Do-it-yourself replacement of VAZ 2106 steering rods

Steering rod is a part of the car that serves as a connecting link between the steering knuckle and the steering mechanism. It is thanks to him that the front wheels of cars change their angle, and the car changes direction.

The realities of our roads are such that after driving a short section of the road you can seriously damage the steering rod of your car and lose a large amount of money. At a service station, repairing a traction rod costs as much as a quarter of a car, so we will repair it ourselves. Let us recall that in the previous article we looked at how to adjust the idle speed of a VAZ 2106 in a garage.

Replacing the VAZ 2106 steering rod

1. The cotter pin is tightened with a nut with a diameter of 22 millimeters. Therefore, we select the appropriate wrench and remove the fastening of the ball joint pin.

2. The trunnion arm holds the tip pin firmly. Therefore, you need to press it out using a puller.

3. Next we will use a socket wrench. With this we will unscrew the fastenings of the rods to the bipod.

4. Place the stop in the lever and press out the ball joint pins. To do this, you need to hit it well with the end of a hammer of a convenient diameter. If there is no such hammer, substitute a suitable rod.

5. Before replacing the tip or side rod, you need to measure the length of the rod that is already installed on the car. You need to measure between the centers of the plugs.

6. The rod installed on the machine must match the length of the previous rod. The most convenient way to change the length of the rod is by turning the threaded coupling, designed specifically for adjustment. After making control measurements, tighten the clamps and coupling.

7. Check the wheel alignment angles. If they are incorrect, remove the rod and adjust them. If the wheels are adjusted incorrectly, there is a possibility of them rubbing against the body elements.

Removal

1. Place the car on an inspection hole or overpass (see “Preparing the car for maintenance and repair”).

2. Clean the nuts and steering rod covers from dirt.

3. Apply penetrating lubricant to the threads of the ball joints.

4. Using pliers, remove the cotter pin of the nut securing the pin to the steering knuckle lever.

5. 22 mm

Unscrew the nut securing the ball joint pin to the steering knuckle arm.

with a 22 mm socket wrench

Using an extension, unscrew the nuts (after removing the cotter pins) securing the side link pins to the pendulum arm (for the right link) and to the bipod of the steering mechanism (for the left link).

7. Use a puller to press out the fingers of the tips and remove the side rods.

8. Before disassembling the side rod, measure and record its length. This is necessary so that during assembly the correct amount of wheel toe is not disrupted. Loosen the bolts of the coupling clamps and unscrew the ends.

Similarly, we remove and disassemble the other side rod.

22 mm socket wrench

with the extension cord from the engine compartment, unscrew the nuts.

10. If the pins of the side link joints are disconnected from the pendulum arm and the bipod of the steering gearbox, then use a puller to press out the pins of the ball joints of the linkage and remove it.

Attention! When performing the following operation (in order not to damage the thread), unscrew the nuts until their ends coincide with the ends of the fingers.

11. If the side links are not disconnected from the eyes of the bipod and the pendulum arm, then the pins of the middle link ball joints can be pressed out by knocking them out using a suitable rod A

.

First, place stop B

under the inner tip of the side rod.

12. After pressing out the fingers, unscrew the nuts and remove the middle steering rod.

How to detect a fault

You can check the serviceability of the steering rods yourself; all you need is an inspection ditch or overpass. It is advisable to do such a check on a VAZ 2106 car every 5 thousand km or after every long trip on bad roads. Such a short interval is due to the quality of manufacture of the parts in question; on average, they last 15-20 thousand km.

To carry out diagnostics, you need to park the car over a ditch or drive onto an overpass and secure the vehicle with the hand brake. Grasping the rod near the tip with one hand, you need to sharply push it up and then down. A serviceable tip either has no play at all, or it is only a couple of millimeters, you can feel it with your hand.

If there is more play, and at the same time the thrust rod easily rotates in both ball pins, then replacing the VAZ 2106 ends is inevitable. In this way, you need to check all 6 fingers, and if they are clearly worn out, it is better to replace the entire steering linkage, which consists of 3 rods.

It happens that there is no play in the connections, but the protective boots are torn or cracked. If they are not changed, then the dust and dirt that constantly accumulates in the hinge will do their job: the unit will quickly fail. Worn anthers must be replaced. To complete the work you will need a minimum of tools:

- a set of spanners or open-end wrenches;

- mounting blade;

- puller for pressing ball pins out of their seats.

