In this article we will tell you why the gearbox is humming.

Every motorist knows about the importance of a gearbox. Many people also know that there is no point in delaying gearbox repairs, because in some cases the cost of restoring the unit is comparable to the cost of a major engine overhaul. During the operation of the vehicle, various breakdowns may occur in the transmission. Some of them can be easily fixed on their own, while others can be fixed with the help of service center technicians. One of the common malfunctions that owners of cars with manual and automatic transmissions encounter is that the gearbox hums or howls. Owners of domestic cars are constantly fighting this unpleasant phenomenon. But also on imported cars, increased noise in the operation of the transmission often occurs. It should be said here that noise can be caused both by a malfunction of the unit and by the design features of the gearbox. Next we will tell you why the gearbox is humming.

The gearbox is humming, what should I do?

Ringing noise in manual gearboxes is a fairly common problem and cannot be ignored.

After all, a hum in the gearbox indicates a serious problem that may result in the failure of the gearbox. Let's figure out why the gearbox or axle gearbox is humming.

As a rule, the hum in a manual transmission, which is heard when the car is moving, is associated with increased gaps between the contact spots of gear teeth or working surfaces of bearings (input shaft bearing or drive gear). Increased gaps can be either the result of wear or the result of the use of low-quality parts when assembling the unit. Sometimes the release bearing hums. This hum is heard when the clutch pedal is depressed.

Another reason for a hum in the gearbox may be a low oil level, as well as its inappropriate viscosity or excessive contamination with wear products.

The hum can be produced not only by the gearbox, but also by other transmission components, for example, wheel and suspension bearings, and driveshaft crosspieces. But this is a topic for another article.

How to eliminate the hum in the gearbox?

To eliminate noise in the gearbox, first check the oil level and its cleanliness. If the oil level is low, add it; if it is dirty, change it. It is difficult to determine the viscosity of the oil by eye. A sign of too high viscosity: in cold weather, the box hums while it is cold, and after warming up it stops humming. Reduced oil viscosity usually occurs if you do not change it on time.

If, after replacing the oil with fresh oil and the appropriate viscosity, the hum in the gearbox does not stop, then the cause is most likely wear on the gears or bearings. In this case, you can simply replace the parts (but there is no guarantee that you will buy high-quality ones!).

Replacing parts may not be necessary if you use a protective and restorative composition for gearboxes and manual transmissions.

Car owners usually call drugs of this class additives. In fact, these are not additives, but tribo compounds. Unlike additives that change the properties of oils, tribo compounds do not affect the oil; they change the properties of the rubbing surfaces.. To eliminate the hum in the gearbox, the protective and restorative composition must simply be poured into the box through the oil filler hole.

Once in the oil, the protective and restorative composition (PRC) will create a protective coating on the rubbing surfaces, which will reduce the gaps between parts. Reducing the gaps will, in turn, reduce or completely eliminate the noise in the gearbox. In addition, the use of ZVS will significantly reduce friction losses, improving the vehicle's rolling forward by an order of magnitude, which will ultimately reduce fuel consumption.

The ZVS packaging for gearboxes and manual transmissions is designed for transmission units with an oil volume of up to 3.5 liters.

The experience of using this composition by specialists from the service station "K-Service" (45v Severnaya St.) showed that after approximately 1.5 - 2 thousand kilometers after pouring the drug into the humming gearboxes of front-wheel drive VAZ cars (and this is a common defect in these units), a hum stopped in these gearboxes.

Aleksandr Rapotsevich, a regular participant and prize-winner of drag racing competitions, got an excellent result in his sports VAZ 2114. He told us that previously he had to change the bearings in the gearbox after 1-2 races, after using the ZVS for gearboxes and manual transmissions, the gearbox on his car had already been used for 8 races and the bearings remained in working condition, that is, the life of the bearings had already been extended by at least 4 times! And once, returning from a competition from Barnaul, he drove about 100 km without oil in the gearbox, without any consequences!

Similar results can be achieved by using VMS for gearboxes and manual transmissions on any mechanical transmission units, be it the front or rear axle, or transfer case. You just need to choose the right dosage and the instructions for use will help with this.

