In progressive vehicle models, various forms of gearboxes are installed. The most common options are: mechanical, automatic, CVT. A manual transmission is characterized by a high degree of reliability; on the other hand, it requires a person to have good machine control skills. The second option is much easier to use, but a little “capricious” in technical terms. As you can see, the characteristics of both types include unique features: pros and cons. It is for this reason that the designers created another gearbox, which has significant differences from other varieties. The robot box is increasingly used when equipping cars.

Robotic gearbox: features and benefits of driving

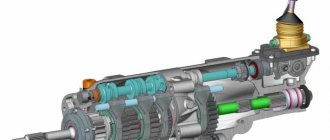

Appearance of manual transmission

This variety is not so complicated when it comes to its structure. The structure includes a mechanical box and an electronic unit designed for control. The finished product has a full range of functions previously performed by a manual motorist. This includes, in particular: moving the lever to a certain position, squeezing the clutch, and so on. The expanded functionality is partly due to the presence of actuators, that is, servos that are located inside the unit.

Structure of a robotic box

The main advantages of the new development include reliability and ease of use. A person driving a car with a robot just needs to move the selector to the desired position and enjoy driving. The electronic unit takes care of ensuring that gear shifts are carried out correctly. I would like to note that most robotic boxes are equipped with manual controls, which gives the driver the opportunity to drive the box and control the car independently. There is only one difference, which is the absence of pressing the clutch.

Scheme of operation of manual transmission

The design and principle of operation of a robotic gearbox with one clutch

Robot with hydraulic gear shifting

The robotic gearbox can be with one or two clutches. A robot with two clutches can be found in the article about Powershift. We will continue talking about a single-clutch gearbox.

The robot's design is quite simple and includes the following elements:

- mechanical part;

- clutch;

- drives;

- control system.

The mechanical part contains all the components of conventional mechanics, and the operating principle of a robotic automatic transmission is similar to the operating principle of a manual transmission.

The drives that control the box can be hydraulic or electric. In this case, one of the drives monitors the clutch and is responsible for turning it on and off. The second controls the gear shift mechanism. Practice has shown that a hydraulically driven gearbox functions better. As a rule, such a box is used on more expensive cars.

The robotic gearbox also has a manual gear shift mode. This is its uniqueness - both a robot and a person can change gears.

The control system is electronic and includes the following parts:

- input sensors;

- electronic control unit;

- actuators (actuators).

Scheme of operation of manual transmission

Input sensors monitor the main parameters of the gearbox operation. These include speed, fork and selector position, pressure level and oil temperature. All data is transmitted to the control unit, which controls the actuators. The actuator, in turn, controls using servos.

In a hydraulic automatic transmission, the control system is additionally equipped with a hydraulic control unit. It controls the operation of hydraulic cylinders.

The robot operates in two ways: automatic and semi-automatic. In the first case, the box is controlled through a specific algorithm, which is set by the control unit based on sensor signals. In the second, the operating principle is identical to manual gear shifting. Gears are sequentially switched from high to low using the selector lever, and vice versa.

How to drive a robotic gearbox?

Some of the robot’s operating formats differ when compared with an automatic model. The list of unique operating modes includes:

- “N” is a neutral option, during which the motor continues to function, rotation is transmitted to the equipment, but it does not go to the wheels, which is explained by the location of the gears. The mode is more relevant to use when parking for a long time, as well as before the start and after the car has stopped.

- "R" - move backward. In order to enter this mode, the car enthusiast must move the selector to a given position, due to which the car begins to move backward.

- "A/M" (sometimes called "E/M") - forward movement. This mode is the same as mode “D”, which is found in all automatic transmissions. When using it, the car moves forward, and the gearbox itself performs the shift. When the “M” mode is activated, control is carried out manually. By moving the selector to a certain position, the user selects the mode that he needs at a given time.

- “+”, “-” - designed to change gears. Briefly moving the selector to the plus or minus side can ensure gear shifting when selecting the control mode manually.

- Heating requirement

From the very first days of using a vehicle with a manual transmission, you can understand that there is nothing difficult in driving. You will understand how to use the new product, because for proper control you just need to move the selector to the selected position and move along the highway. But in order for the device to function without any problems or failures, you need to know how to operate it.

Comparison of two gearboxes: what is the difference between a robot and an automatic machine

The table below shows the differences between robot and automatic gearboxes.

| Type of differences | Robot | Machine |

| Constructive | Mechanical box with electronic control unit | Torque converter, planetary gearbox, valve body |

| Functional | Availability of manual switching function | Manual switching |

| Price | Darling in TO | Low cost service |

| Consumer | Low consumption of fuels and lubricants | Large amounts of oil and fuel consumption |

Now it will be easier for a novice car owner to choose between these two types of automatic transmission. The next block provides some advice from experienced car owners and mechanics on choosing one or another device if the car enthusiast has already taken a step towards one of the types.