The puller is a metal cup with a slot so that it can be put on the bipod of the steering mechanism or pendulum. There is one in almost every garage where a VAZ 2106 or another model of the “classic” Zhiguli is parked.

↑ How to remove steering rods on a VAZ without a puller, video

Keywords

car repair tips from experienced

Similar news

VAZ 2106 (21061) / Steering VAZ 2106

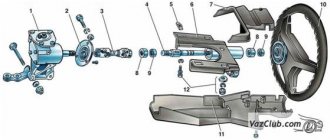

Steering device VAZ 2106

VAZ 2110 - operating and repair instructions / VAZ 2110 steering

Steering mechanism VAZ-2110, 2111, 2112

VAZ 2107 - repair and operating instructions / VAZ 2107 steering

Removal and installation of rod and ball joints of the VAZ 2107 steering drive

VAZ 2107 - repair and operating instructions / VAZ 2107 steering

Removal and installation of the VAZ 2107 steering mechanism

VAZ 2107 - repair and operating instructions / VAZ 2107 steering

General information about the steering of the VAZ 2107 car

VAZ 2107 - repair and operating instructions / VAZ 2107 chassis

Determining the condition of the front suspension parts of the VAZ 2107

Replacement instructions

The steering linkage is replaced in an inspection pit or overpass. The disassembly procedure is as follows.

- Loosen and unscrew the ball pin mounting nut. On some cars you can still find tie rods with cotter nuts. In this case, you will have to first remove the cotter pins by bending their antennae with pliers.

- From the side of the rounded end of the steering bipod, insert the puller so that its support area is under the bipod lever.

- Rotate the bolt at the top of the puller with a wrench and press it out of the socket.

- Repeat the operation on all other tips.

Sometimes when unscrewing the nut, due to contamination of the ball thread, the pin begins to rotate along with the nut, turning in the seat. Then, to unscrew the nut, you need to block it with a mounting blade. A small feature: the left and right outer rods of the VAZ 2106 are different from each other, so it is better to mark them after removal.

Replacement procedure:

- Raise the right front wheel using a jack and remove it.

- Unscrew the steering tip nut.

- Remove the tip.

- We turn the steering wheel to the extreme left position, after which we remove the clamps, then the boots on the slats.

- Unscrew the locknut of the tip, then remove it and the boot.

- Using an adjustable wrench, remove the rod; to do this, you can slip the wrench under the lower engine suspension arm.

- We turn the steering wheel to its extreme position to gain access to the bushing.

- We pry it off with a long screwdriver. For this operation, it is better to use an assistant to turn the steering wheel several times left and right, this will allow you to pull it out faster.

- We install a new steering rack bushing for Renault Megane 2.

After this, we reassemble in the reverse order and be sure to go to the wheel alignment.

Operation of articulated rods

On most modern cars, the wheels are turned by a gear rack. But on cars of the classic Zhiguli family, instead of a rack, outdated technology is used using special rods, called “steering linkage”. This mechanism is not very reliable. The maximum you can count on is 50,000 kilometers, although in reality the resource rarely exceeds 30 thousand km. The structure of the mechanism is simple, and if you have experience in car repair and knowledge of the subject, you can carry out repair work or replace components yourself.

What is a trapezoid for and how does it work?

The articulated rods serve as an intermediate link between the steering shaft and the wheel hub at the front; the force is transmitted through the steering knuckles. The main purpose is to turn the front wheels simultaneously in the direction in which the steering wheel turns.

This mechanism is attached to the front side members and structurally consists of the following parts:

The middle part is a tube with hinge mechanisms on both sides. The side parts consist of a short and a long tip. They are connected to each other with a special clamp and two bolts.

The principle of operation of a trapezoid is as follows.

- When you turn the steering wheel, the steering shaft and the gearbox shank begin to rotate. Thanks to the worm mechanism, more torque is transmitted to the bipod at a reduced number of revolutions.

- The bipod begins to rotate, and with it the middle rod on the left. At the same time, the middle rod transmits force to the right side of the trapezoid via a bracket.

- All three parts turn in one direction or another depending on which direction the steering wheel goes, and at the same time the front wheels begin to turn synchronously.

