The good old “mechanics” is gradually becoming a thing of the past, and in some countries it is already considered exotic; it has long been replaced by various automated gearboxes, allowing the driver not to think once again about which gear needs to be stuck in at the current moment. As a result of total automation and improvement of the gearbox, a completely new principle of gear shifting, the so-called “robot”, has recently appeared. And now we will look at what a robotic gearbox is, the pros and cons of such transmissions.

What is a robotic gearbox

What does a robotic gearbox mean? This is a part of a transmission, the design of which is no different from a manual gearbox, but is controlled using an automatic system that does not require driver intervention in the operation of the device. Due to the ability to operate fully automatically, manual transmissions are confused with automatic transmissions, although they have important design differences. Therefore, it is different how to use a robotic gearbox and how to use an automatic one.

There is also an external similarity between the two types of gearboxes: the car is not equipped with a gear shift lever, and there is also no third pedal - the clutch. Switching is carried out entirely without driver intervention.

Robot and automatic machine - what's the difference?

It would seem that there should be a minimum of differences, because both boxes are aimed at simplifying and automating gear shifting. In reality, automatic transmission differs from manual transmission in the same way as from manual transmission. The main difference between an automatic machine and a robot is the speed change system.

Automatic transmission In the first case, switching occurs using a torque converter. When the engine speed increases, automatic gear shifting occurs: the previous speed is jammed, and the next one is wedged. This allows you to switch almost instantly and unnoticed by the driver.

transmission In the robotic version, switching is performed by squeezing the clutch and engaging the desired gear (in absolute analogy with mechanics).

As can be seen from the information provided, the difference between an automatic machine and a robot is significant.

The difference between automatic transmission and manual transmission

Despite the common goal - to relieve the driver of the need to carry out mechanical actions, the boxes have different designs and differ in operation and maintenance. Robotic gearbox - differences from automatic:

- Automatic transmission requires a large amount of ATF fluid to function properly. Manual transmission also needs lubrication, for which oil is used, but it requires several times less.

- Automatic transmission provides greater softness and smoothness of shifting compared to manual transmission, which is determined by the operating principle of the robotic gearbox.

- Manual transmission allows you to reduce fuel consumption while maintaining dynamic movement. The reasons for this: the large mass of the “automatic” and the lower switching speed.

- Frictions have a longer service life compared to the clutch disc.

- “Robot” allows you to manually raise and lower the gear ratio if the driver switches to manual control. “Automatic” does not give the driver such an opportunity.

An additional difference is a consequence of more specific design features of the “machine” - the high cost of maintenance.

Automatic transmission

General view of the

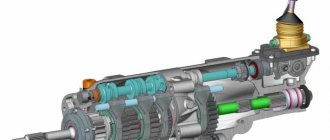

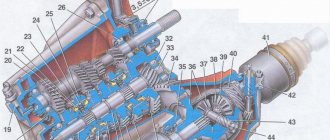

automatic transmission The basis of the automatic transmission is a torque converter, a control system and the planetary gearbox itself with a set of clutches and gears. This design of the machine allows it to independently switch speeds depending on engine speed, load and driving mode. No driver participation is required here.

The machine is installed on cars and trucks; it is also applicable in buses. The final drive and differential complement the design of the automatic transmission when installed on a front-wheel drive vehicle.

Pros and cons of automatic transmission

An automatic transmission has both advantages and disadvantages:

| Advantages of automatic transmission | Disadvantages of automatic transmission |

| 1. Smooth movement and acceleration | 1. Expensive maintenance and repairs |

| 2. Comfort for driver and passengers | 2. Low efficiency |

| 3. Easy to drive | 3. Higher fuel consumption |

| 4. No need to periodically replace the clutch | 4. High cost |

Operating principle of manual transmission

Before buying a car, you need to understand what a robotic gearbox is and how it is designed. A manual transmission has a clutch disc with a flywheel, and the entire structure is controlled by a robot. The electrical control unit operates according to an algorithm embedded in the loaded firmware of the “brains,” sending commands to the servos in accordance with sensor readings. It depends on the firmware how much more dynamic and comfortable the ride in the car will be. Therefore, after updating the “brains”, the car can greatly change its behavior.

How does a robotic gearbox work:

- The gas pedal is pressed.

- The engine speed increases and the car accelerates.

- When certain speed and engine speeds are reached, the clutch actuators and shift forks are activated.

- “Robot” increases the gear.

The process will be repeated until the car reaches its limit on the number of available gears. When braking, the system works in a similar way, only the gear ratios change in the opposite direction.

Drawing conclusions

Which gearbox is better? From the point of view of comfort, the automatic transmission undoubtedly wins, although the robot developers tried to win this position from the automatic transmission.

