The cost of a VAZ 2107 brake caliper in Russia varies from 300 to 3,160 rubles . In this price range, only new products are considered, which are sold either individually (left, right sides) or as a set.

The brake caliper is the main element of the braking system, which mechanically acts on the pads secured with a bracket, thereby reducing the speed of a moving vehicle. The efficiency of the braking system and the length of the path from pressing the pedal to a complete stop depend on the quality of the caliper, namely the small and large pistons.

Buying an assembled is a more rational solution than using a repair kit to restore the system’s functionality. The chamber, and the piston itself, in addition to mechanical wear, are also damaged by corrosion and debris that penetrates under the boot. Even the cheapest Chinese equivalent of a caliper for 300 rubles. will be better than the original product with a mileage of over 100,000 km and a domestic repair kit.

The pressure distribution from the vacuum booster during movement should be evenly dosed between both front wheels. Otherwise, the car will be pulled to the side, which is extremely dangerous in the presence of oncoming traffic. That is why it is strongly recommended and checked as part of the technical inspection, replacing both calipers. A new set of decent quality will cost 1,400 rubles . The purchase will pay for itself over several seasons through even wear of the pads and discs.

After changing the brake fluid, the brake pedal fails

Another common problem is when the pedal fails after bleeding the brakes.

In other words, the owner has just changed the brake fluid and bled the car's brakes, and the pedal is falling out. First of all, this may mean that air remains in the system. Often, two people bleed the system (one person works with the pedal, and the other opens and closes the bleeder fittings). So, problems with the brakes appear if the one who pressed the pedal released it early, while the assistant did not have time to close the bleeder fitting.

Let us also add that if, in addition to replacing the brake fluid, the calipers were also repaired/replaced, the brake pads were changed at the same time, and the brake pedal fails (usually on the first press), this happens as a result of the “breaking in” of the parts.

The pistons of the working cylinders are positioned in such a way that the gaps between the pads and the brake discs/brake drums are minimal. In this case, the reverse stroke of the piston is blocked in one way or another (depending on the design features).

When all the parts are in working position, the brake pedal will stop falling. If the brake pedal fails after repair, then there is a high probability that errors were made during assembly, the system is not pumped well enough, there are brake fluid leaks, etc.

VAZ 2107 caliper: dismantling, replacement, installation

The front wheels of the “Seven” are equipped with disc brakes that are highly efficient. Each of the components of the VAZ 2107 car has two working cylinders, which bring the pads together and clamp the part located between them. This causes the disk to stop rotating. During operation, parts wear out and the faulty caliper needs to be replaced with a new one.

Typically, the cause of unit failure is corrosion processes of the cylinder walls and piston. In a working mechanism, they are protected from moisture by special rubber cuffs. Damage to these elements leads to moisture getting inside; over time, the unit loses its mobility and requires replacement or qualified repairs. Restoring the brake mechanism can be done independently.

Other reasons why front brakes stick

The front wheels do not always jam the same way; this can manifest itself in different ways. Both front wheels can “stick” at once, and you simply won’t be able to move. It happens that they seem to be spinning, but with great difficulty, making a creaking sound. This is a dangerous situation, especially if you ignore the problem and continue driving. Only one front wheel can jam, while the other spins freely. Let's look at the possible reasons.

The brake pedal is poorly adjusted or has no free play at all.

There must be sufficient clearance between the master cylinder piston and the pusher for the pedal to move normally. This is adjustable.

The brake pad tension spring is faulty.

This does not mean that it is cracked or completely torn, perhaps just stretched. There is such a thing as metal fatigue, and a weakened spring will no longer function normally; it is better to replace it.

Another reason why the front brakes stick is that the vacuum booster is not in order.

It can jam for several reasons. Perhaps the diaphragm is swollen, or the protective cap or lid seal is pinched.

Pay attention to the amplifier adjusting bolt

It should not be too tight. It is important that it protrudes slightly above the surface of the master cylinder. There is something wrong with the brake pad friction lining.

There is something wrong with the brake pad friction lining.

The problems can be different: the gasket wears out, breaks, or becomes too thin. This usually leads to damage to the pad itself, so in this case it is necessary to change both it and the lining

Important: if you are changing a worn gasket, then the pair to it should also be replaced; they must be the same in thickness, otherwise the car will be pulled off the line of movement to the side. The reason that the front brakes are sticking may be a stuck piston in the wheel brake cylinder.

The reason that the front brakes are sticking may be a stuck piston in the wheel brake cylinder.

This kind of trouble can happen in any car, so you need to be able to deal with it. The reasons for this situation are different: low-quality brake fluid, uneven position of the cylinder body in the caliper, rust and corrosion on the working surfaces of the piston. Disassemble the problematic cylinder, clean all components, rinse with brake fluid, reassemble the system and bleed. Fill with good quality brake fluid.

The cuffs on the wheel cylinder have lost their shape or are swollen - this is also one of the reasons why the front brakes stick.

