The VAZ 2114 gearbox is one of the key elements of the car. It is this that is capable of ensuring stable operation of the power unit, as well as helping to change the torque from the engine to the wheels during acceleration. With the help of a gearbox, the rotational force becomes a stepwise movement. What to do if the VAZ 2114 gearbox is humming?

The transmission of this car includes many parts, each of which is needed to perform certain functions. Among the key parts are rotating shafts, as well as gears and transmission mechanisms.

Gearbox VAZ 2114

Additional Information. The main pair is the main gear of the main shaft of the gearbox. It helps in reducing the number of engine revolutions. The main pair is also needed to reduce speed in a ratio of 1 to 4. The standard indicator of the main pair is index 3.7. If you change this indicator, you can change the dynamics of the car. The size of the pair determines the maximum speed of the car, as well as acceleration. The reason for such a strong dependence is the effect on transmission length.

Gearbox device on a VAZ-2114

General view of the gearbox

Before proceeding directly to the issue of considering the appearance of noise in the gearbox, it is necessary to consider the design features of the VAZ-2114 gearbox. So, what parts does this unit consist of?

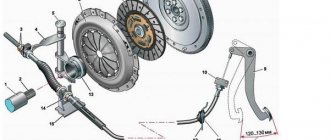

Transmission device diagram

Gearbox: 1 – clutch release bearing; 2 – guide sleeve; 3 – input shaft; 4 – roller bearing of the secondary shaft; 5 – secondary shaft; 6 – retaining ring; 7 – satellite axis; 8 – speedometer drive drive gear; 9 – transport plug; 10 – wheel drive oil seal; 11 – tapered roller bearing of the differential; 12 – axle gear; 13 – satellite; 14 – differential box; 15 – clutch housing; 16 – driven gear of the main gear; 17 – drain plug; 18 – adjusting ring; 19 – driven gear of the 1st gear of the secondary shaft; 20 – synchronizer for 1st and 2nd gears; 21 – driven gear of the second gear of the secondary shaft; 22 – retaining ring; 23 – persistent half ring; 24 – driven gear of the third gear of the secondary shaft; 25 – synchronizer for 3rd and 4th gears; 26 – driven gear of the fourth gear of the secondary shaft; 27 – needle bearing of the secondary shaft gears; 28 – ball bearing of the secondary shaft; 29 – thrust plate; 30 – driven gear V of the secondary shaft transmission; 31 – 5th gear synchronizer assembly; 32 – nut; 33 – thrust washer; 34 – drive gear V of the input shaft; 35 – rear cover of the gearbox housing; 36 – ball bearing of the input shaft; 37 – gearbox housing; 38 – roller bearing of the input shaft; 39 – breather; 40 – input shaft oil seal

Causes of malfunction

Once the design of the gearbox is understood, we can proceed directly to considering all the possible causes of the effect. According to the manufacturer's data indicated in the regulatory literature and the practice of motorists, the following factors can be identified that lead to transmission whining:

- Worn gears, namely the teeth of the part.

- Failure of shaft bearings.

- Low oil level.

Now you can go directly to troubleshooting methods.

Disassembly

Having removed the gearbox, you can proceed directly to the main thing - disassembly. This will allow you to change damaged elements as you work, identify existing faults and solve problems on your own.

- Clean and thoroughly wash all external surfaces of the gearbox.

- Place the box in a vertical position and remove the back cover.

- Remove the clutch cable bracket, then use a rubber hammer to knock the rear cover off the gearbox.

- Remove the old gasket. She will be replaced.

- Engage any of the two gears - 3 or 4.

- Unscrew the bolt that holds 5th gear, then turn it on.

- Simultaneously turning on the indicated speeds will allow you to fix the shaft and prevent it from turning.

- Unscrew the nut on the secondary shaft, and then on the primary one.

- Remove the 5th speed synchronizer along with the fork.

- Remove the fork from the coupling. Remove the synchronizer as carefully as possible. If you allow the clutch to move away from the hub, the spring-loaded balls that secure the synchronizer will simply fall apart.

- Remove the 5th speed synchronizer locking ring.

- Remove the 5th speed driven gear from the output shaft.

- Remove the thrust ring located on the needle bearing.

- Remove the needle bearing itself from the 5th speed gear.

- Remove the drive gear from the drive shaft and remove the bearing plate.

- Now the needle bearing bushings should be removed from the secondary shaft, and the thrust washer should also be removed.

Jewelry work

- Take out the ring that secures the input shaft bearing, and then a similar ring for the secondary shaft.

- Unscrew the locking plug and remove the ball and locking spring. Next you can get a couple more clamps.

- Remove the rear engine mount.

- Unscrew the reverse gear lock plug, tilt the box and thus remove the lock ball and spring.

- Remove the clutch housing and gearbox housing mounting bolts.

- Acting as carefully as possible, separate the two units. To do this, there are grooves in the crankcases into which the ends of a screwdriver are inserted. By shaking, you can disconnect the elements without any problems.

- Remove the gearbox housing.

- Unscrew the bolt securing the 1st and 2nd speed shift fork.

- Remove the fork and stem.

- Unscrew the bolt securing the 3rd and 4th speed forks.

- Separate the rod head from engagement with the lever, remove it along with the fork from your gearbox.

When disassembling the box into parts, be sure to pay attention to the condition of the elements. If you detect faults in time and replace gearbox components, you can get by with inexpensive but very effective self-repair

Disassembled gearbox

What to pay attention to

So, following the instructions, we disassemble the gearbox of your VAZ 2109

Along the way, we pay attention to the following points:

- Bearings. When they wear out, a noise from the box occurs. Plus, worn bearings negatively affect the condition of other gearbox elements;

- Synchronizers and sealing washers. If their condition leaves much to be desired, then the gears shifted poorly precisely because of them. Replace them;

- Clutch system, cotters, coupling hub clamps. All this must be replaced separately if there are signs of wear or defects;

- Blocking rings, synchronizers. If there are chips or nicks, don’t even think about alternative solutions, replace them immediately;

- Bearing tracks. Over time they wear out. If signs of wear are found, perform a complete replacement. In this state, they were only a short time away from breaking;

- Gap between gears and locking rings. Normally it is no less than 0.6 mm. In case of deviations, there is only one solution - replacing the rings;

- Retaining rings. If elasticity is lost, these elements must be changed, since they will no longer be able to perform their functions.

