Why does the hum appear?

Most often the release bearing is to blame. This part is practically a consumable for the VAZ-2114.

The first problems with noise in gearboxes arise on cars that have been in service for more than 10 years, or have logged more than 100 thousand kilometers. This is due to the presence of wear due to the expiration of the service life of some parts, which begins to affect the overall operation of the gearbox.

Main gearbox malfunctions

- The clutch cable has failed or its tension has weakened.

- Broken rod.

- The gear shift fork is faulty.

Causes of noise

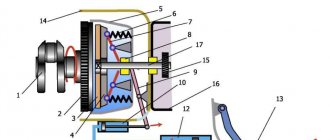

Transmission clutch diagram

There may be several reasons why noise appears from the gearbox, and here are the main ones that occur most often:

- The gearbox was operated with violations , including the use of a car with a non-working clutch.

- , low-quality transmission oil was poured , including counterfeit oil, which did not meet the standards established by the manufacturer.

- Low quality of used gearbox parts

- The period of operation of the gearbox, including its main elements, has expired .

- Carrying out technical and repair work on the “box” by unqualified specialists.

Early signs of a hum in the gearbox on a VAZ-2114

The first, or one might say early signs, after which the box may begin to hum, appear:

- Difficulty changing gears . When this problem occurs, it becomes more difficult to engage any gear, and sometimes it is even necessary to move the lever to neutral several times with the clutch pedal depressed so that it falls into place.

- The gears drop out spontaneously . When driving at certain speeds, the gearbox shifts the speed to neutral.

- Oil is oozing from the “box” housing .

In addition, we can note the fact that the gearbox can make noise under various operating conditions, but most often it manifests itself:

- When depressing the clutch pedal.

- When turning on 3rd or 4th speed.

- When the lever is in neutral position.

- When the vehicle speed is clearly increased.

Replacing the release bearing on a VAZ 2114, the principle of checking it

The release bearing of the VAZ 2114 car is the most important clutch element, acting as a thrust mechanism that transmits the pressing force that comes from the clutch to the drive disc hub and the basket spider. Thanks to the release bearing, the disc disengages from the clutch with the basket, and it also ensures that the clutch is turned off and on. If problems arise with the clutch, then it is often necessary to replace the release bearing of the VAZ 2114. The article examines the main symptoms of its malfunctions and provides step-by-step instructions for replacement.

Signs of breakdowns and how to fix them

All of the above problems are what most VAZ-2114 owners most often encounter; below we will describe how and what to pay attention to if a particular problem occurs.

- The gearbox hum disappears as soon as clutch pedal pressed (this situation is shown in the very first video in the article). In this case, it is possible to indicate the presence of several malfunctions: in the release bearing, as well as in the input shaft bearing. This breakdown can cause the reverse or fifth gear to fail.

Removing the release bearing

- Noise from the gearbox when the engine starts when the gearshift lever is in the neutral position. Such a problem may indicate a bearing failure on the drive shaft or insufficient transmission oil.

- The noise coming from the gearbox disappears when changing gears . Here the culprit must be looked for in the synchronizer clutches, or in the entire locking mechanism.

- The clutch does not disengage completely . In this case, the problem should be looked for in the drive shaft bearing.

Prerequisites – clutch noise

As a rule, the whistle occurs suddenly, but for an attentive driver such a phenomenon will not go unnoticed. Always, before the clutch squeal appears, it will begin to vibrate and make a little noise. This noise can be regarded as follows: press the pedal - the noise appears, release it - the noise disappears.

If you drive for a long time with such noise, you will eventually hear a squeal or a very loud whistle when you press the clutch pedal. A trip with such a problem will not be long, so you need to take action.

ABOUT THE DEVICE AND PRINCIPLE OF OPERATION

It is a regular roller bearing of a specific design.

In the clutch mechanism, it is destined to serve as a stop for transmitting the forces that will come from the pressed pedal. The bearing then transmits this movement to the pressure plate to break the connection between the basket and the flywheel. Without this, it is impossible to turn on the speed and start moving. Its structure can also be judged from the photograph.

Release bearing disassembled

From the photo you can see that it consists of three main parts:

- Clip with guide bushing;

- Roller bearing;

- Fixing washer.