The cuffs of the master cylinder or wheel cylinders swell from fluids such as oil, gasoline and others that have entered the brake system. This jams the cylinders, which results in a problem with the brakes. But you just have to replace the cuff, and everything will work out

It is recommended to at least occasionally check the condition of the cuffs, and when disassembling the car (no matter for what reasons), replace them, even if these elements look absolutely intact

Oxidation stains on the guides.

They need to be cleaned, lubricated, and you will no longer have to think about why the front brakes are sticking.

The compensation hole on the brake master cylinder is dirty.

This is a labor-intensive process, a large and messy piece of work, but no spare parts will be needed, meaning repair costs will be minimal. It is necessary to clean the hole and bleed the brake hydraulics.

The pistons of the master cylinder as well as the wheel brake cylinders are stuck.

In this case, only experienced car owners who have already disassembled and reassembled various systems of their car more than once will be able to figure out why the front brakes are jamming. It is better to entrust the diagnostics to specialists: they will find the cause of the malfunction and immediately begin repairs.

It often happens that it is enough to just thoroughly clean and lubricate the necessary parts. Check the hoses to see if they are in order. It often happens that the hose is pinched by the clamp holding it, especially if it is corroded. This can also cause the front brakes to jam. The best thing in this case, of course, is to replace the clamp with a new one. But you can just loosen it slightly and blow out the hose well.

It is perhaps not so easy to immediately determine why the front brakes are jamming. This can happen for many reasons, and if you yourself are not very versed in the operation of car systems, then it is better to entrust the inspection and repair of the car to service station specialists. After all, a properly functioning braking system is the key to both your safety and that of other road users.

The front brakes are sticking. Causes, elimination. Watch the video:

https://youtube.com/watch?v=qZ70UPly3kc

Removing the brake caliper

To remove the caliper you must do the following:

- lift the car on a lift or jack up the wheel on which the brake caliper needs to be removed;

- Using a wrench, remove the bolt securing the brake hose bracket;

- remove the bracket so that it does not interfere with further actions;

Important: under the bracket fastening bolt there is a spring washer, which must not be lost when dismantling the bolt and bracket.

- unscrew the bolt securing the brake hose;

- remove the bolt after first removing the two o-rings;

- insert a rubber tube or bolt of a suitable diameter into the hole in the brake hose tip to prevent brake fluid from leaking out;

- Use pliers to remove the cotter pins securing the brake pad pins;

- pull out the pins securing the brake pads and remove them using a bit or a thin, but not sharp, screwdriver;

- remove the retaining springs from the brake pads;

- remove the brake pads;

Advice: if you plan to use the brake pads in the future, they should be marked with a marker so that during reassembly they can be installed in the same place where they were. If this is not done, they will wear out faster and brake worse.

- bend the locking plates of the washers on the caliper mounting bolts;

- unscrew and remove the bolts securing the caliper to the steering knuckle;

- Remove the brake mechanism (caliper) of the VAZ 2107 from the brake disc.

Important: the upper and lower caliper mounting bolts differ in the shape of the head. When installing the unit in place, it is necessary not to mix them up.

Solution

If your car has such a breakdown, the main thing is to solve it comprehensively. It happens that malfunctions are associated with several reasons at once. If the problem is that the pedal is simply rusty, it needs to be replaced. It is easy to correct the situation by replacing the brake fluid with a higher quality one. By the way, you will have to update the fluid in any case - in order to “update” the entire system. Otherwise, over time, the pedal will definitely begin to fail when pressed.

If cracks appear in the pumps, the brake may also begin to fail. Moreover, even microdamages can be the cause of such a breakdown. So if you want the brake to function and not fail in the middle of the road, you will have to replace everything that has stopped working. It turned out to be enough for me to make one replacement. At this point, the question of why the brake pedal failed was closed. To be convinced, it was enough to just start the engine. No extraneous sounds. And if before the return after pressing was too slow, now everything works perfectly.

Repair

After preliminary cleaning of the caliper parts, they need to be degreased and painted. Before applying paint, all holes are sealed with masking tape. You need to paint in several layers. To completely destroy traces of corrosion remaining after brushing, parts can be etched with phosphoric acid before painting.

The removed piston of the VAZ-2108 caliper should be carefully inspected for scoring. Then you need to polish the interface between this part and the cylinder with water using 2000-3000 grit sandpaper.

After drying, the piston, lubricated with brake fluid, is installed in place. At the same time, a new bleeder fitting is installed.

The repair kit contains new rubber seals, including rubber bands that protect the guides of the VAZ 2108 caliper. During assembly, all boots, O-rings, and cuffs are installed with new ones.

Car brake system: types, general structure and principle of operation

To better understand why the brake pedal fails when pressed, it is necessary to consider the general operating principle and design of the brake system. This system is usually hydraulic, and problem areas are often common on many car models. Brakes operate on the principle that there is incompressible brake fluid in a closed volume.

Note that the machines previously also used a mechanical braking system with cables and other drive elements, but engineers abandoned such a device long ago. The fact is that although mechanics were not inferior in reliability, but were superior to hydraulics, the performance and smooth operation of such a solution turned out to be insufficient, taking into account the rapid development of the auto industry, the increase in the power of installed internal combustion engines, etc. Mechanical brakes simply no longer cope with increasing speed limits and effectively and safely slow down the car.