By using ZVS for gearboxes and manual transmissions you will get the following effects:

• Significant extension of the service life of transmission units • Reduced vibration and hum in the gearbox and axles • Increased vehicle roll-over • Improved gear shifting in manual transmissions • Facilitated operation of the transmission in cold weather • Manifold increase in the “survivability” of units during oil loss and overloads • Fuel economy up to 5 % on single-wheel drive vehicles and up to 10% on all-wheel drive vehicles • Extending the service life of oil in units by 1.5-3 times To prevent wear, it is recommended to use the air conditioner when changing transmission oil every 100 thousand km.

BOTTOM LINE: If your gearbox or axle is humming, don’t rush to spend money on repairs at a service station; first try changing the oil and applying a protective and restorative compound. I am confident that in most cases you will be able to avoid costly repairs by using this composition. Also use ZVS for wear protection. Remember - prevention is more profitable than repair!

Let's sum it up

Many motorists are faced with such a problem as gearbox noise. It could be an automatic or manual transmission, any version of a modern robot or such a fashionable CVT. There are dozens of diseases of technical components and assemblies that can negatively affect this part of your car.

Therefore, you should pay special attention to the features that the gearbox provides you during operation. If you simply miss the moment when bearings or other parts begin to hum, you may soon find yourself on the side of the road without the ability to move in your car.

There are many types of motorists. Some people want their vehicle to work perfectly, others are content with the fact that as long as the car is driving, there is no need to repair it. But most vehicle owners want the main components of the car to work well and efficiently. Therefore, do not neglect good diagnostics to find out which part of the box is causing the unpleasant hum. Most likely, after such diagnostics, you will want to restore the node. Has your car ever had problems with the gearbox that caused an unpleasant hum?

The gearbox is the most important element in the vehicle transmission structure. At the same time, the gearbox is a complex unit, regardless of the type (manual transmission, hydromechanical automatic, variator, robotic manual transmission, preselective gearbox with two clutches, etc.).

Next, we will talk about why extraneous sounds occur and what they indicate during gearbox operation, for what reasons the gearbox hums, what to do if a manual or automatic gearbox howls, etc.

Read in this article

Why does first gear howl in an automatic transmission?

Sometimes the gearbox hum only appears when driving in first gear. When switching to the second, the unpleasant sound disappears. This means that the problem is in the planetary gear, or rather, in one of its satellites - a group of gears. Over time, the howl of the automatic transmission in first gear only becomes stronger. This leads to transmission scattering and complete engine stop.

The planetary gear needs to be repaired. You can, of course, not rush into a trip to the service station and wait for the mechanism to completely collapse, but such a delay can hurt your wallet. A complete replacement of a planetary gear is more expensive than repairing one of its planetary gears.

By the way, if an unpleasant sound appears only during forced (fixed) transmission, then there is no need to rush into repairs. Try changing the working fluid. But if the noise also appears while driving, this is a serious matter.

A cable that has turned into a “ruff” cannot work normally.

But it's almost a detective story. The owner of the Mitsubishi Pajero asked to diagnose the box. Previously, the clutch was changed at a service center, after which miracles began: release the pedal - a light knock, press a little - the knock is clearer, and squeeze it all the way - silence. The service rejected these complaints, reproaching the owner for buying the clutch on the side: it was his own fault. But is it?

We had to figure out the mystery. At first, the mistake was due to incorrect installation of the box. It is known that to replace the clutch it is moved away or completely removed. The new clutch is centered along the hole in the flywheel using a mandrel: the crankshaft and driven disk must be coaxial, otherwise the splined end of the input shaft may not fit into the splines of the disk hub or, worse, “bite” in them. Then you can only put the box in place with incredible effort, and even by twisting it!

Where the disk is centered with the first mandrel that comes to hand, or even with a rod with electrical tape wound around it, they often manage to bend the input shaft and destroy the bearings. It’s not noticeable on the outside, but it will have an impact later. What kind of accuracy in “hundredths” can we talk about when dealing with electrical tape?! If the repairman has simplified his work, “unexplained” noises in the gearbox are natural. It was with these interesting thoughts that we removed the box from the Pajero. But it turned out to be completely serviceable: the input shaft rotated easily, no play in the bearing, no runout of the shank was found. And the clutch looked like new! Have we witnessed a miracle? And then I accidentally grabbed the driven disk hub.