A pendulum-type lever is attached to the second spar, which serves as an additional hinge. At the ends of all three rods there are conical pins, thanks to which the trapezoid is always in a strictly horizontal position, regardless of the travel of the car’s suspension.

Design features of articulated rods

The middle element is the simplest in its structure. It is a non-separable rod, at the ends of which there are hinges. The conical fingers of the rods are installed in the holes of the bipod and secured with castle nuts, and a cotter pin is used for additional fastening.

The right and left rods consist of an outer tip with a pin and an inner tip with a hinge. They are connected to each other using a threaded clamp and two bolts. The design of the side rods consists of several parts and can be separated. This was done to be able to adjust the wheel alignment/camber. The length can be changed by twisting or unscrewing the threaded clamp, thus adjusting the position of the front wheels.

The hinged ends of all rods are identical in design and consist of the following parts:

- threaded pin and hole for a cotter pin;

- boot (protective cover made of rubber or silicone);

- durable metal body;

- cracker (support liner);

- spring;

- cover installed in the housing.

A ball joint (hinge) works on the same principle as a bearing, i.e. a metal ball rotates in a plastic housing. On more expensive and high-quality ball bearings, manufacturers cut a grease fitting into the cover on the body to allow lubrication using a syringe. External or external rods on both the right and left are the same, internal ones have differences. The right lever is bent so that it does not touch the gearbox housing when moving.

Selection of new steering rod parts for VAZ 2106

Repairing the steering linkage allows you to replace only the failed part. Rarely does anyone change all the components at once. As a result, the articulated rods on many cars are assembled from different parts that differ in quality. At the moment, finding original spare parts for the VAZ 2106 is becoming increasingly difficult, since the car has long been out of production.

Due to the low resource, standard kits have long become a rarity. However, there are many other manufacturers that produce analogues of factory steering linkage parts:

These brands have proven themselves well among car enthusiasts; their products are of good quality. When choosing, it remains to recommend not to buy spare parts in dubious places, since the likelihood of purchasing a fake in this case increases sharply. You should not chase low prices; high-quality parts cannot be suspiciously cheap.

All steering rods of VAZ 01-07 models are identical, so when purchasing, do not worry about reading the numbers 2101 on the packaging. The only thing worth paying attention to is the mobility of the ball pin in the rod end. In the new product, it should be difficult to turn in the socket due to manual effort. After successfully replacing even just one tip, you cannot drive right away; you must definitely adjust the toe angles of the front wheels at the nearest service station.

How to unscrew the steering wheel nut

If there is a broken thread that cannot be unscrewed, there are three ways:

- You shouldn’t immediately take a radical approach to this matter; perhaps not everything is as bad as you think and just simple manipulations are enough. First, let's clean the entire surface on which we will work with a wire brush and drop a little penetrating lubricant. If you do everything described above, then there is a chance that a regular spanner will help you to unscrew a bolt or nut with torn edges. If not, there are other ways. You can try to simply tap the ill-fated object (but not too hard!).

Lubricating a soured nut with WD-40

- How to unscrew a bolt or nut with broken edges? Of course, a gas wrench will help you a lot in this case. This is truly a magical tool. This tool, of course, requires a lot of space since it is very large, but at the same time it is able to hold even the most even objects, which helps a lot in this problem.

Gas key

- In those equally frequent cases when a gas wrench will not help, but the nut (or bolt) is large enough, an angle grinder will come to the rescue. You can simply take and carefully cut the edges, which will be smaller than those that have been erased. Four of these newly cut edges will be enough; there is no need to try to cut out all six. After this, the nut (or bolt) can be easily unscrewed with a socket or socket wrench, or using a gas wrench for greater confidence in a positive outcome (it is not recommended to touch the open-end wrench). You can also restore the edges using a file, although this, of course, takes more time.

Cutting the nut thread with a grinder

Payment via Yandex Cashier

After selecting payment via Yandex, the Yandex Cashier payment system will launch, where you need to select a convenient payment method (bank card, QIWI, Yandex Money account, etc.)

After specifying payment details and confirming payment, payment for the goods will occur.

If you have a bank card in a currency other than the ruble, then the money will be debited from the card at the rate of the Central Bank of Russia at the time of the purchase.