There is also a pneumatic braking system, which is used on special vehicles (trucks, large buses, various equipment). Air brakes are no worse in efficiency than hydraulics, but the system itself is too heavy and bulky to be installed on compact passenger cars. So it turns out that the hydraulic braking system has become widely installed on civilian and commercial vehicles, as well as on many other types of wheeled vehicles.

Hydraulic brakes have the following elements in their design:

- GTZ (brake master cylinder)

- RTC (brake wheel cylinders)

- Hydraulic lines

- Compensatory device

- Brake discs and brake pads

The working fluid for the brake system is brake fluid, which has certain properties. At the moment when the driver presses the brake pedal, the force is transmitted to the GTZ, which is filled with working brake fluid. The GTZ device has a piston that exerts pressure on the liquid. Through the working fluid, the force is transmitted to the RTC, which are installed in the area where each of the vehicle wheels is located. As a result, the brake pads are pressed against the brake discs or brake drums. If the force is maximum, then the pads completely block the rotation of the wheel. Let us add that depending on the type of brakes installed, the latter are divided into drum or disc. There is also a combination where the front wheels have disc brakes, while the rear wheels are equipped with drum brakes.

The main advantage of hydraulics is smooth and predictable force; the pads are pressed evenly against the brake discs. As for the force on the brake pedal itself, it is proportional to the force that compresses the pads. It turns out that the driver can clearly measure the applied force, thereby determining the degree of wheel locking and the intensity of braking. After releasing the brake pedal, the return springs, which are present at the place where the pads are installed, move them apart, that is, they allow the pads to take their original position. At the same time, the brake fluid is forced back into the master cylinder. This is the general operating principle of the entire system. At the same time, modern cars have additional elements: a vacuum brake booster, a brake force compensator, an ABS system, etc.

Now a few words about the brake circuit. This solution allows you to reduce the risk of complete failure of the braking system in the event that the brake mechanism on one of the wheels is faulty

This is very important for hydraulics, since a leak in one of the RTCs is a common malfunction. There are several schemes of multi-circuit brakes, according to which the circuits of brake systems are implemented

Let's look at some of them. The axial design allows the braking system to be divided into circuits for the front and rear axles. If the brake wheel cylinder leaks on one axle, then the other will be able to operate normally. There is also a pattern where the braking force distribution pattern is made diagonally relative to the rear and front wheels. There are also solutions that combine the wheels of the front axle and one rear wheel; RTC pistons are additionally installed (double-piston and multi-piston brakes), etc.

Causes of jamming and creaking

Now directly about how to determine the presence of a problem.

The primary sign indicating a malfunction in the calipers of a car brake system is squeaking.

See also: Lift kit for Niva: which one to buy and how to install it yourself

It is the creaking that indicates that the element is seriously worn out. In the near future, the unit must be replaced without fail, which the car literally and figuratively screams about. It is extremely difficult not to hear such a creak. But for some reason, thousands of motorists still stubbornly ignore it. As a result, they pay a rather high price. Sometimes even to the point of road accidents resulting from brake failure while driving. To prevent this, you need to understand the issue and understand the essence of what is happening.

The first step is to look at the possible causes. In fact, there are several potential problems to look for. Some of them arise due to the fault of the motorist, others are caused by the natural process of wear and tear.

In any case, the appearance of a squeak as a symptom is a harbinger that at the most inopportune moment the caliper may simply jam.

If you know the reasons, you can prevent them and troubleshoot them by contacting a car service center or solving the problem yourself.

The reasons are:

- The brake pads were initially installed incorrectly. As a result, they are not strictly parallel to the response drives. Because of this, creaking often appears;

- The brake discs are seriously worn out. The reasons are natural wear and tear and aggressive use of the car;

- There is no lubrication in the unit. Initially there was little of it, or it was used up;

- The lubricant was selected incorrectly. Many people skimp on lubricant intended for calipers, hence the consequences.

The most undesirable and dangerous situation is rightly considered when the piston does not return and the unit begins to jam during operation.

Imagine that you are driving a car, press the brake, and then accelerate again. But at the same time, the calipers do not release the front brakes. Additional resistance arises, the car tries to move, but cannot. The result is uncontrolled braking, extremely intense wear and serious overheating of the entire system.

General information about the brake system

To better understand why the brake pedal fails in a given situation, it is important to first understand how the entire braking mechanism works and how it all works. By the way, most often the brake system in modern cars is of the hydraulic type, and all the main components and problem areas in it are similar in different vehicle models

In this case, the principle of operation of the brakes is that inside the closed system there is a special incompressible fluid, which is called brake fluid.

Brake system design Why does the brake pedal fail?

Despite the fact that mechanics are much better than hydraulics in terms of reliability, their performance is still much lower, and it does not work as smoothly as we would like. Especially with modern powerful engines and increasing speeds. Mechanics are simply not able to cope with the modern level of tasks assigned to it - it cannot stop the car as smoothly, efficiently and safely as we would like.

How should the brake pedal move?

There is also a pneumatic braking system, but it is used only on special vehicles - trucks, heavy and powerful equipment, buses, and so on. The system is effective, but is not suitable for passenger cars, as it is too heavy and bulky.