Automatic transmission hums at speed: what to do?

There may be a buzzing noise in the area of the gearbox when accelerating. As a rule, the automatic transmission hums at a certain speed limit, and then the hum only intensifies. A detailed diagnosis reveals that the place where the noise is generated is the rear part of the automatic transmission, where the connection to the driveshaft occurs. In this case, the system does not generate any errors. This is not yet a reason to panic, and the appearance of unpleasant sounds in this area is not evidence of the “death” of the gearbox. A possible cause is a broken transfer case front bearing (the bearing closest to the front driveshaft).

With such a malfunction, almost all bearings in the transfer case need to be replaced. For repairs, the box will have to be dismantled. The problem is that the transfer case is located in the same unit with the automatic transmission.

Repair procedure:

- dismantling and disassembling the transfer gear;

- accurate determination of the causes of the malfunction;

- bearing replacement;

- flushing the transfer case housing;

- reassembly;

- adding working fluid to the hydraulic transformer.

Features of noise from automatic transmissions, determination of the nature of breakdowns, methods for eliminating them

When stopping a vehicle, you can often hear a sound similar to the piercing wail of a siren. This type of noise occurs when the torque converter is operating. This signal should not cause much concern to the driver if it is short-term in nature. The appearance of an incessant howl, changing the tone depending on the engine speed, indicates the appearance of serious defects in the automatic transmission:

What causes the buzzing noise? It has been noted that the intensity of noise of this type depends on the rotation speed of the output shaft of the power unit. They arise due to increased vibration and oscillations of the line pressure oil valve (regulator valve). To eliminate unpleasant noise, it is necessary to replace thinned oil seals, cuffs and other sealing elements that have failed.

Continuous rattling appears when the engine is running at low speeds. In this case, you need to check:

What do metallic clanging noises indicate when idling? Typical causes here are worn clutch friction disc gaskets. To eliminate this defect and replace the clutch packs, you will have to dismantle the automatic transmission using special lifting equipment in a service station.

The hum and rattle in the area where the differential mechanism is located is the result of problems arising in this device:

What does the noise in the automatic transmission indicate when you engage a gear or change from one mode to the next? The main reason is a malfunction of the operating gear elements in the corresponding rows of the planetary mechanism. When noises change in volume and pitch when the next gear is engaged or the automatic transmission selector is switched to reverse mode, most likely the thrust bearings (liners) have become unusable.

Automatic transmission hums when accelerating

Sometimes the car makes unpleasant sounds when starting to move. Perhaps it's the automatic transmission whining. It starts making noise when shifting into third gear or at a speed of 60 km/h. With further acceleration, the unpleasant noise intensifies. After reaching a certain speed (80-90 km/h), the sound from under the hood subsides. If you stop pressing on the gas, the sound will no longer appear, but further acceleration will provoke its appearance again.

Replacing the rear gearbox can solve this problem. It is also worth inspecting the rear brake discs. You need to check the back side (where the brake cylinder is located). Rusty deposits may accumulate on the discs. If their width is more than 1 centimeter and they are over the entire surface, this may cause extraneous noise. The problem is solved by cleaning the inside of the disks.

Lack of oil

Another common cause of noise in the gearbox is insufficient oil level. In order to solve this problem, you just need to add oil.

The source of noise can be worn seals and mechanisms. To fix the problem, they need to be replaced with new ones.

In some cases, problems occur during gear shifting. Here you first need to look at the drive rods. It is possible that they have already used up their resource and need to be replaced. After this, you need to check the reliability of the hinge fastening. It wouldn't hurt to take a look at the gearshift lever rod.

Automatic transmission whine when shifting gears

Sometimes when you start driving, you can hear a suspicious sound resembling a howl from under the hood. This usually happens when shifting into second gear. In most cases, the source is the front planetary gear. This unit begins to make sounds when the transmission is heavily worn. Some drivers do not attach much importance to this and wait until the planetary gearset completely falls apart and a “meat grinder” of gears is formed, but this should not be allowed to happen.

The constant desire to reduce the cost of mechanisms simply cannot but affect their quality. The planetary mechanism quickly begins to break down the axes of the satellite gears. This leads to a change in the contact patch between the sun gears and satellites, which causes the destruction of their “teeth”. There is only one way out of this situation - replacing the planetary mechanism.