Replacement process

It is more convenient to carry out work on replacing and repairing the clutch on an inspection pit, overpass or lift. The photo shows the clutch diagram:

Car clutch diagram

Tools

To complete the work you will need the following materials and tools:

- flat screwdriver;

- a set of keys;

- lubricant "Shrus-4".

Stages

Replacement consists of the following steps:

- First of all, you need to remove the gearbox.

- Next, the ends of the retainer are retracted from the place where the clutch associated with the bearing engages.

- Then the release bearing is removed from the guide sleeve along with the coupling.

- After squeezing out the four tabs associated with the spring holder, you should remove the holder itself.

- After complete release from the clamps, remove the release bearing from the clutch.

Release from the retainer

- Each removed part must be inspected. If damaged or faulty, parts must be replaced.

- Before installing a new bearing on a VAZ 2114, it must be checked. It is easy to determine serviceability: it should rotate freely without stopping, in addition, there should be no even slight play.

- If the check shows that the part is in good condition, it is installed on the coupling. When installing, pay attention that the protruding part of the inner ring must be directed towards the coupling. After checking that the installation is correct, you can clamp the part onto the coupling using a spring holder.

- Now you can mount the release bearing on the guide sleeve. To extend the life of the part, a preliminary procedure should be carried out: a thin layer of special lubricant must be applied to the surface of the guide bushing.

Car clutch repair

- At the last stage, using a spring clamp, the coupling along with the bearing fixed in it is fixed.

- After the replacement is completed, the gearbox is put back in place.

Replacement does not present any difficulties, you just need to follow the correct disassembly and assembly process without violating the sequence. After carrying out the work, it is necessary to adjust the tension of the handbrake cable and check the functionality of the clutch drive.

FakeHeader

Comments 31

this is the input shaft bearing... the same problem, but I stopped paying attention a long time ago, since you install a new one and there is an option that the same thing will happen... spare parts are crap. I advise you not to touch it yet

By the way, when you remove the box, be sure to check the plug for cracks, they often break

This is a box. When depressed, the clutch disengages and the sound disappears. In most cases this is the large input shaft bearing. If the noise is minor, it's okay. I drove 40 thousand with such a bearing, changed all the bearings when the noise really became annoying. The release mechanism makes just the opposite noise when squeezing, as described below.

the noise is not annoying, but as if delaying this problem would lead to consequences) and they seem to be there)

In the best case, if the bearing jams, it will turn, in the worst case, the bell will break, but that’s when it will make a terrible noise. If possible, you can change

And the fact that the clutch is hard and gives vibration to the pedal is already a problem for the clutch. First, check how the working cylinder rod moves. For a long time I had the problem that the pedal became hard and the gears were difficult to engage. The reason was in the hose that runs from the body to the working cylinder, for some reason it was corroded, it was all swollen and, as a result, it did not allow fluid to pass through well. I’ve never encountered anything like this before, and I’ve never heard from people about it. But I had the same problem.

Take off the gearbox and see if you buy a used clutch, then buy a centering device for the clutch disc) otherwise I’m tired without it

I already thought about this by the way) I was looking at the Schemers program on Discovery and just saw how Ed used a shaft from some machine to center the disk, you will definitely need to get a centering machine)

here it costs 50 rubles)

- there is no lubrication in the release lever - the clutch basket may have fallen apart - perhaps the damper on the clutch disc has fallen apart, that’s what happened)

The lubricant has run out and it whistles.

When the noise died down, did you press the pedal or let it go? Maybe try adjusting it first. Regarding the clutch, the Master said that now the easiest way is to take a VIS and skate 50-60 thousand freely, and then maybe the whole hundred.

6 seconds squeezed the clutch, 9 seconds released, also 15 squeezed the clutch 16 released. We regulated it a year ago, we should try to start with this

It’s not a release lever, it’s the other way around, when you squeeze it out it starts to make noise, it’s the input shaft bearing, most likely yours is noisy, when you squeeze the clutch it goes quiet, the release starts making noise. They are there for 100k mileage, it seems, they are designed taking into account spare parts, or rather their quality, they last less

I have the same crap, but the mileage is 23,000 km

At first, the bearings can howl in cold oil in the box, then you can’t hear them, the mileage after overhauling the box itself is 3k, but the primary bearings also make a little noise in cold oil. I try to ride the first 100-200 meters at XX to warm up the oil in the axle box. Everything also depends on the oil, change the oil in the axle box every 60k, but in fact the axle is 15k, the gearbox is 30, then it’s better to change it. Well, again, the quality of the spare parts, I had almost 100k mileage, the bearings were all on the verge of death, and the fork was also very worn out.