The simplest diagram of air brakes for a car

Where can I buy?

VAZ 2107 calipers can only be purchased in city auto stores or online trading platforms. This is due to the fact that the production of original models for retail sales was discontinued back in 2014. Therefore, any caliper sold in a new condition has an old restored body at its base, on which completely new cylinders, tubes and other small elements are placed.

Purchasing a frankly Chinese analogue is not considered, since the complex of measures to modify them out of the box consists of cutting new threads and fitting the goujon, replacing rubber products, as well as filling the space under the boot with anti-squeak lubricant.

Brake bleeding and fluid replacement procedure

Brake fluid needs to be changed every two years. After this, bleeding of the brakes is always required. This procedure is not complicated, but it is inconvenient to carry out alone. However, nothing is impossible.

Procedure for bleeding the brake system

Step 1. If the car has ABS, then under the hood you need to find the fuse relay box and turn off the system by pulling out the fuse responsible for ABS. Then the system will be pumped in exactly the same way as in a car that does not have ABS. Bleeding should be started depending on the location of the master brake cylinder. In this case, the rear far left wheel will be pumped first. That is, you need to start from the farthest highway. Then you need to work on the wheel on the right and front, then on the right rear wheel, and complete the pumping by treating the left front wheel.

Locate and remove the ABS fuse

Step 2. Next, you need to put the car on the handbrake. The engine can be started, but only if the brakes are bled outside. If the procedure is done in a garage, then you will simply have to press the pedal a little harder if the engine is not running. If pumping is done with someone in pairs, then the second person needs to be put behind the wheel and told him what to do. That is, for example, the assistant will press the brake pedal 3-5 times slowly, with an interval of 1.5-2 seconds.

Apply the brake after starting the engine

Step 3. When you press the brake for the last time, you need to fix the pedal pressed and hold it, informing the second person about this.

Keep the pedal pressed

Step 4. After step 3, while an assistant holds the brake, you need to unscrew the fitting in the area of the wheel being processed. When the brake fluid stops flowing, tighten the fitting, and then ask an assistant to pump the brake again using the system described above. After this, you need to look at the fluid level in the tank.

Drain the brake fluidPump the brake after draining the fluid

Step 5. You can use a ratchet and a wrench to loosen and tighten the fitting. And to drain the brake fluid, you can take any thin transparent tube - it can be replaced with a conventional dropper system. The tube is put on the fitting.

Use the key to open the fitting

Step 6. The cycle must be repeated until all the air from the system has been released or until the fluid has been completely replaced. You need to go through all the wheels. For the rear axle, 15 approaches are enough, for the front axle – 10.

Repeat the procedure at least 10 times

Step 7. Before replacing the fluid with a new one, you can pump out the old one from the reservoir with a pump.

Pump out the brake fluid

Step 8. Then you need to pour new liquid into the empty tank to the very top.

Refill with fresh brake fluid

Step 9. If bleeding is done without an assistant, then you can do this: open the fitting and let the brake fluid flow out by gravity. You can open all 4 fittings at once. The process will take about 4 hours. The main thing is not to forget to add fresh brake fluid to the reservoir.

You can do pumping yourself or with an assistant

If pumping occurs without an assistant, and the gravity-feed option is not suitable for some reason, then you can do this.

Step 1. You need to purchase a cap for the brake reservoir and install a nipple from a tubeless tire on it. The prepared lid must be screwed onto the tank.

Install a special lid on the tank

Step 2. Next, you will need to build up pressure (0.5-1 atmosphere is enough) using a compressor or foot pump connected to a lid with a nipple. Thus, the air will put pressure on the liquid in the system and squeeze it out. The liquid also drains into the jar through tubes, as in the instructions above.

Increase pressure to 0.5-1 atmosphere

Step 3

It is important to monitor pressure readings and add it if necessary. It is also important to monitor the level of brake fluid in the reservoir - it always needs to be added

Monitor brake fluid pressure and level

It is worth understanding that this procedure is carried out only if the brake system is in good working order and has no leaks. This will have to be repeated until the brake pedal no longer sinks or is easily pressed.

How often should you change front pads?

Let's start with the fact that on the VAZ 2107 the front brakes are represented by a disc system, which in some ways is much better than a drum one, but that’s not about that now. There are 2 pads on each caliper at the front, which are responsible for effective braking of the car. The front brake pads of the VAZ 2107 have the following appearance, shown in the photo above.

Essentially, the products are a steel plate onto which a special friction layer is applied. It is this friction layer that is the basis for car braking. When this layer wears off, which depends not only on the frequency of use of the brake pedal, but also on the nature of driving, then the car owner urgently needs to replace the brake pads on the VAZ 2107. If this is not done in a timely manner, then you understand what the outcome may be.

How often it is necessary to change the parts in question depends on the following factors:

- condition of the brake system;

- character and driving habits;

- product manufacturer;

- regular maintenance.

But our mentality is such that we don’t pay attention to how often we need to change the pads, and we do it when it’s pressing. The reasons that indicate that the car requires repair work on the brake system are due to the following symptoms:

- the appearance of extraneous sounds when you press the brake pedal: creaking or grinding;

- to brake, you need to apply force;

- When braking, the car begins to skid.