What noise additives are best to use?

There are many additives to eliminate noise. Manufacturers promise that their use will increase the service life of the mechanism and ensure smoother operation of the automatic transmission. Let's highlight the following additives:

- ATF Additive. Slows down oil oxidation and restores the performance of rubber seals. At the same time, it cleans the valve body channels and forms a protective film on the parts. This leads to a reduction or complete elimination of extraneous noise. According to the manufacturer, the additive increases the service life of the automatic transmission. The product consists of the same components as the oil, only their concentration is increased several times.

- EX120. This additive prevents early wear of the automatic transmission and protects rubbing parts. Its use helps eliminate extraneous noise. In addition, the geometric parameters of worn parts are partially restored due to the formation of a special metal-ceramic film on the metal surface. The product can be used in all types of transmissions and mixed with any oil. This revitalizant does not enter into a chemical reaction, which means it does not cause changes in the viscosity and other parameters of the working mixture.

The appearance of extraneous noise in the automatic transmission area is a reason to diagnose and repair the mechanism. A normally operating automatic transmission never hums or makes a grinding noise; it emits only a uniform, monotonous sound. The presence of noise is a sign of a malfunction that can occur both in the selector and in the working part of the mechanism.

How to prevent gearbox failure

Early signs of future failure include:

- Difficulties appearing when changing gears. It becomes more and more difficult to change gears. Sometimes you have to squeeze the clutch and move the lever to neutral.

- The transmissions are flying out.

- Oil is leaking from the gearbox.

Another common cause of problems during gear shifting is due to improper adjustment of the shift actuator. Assembly parts often break and can also cause the problem. To eliminate problems, it is necessary to correct or replace the rod as soon as possible, as well as tighten the screws. Then you can start adjusting the drive and replacing the remaining non-functioning parts.

On some VAZ 2114 vehicles, a gear reset occurs. This process occurs spontaneously. The reason is wear or breakage of the teeth (end teeth) on the coupling. Sometimes the teeth on the gears fail. A similar problem arises due to insufficiently competent debugging of the drive. In other cases, the reason lies in inaccuracy during the installation of the traction cover, which is intended for protection.

To correct this problem, you may need to replace all faulty parts. Next you should start debugging the drive.

The next step is to install the cover in the required position. If an oil leak occurs, then it is necessary to install the crankcase and change any gaskets that look worn out. Do not forget about the need to remove the box before repairing.

Symptoms of manual transmission malfunctions

Many drivers unknowingly confuse the symptoms of a manual transmission malfunction with signs of a breakdown in the gear selection mechanism or clutch. Fortunately, manual transmissions require much less attention than automatic transmissions, CVTs, DSG and robotic gearboxes. But even highly reliable units eventually begin to make noise at idle, while driving, and suffer from poor gear shifting.

The transmission is noisy in neutral and howls at speed.

Main causes of malfunction:

- insufficient oil level in the manual transmission. If there is a lack of transmission fluid, the lubrication of the rubbing pairs deteriorates. Thermal expansion and dry friction leads to noise and howling when moving. If the car has covered hundreds of thousands of kilometers, you should not be alarmed by slight noise when operating in neutral. We recommend limiting yourself to only changing the oil in the manual transmission.

If extraneous noise from the gearbox occurs when the clutch is depressed, the release bearing is faulty.

- gear wear. The reason is the development of gear teeth at the contact points. In this case, only replacing worn parts will help eliminate noise and howling;

- wear of the bearings of the driven, drive or intermediate shaft. As a result of oil starvation, heavy loads, increased torque after boosting the engine, or natural wear, abrasions, scuffing and uneven performance appear on the rolling elements and bearing races;

- production of differential parts for front-wheel drive cars. In such cases, vibrations are common when accelerating.

Some VAZ models are worthy of a special note, in which the manual transmission begins to make noise, howl and vibrate at relatively short distances. Many people attribute the malfunction to a design defect and the quality of manufacturing of transmission parts, which makes the idea of any repair very doubtful.