Do you need to warm up your car in winter?

How to control a robotic gearbox? First you need to decide whether there is a need to warm up the box before using it in winter. If you use an automatic device, then you know that in cold weather you cannot do without pre-warming, which is done by briefly moving the selector to all existing positions.

Driving a car with a robotic gearbox does not require additional manipulations, even if the temperature outside is sub-zero. However, in winter the gearbox should still be prepared for upcoming use. The fact is that while the car is standing, the oil inside the device flows down and, due to low temperatures, its consistency changes: the substance becomes much thicker.

For this reason, in the cold season, it is recommended to start the engine and wait some time for the oil to warm up and distribute throughout all the elements that make up the box. This will reduce friction and reduce wear on parts in contact with each other. For the process to be successful, you need to wait two minutes and start the engine.

Then you can smoothly, trying not to make sudden jerks, move for a kilometer, which will contribute to optimal heating of the oil fluid.

In this case, it is absolutely not necessary to move the selector to different positions; it is enough to leave it in neutral mode.

Dry and wet clutch

Dry clutch boxes are structurally similar to conventional mechanics. The clutch disc contacts the flywheel directly. Coolant circulates in “wet” boxes, which lowers the temperature of parts during intensive work.

“Dry” boxes are installed on cars that do not have much power. This transmission is designed for a torque of no more than 250 Nm. Many car owners believe that this is not enough, so they do engine chip tuning. As a result, the transmission quickly fails.

It should be remembered that a dry clutch is not designed for aggressive driving. They are equipped with economical city cars, not sports cars. If you accelerate sharply for a long time and try to squeeze the maximum out of the car, the clutch parts will overheat and fail prematurely. After short episodes of sharply pressing the accelerator pedal, you need to switch to a calm driving style. This will allow the transmission to cool down.

A wet clutch does not suffer from overheating. The circulating fluid removes excess heat and protects parts from damage. Owners of such a robotic gearbox can afford to drive more aggressively.

Features of driving with a robotic gearbox

Most of the cars equipped with the most advanced models of gearboxes are not equipped with a start assist system for lifting, and therefore experts recommend starting the movement yourself. In such a situation, you need to act as in the case of a mechanized gearbox, that is, the selector should be switched to mode “A”, and then press the accelerator, while simultaneously removing the car from the handbrake. This will eliminate the possibility that the vehicle will start to roll back. It is worth practicing in advance in performing these actions in order to learn how to control, feel the engine and immediately recognize the moment when the clutch has already engaged and you need to remove the car from the handbrake.

Have you used a car in winter? In this case, you know that in order to use the manual mode by setting the first gear, it is not recommended to accelerate hard, otherwise there is some risk that the wheels will start to slip.

When driving uphill in a certain mode selected automatically, the device shifts into lower gears without human assistance, which can be explained from a logical point of view: if the speed is too high, it is much easier to overcome the climb. The manual transmission is equipped with a gyroscope that determines the location of the car in space. If the indicator shows a rise, the device begins to work adequately to the situation. It is possible to move in manual mode; to do this, you need to lock the selected gear. We must not forget that the gearbox does not allow tight movement, and therefore when climbing, the engine speed changes and is at least 2500 rpm.

During the descent, nothing is required from the person driving the machine. He just needs to move the selector lever to position “A” and remove the standing brake. In such a situation, the car will slow down due to the motor.

Correct mode switching and parking

DSG does not like sudden movements. That is why you need to switch modes smoothly. Automation is quickly rebuilt, but for this it needs some time. Just a second delay when changing the selector position will significantly extend the life of the transmission. Don't pull the gearshift knob.

When parked, the car is held in place using a locking mechanism. But if you often park your car on a slope, it is recommended to use the parking brake. This takes the load off the limiter and extends its service life. But remember that in winter the brake pads may freeze when using the handbrake.

How to stop?

The issue of stopping and parking is also important for drivers. It is very important to know how to drive correctly so that your car will serve you well for a long time. After the car has completely stopped, you need to move the selector lever to “N” mode, set the standing brake, and turn off the engine. During short stops, moving the lever to the specified mode is not necessary. It is allowed to remain in mode “A”, but we must not forget that during a stop the clutch remains depressed. Therefore, when standing at a traffic light or in a traffic jam, if the delay lasts for an indefinite period, you need to switch to neutral mode.