Having your own car does not require a thorough knowledge of its structure. But the baggage of technical knowledge is never a burden. Knowing the signs of a faulty clutch release bearing, you can prevent an accident or equipment failure at the most inopportune moment. Acting proactively always minimizes repair costs. It is more difficult to deceive an informed person and inflate him with an unjustified price. It’s easier for him to know how to identify a problem and what to do in trouble.

What kind of noise could there be in the gearbox?

The noise from the box can come from a different nature; depending on the damage, it not only operates with increased noise, but also howls or hums. Let us briefly describe the reasons why the above components lead to the gearbox howling and humming. So that you understand what to do about it and how to fix the problem.

Gearbox howls

The most common reason for noise in the gearbox resembling a howl is old, contaminated or incorrectly selected gear oil . If its level is insufficient, then as a result, the bearings and other moving parts of the box will run dry, producing significant noise. This is not only uncomfortable when driving, but also harmful to parts. Therefore, you should always monitor the oil level in the gearbox and its viscosity.

The second reason why a gearbox howls is because its bearings are worn out . They can howl due to natural wear, poor quality, a small amount of lubricant in them, or dirt that has gotten inside.

If the gearbox is noisy at idle when the clutch is released, in neutral gear and when the car is stationary, then most likely the bearing on the input shaft is noisy. If the box hums more in first or second gear, then a greater load is placed on the front bearings . Accordingly, it is necessary to diagnose the input shaft bearing.

Likewise, the input shaft bearing can make noise when the car is coasting or simply after starting the engine, and it doesn’t matter at what speed. Often the noise disappears in this case when the clutch is depressed. The reason for this is that when the clutch is depressed, the primary does not rotate, the bearing also does not rotate, and, accordingly, does not make noise.

Worn gearbox gear

If the box is noisy in 4th or 5th gear, then in this case a large load goes to the rear bearings , that is, the secondary shaft. These bearings can also make noise not only in high gears, but in any gear, including reverse. Moreover, the hum intensifies in this case with increasing gears (in the fifth gear the hum will be maximum).

Gear wear is the third reason why the gearbox howls. This noise occurs in two cases: teeth slipping and improper contact patch between them. This sound is different from noise, it is more like a metallic screeching sound. This squeal also occurs under load or during acceleration.

Often the cause of noise is the gear itself if the sound occurs in one specific gear. The gearbox makes noise when driving at speed due to banal wear of the corresponding gear on the secondary shaft. This is especially typical for gearboxes with high mileage (from 300 thousand kilometers or more) as a result of significant metal production and/or low oil level in the box.

Automatic transmission howls

In an automatic transmission, the “culprit” of the howl can be the torque converter . This knot is colloquially referred to as a "doughnut" because of its corresponding shape. The torque converter hums when changing gears and at low speeds. As driving speed increases, the noise disappears (after approximately 60 km/h). Additional signs that the donut is broken include:

- car slipping at start;

- vibration of the car when driving;

- jerking of the car during uniform movement;

- the appearance of a burnt smell from the automatic transmission;

- The speed does not rise above certain values (for example, above 2000 rpm).

In turn, torque converter malfunctions occur for the following reasons:

Torque converter with automatic transmission

- wear of individual friction discs, usually one or more pairs of them;

- wear or damage to blade blades;

- depressurization due to destruction of seals;

- wear of intermediate and support bearings (most often between the pump and the turbine);

- failure of the mechanical connection with the box shaft;

- overrunning clutch failure.

You can check the torque converter yourself, without even removing it from the automatic transmission. But it’s better not to carry out repairs yourself, but instead delegate the diagnosis and restoration of the “donut” to qualified craftsmen.