When assembling the gearbox, do not forget to lubricate the new gaskets with a layer of lithol. And when pressing the oil seals, do it with the working edge inward. The metal clip should be located on the outside.

During the process of reassembling the gearbox, all rubbing components should be treated with oil, and do not forget about the sealant for connecting the clutch housings and gearbox. Doing everything yourself is quite possible.

Causes of malfunctions

The gearbox, like many other VAZ 2114 units, needs maintenance. There are not so many main reasons that can lead to breakdowns or minor malfunctions of the gearbox. For example, if the gearbox of a VAZ 2114 is noisy, then one of the possible reasons is the gear teeth.

Gearbox device

Over time, they wear out and become unusable. Noise from the gearbox is not a reason to panic, because even an insufficiently qualified technician can repair the gearbox.

Gearbox gears

The gearbox of this model from VAZ is a unit consisting of five stages.

Troubleshooting methods

Gearbox repair

- If all the gears in the VAZ 2114 gearbox are lost, this means that the problem lies in the bearings. If the breakdown is not repaired in time, repairs will cost even more.

- Noise after starting the engine. The cause of the malfunction also lies in the bearing (drive shaft) or lack of transmission oil.

- The noise disappears after changing gears. The trouble lies in the synchronizer clutch. It is possible that there are problems with the locking mechanism.

- It is not possible to disengage the clutch completely. The “culprit” is the same drive shaft bearing.

To obtain reliable data about the condition of the car and the number of faults in the gearbox, you should trust only high-quality diagnostics. Garage technicians usually do not have modern equipment that allows them to accurately determine the cause of some malfunctions, and today they cannot do without technology.

General information about the process

The initial one is provided by the manufacturer at the stage of assembling the machine. But gradually, due to temperature changes, any material loses its beneficial properties.

Before you start carrying out the “Shumka” on your own, it is recommended to dismantle the seats, door trims, mats and free the car from the old standard insulation.

Note. Only by carrying out a complete and thorough soundproofing procedure can one hope for a significant reduction in noise from the outside. Only in this case will the cabin be perfectly quiet and comfortable.

Soundproofing panel VAZ 2114

It is especially important to treat doors, as they often become the main installation location for speakers. It is clear that this place should be well protected not only from noise penetration, but also from plastic vibrations and other negative phenomena.

Acoustic speakers in the doors

Along with sound insulation, the interior will also receive high-quality insulation. In Russian conditions this is extremely important. To achieve this effect, you need to combine vibration and sound insulation.

Soundproofing for VAZ 2114

“Shumka” carried out on a VAZ 2114 is often called tuning. This is true, because a real modernization of the car is being carried out. Operational parameters are increased and comfortable conditions are created when the vehicle is moving.

The driver is no longer oppressed by engine noise, his nervous system is not irritated by the strumming and vibration of plastic elements. All this cannot but have a positive impact on overall driving safety.

As mentioned above, the standard “Shumka” will not be of good quality; relying on it is the last thing. The process of carrying out “Shumka” on cars with high mileage is especially relevant. In general, such cars are very difficult to drive, since the noise penetrates everywhere, interferes with the normal operation of the acoustics, creates complete discomfort, and the trip turns into a very tedious task.

On sale today you can find a sufficient amount of high-quality materials for carrying out “Shumka”. There are a lot of them and making the right choice can sometimes be extremely difficult. One of the main indicators of a good material is not only the ability to absorb sounds, but also to be light in weight (details about materials in the table below).

Note. If the material itself is heavy, making noise will be difficult. As a rule, good and proper insulation involves laying several layers of material, a kind of sandwich consisting of layers of vibration and noise absorbers. Heavy materials will create excess weight that is dangerous for the car and its body, which will inevitably affect fuel consumption and the overall dynamics of the car.

Splen with foil

Among other things, you also need to lay out materials skillfully. The fact is that if you don’t pay attention to this, the materials will simply turn into a time bomb for the metal component of the car.

Poorly laid material creates gaps through which air, moisture, etc. will penetrate. And all this will inevitably lead to the appearance of the most terrible enemy of the body - corrosion.

Correct installation of the material always means following the instructions in a step-by-step sequence, using the right tools, using a hair dryer and much more.

In some cases, especially when carrying out the noise yourself, partial sound insulation is also appropriate. In this case, the target is the most noise-producing parts of the machine. Definitely the doors, then the trunk, the rear parcel shelf, and so on.

It is important, when working on your own, not to damage the upholstery. Unfortunately, this often happens due to the inept actions of the car owner who is carrying out such an operation for the first time. In general, conducting a “Shumka” is a painstaking and lengthy process, but it’s worth it.

Before carrying out soundproofing, it is recommended to carry out a partial or complete inspection of the machine. The causes of all vibrating and knocking sounds produced by suspension elements or other vehicle components must be eliminated. They may be loose or need to be replaced. The body and its parts must also be checked.

Let's sum it up

Many motorists are faced with such a problem as gearbox noise. It could be an automatic or manual transmission, any version of a modern robot or such a fashionable CVT. There are dozens of diseases of technical components and assemblies that can negatively affect this part of your car.

Therefore, you should pay special attention to the features that the gearbox provides you during operation. If you simply miss the moment when bearings or other parts begin to hum, you may soon find yourself on the side of the road without the ability to move in your car.

There are many types of motorists. Some people want their vehicle to work perfectly, others are content with the fact that as long as the car is driving, there is no need to repair it. But most vehicle owners want the main components of the car to work well and efficiently. Therefore, do not neglect good diagnostics to find out which part of the box is causing the unpleasant hum. Most likely, after such diagnostics, you will want to restore the node. Has your car ever had problems with the gearbox that caused an unpleasant hum?

