The car should always respond clearly to rotations of the steering wheel. If this does not happen, then there can be no talk of any security. This applies to all cars, including the VAZ 2107. The main steering unit is the gearbox, which has its own faults, which can be identified and eliminated without visiting a service center.

- Steering column

VAZ 2107 steering column deviceSteering wheel

- Steering shaft

- Gearbox

- Lubricant leak

- How to remove a column

Video: how to replace the steering gear on a “classic”

- Video: repairing the steering column of classic Zhiguli cars

- Video: how to change the oil in the steering column

- Video: how to reduce play in the classic steering gear

Adjusting the VAZ 2107 steering gear

The VAZ 2107 gearbox does not require excessive intervention.

The main condition for normal operation is the presence of lubrication. Creaks or strange sounds in a structure are common damages. Since in this model the steering wheel is attached to the shaft using splines tightened with a nut, if the fastening is loosened, the splines will be most subject to wear, and the steering wheel will dangle. Squeaks may be heard from the driveshaft crosspieces, which appear as a result of wear of the mechanism parts or lack of lubrication. Also, damage to the steering wheel play is common. The driveshaft may come off and, as a result, a gap appears. To adjust the steering column, a bolt with a lock nut is provided. The nut is pulled back and the bolt is screwed in until the play returns to normal. This nut is then tightened and secured in position. After this process, the steering wheel will turn much tighter, but the play will be reduced.

Steering gear VAZ 2107

Before you start checking the steering mechanism malfunction, subject to the identified symptoms, you need to adjust the gearing. If the adjustment is unsuccessful (for example, the steering wheel rotates tightly, but the play has not disappeared), then you should disassemble the gearbox to find faulty or non-functional parts of the mechanism.

Required Tools

To repair the VAZ 2107 steering gear or replace it you will need:

- set of wrenches;

- beard;

- screwdriver;

- hammer;

- vice;

- mandrel or similar-sized pipe section;

- rags.

Independent work is completely justified economically, since as of March 27, 2022, replacing a unit in car services costs an average of 2,400 rubles. Plus 450 rubles for adjustment. So the work costs as much as a new gearbox.

But you should start working only if the car owner clearly understands how to repair the unit. Below is the sequence of operations in the text.

What is the steering column of the VAZ 2107? Replacement and adjustment

In this article you will learn about what a VAZ-2107 steering column is, how it is replaced, and also what differences there are from those gearboxes that were installed on earlier models - 2101-2106. But first things first. First, you need to consider the operating principle of the entire steering system, after which you can begin replacing and removing the gearbox. Everyone can do all the work independently, no problems will arise. But after installing a new gearbox, it is necessary to correctly set the toe-in and camber angles of the front wheels.

Types and prices

The original steering column for passenger cars of the VAZ 2101-07 family has catalog number 21050-3400010-00 . Its cost varies from 2,172 to 4,449 rubles . In order for the classification of goods to be as complete as possible on the part of the buyer, the price can be divided by series and compatibility. The latter looks like this:

- VAZ 2102, 1973-1985 – 2,797-4,449 rubles.

- VAZ 2103, 1972-1984 – 2,797-4,449 rubles.

- VAZ 2106, 1975-2006 – 2,430-4,300 rubles.

- VAZ 2101, 1970-1988 – 2,172-4,301 rubles.

- VAZ 2106, 1975-2005 – 2,430-4,250 rubles.

- VAZ 2104, 1984 – 3,934 rubles.

- VAZ 2105, 1981 – 4,012 rubles.

- VAZ 2107, 1982-2012 – 2,640-4,449 rubles.

- VAZ Niva (2121), 1976 – 2,970-4,440 rubles.

- VAZ 2121, 1994-2006 – 2,970-4,440 rubles.

- VAZ 21213, 2001-2006 – 2,700-4,449 rubles.

If we take into account the gradation by series, the pricing policy is as follows:

- 2101, 1970-1988 – 1,450-4,449 rubles.

- 2106, 1975-2005 – 2,797-4,449 rubles.

- 2107, 1982-2012 – 2,400-4,449 rubles.

Prices are given for original AvtoVAZ products and their copies in similar packaging, configuration, as well as manufacturer’s warranty. Each of the items contains oil in the crankcase of the lubrication system.

↑ Checking the ball joints of the steering rods

- First of all, check the movement of the rod tips along the axis of the fingers. To do this, using the lever and support, move the tip parallel to the axis of the finger.