Gearbox hums

Wear of the synchronizer clutch is the main cause of gearbox hum at speed. In this case, it will be difficult to engage any gear, and often the box will hum in this particular gear. If the wear is significant, the transmission may “fly out” when the car is moving. During diagnostics, you need to pay attention to the condition of the splined connection of the couplings!

If the springs in the clutch weaken or break, this can also cause noise in the gearbox. Similarly, this happens in a certain gear, the springs of which have weakened or broken.

Gearbox is noisy

The transmission of front-wheel drive cars has a differential that distributes torque between the drive wheels. Its gears also wear out over time, and accordingly, they begin to make a metallic noise. It usually appears smoothly and drivers do not notice it. But it manifests itself most of all when the car is slipping. In this case, the drive wheels rotate unevenly, but with high torque. This puts significant stress on the differential, and it will fail faster.

You can indirectly check the wear of the differential by the sign when the car starts to twitch after moving off (rocking back and forth). If we rule out that the engine is to blame, then you need to check the condition of the differential in the gearbox.

It happens that over time the threaded fastening of the gearbox itself weakens. As a result, it begins to vibrate during operation. Vibration, which turns into continuous noise, occurs when the car is moving and intensifies as the engine speed and the speed of the car as a whole increase. For diagnostics, the car must be driven into an inspection hole to provide access to the gearbox. If the fasteners are really loose, they need to be tightened.

We change the release bearing on a VAZ 2114 with our own hands - dismantling the gearbox

Please note that it is recommended to perform operations on a pit or a lift. The instructions provide an example of car repair on an overpass, but if there is none, then watch the video at the end of the article, where the replacement is carried out in a garage without a pit. To properly dismantle the gearbox, refer to the figures presented above.

Provide sufficient lighting above the hood of the car, put the car in first gear, and release the handbrake. If possible, ask a partner for help. Below is a detailed dismantling technology, according to the diagrams presented above.

- Open the hood, unscrew the air filter mounts, disconnect the wire and remove the assembly (see photo). After this, disconnect the battery terminals, and to be safe, remove the battery.

- Now we get access to the upper gearbox mounting bolts. Unscrew the long bolt at the back, the short one at the front.

- Let's move on to the starter. We unscrew the two upper studs, then remove the terminals. Now we look for the clutch cable that comes out of the gearbox, twist the nut to loosen the tension.

Reasons for replacing and adjusting the VAZ 2107 clutch

Replacing a VAZ 2107 clutch is a rather labor-intensive and expensive process. Therefore, before replacing, you should consider adjusting the mechanism.

Clutch replacement

To install a new clutch, you will need an inspection hole, overpass or lift. It is important to detect in time the signs indicating the need to replace the clutch (it is impossible to replace it on the road), and take the car to a garage or car service center. Driving with a faulty clutch is very dangerous - you can get into an accident when crossing a railway crossing or a main road.

The entire VAZ 2107 clutch is replaced, so auto shops sell a kit consisting of a driven disc, a basket and a release bearing. You should consider replacing the clutch in the following cases:

- the car climbs heavily uphill when the accelerator pedal is pressed all the way down, and you can smell a burning smell - these are signs of slipping of the driven part of the clutch;

- when the clutch is disengaged, noises appear in the area of the flywheel housing - this indicates a malfunction of the release bearing;

- when starting the car, it is difficult to engage first gear (the gearbox “growls”) - this is a sign that the clutch is not completely disengaged (the clutch is moving);

- when accelerating, the car begins to twitch, rattling sounds are heard - the reason for this is usually broken damper springs or loose sockets for them on the driven disk, deformation of segments or loose rivets on the hub.

Any noise, vibration, or whistle in the clutch area requires more detailed diagnostics and diagnosis.

Clutch adjustment

If the clutch pedal becomes too soft, falls down, and does not return to its original position, then most likely air has entered the system or the hydraulic drive adjustments have been disrupted. Clutch slipping after prolonged use usually indicates a failure of the clutch. It will probably have to be changed.

If the clutch drives, that is, shifts gears with difficulty, in about half of the cases the reason is a discrepancy with the required values:

- play between the rod and the piston in the working cylinder;

- clearance between the release bearing and the fifth basket;

- free and working travel of the foot pedal.