Lack of oil

Another common cause of noise in the gearbox is insufficient oil level. In order to solve this problem, you just need to add oil.

The source of noise can be worn seals and mechanisms. To fix the problem, they need to be replaced with new ones.

Checking the oil level

In some cases, problems occur during gear shifting. Here you first need to look at the drive rods. It is possible that they have already used up their resource and need to be replaced. After this, you need to check the reliability of the hinge fastening. It wouldn't hurt to take a look at the gearshift lever rod.

How to prevent gearbox failure

Early signs of future failure include:

- Difficulties appearing when changing gears. It becomes more and more difficult to change gears. Sometimes you have to squeeze the clutch and move the lever to neutral.

- The transmissions are flying out.

- Oil is leaking from the gearbox.

Bearing wear

Another common cause of problems during gear shifting is due to improper adjustment of the shift actuator. Assembly parts often break and can also cause the problem. To eliminate problems, it is necessary to correct or replace the rod as soon as possible, as well as tighten the screws. Then you can start adjusting the drive and replacing the remaining non-functioning parts.

On some VAZ 2114 vehicles, a gear reset occurs. This process occurs spontaneously. The reason is wear or breakage of the teeth (end teeth) on the coupling. Sometimes the teeth on the gears fail. A similar problem arises due to insufficiently competent debugging of the drive. In other cases, the reason lies in inaccuracy during the installation of the traction cover, which is intended for protection.

To correct this problem, you may need to replace all faulty parts. Next you should start debugging the drive.

The next step is to install the cover in the required position. If an oil leak occurs, then it is necessary to install the crankcase and change any gaskets that look worn out. Do not forget about the need to remove the box before repairing.

Lada 2114 2008, 84 l. With. - observation

Cars for sale

Lada 2114 Samara, 2005

Lada 2114 Samara, 2011

Lada 2114 Samara, 2009

Lada 2114 Samara, 2007

Comments 27

Still haven't solved the problem?

No, I haven’t solved it, because the problem is gradually eliminating itself. The extraneous sound has become almost inaudible, apparently, break-in is occurring. Soon I will change the oil in the box, I will look for the presence of metal inclusions: how many there are and what kind. I really don't want to remove and disassemble the box.

Interesting, I haven’t heard this from anyone in Samara

Rare malfunction. Nobody knows what it could be?

An autopsy will show. Maybe a tooth has fallen off the gear. Or don’t go there yet

I decided not to climb for now.

Maybe it will go away on its own. I remember at a mileage of up to 15,000 km the starter clicked after starting the engine, then it stopped on its own

Maybe it will pass. I'll wait, anyway. Long trips are not expected yet, and in the city sudden adventures with the box are not scary.

Damn it's the same nonsense. If you find out, let me know, but in the meantime I’ll repost!

I'm already glad that I'm not alone))). If I find out, I’ll write back, but my hopes are melting like the first snow. I'm very reluctant to remove the box, especially in winter. If people don’t suggest anything, I’ll drive until the summer, and then we’ll see.

Why does a hum appear in an automatic transmission?

An automatic transmission is more complex than a manual transmission. In an automatic transmission, the appearance of uncharacteristic noises indicates serious malfunctions. At the same time, the cost of simple disassembly and assembly of the box is quite high. It is more profitable to carry out diagnostics to save your budget. The causes of noise in automatic transmissions are as follows:

- the formation of backlashes between the elements of the main pair;

- increased friction as a result of gear misalignment;

- axle shafts with poor fixation create gaps leading to hum;

- bearing wear or damage;

- significant wear of gear teeth or shaft.

The formation of noise in the variator is the main sign of a serious breakdown that requires major repairs or complete replacement of the device.

Causes of hum in manual transmission

Mechanical boxes are considered more reliable and durable, so the formation of a hum does not always require complex and expensive repairs. Noise in a manual transmission usually appears as a result of:

- wear or defects of the main pair elements;

- violation of gear geometry (when noise is generated in a specific gear);

- incorrect assembly of the box after repair;

- use of low-quality or unsuitable spare parts;

- significant wear or damage to bearings.

- Lowest price for engine overhaul in Moscow

- Diagnostics using modern equipment

- Individual approach to each client

- Guarantees for work performed

- After the repair, you will receive a video report

In addition to these reasons, there are also individual problems that can only be identified during diagnosis.

How to eliminate hum?

After checking the gearbox and identifying problems, our service technicians select the most profitable and reliable repair method. It is usually carried out in the following ways:

- maintenance (replacement of consumables and oil);

- dismantling faulty parts and installing new spare parts;

- overhaul (restoration of geometry and replacement of mechanisms);

- complete replacement of the gearbox.

LEAVE YOUR PHONE and we will contact you in 15 minutes

Sometimes the cause of noise is the lack of oil in the box, so replacing it helps solve the problem. True, in most cases, this is caused by depressurization of the structure (plays and gaps).

Our company offers to perform computer diagnostics to determine the causes of noise in manual transmissions and automatic transmissions. We will quickly identify problems and offer several options to resolve problems. With us you will save your budget on gearbox repairs, achieving a long service life of the car. We will also help you inexpensively purchase original spare parts for repairs in Moscow.

Strong vibration when accelerating: reasons

Many car enthusiasts are familiar with the problem when vibration occurs when accelerating. There are many reasons for this phenomenon. Often, searching for a source can even drive a car enthusiast crazy. Let's look at the main reasons for shaking, because you really want the car to drive quietly and smoothly. In 75% of cases, the problem is detected and fixed, and the car owner can again feel calm and comfortable.

Characteristic

As we said earlier, a 4-speed transmission was also installed on the car. The assembly of the gearbox for the VAZ-2109 of this type did not last long. Therefore, it is now very difficult to meet “short-winged” cars with a 4-speed manual transmission. It's practically a rarity. 95 percent of the “nines” came with a more modern, 5-speed manual transmission. It was two-shaft, with synchronizers in all gears (except reverse). In Russia, these cars stopped being produced back in 2004. But you can still find spare parts for the VAZ-2109 gearbox in stores. Their price is quite reasonable. If necessary, you can buy a complete transmission for 5-6 thousand rubles.