Gears engage poorly and with a crunch

Difficulty shifting gears and a metallic grinding noise at the moment of shifting are clear signs of a malfunction of the manual transmission synchronizers. But before removing the gearbox for repairs, check the gear selector and clutch. Play in the gearshift lever, cable jamming, and incorrect adjustment of the gear selection mechanism lead to unclear and often poor gear shifting. And incomplete disengagement of the clutch after pressing the pedal (the clutch is moving) will cause crunching and grinding sounds. Driving with such a malfunction will quickly damage the synchronizers.

If your car only shifts into second or, for example, third gear with a crunch, then the problem is most likely with the synchronizers. These elements are intended to equalize the rotation speed of the output shaft and the gear engaged in the transmission. Wear of the conical friction part leads to slipping of the blocking ring and rigid engagement of the clutch with the gear teeth. When disassembling and troubleshooting, you should also pay attention to gears, gear clutches and their forks.

Knocks out the speed

The synchronizer blocking ring and gears have specially shaped teeth with which the clutch engages when changing speeds. If the coupling splines, teeth on the ring and gear are ground down, then when the load is applied and the gas pedal is released, the transmission spontaneously switches off. In this case, it will not be possible to limit yourself to replacing synchronizers; you should definitely change the gear of the damaged transmission and the gear shift clutch.

The speed will be knocked out even if it is not turned on completely. Possible causes of manual transmission malfunction:

- wear of the rod, gear shift fork;

- cable jamming;

- incorrect installation, wear of the intermediate shaft bearing;

- wear of the manual transmission cushion, which causes the box to shift under load;

- loose gearbox housing bolts.

Oil leak from manual transmission

Possible causes of oil leakage:

- wear of the drive shaft oil seal;

- torn boot of the inner CV joint;

- loose pressure of the manual transmission pan, loose inspection hole bolt.

The cause of insignificant oil consumption may be a worn out oil seal on the speed selector rod. If you notice an oil leak, be sure to check the transmission breather. If it is clogged, excess pressure inside the gearbox housing will lead to squeezing out the seals and causing oil leakage.

The inspection hole at the bottom of most units is designed to check the transmission oil level. Often, the liquid level is level or 5-10 mm below the control hole is considered normal. If the manual transmission is noisy due to lack of oil, you can add fluid through the breather. If access to the upper gearbox cover or breather is limited, you can use a special syringe to fill the gap through the control hole. You can read about what kind of transmission fluid is poured into the manual transmission and how to change it correctly in the article “When to change the oil in a manual transmission.”

Let's sum it up

Many motorists are faced with such a problem as gearbox noise. It could be an automatic or manual transmission, any version of a modern robot or such a fashionable CVT. There are dozens of diseases of technical components and assemblies that can negatively affect this part of your car.

Therefore, you should pay special attention to the features that the gearbox provides you during operation. If you simply miss the moment when bearings or other parts begin to hum, you may soon find yourself on the side of the road without the ability to move in your car.

There are many types of motorists. Some people want their vehicle to work perfectly, others are content with the fact that as long as the car is driving, there is no need to repair it. But most vehicle owners want the main components of the car to work well and efficiently. Therefore, do not neglect good diagnostics to find out which part of the box is causing the unpleasant hum. Most likely, after such diagnostics, you will want to restore the node. Has your car ever had problems with the gearbox that caused an unpleasant hum?

Probably, almost every motorist has encountered the fact that the gearbox of a car began to howl. The VAZ-2114 is no exception in this case, and even such a “simple” car can have such an unpleasant effect. But not everyone knows why this problem occurs. In this article we will look at the causes of howling at checkpoints and methods for eliminating the effect.

The consequences of the howl of the checkpoint on video. Gearbox from VAZ-2114:

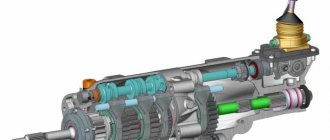

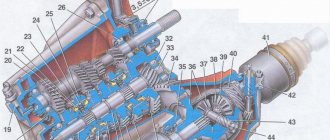

General view of the gearbox

Before proceeding directly to the issue of considering the appearance of noise in the gearbox, it is necessary to consider the design features of the VAZ-2114 gearbox. So, what parts does this unit consist of?