Service

The manufacturer claims that the DSG “robot” does not require maintenance, and the oil filled at the factory is designed for its entire service life. But the experience of the masters says otherwise. If you want the transmission to last as long as possible, the transmission fluid must be replaced every 50-60 thousand kilometers.

Before you get behind the wheel of your new car, be sure to read the recommendations for using the DSG robotic gearbox. Its operation is similar to a classic machine gun, but there are still some nuances. If you take them into account, the transmission will serve properly for a long time and will delight you with smooth and quick gear changes.

edit this post

What other modes exist?

Listed above are the basic rules that should be followed when driving a car with a robotic gearbox. However, there are other features that you should be aware of. For example, some products offer auxiliary modes other than those listed above. These are such types of gears as: sports and winter (it is also called “snowflake”). The last of the presented modes is needed in order to safely navigate along an ice-covered track. It provides a smooth transition to higher speeds.

Quick start: to be or not to be?

Fans of dynamic acceleration often start from a standstill, simultaneously squeezing the gas and brake. This is done in order to increase engine speed, and then release the brake and rush forward as quickly as possible. This technique is not suitable for robotic boxes.

Modern “robots” are equipped with a protective mechanism. When you press the brake, the electronics prevent the clutch disc from closing with the flywheel, so engine speed will not increase. The car will not be damaged in such a situation, but there is no point in this manipulation.

The situation is worse on machines where such protection is not provided. When you press the gas, the discs close, but the brake pedal does not allow the car to move. As a result, the disks slip, damage appears on them, and the life of the flywheel is prematurely exhausted.

What is DSG on Skoda?

Direct Shift Gearbox ( DSG)

) - direct shift gearbox - combines two clutches and two gearboxes.

Thanks to this, one gear replaces another literally in an instant. DSG

combines the driving comfort of a traditional automatic system with the dynamics of a manual unit.

Interesting materials:

Why is water ozonation necessary? Why spray indoor plants with water? Why settle water for flowers? Where is the artesian water? Where to get water while hiking? Where to store water in the kitchen? Where to dig a well for water? Where can you find water in nature? Where is the water supply valve in the washing machine? Where is the water supply valve located?

General recommendations

We have looked at how to drive a robotic gearbox correctly, now we will give some practical advice:

- At the start, you should not squeeze the gas; when you need to increase speed, you should press the pedal confidently, but smoothly.

- It is better to carry out initialization at a service center several times a year - this will minimize jerking and jerking.

- When accelerating, follow the logic of the manual transmission.

The last thing that can be added about robotic and CVT gearboxes is the manual control mode or the so-called tiptronic. It is implemented by moving the gear selection lever into a special additional groove, indicated by the signs “+” and “-” for upshifting and downshifting, respectively, and you can find out more about this gearbox option in our material. In general, we can say that, even despite the variety of nuances in controlling a CVT and a robot, with some driving experience, habits and skills are developed that greatly help in the process of driving a car. Following our advice and the above rules will help to significantly extend the life of the gearbox and the entire car.

“>

About the device

One of the branches of development of mechanical transmissions led to the creation of a robotic gearbox, which combined the reliability of a “mechanics” with the convenience of an “automatic”. Due to the fact that all the driver’s work began to be performed by actuators - servos of the unit, the characteristics increased. Now the electronic unit takes care of gear shifting itself. All a person needs to do is set the selector to the desired position, like in a gearbox, and enjoy the ride.

There are robots with manual gear shift mode. For example, a 2-Tronic box can serve in three modes. The first is automatic, when a person does not touch the gears at all. The second is semi-mechanical, in case the driver wants to control the clutch independently, for example, when overtaking another car and at the same time is in automatic mode. The third mode is completely manual, where everything depends only on the driver.

As for those who like to drive fast, a cam robotic gearbox is just right for them. It is the fastest of all types of robotic boxes; you can switch speeds in 0.15 seconds. Cars with such a box contain a clutch pedal, but it is used only when the vehicle starts moving. Further, shifting occurs as in a sports motorcycle - without using the clutch.

Preselective gearbox

Manual transmissions can have an electric or hydraulic clutch drive. In the first version, the “organs” are servomechanisms (electric motors). As for hydraulic, everything here is based on hydraulic cylinders. Automakers such as Peugeot, Fiat, Renault, BMW, Volkswagen, Citroen and others equip their robotic gearboxes with a hydraulic drive. As for the electric drive, the following companies are working with it: Ford, Opel, Nissan, Toyota, Mitsubishi. Other Korean manufacturing companies have not yet decided to introduce robots due to the complexity of design and maintenance.