But a robot will be more cost-effective. The cost of the box itself, its maintenance and repairs will be cheaper. And a car with a robotic gearbox consumes less fuel and oil than with an automatic one.

Now reliability. This is debatable. Neither one nor the other box can be called absolutely reliable in comparison with the same mechanics. It is also unclear how both boxes will behave in difficult conditions. But the automatic transmission is at least more predictable than a robot from which you don’t know what to expect.

Therefore, which gearbox will be better, each driver decides for himself, based on his ideas about the convenience and comfort of driving. It is worth noting that the robot can easily be mistaken for an automatic transmission: often the absence of a clutch pedal in both automatic and robotic transmissions confuses inexperienced drivers. Therefore, it is necessary to carefully study the characteristics of the selected car during the purchasing process.

Pros and cons of manual transmission

Like any other power design, the pros and cons of a robotic gearbox determine the target owner of cars with such a control system.

Pros:

- The acceleration time is as close as possible to that which can be obtained with ideal switching to a manual transmission.

- Lower cost of repair and maintenance compared to automatic transmission.

- Increased service life of the clutch disc when compared with manual transmission.

- Low fuel consumption.

- Less wear and tear during operation compared to manual operation.

Minuses:

- The electronic control unit cannot independently react to extreme situations on the road, so the driver must be ready to urgently accelerate or brake.

- The box may be designed in such a way that jerking will be felt when changing gear ratios.

- The “robot” works more comfortably in long gears.

- Traffic in traffic jams is “killed” by the manual transmission; components and mechanisms begin to deteriorate earlier.

- For correct operation, electronic assistants are required, for example, a lifting assistance system. Otherwise, the car may refuse to reverse when starting to move uphill.

Advantages and disadvantages of robots in comparison with other automatic transmissions

So, in order to understand how a robotic box differs from its analogues, you need to consider its features, design and operating principle. Let's start with the fact that the main advantage of any automatic transmission compared to a manual transmission is comfort, since the driver does not need to change gears independently while driving. Moreover, each of the automatic transmissions copes with this task, but there are differences.

For a better understanding, we immediately note that the robotic gearbox also comes in two types: a single-disk robot of the AMT type (robotic mechanics) and a preselective robotic gearbox with two clutches of the DSG or Powershift type.

So, in short, the most comfortable gearbox today is the continuously variable CVT, then we can highlight the “classic” hydromechanical automatic transmission and DSG/Powershift robots, and at the end of the list in terms of comfort is a robotic gearbox with one clutch.

Moreover, as mentioned above, each type of gearbox has its own strengths and weaknesses. Now let's look at the robot gearbox in more detail.

- Initially, such a gearbox was developed at the dawn of the automotive industry, but a number of problems and a lack of technology did not allow in those years to create a unit that would be able to compete with the increasingly popular hydromechanical automatic transmissions.

However, this idea was not abandoned, as a result of which, thanks to modern technologies, robotic boxes appeared relatively recently. To put it simply, the robotic gearbox is a regular mechanic, but the operation of the clutch and the gear shifting process are controlled by separate servomechanisms instead of the driver.

The advantages over automatic transmissions and CVTs are obvious: simple design and low cost of production, the ability to install such a transmission in tandem with any engines, affordable maintenance, and good maintainability. Also noteworthy is the reduced fuel consumption and, as a result, increased environmental friendliness.

It would seem that everything is simple, ordinary mechanics, a clutch similar to a manual transmission, an electric or hydraulic drive of the clutch and gears under the control of the ECU completely controls all processes. However, this solution also has big disadvantages.

First of all, comfort suffered. On single-disc manual transmissions (with one clutch), jerks, delays, and dips when downshifting and upshifting are the norm. It turns out that in terms of comfort, these units are very far from automatic transmission or CVT. Another weak point of the robots turned out to be the servomechanisms themselves (servos, actuators).

To make it clear, the device is an electric motor with a gearbox and an actuator; it is also possible to install hydraulic actuators (depending on a particular box). So, these elements have a short service life (about 80-100 thousand km), are often difficult to repair and are quite expensive.

The clutch on such boxes does not have a long service life either. As a rule, every 50-60 thousand km. It needs to be replaced, and in intervals (every 20-30 thousand km) it is also recommended to adapt the clutch of the robot box.

Naturally, such manual transmissions are not capable of competing with other automatic transmissions. Their main advantage is their affordable price, which allows them to actively equip budget cars with gearbox data without significantly increasing the cost of the car itself.

- Taking into account such shortcomings, manufacturers have recently introduced another version of robotic gearboxes - a preselective dual-clutch robot. The most famous type is the DSG from Volkswagen.