Approximately, it is necessary to replace the front pads on a car every 25-30 thousand km. But this range is average, since someone can travel 50 thousand km without replacing products, but they can only do 10. Let’s look at what it is to replace the front brake pads of a VAZ 2107 in more detail.

Detailed description of replacing front pads on a VAZ 2107

Replacing pads on a VAZ 2107 is a simple process that needs to be taken seriously. First you need to purchase new products. You need to buy them as a set, and replacement should be done on both wheels at once. After this, make sure that you have a basic list of tools:

- screwdriver;

- hammer and chisel;

- pliers;

- standard set of wrenches;

- WD-40 lubricant;

- Brake Cleaner (optional).

Let's start the workflow:

- Initially, some of the fluid should be removed from the brake reservoir, which is done to prevent it from overflowing and entering the engine compartment.

- Place shoes under the wheels, then install a jack and lift the front end. Afterwards, the wheel is removed, and then the surface of the caliper is cleaned of dirt and dust.

- Using a thin screwdriver, remove the two visible cotter pins. These cotter pins are designed to hold the pad rods. The photo below shows the location of these two cotter pins.

- Using a screwdriver, you need to press out the pad rods. If your own efforts are not enough, then you can use a hammer and a punch.

- The products are additionally held by spring structures, which can be seen in the photo above. They also need to be dismantled, for which you need to use pliers.

- When the rods and springs are removed, you can begin to dismantle the products themselves. Usually the pads do not sit tightly, so you just need to pry them off with a screwdriver and remove them, as shown in the photo below.

- Once the pads are removed, it is recommended to clean the seat using special products, and you can begin installing new ones.

- To do this, using a mounting tool or a screwdriver, you need to separate both cylinders, thereby preparing a place for new (thicker) pads. At the same time, do not forget to monitor the level of the displaced liquid in the barrel and, if necessary, remove it.

After installing the new products in their places, install the rods and mounting springs in the reverse order. This completes the replacement of the front pads on the popular VAZ 2107 car. As you can see, there is nothing complicated at all. Everything is simple and clear, but the main thing is to perform all the steps in the order described above. After installing new system elements according to the instructions, there is no need to bleed the brakes.

If you decide to replace worn-out products, then it is recommended to purchase new ones from companies such as Ferodo, ATE or Nippon. They will last much longer and will also delight you with their quality and braking performance. If you still don’t know how to change the front brake pads on a Zhiguli, then this material will be a good help. And remember that you will always have time to overpay the mechanic at the service station, but only then will you not be able to gain invaluable experience in repairing your car.

Improperly performed fluid change or brake bleeding

If you bleed the brakes, but the pedal still falls, this indicates a failure to comply with the procedure. The sequence of actions differs for right- and left-hand drive cars, and each individual car model may have its own characteristics. In this case, you need to check the correctness of execution, or contact a specialized service center.

Many experts prefer to use special pumping equipment for pumping. It allows you to create higher pressure in the system and make the hydraulics work as efficiently as possible. After bleeding the brakes in the usual way by pressing the pedal, the brakes often become sluggish and require repeating the procedure.

Where is the front caliper located?

A caliper is a kind of housing for the brake system of the front wheels, in which replaceable pads are mounted, as well as working cylinders. This part is made of steel. Located on the brake discs. The design of this device has parallel holes on both sides in which the brake cylinders are located. These cylinders drive pistons, which move when you press the brake pedal.

The pistons in the working cylinder act on the pads, which are pressed by a friction layer against the brake disc rotating with the wheel. Thus, the vehicle's movement slows down. Without this housing, it is almost impossible to implement a disc brake mechanism, therefore, when malfunctions of the device occur, they must be eliminated as quickly as possible. This mechanism fails extremely rarely, and it can last up to 500 thousand km, however, under the influence of certain factors, its service life can be reduced by 2-3 times.

The mechanism belongs to the category of non-repairable devices that, if they fail, need to be replaced. Exactly how to remove the caliper on a VAZ 2107 is discussed in detail in the material, which will allow not only beginners, but also experienced professionals to remember how to do it correctly.

What tools are needed for removal

Before you begin repairing or replacing the brake caliper on a VAZ 2107, you will need to find out what exactly caused the breakdown. Most often, the pads are changed; when the friction layer wears out, they must be replaced. However, to replace the pads, there is no need to remove the part.

In addition, the working cylinders may fail, and if they fail, they will need to be repaired or replaced. To make the replacement, you first have to remove the caliper. To dismantle it you will need tools and materials:

- The caliper is complete with new working cylinders. If the mechanism body itself is in good condition, then only the working cylinders, of which there are 2 in the design of each device, must be replaced.

- A set of keys for 10, 14 and 17.

- Slotted screwdriver.

- Pliers with a hammer.

- Jack and goatee.

After replacement, you will need to fill the brake fluid into the system and remove the air - bleed it.

Removing the caliper on a VAZ 2107

Removing the caliper on a VAZ 2107 car is performed in the following cases:

- If the slave cylinder needs to be repaired or replaced.

