repairs.

If there is a need to adjust the mechanism in question on the VAZ 2107, then detailed instructions are presented below.

Adjusting the clutch pedal free play

To set the free play of the pedal, you will need to adjust two units - the main and working cylinders. This will allow you to perform the most precise adjustment of the clutch on the VAZ 2107. Procedures for adjusting the travel of the clutch pedal are performed:

- Using two keys at “13” in the car’s interior below, you need to adjust the full pedal stroke. A special rod acts as a full stroke limiter, which is secured with two nuts. Using one wrench you need to hold the travel stop fastening, and with the second you need to loosen the nut a few turns. The full pedal stroke should be about 140 mm, which can be measured using a ruler.

- In the next step, you should set the free play of the pedal. In standard mode, the free play should be approximately 30 millimeters. However, this value is not a reference value, and each car enthusiast can set the idle value based on his preferences. To set the free play of the pedal, you will need to rotate the nut of the limiter itself towards the bracket, which is indicated by the number “2”. As soon as the free play reaches the desired value, you need to hold the nut with a wrench and use a second tool to tighten the lock nut.

- At the final stage of self-adjustment of the clutch pedal, it is necessary to check. We take a ruler in our hands, and resting it on the body as the pedal moves, we take measurements. You immediately need to press the pedal with your hand and press until resistance occurs.

Adjusting the free play of the clutch fork pusher

Let's start adjusting the free play of the clutch fork push rod (working cylinder). First you need to clarify the amount of free play. This is done like this:

HOW TO REPLACE THE CLUTCH SLAVE CYLINDER ON A LADA 2107 WITHOUT THE HELP OF SPECIALISTS?

Nobody wants to experience discomfort while driving, especially if it is associated with problems in driving. Owners of domestic “classics” have to devote more time and effort to the condition of their car, because they are used to doing everything with their own hands. We can say with complete confidence that if the car owner has already mastered the process of adjusting the wheel alignment, then he can also repair the hydraulic drive of the transmission clutch, just study the technology.

GENERAL INFORMATION

In order for the replacement of the VAZ 2107 clutch slave cylinder to be justified, it is good to know its purpose and the first signs of a malfunction. The torque transmission system on classic VAZ models is driven by a hydraulic drive, the main task of which is to transmit force when pressing the clutch control pedal. In turn, the hydraulic drive consists of two cylinders: the main and the working. When the pedal is applied, pressure is created in the main center, as a result of which the brake fluid is pumped through the valve into the working cylinder (WC). The latter activates the rod, which squeezes the fork, thereby selecting gears.

Traditionally, the control center is located on the gearbox housing and secured with two bolts, so it can only be reached from under the bottom of the car. The operation of both cylinders depends on the presence of brake fluid, so you need to monitor its level, especially since this is not difficult to do - the container is located in the engine compartment.

WHEN YOU NEED TO REPLACE A DAMAGED CLUTCH WORKING CYLINDER ON A VAZ 2107: SIGNS AND REASONS

In most cases, clutch control problems are associated with loss of tightness, when the pedal loses its elasticity when pressed. However, this fact is not so bad, but the inability to engage the gear is already serious.

If we put together the signs indicating the need to replace the clutch slave cylinder on a VAZ 2107, we get the list:

- A drop in the level of brake fluid in the reservoir, which indicates a loss of tightness of the hose or brake fluid. The breakdown is also determined by the spots under the car.

- Periodic “failures” of the pedal or its soft movement indicate air entering the system. Failure may be the result of a worn cuff or cracks in the working cylinder body.

- A gradual loss of pedal stiffness and difficult gear shifting indicate a broken RC spring. In this case, the fluid level remains unchanged, and adjusting the pedal does not produce any results.

Liquid leakage from the master cylinder is signaled by similar signs, so during inspection you need to pay attention to its condition.

HOW TO CHANGE THE WORKING CYLINDER OF A LADA BY YOURSELF?

To work you will need the following set of tools:

- Pliers.