- The axial movement of the tip relative to the finger should be 1–1.5 mm. This movement indicates that the pin insert is not jammed in the rod tip socket and moves along with the pin, compressing the spring. Replace the hinge with a jammed insert.

- While rocking the steering wheel in both directions, check by touch that there is no free play in the steering rod joints. If you feel free play in the ball joint, replace the tie rod end or tie rod assembly.

- Check the condition of the protective caps of the steering rod ball joints.

- If the protective caps are in good condition and ensure cleanliness inside the hinges, then the service life of the latter is practically unlimited. When moisture, dust, etc. gets into the hinge, premature wear of its parts occurs.

The cap must be replaced if it has cracks, ruptures, and also if lubricant penetrates out when squeezing it with your fingers.

What is included in the scope of delivery of the electric amplifier?

Repair of the rear axle gearbox on a VAZ 2107

Experts recommend installing only electric amplifiers manufactured in Russia by JSC Avtoelektronika, Kaluga. The mechanism kit consists of the following elements:

- electric booster;

- adapter plate;

- intermediate shaft;

- steering column switches;

- wires;

- egnition lock;

- steering wheel from Priora or Kalina;

- decorative casing;

- speed sensor.

By purchasing an electric power steering kit, you will not need any additional elements to install the mechanism.

How to install

To install the EUR on a VAZ 2107, in addition to the parts from the kit, you will need a standard set of tools consisting of keys and screwdrivers. The assembly procedure is carried out in the following sequence:

- We de-energize the vehicle's on-board network, for which we remove the negative terminal from the battery.

- Remove the decorative cover of the steering column by unscrewing the corresponding fastening screws.

- We dismantle the old steering wheel and cardan.

- According to the instructions, we mount the new mechanism through a special plate.

- We get down under the car, unscrew the speedometer cable from the gearbox and install a speed sensor onto which we screw the cable.

- We connect the wiring according to the diagram.

- We install the protective cover.

- We connect the terminal to the battery and check the functionality of the electric amplifier. If installed correctly, there should be no problems.

Replacing the steering gear of a VAZ 2107 with your own hands

If uncharacteristic sounds are heard while the “Seven” is moving, oil leaks from the radiator, and considerable effort is required to move the steering wheel, repair or replacement of the VAZ 2107 steering gear is inevitable. The unit transmits force from the steering wheel to the performance mechanisms. The unit itself is quite reliable, it is capable of operating stably for up to 300 thousand kilometers, provided that the operating rules are followed. But there comes a time when the unit fails. Do-it-yourself repairs are quite affordable. Before work, you need to stock up on the necessary spare parts, tools, and familiarize yourself with the design.

Repair and maintenance

Over the years of operation it has been proven that the steering on VAZ 2107 vehicles has impressive reliability. However, this does not take away the fact that the machine requires periodic inspection and repair.

- When performing maintenance, it is important to check for increased play as well as increased wear on the ball joints. To do this, you need to turn the steering wheel from one side to the other. If the wheels do not respond when the steering wheel is turned 5 degrees from its original position, this indicates severe wear. Here you will need to repair the steering column on a VAZ 2107.

- To avoid the need for urgent and rather expensive repairs of the steering gear on a VAZ 2107, it is necessary to change the oil in the worm gear housing. This is done at intervals of 60 thousand kilometers. Leaks may occur through the seals, so they are carefully checked 2-3 times a year. This is one of the weak points of the system.

- The swing arm should be inspected by slowly rotating the steering wheel from side to side. If the parts move in a vertical plane, then surgical intervention is required.

If any malfunctions are detected, the breakdowns should be repaired immediately.

To do this, the drive and steering mechanism are dismantled completely or partially. Everything depends directly on the nature of the breakdown.

Check which parts have defects and what has failed. Inspection is required for each component of the mechanism. If parts are worn out, there is no point in trying to repair them. There is only one way out - a complete replacement of worn-out components of the steering system on a car from a Volga company.

If problems arise with the steering, it is advisable to contact a professional service station.

Photo of the VAZ 2107 steering gearbox

You can replace the gearbox yourself, but the process is complicated and requires at least minimal experience and skills.

The VAZ "Seven" is a true classic of the domestic automotive industry. Unlike modern LADAs, they are more reliable and durable, which is proven by the huge presence of these cars on our roads.

Of course, the VAZ 2107 has long been outdated, it does not have a hydraulic booster, and you have to apply sufficient force to turn and maneuver. But for connoisseurs this is not a problem.