- In case of deformation and damage to the mechanism body.

Replacing brake calipers on a VAZ 2107 is performed in the following sequence:

- Pump out fluid from the brake system expansion tank if it is still serviceable. If it is not suitable, then you don’t have to do this, since when unscrewing the hoses, it will flow out of the system.

- First, the desired car wheel is lifted with a jack.

- Using a wrench, unscrew the bolt of the brake hose mounting bracket.

- Remove the bracket so that it does not interfere with subsequent manipulations.

- Unscrew the bolt securing the rubber hose.

- Remove the bolt from its seat. Remove the two o-rings.

- Drain the liquid from the hose into a previously prepared container. The liquid does not need to be drained, but to do this you will need to insert, for example, a wooden cap into the hole in the tip.

- Remove the cotter pins that secure the friction pad fingers.

- Remove the pins that secure the pads. To remove them you will need to use a beard and pliers.

- Remove the springs from the brake pads that hold them in place.

- Remove the friction pads. If you do not plan to change the pads, then you need to note which part and where it was located.

- Using pliers, straighten the lock washers on the bolts that secure the device.

- Unscrew the bolts that secure the mechanism to the steering knuckle.

- Remove the device from its seat.

When dismantling the caliper, you need to take into account that the brake mechanism mounting bolts have different head shapes. You need to remember or mark which bolt was removed from which seat.

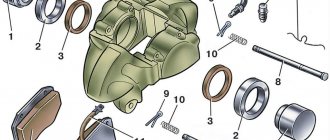

How the repair is carried out

If the mechanism is damaged or there are deformations, it must be completely replaced. Repairing a VAZ 2107 caliper involves replacing non-working cylinders. The repair procedure is as follows:

- The device is fixed in the jaws of a vice.

- Unscrew the fastenings of the connecting metal tube. After this, the tube must be removed.

- Knock out the working cylinders from the guides.

- If there are none, remove the clamps and replace them with new cylinders.

- Place the cylinders in the guides, and then install the connecting tube, followed by tightening the fittings.

- If it is necessary to repair the brake cylinders on the caliper, then the essence of the repair actions is to change the rubber seals.

- To make repairs, you will need to remove the cylinder and then remove the rubber cap from the cylinder using a screwdriver.

- Press the piston out, then remove the sealing ring using a screwdriver.

- In place of the old ring you need to install a new one from the repair kit. The cylinder, as well as the piston and ring, must be lubricated with brake fluid.

- Install the piston into the mechanism cylinder.

You can install old parts in place only if they are in full working order and without scratches, deformations or damage. Otherwise, if there are any, they should be replaced.

Device installation

Installing the front caliper on a VAZ 2107 will not be difficult after removing, repairing and replacing it. The installation is completed by bleeding the system to remove air. If the fluid is outdated (changed color and darkened), then it must be replaced.

When replacing calipers completely, you need to take into account that these mechanisms are different for the left and right wheels. After completing the work, you need to check that the system is working correctly. This completes the process of repairing the mechanism, and in conclusion it is worth noting that it is recommended to change them in pairs.

If your car's brakes fail while driving, it won't lead to anything good. The rule is true for all cars, and the VAZ 2107 is no exception. This car, for all its popularity in the vast expanses of our vast country, could never boast of reliable brakes. Most often, on “sevens” the brake caliper fails, which has to be urgently replaced. Is it possible to make such a replacement yourself? Yes. Let's try to figure out how this is done.

Vacuum booster diagnostics

Often, a sign of depressurization is unstable engine operation (tribbing). This happens due to air entering the intake manifold. It sharply depletes the air-fuel mixture entering the cylinders. If the pedal does not press when the car is running, first of all you should check the reliability of the connections.

To pinpoint the problem, turn off the engine and wait a few minutes without pressing the pedal. If after this time the pedal remains hard, the most likely cause is a broken check valve.

Also interesting: How to bleed the brakes of a Niva Chevrolet

It is very easy to diagnose the correct operation of the vacuum booster

. To do this, without starting the car, you should “pump” the pedal, then, continuing to hold it, start the engine. If the vacuum seal is working properly, the pedal will go down.

Causes of jamming and creaking

Now directly about how to determine the presence of a problem.

The primary sign indicating a malfunction in the calipers of a car brake system is squeaking.

It is the creaking that indicates that the element is seriously worn out. In the near future, the unit must be replaced without fail, which the car literally and figuratively screams about. It is extremely difficult not to hear such a creak. But for some reason, thousands of motorists still stubbornly ignore it. As a result, they pay a rather high price.

The first step is to look at the possible causes. In fact, there are several potential problems to look for. Some of them arise due to the fault of the motorist, others are caused by the natural process of wear and tear.

In any case, the appearance of a squeak as a symptom is a harbinger that at the most inopportune moment the caliper may simply jam.

If you know the reasons, you can prevent them and troubleshoot them by contacting a car service center or solving the problem yourself.