Reason: poor balancing or worn tires/rims

Problems with steering wheel shaking when driving can arise due to malfunctions in the chassis:

- improper balancing;

- seasonal features;

- wear.

Quite often, the main problem that causes the steering wheel to shake when driving a VAZ 21099 is poor wheel balancing. Seasonal changing of tires or wheels without checking with special equipment in a tire shop leads to different wheel speeds.

The heavier the wheel, the greater the centrifugal force it creates. If the left and right front wheels have different weights, then the steering wheel vibrates constantly. And the higher the speed, the more often the fraction appears.

Subjective factor - excessive adhesion of dirt and snow on one wheel can upset the balance and lead to unpleasant vibration of the steering wheel on the VAZ 21099 both at speed and in slow motion.

Finally, the obvious factor is simple wear and tear. Moreover, it concerns tires, which seriously deteriorate the court due to the poor quality of the roads. Wheels suffer from holes, ditches, and curbs. A dent in a disc is sometimes difficult to detect because the defect often appears on the inner part, hidden from view.

How to fix

When it comes to the poor condition of wheels and tires, the solution is obviously simple: you will need to buy new ones.

If the balancing is poor, you need to come to the nearest tire shop, where they will check the wheel alignment using specialized equipment. Tire pressure is also checked there, which is uneven in different wheels and also, albeit slightly, causes unpleasant vibration in the steering wheel.

Look at the tightness of the wheel bolts. It happens when the fastening becomes loose and the wheel begins to vibrate, transferring force to the steering wheel.

A fairly common problem for the VAZ family is the desire of the owners to install beautiful, large wheels that are not recommended by the manufacturer. The size of the mounting holes with the bolts on the hub sometimes does not match, causing the wheel to be poorly secured.

What exactly is making noise and why?

Let's try to understand this issue. The main causes of noise coming from the gearbox are:

- improper operation of the gearbox, in particular the use of counterfeit transmission fluid purchased on the black market and operation of a vehicle with a non-working clutch;

- poor quality of gearbox components;

- maximum service life of manual transmission;

- unskilled technical work on diagnostics and repair of gearboxes.

New manual gearbox from VAZ 2109

In addition, the main malfunctions that can result in noise in the gearbox are:

- sudden difficulty switching on speed: in order to engage one or another gear, the driver will sometimes need to move the gearbox lever several times to the neutral position with the clutch depressed;

- The box automatically switches off the car’s gear while driving;

- Transmission fluid may leak from the gearbox.

It should also be noted that the VAZ 2109 gearbox can make noise in various conditions: at neutral speed, while shifting gears, or simply while driving at a certain speed. And each of these noises can indicate a different malfunction of the box.

In addition, during diagnostics, one must not forget that only one external sign may indicate several malfunctions in the gearbox. Therefore, it is virtually impossible to visually (i.e., by the type of hum) calculate which component of the box has failed. The damage can only be determined by removing and disassembling the box.

It is also necessary to add that repairing a transmission and eliminating defects requires a lot of knowledge, so it is better not to do this at home. The gearbox is an important unit in the structure of any vehicle, so it is better to entrust its repair and diagnostics to a qualified specialist.

Tuned VAZ 2109

Often the hum of the unit manifests itself:

- when you press the clutch;

- when turning on the third and fourth speeds;

- at neutral speed;

- when driving a car at high speeds.

Most domestic VAZ 2109 car owners face such problems. But if when you press the clutch, extraneous sounds disappear, then this may indicate several breakdowns. In particular, the fifth speed or reverse gear may fail. In addition, the input shaft bearing or release bearing may be faulty.

As practice shows, in the case of bearings the problem is not critical. If noise appeared in your car and then disappeared after several hundred or thousand kilometers, then most likely the remaining bearings were simply ground up by the unit system.

If your VAZ 2109 starts making noise, this does not mean that the bearings or reverse gear have failed. These problems are the most common, but only high-quality diagnostics can specifically determine what has gone wrong.

Prevention measures

In order to prevent any damage, you should use only high-quality oil. It is this that allows us to achieve the most coordinated and precise operation of every part and every component of the vehicle’s transmission.

In order to improve the quality of car service, it is better to give preference to oil of the GL-4 category. The best choice is a mineral lubricant, but its cost may not be affordable for the owner of a VAZ 2114. In this case, you can think about purchasing semi-synthetic or synthetic oil.

How to choose a new release bearing

If the release bearing is clearly damaged, you should immediately buy a new one and replace it.

On the auto parts market there are release bearings of both domestic and foreign production, their cost ranges from 300 to 1600 rubles.

These are models from the following manufacturers:

- AvtoVAZ (TZA) - Russian Federation (this VP is original and is produced in two versions - standard type and with a reinforced coupling);

- TORQUE – Finland;

- VBF – Russian Federation;

- SKF - Sweden (is an analogue of the premium class);

- LUK - Germany (like the previous one, it is an analogue of the premium class).

The new release bearing must last at least a million on-off cycles. The strength and quality of materials of most release bearings correspond to this figure. But without following some recommendations, even the best release bearing will quickly fail.

There are five easy-to-follow recommendations in total:

- After replacing the VP, all bolted connections of the assembly parts must be coated with a sufficient layer of graphite lubricant;

- When installing it, the release bearing itself must be lubricated with the recommended lubricant in the required quantity;

- During operation, you need to ensure that water and dirt do not enter the transmission - if this happens, then breakdown is inevitable;

- Do not hold the clutch pedal down for a long time;

- Follow the order of pressing the pedal - fast pressing and slow release, without delays in the intervals between the extreme points.