How to remove the steering column on a VAZ 2107

VAZ cars, which are classic models, are distinguished by pleasant reliability. This also applies to the steering mechanism.

It is quite complex, but its design allows you to maneuver and ensure reliable vehicle control even in the most difficult road conditions.

The modernization process led to the installation of a composite shaft and a safety column. Due to the size of the steering wheel, the driver makes the necessary maneuvers without any problems. From lock to lock, it takes 3.5 turns to turn the steering wheel completely. The force from the steering column is transmitted to the drive via a composite shaft.

Mechanism design

To repair the steering column on a VAZ 2107, you first need to understand its structure, as well as the principle of operation.

The seven is in many ways similar to the “penny”. Therefore, the device and design received minor changes. The structure includes:

- A mechanism that transmits the driver’s force to the executive components;

- A steering drive that turns at an angle specified by the driver.

In turn, the steering mechanism consists of:

- Composite shaft with cardan transmission;

- Steering wheel (steering column together with a steering wheel with a diameter of 520 mm);

- Worm gearbox of the VAZ 2107 steering mechanism.

The control system has the following components:

- Bipod;

- Pendulum arm;

- Swivel arms;

- Steering rods for VAZ 2107 (one middle, two side).

The outer rods include two parts, which allows you to change their size by adjusting the toe angle.

Tie rod/end set for VAZ 2107

The operating principle of the steering mechanism looks like this:

- The driver begins to rotate the steering wheel, the wheel size of which ensures that this task can be performed quite simply;

- By means of a composite shaft, a worm gear is activated, which reduces the speed;

- The steering mechanism is lubricated with special oil (TAD 17) poured into the gearbox;

- The worm gears rotate, which causes the double ridge roller to move;

- This, in turn, causes the secondary shaft to rotate;

- The tray mounted on the secondary shaft makes a turn and pulls the rod system behind it;

- These components influence the levers that synchronously rotate the wheels to the required angle specified by the driver.

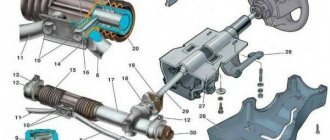

Parts of the steering gear housing: 1 - housing; 2 - bipod; 3 — lower crankcase cover; 4 — adjusting shims; 5 — outer ring of the worm shaft bearing; 6 — separator with balls; 7 — bipod shaft; 8 - adjusting screw; 9 — adjusting plate; 10 — lock washer; 11 - worm shaft; 12 — upper crankcase cover; 13 - sealing gasket; 14 — bipod shaft sleeve; 15 — worm shaft seal; 16 — bipod shaft seal.

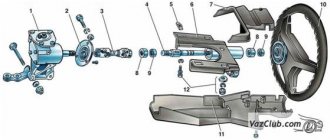

Steering column parts: 1 — steering gear housing; 2 - shaft seal; 3 - intermediate shaft; 4 - upper shaft; 5 — fixing plate of the front part of the bracket; 6 — bracket for fastening the steering shaft; 7 - upper part of the facing casing; 8 — bearing sleeve; 9 — bearing; 10 — steering wheel; 11 — lower part of the facing casing; 12 — bracket fastening parts

everything useful is here

Replacing the steering shaft

Remove the negative terminal from the battery. Remove the steering wheel, steering shaft mounting bracket covers, steering column switches, disconnect the ignition switch connector

Using a 13mm wrench, unscrew the nuts from the coupling bolts of the intermediate shaft universal joint forks and remove the bolts.

Using a 10mm wrench, unscrew the two shear screws securing the steering shaft bracket.

If the bolts have their heads cut off, then use a chisel to loosen the tightening of the remaining round heads and finally unscrew them with pliers. Locking washers are installed under the screws. Using a “13” wrench, unscrew the two nuts securing the steering wheel bracket......and remove the bracket. Remove the upper shaft from the splined joint with an intermediate shaft. Remove the intermediate shaft from the splines of the gearbox worm shaft. Flare the curved edges of the bracket pipe on the steering wheel side, insert the key into the ignition switch and turn off the lock. With light blows we knock the shaft together with the bearing out of the pipe.

The second bearing can be knocked out using a suitable piece of pipe. The needle bearings are installed in shock-absorbing plastic cages. If the shaft or its bearings are worn or damaged, replace them.

Install the steering shaft in the reverse order of removal. Before finally tightening the steering shaft bracket, turn the steering wheel in both directions several times to self-install the bracket.