The reasons are:

- The brake pads were initially installed incorrectly. As a result, they are not strictly parallel to the response drives. Because of this, creaking often appears;

- The brake discs are seriously worn out. The reasons are natural wear and tear and aggressive use of the car;

- There is no lubrication in the unit. Initially there was little of it, or it was used up;

- The lubricant was selected incorrectly. Many people skimp on lubricant intended for calipers, hence the consequences.

The most undesirable and dangerous situation is rightly considered when the piston does not return and the unit begins to jam during operation.

Imagine that you are driving a car, press the brake, and then accelerate again. But at the same time, the calipers do not release the front brakes. Additional resistance arises, the car tries to move, but cannot. The result is uncontrolled braking, extremely intense wear and serious overheating of the entire system.

The brake failed at full speed: what to do?

First, try pressing the pedal sharply several times: perhaps its functionality will be partially restored. Next, assess the situation and identify a place where you can gradually turn. Then tighten the handbrake (don't do it too hard) and start shifting (if you have a manual transmission) to a lower gear. At the same time, when the lever is in “neutral”, press the accelerator (perform “re-throw”) to “prepare” the gearbox gears for emergency operation. As a last resort, choose the lesser of two “evils” - it is better to run into some obstacle near the road (roadside bushes are a good option) than to collide with a car.

https://youtube.com/watch?v=RLKzha1KnDk

Guide faulty

The main problem if the brake does not work can be jamming and souring of the caliper guides.

Repairing this malfunction with your own hands will not be difficult. By the way, in this case there is no difference when disassembling both the front and rear calipers. To do this, you need to unscrew and pull out both guides. Clean them from dirt or poor-quality lubricant, remove and replace the torn boots with new ones, after filling them with special grease for calipers.

Then put them in place, insert and screw the guides back. Then you should try how freely the pressure bar moves along them. This can be seen visually in the attached video at the end of the article.

We should not forget about the housing of this brake element. If significant rust, dents, sagging or other mechanical damage is found on it, it should be replaced completely.

If the repair had to be done on a removed caliper, then after installing it in place, the brake system should be bled.

The situation when the brake caliper jams is not just unpleasant, but dangerous for the driver and passengers in the car. The caliper is the most important element of the braking system of a modern car. Its job is to press the brake pads against the brake disc when the driver presses the brake pedal. The caliper is a complex mechanism, and its serviceability must be monitored. You should not only allow the caliper to jam, but also the appearance of squeaks and knocks in it.

The brake pedal is too soft

If pressing the pedal has become too soft, it means there are air bubbles in the hydraulics and then the system should be pumped, or there is a loss of working fluid. The first thing you need to do is check the brake fluid level. If it is below the permissible level, the hydraulic system must be carefully checked for leaks. A leak may occur at the connection points between the tubes and fittings due to poorly clamped clamps, and the hoses themselves may be damaged. Working fluid can also be lost in wheel brake cylinders if the seals are damaged. After eliminating the leak, you will also need to bleed the brake system hydraulics to remove air from it.

If the brake fluid is of poor quality, contaminated, or has not been changed for a long time and has lost its properties, then heating during sudden braking can quite easily lead to its boiling, and then the brakes will become “wobbly” and the car itself will be difficult to control. An old, dirty, or inadequate brake fluid can cause seized brake cylinders, damaged seals, and other problems.

The conclusion is obvious - pay attention to the condition of the brake fluid and change it in a timely manner

Another reason for a soft brake pedal is the hoses, which are made of rubber and wear out over time, becoming loose. When hydraulic pressure builds up during braking, they simply inflate. As a result, the brakes become too soft and braking becomes less effective.

An extreme and very dangerous manifestation of soft brakes is pedal failure. This occurs due to significant leakage of fuel fluid or damage to the sealing rings in the gas turbine engine.

An excessively soft brake pedal, and even more so if it fails, requires an urgent solution to the problem. You need to stop immediately, braking with the engine or handbrake, and then find and correct the problems.

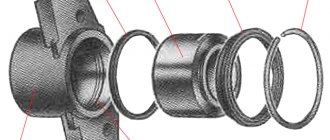

Device

The unit is a cylinder with a piston running inside it. The system also includes brackets - they hold the brake pads. On passenger cars, products driven by a hydraulic system are installed; on trucks, a pneumatic system is installed.

This is what the caliper consists of:

- frame;

- caliper guides - must be coated with lubricant;

- the anthers of the fingers on which the caliper runs;

- internal and external pads;

- brackets in which the braking elements are secured;

- sealing and fastening rings;

- piston boot;

- hoses supplying brake fluid.

The main element is a piston with a cylinder. The design includes a valve that removes air. Under the influence of pressure, the air temperature increases, which is why there is a risk that the liquid will boil, and this negatively affects braking. The hole in the rear caliper is opened when bleeding the brakes. The rear brake caliper is connected to a cable, so the piston can be pressed mechanically by the parking brake.

Dips when pressing the pedal

Brake pedal

High-quality and clean brake fluid is the key to normal brake operation. It is thanks to its high density that the braking force is quickly transmitted to the wheels. Over time, it deteriorates its properties, air bubbles form in it, and moisture accumulates.

If a slight depressurization occurs in any area, the liquid flows out and air gets in its place. As a result, the brake pedal is either soft or hard. Several gentle pressures lead to the accumulation of pressure in an insufficiently dense liquid. Then it works, and effort appears.