Automatic transmission whine when shifting gears

Sometimes when you start driving, you can hear a suspicious sound resembling a howl from under the hood. This usually happens when shifting into second gear. In most cases, the source is the front planetary gear. This unit begins to make sounds when the transmission is heavily worn. Some drivers do not attach much importance to this and wait until the planetary gearset completely falls apart and a “meat grinder” of gears is formed, but this should not be allowed to happen.

The constant desire to reduce the cost of mechanisms simply cannot but affect their quality. The planetary mechanism quickly begins to break down the axes of the satellite gears. This leads to a change in the contact patch between the sun gears and satellites, which causes the destruction of their “teeth”. There is only one way out of this situation - replacing the planetary mechanism.

Why is the VAZ 2114 gearbox humming?

Why might there be a hum? Typically, noise problems occur on machines that are already 10 years old. This problem also applies to cars with a mileage of more than 100,000 km. The main cause of hum is wear and tear.

Replacing the release bearing

Other reasons for the appearance of any noise from the gearbox include:

- low-quality spare parts;

- developing the service life of the main elements of the car;

- improper operation of the vehicle;

- use of low-quality gear oil;

- repairs carried out by an illiterate technician who has ruined something.

Automatic transmission - the hum is definitely not good

If you have an automatic transmission, CVT or robotic manual with automatic shifting, the hum definitely does not bode well for you. At any service, disassembling and reassembling your box alone will cost incredible amounts of money. Today you will not be too pleased with the prices for spare parts. Sometimes it is better to listen to the hum than to hear the price it takes to eliminate it. Use the help of specialists to diagnose the gearbox, but remember that a complete diagnosis of your machine is only possible if the box is disassembled. The most common causes of automatic transmission humming are as follows:

- in a conventional machine or in a robotic box, one of the elements of the main pair may wear out, causing a backlash in operation;

- the gears do not touch each other in normal modes, excessive friction of the mechanisms in the gearbox occurs;

- for a variator, a hum almost certainly means death or the need for major repairs - stretching of the main working mechanisms is not so rare;

- the box can also hum due to poor fastening of the axle shafts, which causes play at the joints and a rather strong hum;

- Bearings that have failed often hum; they will definitely show themselves in the near future;

- worn teeth on the drive gear or shaft will indicate the presence of backlash and constant hum in one or more gears.

Often, along with the hum, some other troubles with the gearbox begin to occur. For example, the transmission begins to throw out one of the gears after you release the gas pedal to slow down. The gear forks may be to blame for this, but it all depends on the gearbox, its type, design and other features. If for a manual transmission this problem is quite easy to overcome, then for an automatic transmission, dropping gears in unauthorized mode means the impossibility of operating the car. Otherwise, traveling in such a car will be unsafe. So always watch out for sounds coming from the machine and contact the service center to eliminate them.

Price issue

The cost of repairing each box is determined by the number of worn parts.

When performing work in the service, the average cost will be:

- gearbox overhaul - from 2500 rubles;

- removal and installation of the unit - about 4,000 rubles;

- changing the oil in the box - up to 1000 rubles;

- installation of new bearings on the input shaft - approximately 5,000 rubles.

Service costs are approximate and may differ depending on the city, workshop location and general condition of the box. In most cases, it is more profitable to purchase and install a less worn unit than to rebuild an old one.

Replacement

Many people turn to a service station to replace this bearing. It is noteworthy that car services often refuse to perform such work. It’s understandable, because the procedure is painstaking, and you can’t get a lot of money for it.

To do the job yourself, follow the instructions.

- You can often find advice about the need to completely disassemble the gearbox to replace the bearing. But this is optional. You can do without such complex manipulations.

- In any case, you will have to remove the box, so familiarize yourself with this procedure.

- Before removing the gearbox, remove the negative terminal from the car battery.

- All the chips are removed from the box, the wire from the speedometer is unscrewed.

- Next, the trousers of the vehicle exhaust system are dismantled.

- After this, you can completely remove the gearbox.

- At the next stage, the bell is dismantled. You can try to do without it, but then it will definitely constantly interfere with your work.

- Thoroughly clean the box from accumulated dirt.

- The bearing is secured using retaining rings. To remove them you will need a flathead screwdriver.

- The rings are pryed off and loosened a little, after which there will be no more problems with removal.

- To make it more convenient, arm yourself with tweezers that can be used to remove the ring.

- Using a flat-head screwdriver, pry the bearing by the ring groove, and at the same time move the input shaft slightly forward.

- Insert a pry bar between the gearbox and the bearing. It is unlikely that you will be able to do this without an assistant.

- You will operate the tools, while your friend will hold the pry bar.

- Your main task is to press out the bearing. To do this, precise, strong, but most accurate blows are applied to the input shaft.

- In the process of striking, the shaft must rotate.

- This work will take you about 20 minutes. But if you have a special puller at your disposal, you can speed up the work. Although it is really convenient to work with a puller only if you decide to disassemble the gearbox.

- Before installing a new input shaft bearing, be sure to lubricate the element with regular engine oil.

- Carefully press the component into place using gentle, light blows with a hammer. It is better to use a pipe of diameter or a stand.

- When pressing, apply blows to the inner race, in a circle, as evenly as possible.

- Once the bearing is pressed in, make sure it is seated properly. Scrolling should be calm, without obstacles.

- Reassemble the box in reverse order and install it on the car.

Disadvantages, breakdowns and problems of the Lada 2110 box

This manual transmission is famous for its low reliability, unclear shifts and howling in operation.

Most complaints about noise and crackling when switching due to wear of synchronizers

In second place are endless oil leaks from various seals, gaskets or breather

Next comes the wear of the plastic bushings in the manual transmission and failure to engage or knock out the gear.

Closer to 100,000 km, gears and bearings are already exhausting their service life

You can contact the site administrator by email:

All texts were written by me, are authored by Google, included in the original Yandex texts and notarized. For any borrowing, we immediately write an official letter on company letterhead in support of search networks, your hosting and domain registrar.

Next we go to court. Don’t try your luck, we have more than thirty successful Internet projects and have already won a dozen lawsuits.