Such a box is essentially two manual gearboxes in one housing (one with even gears, the other with odd gears). The unit already has two clutches, which allows you to change gears in a split second.

The result is that the driver does not feel the moment of switching, the traction is practically uninterrupted. As it may seem, this type is capable of displacing automatic transmissions and CVTs. However, it is not.

Although the service life and reliability of such gearboxes is higher than that of single-disc analogues, the weak point is still considered to be clutch units, and a number of problems arise with actuators, mechatronics, etc. Repairing such boxes is also very expensive.

At the same time, robots, both with a single disc and with a double clutch, are less reliable compared to manual transmissions. This means that it is still not recommended to skid with such a box, transport heavy loads, tow a trailer, actively drive off-road, etc.

Let us also add that preselective gearboxes, especially those with a “wet” clutch (the clutch packs are in oil), are also sensitive to the quality and level of this same oil. The presence of mechatronics (in fact, a hydraulic unit) obliges the owner to promptly change the lubricant, use only original transmission fluids, etc.

In other words, a preselective robot is a symbiosis of mechanics and a classical machine with all the ensuing consequences. Although the torque converter (GDT) is missing, the sensitive, difficult to repair and expensive valve body has not gone away. It should also be noted that there are a large number of sensors and electronics, which are also not reliable.

Principle of operation

The driver, turning on the shift lever, gives a signal to move. First, the clutch is engaged through the actuator, the gearbox begins to rotate at the command of the control unit. The clutch located on the inner input shaft is engaged first. In this case, the actuator brings the synchronizer to the first gear gear, it is blocked, which activates the secondary shaft gear. The car begins to move and accelerate smoothly.

The second shaft and clutch make it possible to reduce gear changes without damaging the mechanism parts. The principle is to wait for the signal to engage the next gear while the previous one is in operation. The second clutch, external input shaft and second gear are engaged immediately upon signal. The further process involves repeating the algorithm. Thanks to this scheme, gear shifting is reduced to a minimum of time.

The control unit, based on data received from the sensors, issues various commands for execution. For example, when reducing speed or increasing load, gears are switched from top to bottom.

If it is necessary to engage a lower gear, the driver signals this by acting on the sensor; the unit interprets this as canceling all gears except the first.

Double clutch robotic gearbox

Over the past couple of years, robotic gearboxes with a dual-clutch system have become widespread. The fact is that the main disadvantage of a standard robotic gearbox is the rather long time it takes the unit to change gears. This often causes dips in dynamics and jerking during an active driving style, which negatively affects the comfort level of the entire trip as a whole. This negative feature scares off a considerable number of potential car enthusiasts from the prospect of purchasing a car equipped with a robotic gearbox. The solution to the problem was the use of a double clutch system, which eliminates the interruption of the power flow at the moment of gear shifting. The double clutch makes it possible to select the required gear while the previous gear is engaged, and, if necessary, engage the next gear without interrupting the operation of the gearbox. Due to this design characteristic, double-clutch transmissions are called preselective gearboxes.

Another important advantage of dual-clutch transmissions is their speed when changing gears. Here, the speed of transition from one gear to another depends solely on the speed of the clutches. Thus, DSG “robots” from Volkswagen spend no more than 0.2 seconds on switching, and DCT M Drivelogic units produced by BMW – only 0.1 second. In addition, the “robot”, equipped with two clutches, is a very compact unit, which is especially important for small city runabouts.

Advantages of a robotic gearbox

The clear advantages of the robot box include fuel economy. Compared to a classic automatic, the fuel consumption of a car with a robot is comparable to the fuel consumption of a manual car - a liter or two less.

Also, the undeniable advantages of some (!) robots include their “operational features of manual transmission.”

There are two fundamentally different designs of the robot - in the first, shifts are controlled by special drives (Toyota and Opel robots), in the second, gear shifts are performed “on the automatic principle” - using oil pressure (Fiat, Audi, BMW, VW, Peugeot/Citroen).

In the first design, oil is not the working fluid; its quantity is comparable to the amount of oil in a manual transmission. Such a robotic gearbox (just like a manual transmission) is less sensitive to the quality of the transmission fluid.

This means that in difficult Russian operating conditions (with large temperature differences), the oil change time in a robot can be noticeably longer than in an automatic transmission, and the amount of oil replaced can be less. This fact greatly saves the owner’s money.

The second design of the robot does not have such properties; the oil in it needs to be changed in the same way as in an automatic machine (at least once a year).

Many experts also consider the service life of the clutch on a robot to be a plus - as a rule, it is longer than with conventional mechanics. However, such a plus on many car models with a robot is quickly negated by the complexity and high cost of replacing this very clutch.