First of all, you need to check the presence of fluid in the expansion tank of the brake system; it is located on the master cylinder. If there is no liquid in it, you cannot drive; simply refilling it will not solve the problem. If you are planning a DIY repair, you will have to find the location of the leak - it could be any of the cylinders or some kind of tube.

Article on the topic: Registration of an accident according to the European protocol, how to fill out the form correctly

Dismantling the unit

To carry out repair work on the brake system of a VAZ 2107, you will need spare parts: a caliper assembly or a set of cylinders. Tools you will need: a set of keys, screwdrivers, pliers and a hammer. It is advisable to organize the work in a garage box; a portable lamp is used to illuminate the workplace. Repair of the brake system is carried out in the following order:

- The front part of the car is lifted with a jack and placed on a support, the wheels are removed.

- A thorough inspection of the caliper is carried out and it is cleaned of contaminants, using a key set to “17” we unscrew the bolt securing the brake hose and drain the liquid into a previously prepared container.

- Carefully move the brake pads apart using a screwdriver, applying force to the metal parts of the base. Using a drift of a suitable size, the guides are knocked out and the pads are pulled out.

- We unscrew the bolts securing the housing to the knuckle, thereby releasing the mechanism, and remove it from the brake disc.

Replacement of faulty cylinders installed in the caliper grooves is carried out by knocking it out. It is advisable to carry out repairs in a vice, having previously treated the grooves with a special penetrating liquid. Installing new cylinders usually does not cause any particular difficulties; they are inserted into the housing and driven all the way to the stop using a hammer and a soft metal drift.

What's the result?

As you can see, there can be many reasons for a failing brake pedal. If you are not confident in your abilities and skills, then you should refrain from trying to fix the problem yourself and immediately contact experienced specialists. It must be remembered that it is recommended to change the brake fluid in a timely manner, since the maximum service life is no more than 24 months. Also a sign of the need for replacement is cloudiness and blackening, and the appearance of a characteristic odor. Note that brake fluid tends to accumulate water, which significantly deteriorates its properties over time and serves as an additional reason for replacement.

Finally, I would like to note that in the event of unexpected problems with the brakes, you should not panic. There are certain techniques you can use to slow down and stop your car without using the brake pedal. First of all, don't forget about the parking brake. The so-called “handbrake” may well slow down or even stop the car if the car was moving at low speed (20-40 km/h). At the same time, an untrained driver should not sharply pull the handbrake at medium and high speeds (especially on a wet, icy or snowy road), since the car can skid, spin, be thrown off the road, into the oncoming lane, etc.

In such a situation, it is better to brake by gradually lowering the gear from high to low with shifting in a car that is equipped with a “mechanics” (manual gearbox). In some cases, you can use the contact emergency braking method, when the car deliberately collides with an obstacle and slows down after such contact or several contacts. This technique allows you to stop with minimal risks for the driver of a faulty vehicle and other road users.

Service

The calipers get very hot and work in aggressive conditions; these are the factors that have a destructive effect on the parts. Chinese analogues are generally destroyed by high temperatures. Professionals recommend installing either spare parts from well-known brands or originals on your car. You can't skimp on brakes.

- squeaking brakes;

- brake lock;

- deviation of the car's course when braking;

- change in brake pedal hardness.

An important detail on which the service life of the parts depends is the boot. The boot protects structural elements, in particular the piston surface and the oil seal, from dust and dirt. If the boot ruptures, dirt and sand instantly gets inside, the parts rust, the lubricant is washed out or dries out, the tightness of the seal is broken and a leak occurs. Running the piston dry leads to disastrous consequences: braking efficiency is significantly reduced, or it becomes impossible, the piston is blocked and the wheel jams.

Piston souring occurs when a worn brake pad is used for a long time. Insufficient thickness of the lining leads to the fact that the piston extends too much, and deposits form on its side surface, which prevent it from returning to its original position. If you install new pads on such a caliper, the following problems will arise:

- rapid pad wear;

- disk failure;

- uneven pad wear;

- creaking caused by overheating of rubbing parts;

- steering wheel beating, which appears due to constant pressure on the rotating disk. It is especially noticeable when braking at high speeds.

Steering wheel wobble when braking

Noise in the assembly can be noticed some time after installing new parts. Causes:

- design features of the unit;

- low quality parts.

To eliminate this drawback, springs are additionally installed.

Corrosion of the inner surface of the piston occurs due to neglect of the timing of brake fluid replacement. It is capable of absorbing water even from the air. Therefore, over time, even parts that only come into contact with brake fluid are exposed to water and begin to corrode.

Important! The frequency of replacing brake fluid is every 3 years.

In order for the caliper to serve for a long time, it is necessary to change the lubricant in a timely manner. This action will ensure reliable operation of the piston and safe operation of the vehicle.

For calipers, you cannot use conventional lubricant such as graphite grease or Litol. It will dry quickly even with a whole anther. The main requirement for lubricant is resistance to temperature changes. Specialized lubricant is sold in packages of 45 g. This is enough for one-time maintenance.