Transmission device diagram

Gearbox: 1 – clutch release bearing; 2 – guide sleeve; 3 – input shaft; 4 – roller bearing of the secondary shaft; 5 – secondary shaft; 6 – retaining ring; 7 – satellite axis; 8 – speedometer drive drive gear; 9 – transport plug; 10 – wheel drive oil seal; 11 – tapered roller bearing of the differential; 12 – axle gear; 13 – satellite; 14 – differential box; 15 – clutch housing; 16 – driven gear of the main gear; 17 – drain plug; 18 – adjusting ring; 19 – driven gear of the 1st gear of the secondary shaft; 20 – synchronizer for 1st and 2nd gears; 21 – driven gear of the second gear of the secondary shaft; 22 – retaining ring; 23 – persistent half ring; 24 – driven gear of the third gear of the secondary shaft; 25 – synchronizer for 3rd and 4th gears; 26 – driven gear of the fourth gear of the secondary shaft; 27 – needle bearing of the secondary shaft gears; 28 – ball bearing of the secondary shaft; 29 – thrust plate; 30 – driven gear V of the secondary shaft transmission; 31 – 5th gear synchronizer assembly; 32 – nut; 33 – thrust washer; 34 – drive gear V of the input shaft; 35 – rear cover of the gearbox housing; 36 – ball bearing of the input shaft; 37 – gearbox housing; 38 – roller bearing of the input shaft; 39 – breather; 40 – input shaft oil seal

Causes of malfunction

Once the design of the gearbox is understood, we can proceed directly to considering all the possible causes of the effect. According to the manufacturer's data indicated in the regulatory literature and the practice of motorists, the following factors can be identified that lead to transmission whining:

- Worn gears, namely the teeth of the part.

- Failure of shaft bearings.

- Low oil level.

Now you can go directly to troubleshooting methods.

Why does a manual transmission howl?

Many manual transmissions, even in good condition, are not very quiet. Even on a new car, the transmission can make sounds while driving, this is especially true for vehicles in the budget segment. For example, the whine of a VAZ gearbox is the norm for many cars. Every owner knows what the normal noise level is inside his car, and will always notice changes. If the noise of the box changes in tone, competes in volume with the sound of the engine, or appears in some specific conditions, you need to think about a visit to a car service center.

Many people confuse noise in the box with malfunctions of other elements. Often, while driving, a worn-out release bearing howls. The volume and tone of the noise directly depends on the speed of movement, so the diagnosis of “box whine” is mistakenly made. A clutch that requires replacement can also cause a similar problem. Without diagnostics, it is difficult to figure out what causes the unpleasant sound, so it is better to contact a car repair shop.

If the manual transmission itself makes a hum, there may be several reasons:

- If there is insufficient lubrication, a hum may occur due to intense friction of parts. The howl is heard especially clearly in higher gears.

- Noise may occur after improper repair of the gearbox. Assembly requires precision. If the shafts and gears are misaligned relative to each other, the box will make noise.

- A common cause of noise is failure of synchronizers. This malfunction is usually accompanied by a grinding noise when engaging certain gears.

- If the noise is present when the gear selector is in neutral, there is likely a problem with the input shaft bearing.

- The pinion bearing may also make a noise.

- Wear of the main pair is another source of box howling. If measures are not taken in time, other parts will also fail.

- If the whine is only heard in a certain gear, the cause lies in the gears. If their teeth are damaged, the box will hum.

- If the box hums when cold, especially in the winter, the culprit may be that the oil is too thick. After warming up, the transmission is much quieter.

- Old oil in a box may contain metal shavings and other impurities. This may be the cause of the noise.

conclusions

The howling of a Renault, Lada Vesta, Grant or any other car is a problem that cannot be ignored. A working transmission does not make any strange sounds, so if they appear, go to a service center as soon as possible. The sooner the diagnosis is carried out, the cheaper the repair will cost. If you constantly postpone this event, then the howl may end in buying a new box.

The gearbox is a rather complex unit, especially when it comes to an automatic transmission. Do not trust repairs and diagnostics to random people. It is better to contact a specialized auto repair shop that has the necessary equipment and tools.

VAZ checkpoint, a frequent source of howling.

Worn synchronizers are a source of increased noise. For replacement.

A worn input shaft bearing is another enemy of silence.

A faulty release bearing is a frequent source of additional noise.