- Open-end wrench “17”.

- Head "13".

It is more comfortable to carry out the repair process on an inspection pit or overpass. If this is not possible, the front part of the machine must be jacked up and placed on supports, having previously secured the rear wheels with shoes. Further work is carried out on the following transitions:

- Loosen the nut of the hose tip in the RC plug using a 17-mm open-end wrench.

- Using pliers, disconnect the tension spring.

- Unbend and remove the cotter pin at the end of the pusher using pliers.

- Using a 13mm socket, unscrew the two bolts securing the cylinder to the gearbox housing.

- Disconnect the bracket that was secured with bolts.

- Having removed the pusher from the fork, take the RC in your hand and, using a 17mm wrench, completely unscrew the tip nut and remove the hose.

- Replace the clutch slave cylinder on a VAZ 2107, and immediately tighten the hose tip to avoid loss of brake fluid.

- Attach the new part in reverse order.

A certain part of car enthusiasts prefer to drain the old brake fluid before surgery, believing that this will allow them to get rid of dirt in the system. Be that as it may, you will have to bleed and adjust the clutch in any case.

HOW TO BLEED THE CLUTCH CONTROL SYSTEM?

For the quality of transmission operation, the absence of air in the system is important, which is why bleeding is done. The procedure is similar to bleeding the brakes. An assistant is needed to complete the work:

- Fill the reservoir on the master cylinder with brake fluid.

- Place a rubber hose of the appropriate diameter onto the fitting. Place the other end of the hose in a container with some liquid.

- Ask an assistant to press the pedal 5-6 times and hold it in the pressed position.

- Using a “10” wrench, unscrew the fitting half a turn and release air bubbles, then tighten the fitting and repeat the procedure until the air in the liquid completely disappears.

During work, it is important to monitor the fluid level in the tank and replenish it in a timely manner.

Source

Reasons for replacing and adjusting the VAZ 2107 clutch

Replacing a VAZ 2107 clutch is a rather labor-intensive and expensive process. Therefore, before replacing, you should consider adjusting the mechanism.

Clutch replacement

To install a new clutch, you will need an inspection hole, overpass or lift. It is important to detect in time the signs indicating the need to replace the clutch (it is impossible to replace it on the road), and take the car to a garage or car service center. Driving with a faulty clutch is very dangerous - you can get into an accident when crossing a railway crossing or a main road.

The VAZ 2107 clutch cannot be repaired, but is replaced as a kit, which includes a basket, driven disc and release bearing

The entire VAZ 2107 clutch is replaced, so auto shops sell a kit consisting of a driven disc, a basket and a release bearing. You should consider replacing the clutch in the following cases:

- the car climbs heavily uphill when the accelerator pedal is pressed all the way down, and you can smell a burning smell - these are signs of slipping of the driven part of the clutch;

- when the clutch is disengaged, noises appear in the area of the flywheel housing - this indicates a malfunction of the release bearing;

- when starting the car, it is difficult to engage first gear (the gearbox “growls”) - this is a sign that the clutch is not completely disengaged (the clutch is moving);

- when accelerating, the car begins to twitch, rattling sounds are heard - the reason for this is usually broken damper springs or loose sockets for them on the driven disk, deformation of segments or loose rivets on the hub.

Any noise, vibration, or whistle in the clutch area requires more detailed diagnostics and diagnosis.

Clutch adjustment

If the clutch pedal becomes too soft, falls down, and does not return to its original position, then most likely air has entered the system or the hydraulic drive adjustments have been disrupted. Clutch slipping after prolonged use usually indicates a failure of the clutch. It will probably have to be changed.

When adjusting the hydraulic clutch of a VAZ 2107, the regulated values of the gaps and the pedal stroke are set

If the clutch drives, that is, shifts gears with difficulty, in about half of the cases the reason is a discrepancy with the required values:

- play between the rod and the piston in the working cylinder;

- clearance between the release bearing and the fifth basket;

- free and working travel of the foot pedal.