Probably, almost every motorist has encountered the fact that the gearbox of a car began to howl. The VAZ-2114 is no exception in this case, and even such a “simple” car can have such an unpleasant effect. But not everyone knows why this problem occurs. In this article we will look at the causes of howling at checkpoints and methods for eliminating the effect.

The consequences of the howl of the checkpoint on video. Gearbox from VAZ-2114:

Conclusion

A gearbox is too complex a mechanism to entrust repairs to unqualified technicians. Some faults can indeed be fixed on your own, but in the case of a gearbox it is better not to take risks.

- We find out which clutch is better to use on the VAZ 2114

- VAZ 2114 gearbox: what you need to know about it

- Gear knob VAZ 2114: eliminating rattling

Thank you for the article. Alas, breakdowns are not always so easy to prevent, since not everyone has enough money for high-quality oil. This, in my understanding, is one of the main problems.

Due to the wear of the oil seal, oil was leaking from the box, so when the oil level dropped below average and when switching to 5th gear, the box hummed (or rather whistled), so we can say that if the oil level in the box is insufficient, first of all The 5th gear gear suffers, as it is located higher than the others.

The author of the article is a knowledgeable person! Since I am a novice driver and my first car is a VAZ 2114, I had problems with the gearbox, using this article I could quickly understand the cause of the breakdown and how to fix it. I recommend to all.

In my case, the gearbox began to hum due to wear on the gears. My wife and I had one car between us, and as the mechanic said, my wife engages the clutch incorrectly or tries to engage the gear without it at all. For this reason, the gear teeth are worn out. I had to learn how to use the clutch correctly.

Source

Noise in the box area on a cold VAZ-2115

December 26, 2012, 05:47 #1

I'm shocked. my machine is 1 year old. mileage 22 tons. I recently noticed this topic: about starting the engine “Cold” and this is about -20 -25 below I don’t start it, it’s a pity. I noticed a noise that sounded like a bad bearing. I press the clutch pedal and the noise stops. This is probably important to know for advice. When my machine warms up everything goes away and does not bother me during operation. and one more thing - since I bought it from the dealership, I did not change the oil in the box. Is this a crime? In any case, as soon as it gets warmer, immediately change the station. please tell me what it is. I hope for a faulty release bearing because replacing it costs only 1200+ the bearing itself.

December 26, 2012, 08:03 #2 + 1

Augustan Andrey, December 26, 2012, 05:47, #1

I'm shocked. my machine is 1 year old. mileage 22 tons. I recently noticed this topic: about starting the engine “Cold” and this is about -20 -25 below I don’t start it, it’s a pity. I noticed a noise that sounded like a bad bearing. I press the clutch pedal and the noise stops. This is probably important to know for advice. When my machine warms up everything goes away and does not bother me during operation. and one more thing - since I bought it from the dealership, I did not change the oil in the box. Is this a crime? In any case, as soon as it gets warmer, immediately change the station. please tell me what it is. I hope for a faulty release bearing because replacing it costs only 1200+ the bearing itself.

no, it’s not the push-out input shaft that’s making noise, I’ve had it like that again for four years

Nissan Avenir 2.0 Type Si ATESSA

December 26, 2012, 10:06 #3 + 2

Renault Megane Extreme

December 26, 2012, 16:53 #4 + 2

It's the bearings in the gearbox that are noisy, forget about it. You can apply under warranty, they may change them, but it won’t do any good, it’s already been checked. Just in case, check the oil level, this also affects it.

Lada Niva 2131M Nissan Patrol

December 26, 2012, 16:57 #5

And change the oil to at least semi-synthetic. And forget about the noise!

Lada Priora 21703-018

December 26, 2012, 17:23 #6

Similar bearing noise again, changed the oil, the noise remained. I applied under warranty, while driving to the service station the car heats up and the noise disappears.

December 26, 2012, 10:41 pm #7

The release bearing is noisy. It may help (if the hum disappears when squeezing) by adjusting the clutch pedal travel along the length of the cable. But he is no longer a tenant. It is better to change the entire set, with basket and disk, at once. Transmission oil mileage 75 thousand km

UAZ Patriot Lifan Breez

December 26, 2012, 10:53 pm #8

forget this in all of ours, especially when it’s cold. everything needs to warm up. Liquid oil, moth, synthetic oil. excellent malso

December 27, 2012, 10:58 #9

thank you all so much for the advice! Today on our street -20 I needed the car and how strange it started but there was no noise, probably because of the oil. that it’s probably very thick from the factory today after work I’ll go and change it. there it probably worked on a dry gearbox at -30 until it warmed up from the engine. I'll change it and write it. Happy New Year everyone. I wish that your cars never upset you and serve as faithful horses.

December 28, 2012, 05:37 #10

Good health to everyone! Yesterday after work I went to change the oil in the transmission. It turns out that after 17.00 our auto services don’t want to work. But I found where they can change it; in short, I filled it with semi-synthetic and everything is ok today -20, it started from the bullet perfectly, the specialist came out of the house and listened to the box and she is silent and does not swear, which means she likes everything and her Everything suits me and I’m incredibly happy, so everything is OK now. That's what I wish for everyone.

Eliminating noise

Let's look at the signs and corresponding breakdowns of the gearbox in the VAZ 2109

| Signs | Breakdowns |

| The transmission is noisy when driving in neutral |

|

| There is noise coming from the gearbox and periodically disappears when the gears are turned on. |

|

Replacing the drive shaft bearing

Gearbox drive shaft 2109

If you decide to repair the drive shaft bearing yourself, then for this you will need a hammer, a vice, and a bearing puller. Let's start the repair:

First you need to dismantle and disassemble your gearbox; then take the drive shaft and clamp it in a vice

Attention! The vice must have soft metal pads; the rear bearing must be pressed using a special puller; then turn the shaft over and compress the inner race of the primary bearing in the same way; Now you need to push the rear bearing all the way onto the shaft. This is done using a metal mandrel and a hammer; the same operation must be done with the inner ring of the front bearing.