The howl of an automatic transmission, robot or variator

Automatic transmissions are normally quieter than manual transmissions. If the howl of a manual Niva or Lada Kalina transmission may be a normal condition of the transmission, then third-party sounds from the automatic transmission should alert the car owner. Diagnosing the causes of third-party sounds when operating automatic transmissions is quite difficult. Sometimes computer diagnostics can help identify the problem, but in most cases you have to remove and disassemble the transmission. Having learned the cost of this procedure, many continue to drive a car and drown out the howling with loud music. But this is wrong; with significant wear of all internal components, repairs will cost more than with minor problems. In addition, a faulty transmission can fail at any time.

The main reasons for howling automatic transmission:

- If there is little transmission fluid in the box, usually not only extraneous sounds appear, but also kicks when changing gears.

- If the automatic transmission starts to howl after repair, it may have been assembled incorrectly. Even a slight displacement of parts leads to the appearance of third-party sounds.

- If the axle shafts are poorly secured, play occurs, which leads to noise.

- The quality of the transmission fluid also affects the operation of the automatic transmission. If the oil is old, contains mechanical impurities, or a fluid that does not meet the manufacturer’s requirements is filled in, the box will begin to hum.

- Worn or damaged gears, bearings and other mechanical parts lead to the appearance of extraneous sounds.

An automatic transmission is a rather complex mechanism compared to a manual transmission, which is why it is more difficult to identify the cause of the howling. But even if you need to disassemble the transmission with troubleshooting, it is better to perform this procedure than to face a critical breakdown along the way.

recommended products

ExtraSURM ES-1W

Universal anti-friction, water-resistant composite lubricant

215-SURM-Automatic transmission

Preventive additive for automatic transmission

305-SURM-TrV

Transmission rebuilder

306-SURM-CV joint

Bearing and CV joint restorer

Write to us

- Contacts

- Where can I buy

- Articles

- Cooperation

- Online store

- YouTube channel

- TikTok

- Buyer information

- ExtraSURM

- Lubricants

- For engine

- For transmission

- For hydraulic booster

- Ready solutions

- Catalog

- Application experience

- Terms of use

- © PIOTR LLC

- 1991 — 2022

What to do if the box howls

The first thing a car owner should think about when a howling noise appears in the transmission is a transmission fluid leak. Inspect the car's riser for oil stains, assess the oil level in the box using the dipstick, which most car models have. If the transmission fluid level is below the minimum mark, it must be topped up immediately. Use only the brand of oil that comes in the box. You cannot mix liquids from different manufacturers. You should know that automatic transmissions are very sensitive to the level of lubrication, so an overflow of transmission fluid is as unacceptable as a lack of it. If the oil has not been changed for a long time, it should be done. Automatic transmissions are especially sensitive to the quality of transmission fluid.

If it was not possible to eliminate the howling of the box by replacing or adding oil, you need to go to a service station for diagnostics. Specialists will assess the condition of the transmission and tell you how much repair is needed.

If you decide to sort through the box, you should take into account that the cost of such work is quite high. That is why it is advisable to purchase new original spare parts. Only in this case can you count on a long service life of the transmission after repair. Buying used spare parts or cheap parts from a dubious manufacturer is an imaginary savings. There is a high probability that soon after such repairs the gearbox will have to be disassembled again.

If the main pair is damaged, it is rarely possible to get by only by replacing it. Usually in such a situation other parts also suffer, so you need to evaluate their condition and, if necessary, also replace them.

Sometimes repairing a box turns out to be very difficult and expensive. In this case, it is advisable to replace the entire transmission. You can buy a new unit or find a used box in working condition.

Repair in a car service

If preliminary diagnostics show that the automatic transmission needs repair, do not rush to contact the first car service center you come across. It is better to spend time searching for a technical center that repairs your automatic transmission model:

- In specialized services, there is less chance of getting replacement parts: instead of original ones, you will get cheap junk.

- The client is allowed to be present in the technical area during the removal of the pallet and during repairs.

- Our technicians know all the weaknesses of your automatic transmission and can perform high-precision repairs.

The technical center will not indicate short repair times, because serious problems with the automatic transmission will require a complete overhaul, ordering new spare parts or repairing important components. Also, don’t be fooled by low prices—cheap automatic transmission repairs are only possible with your own hands.