If it is necessary to remove only the steering gear reducer, unscrew the bolt securing the lower end of the intermediate steering shaft to the worm shaft and the bolts securing the gearbox to the body side member.

Install the steering shaft in the reverse order of removal.

Procedure

The procedure is performed in two stages. The first is the removal of the VAZ 2107 steering gear:

- The machine is installed on a pit or a lift.

- The rod fingers are cleaned. Then the rods are separated from the bipod: first, the cotter pins and nuts are disconnected. Then the finger is simply squeezed out of its normal place.

- Now the intermediate shaft fasteners, which connect the mechanism to the steering wheel, are dismantled.

- Then you need to unscrew the three fastening nuts that secure the unit to the body, and you can remove the mechanism from the car. To make the operation easier, the bipod needs to be turned all the way into the body.

- Further, if individual elements fail, they are replaced on the desktop after complete disassembly:

- The gearbox is clamped in a vice, the bipod nut is unscrewed, and the rod is pressed off the shaft with a puller.

- Unscrew the filler plug, pour out the crater grease, unscrew the adjustment nut, and remove the stop washer.

- Remove the four bolts and remove the cover.

- Remove the screw from engagement. The cover can now be removed.

- The thrust shaft along with the roller is removed.

- The fasteners of the worm cover are unscrewed and it is dismantled along with the adjustment gaskets.

- With light blows of a hammer, knock out the shaft; it should come out along with the bearing.

- Use a screwdriver to remove the oil seal and use it to remove the seal.

- Using a tool and a hammer, remove the outer race of the 2nd bearing.

All elements are washed from contaminants and troubleshooting is performed.

Installation of a repaired or new VAZ 2107 steering gear is performed in the reverse order of dismantling the unit into the car. After completing the operation, you need to make adjustments.

For events you will need an assistant, as well as a screwdriver and a wrench 9:

- The car is installed on a flat floor, the wheels are straight;

- hood - open, remove the plastic casing over the screw used for adjustment;

- here you need to loosen the nut, which protects the screw from spontaneous movements;

- The assistant rotates the steering wheel in both directions, and the master achieves the optimal position in the hooks. It is clear that the steering wheel should have a small amount of travel, but it should be easy to rotate.

Also see the video for replacing the VAZ 2107 steering gear.

Note! To extend the service life of unit parts, it is necessary to reduce their friction against each other. Many car owners use the TAD-17 composition. But it is better to use gear oils with a viscosity of SAE85W90, SAE80W90 or SAE75W90. GL-4 or GL-5 has such indicators. The volume for refilling is 0.215 liters.

Steering wheel play

The appearance of steering play can be caused by two reasons. First, the nut securing the steering wheel to the shaft is loosened. If the nut is not tightened promptly, the splines on the handlebar and shaft will become damaged over time and one of these parts may need to be replaced. The second reason may be wear of the worm gear. To eliminate this malfunction, a special device is provided - an adjusting bolt with a lock nut.

In order to adjust the worm gear, the nut is released, the screw is turned using a screwdriver until the backlash is eliminated, after which the nut is tightened to prevent spontaneous unscrewing. If it is impossible to eliminate the backlash by adjustment, it means that the gearbox needs to be repaired and the worm pair replaced.

To prevent premature wear of gearbox parts, periodic monitoring of the oil level and its replacement is recommended. Level control is carried out as follows:

- Using a 8 key, unscrew the filler plug;

- Use a screwdriver or other object to check the oil level. It should be level with the bottom edge of the filler hole.

- If necessary, add oil using a special supercharger until it begins to flow out of the hole.

To change the oil, unscrew the screws securing the gearbox cover, having previously placed a container under it to collect used oil. Since complete removal of the cap is not required, it is moved to the side and the oil is drained. This operation is best performed on a hot engine. Warm oil has greater fluidity and drains faster. After all the oil has drained out, the cap is screwed into place and new oil is poured into the gearbox using the method described above.

Auto Private

Steering column device

The purpose of the steering wheel shaft ( steering

column) consists of transmitting torque from the steering wheel to the worm gear of the steering mechanism.

column

(injector), like similar units on all AvtoVAZ classic models, is rigidly attached to the car body using a bracket.

Structurally, the column

consists of a pair of hinges that can fold in the event of an accident. This ensures driver safety. To facilitate control, the upper shaft of the column rotates on a pair of needle bearings, the condition of which determines the force of rotation of the steering wheel.