Add oil

Checking the transmission fluid level in manual transmission 2109

If you decide to fix the noise problem by adding transmission fluid to the box, then prepare new manual transmission oil and some rags in advance:

- we find the dipstick for monitoring the fluid level in the box - it is located in the engine compartment on the left side, next to the battery;

- take out the dipstick and wipe it with a rag;

- then insert the dipstick back all the way and pull it out. The transmission fluid level should be somewhere between o and “Max”;

- if you see that there is less oil than necessary, then take a new one and fill it through the hole to check the level to o.

Replacing locking rings

Manual transmission synchronizer locking rings 2109

To replace the rings of the locking mechanism, perform the following steps:

- remove and disassemble the gearbox;

- we find the blocking device;

- We see blocking synchronizers on it: you need to visually assess their condition. If fragments are visible on the rings or they themselves have expired their service life, then they need to be replaced;

- We put the box back together and put it in place.

If the hum in the manual transmission appears as a result of wear on the rings, then when they are replaced, the extraneous sounds will disappear.

Replacing the synchronizer clutch

Here you need to stock up on clutch and patience in advance:

- Having disassembled the gearbox, you need to remove the secondary shaft synchronizer;

- To get to the clutch, the synchronizer must be completely disassembled. Be careful - the parts are very small and can be easily lost. The clutch is a small ring on the inner diameter of the synchronizer;

- Having disassembled the synchronizer, check all its components for mechanical damage. If the springs are too stretched, then it is also better to replace them with new ones, but you need to buy a complete repair kit in advance;

- before installing the clutch in place, lubricate it, as well as all other synchronizer components, with engine oil;

Clutch adjustment

Adjusting the clutch pedal in a VAZ 2109 car.

Incomplete disengagement of the clutch is “treated” by adjusting it:

- The clutch pedal must be pressed to the floor all the way and a meter or ruler should be placed next to it, one end of which should also be rested on the floor. Then you need to fix the value at the center of the pedal;

- now release the pedal and in the uppermost position mark the number of centimeters to it from the floor;

- then slowly press the pedal with your hand and mark the place where the clutch begins to provide resistance for further pressing;

- the amount of free play is the same distance from the pedal position until the moment the clutch begins to exert resistance;

- Now open the hood and look for the cable that connects to the pedal. There are two nuts on it, with the help of which adjustment is carried out;

- To increase free play, you need to unscrew the nut located inside the bracket. You also need to tighten the nut located outside;

- This is where the adjustment lies. If everything is correct, then the full stroke will be about 13 centimeters. If this indicator is significantly more or less, then the adjustment process should be repeated.

Technical characteristics of the VAZ 2110 gearbox

| Type | Mechanics |

| Number of gears | 5 |

| For drive | front |

| Engine capacity | up to 1.6 liters |

| Torque | up to 140 Nm |

| What kind of oil to pour | Lukoil TM-4 75W-90 GL-4 |

| Lubricant volume | 3.5 liters |

| Change of oil | once every 65,000 km |

| Replacing the filter | every 65,000 km |

| Approximate resource | 150,000 km |

Recommendations

Comments 33

Fill the box with oil just above the maximum level and you won’t even know about the problem of howling in 5th gear.

What oil do you recommend?

How I took my father’s car in 2013. The mileage was then 48,000, the gearbox oil was changed to ZIK 75w90. after the factory mineral water there was heaven and earth. the gears became easier to engage; in winter, at temperatures below -25, the gearbox lever was not as tight as with mineral water (on it at -25 it was tight, at -30 and -35 until the car warmed up, the gears stuck in with difficulty with force)

I recently decided to change the oil in the gearbox (mileage 92,000 km) and filled it with half-blue Lukoil 75w85. After Zika, the gears are also switched on, there is no noise or crunching when switching on, it was filled as usual just above the maximum mark. I didn’t notice the difference between ZIK and Lukoil, I can’t tell you about the prices, because... I don’t remember how much Zeke bought for at that time.

Regarding the choice of oil, I can only write what I filled in myself and my feelings after the change; it’s up to you to decide which oil to buy.

Thank you! I'll change it this weekend. And I also wanted to know how much oil to buy for changing, 3-4 liters?

The canisters hold 4 liters. you will need approximately 3.3-3.5 liters for replacement. Half a liter will be left in reserve in case of refilling, but if it is not necessary, you can lubricate the door locks and door stops, I do this myself with the remains of the moto. I lubricate the oil and gearbox and in the summer I spill the sills to make the car feel better)

The problem with fifth gear whistling is a lack of lubrication and, of course, poor quality parts. Well, if it didn’t buzz before, and then it started buzzing, it’s because of the lubrication. I missed the oil part myself. Now I'm pouring more levels, but it doesn't help anymore.

Well, I'm going to give it to a mechanic I know in Armavir so that he can reassemble it

While I'm driving, I'll sort it out myself, because... I feel like the synchronizers are already tired

Lubrication

If the bearing is dry, but there is no damage on it, then you can completely get by with lubricating it and install it back. It’s only better to do this if you don’t have a new spare part on hand. There are two ways to lubricate the bearing. The first is to boil it in lithol, preferably in a water bath. A safer method of lubrication is by injection. Using a syringe, lithol is driven into the bearing; this method takes quite a lot of time.

Read more: How to sew a car seat along the seam

Noise additive in gearbox

As you can see, you can give an affirmative answer to the question whether the automatic transmission can hum. At the same time, as in any other unit, noise in an automatic transmission can appear for various reasons (wear, malfunctions, loss of properties of ATF transmission oil, etc.). It is also a common situation when noise appears in the automatic transmission after changing the oil. This is often due to the fact that unsuitable oils are used, errors were made during replacement, etc.

Owners often note that noise in the automatic transmission occurs in neutral and in parking; in some cases, noise in the automatic transmission appears when the car is stationary or in motion when the gear is engaged. It also happens that the problem manifests itself only under certain conditions and modes (for example, noise in the automatic transmission when engaging reverse gear or howling of the automatic transmission during acceleration).

In any case, the problem needs to be solved. Moreover, in the case of a manual transmission, unlike an automatic transmission, it is easier to determine the cause of the malfunction and also to eliminate the defect. If the release bearing of a VAZ 2114 is humming, the noise in the gearbox disappears when the clutch is pressed, the howling of the Lada Granta gearbox is noticed, specialists from any car service center know how to fix the problem and get rid of the noise and howling.

Moreover, the list of “childhood” diseases allows you to quickly find out why the gearbox on a Lada Granta or other car with a manual transmission is humming. At the same time, diagnosing a manual transmission actually does not take much time. The repair itself is also often limited to changing the oil and replacing the manual transmission clutch or, in the worst case, rebuilding the transmission and replacing worn parts.

When it comes to automatic transmissions, both on domestic and foreign cars, everything is much more complicated. Owners often ask why the gearbox hums on a Lada Granta automatic transmission, or the automatic transmission howls on a Nissan, Lexus, Audi or BMW. So, in this case, diagnosing the cause is difficult and expensive. It is for this reason that quite often owners of cars with automatic or manual transmission begin to look towards additives.

As is known, an additive in a manual transmission to reduce noise or an additive in the transmission oil of an automatic transmission in some cases can reduce or completely eliminate the appearance of extraneous sounds. In practice, manufacturers of such compounds promise normalization of unit operation, increased service life, softer and smoother operation of the automatic transmission, etc.

There are a large number of products from different manufacturers on the market, and among additives for automatic transmissions we can single out Liqui Moly and Xado. In the first case, the Liqui Moly ATF Additive is quite popular.

This additive in automatic transmissions has a positive effect on the oil, slows down its aging and oxidation, and also helps restore the elasticity of rubber and plastic seals. This property makes it possible to stop oil leaks through oil seals, gaskets and seals.

At the same time, intensive cleaning of the hydraulic unit channels occurs, a protective film is formed on the parts, which improves the operation of the box, reduces noise and eliminates extraneous sounds. According to the manufacturer, ATF Additive increases the service life of the automatic transmission.

This additive can be mixed with any ATF fluids, since the composition does not contain additives that can lead to the loss of properties of the base oil or lead to swelling of the rubber. In fact, the additive has the same components as oil, only in high concentration. The composition does not affect the coefficient of friction, that is, there is no risk of friction clutches slipping, etc.

You can also select XADO revitalizant (gel-revitalizant EX120) for automatic transmissions. This solution protects the box from wear and tear and is also a means of partial (restorative) repair. According to the manufacturer, the Hado automatic transmission additive protects surfaces and restores rubbing parts, which allows you to get rid of noise.

A special metal-ceramic coating is formed on the surfaces, and the geometry of the parts is restored. Revitalizant itself can be used in all types of automatic transmissions, added to any oil, since the additive does not enter into chemical reactions and does not cause changes in viscosity, friction, or other physical and chemical properties of ATF.

Diagnostics and repair

As for transmission repair, it is very important to first carry out a correct diagnosis of a possible malfunction of the unit, try to determine why the gearbox makes a howling noise without removing the unit. Usually the box does not howl in all modes, but at some speeds. If a howl accompanies movement in 1st, 2nd, 3rd gears, then this usually indicates problems with the bearing connecting the primary and secondary shafts, or more precisely, its wear. The only solution is to replace it. But there is a small nuance - if the bearing is a needle bearing without a cage, then simply replacing the needles may not help. This will require replacement of the shafts. And this is already a serious repair.

It is also possible that there may be a howling noise when the working pair of gears located on the primary and secondary shafts of these gears wear out. Or due to poor quality factory processing and installation after repair. One of the characteristic features of gear wear is howling under load and its reduction in the absence of traction. A worn bearing will make noise regardless of whether there is a load or not. But you can determine the exact reasons only by disassembling the gearbox and showing it to a specialist if the repair is done by yourself.

If there is a whine in 5th gear, the first thing that needs to be done is to check and add oil to the unit if necessary, as discussed earlier. But if this does not help, then most likely the fifth gear gear needs to be replaced. This is determined by opening the box. Preliminarily, by the sound at high speed, you can determine the cause - if there is an outright whine, the gear is worn out; if there is a squeaking sound over 100 km/h, it is most likely the bearing.

If the gearbox of front-wheel drive cars howls in all gears, then there is a high probability of wear on the input shaft bearing. But replacing it often does not lead to a positive result, so changing it in the presence of minor howling is not recommended.

Or maybe it's not a box at all?

When diagnosing a gearbox, be sure to carefully consider the fact that if there is a constantly increasing howl in all gears, it may not be only the gearbox that is to blame for the origin of the sounds. On models with a classic drive, the source of the howl may be the rear axle gearbox, which has a bevel hypoid gear. If the gear teeth are worn out or there is significant play in the bearings, a howl will accompany all driving modes. Similar symptoms also accompany an all-wheel drive vehicle when the front axle malfunctions. The sound will come from the center of the cabin and be observed under load.

Signs of failure

All bearings, of which there are quite a few in a car, have approximately the same signs of failure. But since you know the location of the input shaft bearing, it will not be so difficult to determine that the problem arose with it.

There are several characteristic signs of its breakdown.

Peculiarities

Howling when the clutch is released in a parking lot

The element has failed and needs to be replaced. The howling is usually caused by the formation of chips, cracks, or the destruction of 1-2 rollers

Whistle when driving

The bearing is partially damaged or there is no lubrication. The problem in the absence of lubrication can only be determined by dismantling and visual inspection. To solve the problem, sometimes it is enough to simply lubricate the element and return it to its place

Clutch won't engage or disengage

Most likely the bearing is stuck. If the damage is serious, the input shaft may need to be replaced.

Knock in the area where the element is located

The bearing knocks only when the part is completely destroyed. If you do not replace it in time, the bearing will be welded to the shaft, so you will also have to replace the shaft itself

If you notice the first signs of a malfunction of the input shaft bearing on your gearbox, you should immediately check the condition of the element and, if necessary, replace it.