This payment method is optimal for residents of Russia, Kazakhstan and Belarus.

Official website of the Yandex Kassa payment system https://kassa.yandex.ru

Payment via Portmone

After selecting payment through Portmone, the payment system will launch, where you need to select the payment method: bank card or Portmone account.

The price in the Portmone payment system is converted into dollars at the exchange rate of the Central Bank of the country where you are located.

If you have a bank card in a currency other than the dollar, then the money will be debited from the card at the rate of the Central Bank of your country at the time of the purchase.

After specifying payment details and confirming payment, payment for the goods will occur.

Official website of the Portmone payment system https://www.portmone.com

Payment via PayPal

After selecting payment via PayPal, the PayPal payment system will launch, where you need to select the payment method: bank card or PayPal account.

If you already have a PayPal account, then you need to log into it and make a payment.

If you do not have a PayPal account and you want to pay using a bank card via PayPal, you need to click on the “Create an Account” button - shown with an arrow in the picture.

PayPal will then prompt you to select your country and provide your credit card information.

After specifying the information required to make the payment, you must click on the “Pay Now” button.

Official website of the PayPal payment system https://www.paypal.com

Tools for repair

In order to replace the elements of the VAZ-2107 steering linkage, you need to prepare the following tools:

- Socket and open-end wrenches.

- Pliers.

- Tip remover.

It is best to dismantle the VAZ-2107 steering linkage rod using a special device. Be sure to buy a puller - it is not very expensive, but the work will go well with it.

It is very difficult to remove the pins of the tips from the holes - they are conical in shape, and the metal often sticks. You can benefit if you buy a universal puller - you will also need it when repairing the suspension (for removing ball joints).

Payment via WebMoney

After selecting payment via WebMoney, the payment system will launch, where you need to select the payment method: bank card or WebMoney wallet.

If you already have a WebMoney wallet, then you need to log into it and make a payment.

If you do not have a WebMoney wallet and you want to pay in another way, you need to select any of the methods that WebMoney offers and make the payment

After specifying payment details and confirming payment, payment for the goods will occur.

Official website of the WebMoney payment system https://www.webmoney.ru/

Video - Steering gear repair

In most cases, this unit is not repairable, since it is relatively inexpensive and consists of only two main parts. However, the manufacturer left the option for car technicians to purchase a repair kit.

Before repairing the steering gear, let's determine the malfunctions.

- Firstly, it can be repaired if the steering wheel rotates but the wheels do not. This means that there are defects on the threaded part of its shafts that prevent the two interacting parts from touching.

- The second type of fault is oil seals. If they have reached critical wear, then the oil from the gearbox will certainly leak, which already leads to its accelerated wear. If there are other mechanical damages, the gearbox must be replaced.

First, remove the faulty unit from the car. After this, press the bipod off its shaft using two hammers. Drain the oil from the gearbox through any technological hole. Now unscrew the four bolts that secure the cover and remove it. To access the worm shaft, you need to unscrew a similar cover on the other side of the mechanism. Pull out the remaining parts and replace the faulty ones. These may include oil seals and damaged shafts. After this, reassemble the gearbox in the reverse order. Don't forget to add oil!

Downloading a book

After successfully completing the payment (by any method) and returning to the KrutilVertel store from the payment system website, you will be taken to the successful payment page:

On this page you need to indicate your e-mail, where access to download the book will be sent.

If you are already registered on our website, then simply follow the link to your personal account.

The book you purchased will be in your personal account, from where you can always download it.

Please note that after making the payment, you need to return back from the payment system website to the KrutilVertel website.

If for some reason you did not return back to the site and closed the payment system tab with a message about the successful completion of the payment, please let us know - we will send you a letter indicating access to download the book.

Manufacturers of steering linkages

And now a question that interests many motorists - which is the best steering linkage for the VAZ-2107? There are many manufacturers on the market, it is quite difficult to choose a decent one. Here are just a few of the most popular manufacturers:

- "VIS" - have high reliability, their cost is relatively low. According to reviews from motorists, this is one of the high-quality manufacturers of elements.

- "TRACK" - the highest quality elements from this manufacturer. Rubber boots last quite a long time - there are practically no equal ones in terms of service life.

- "BELMAG" - good quality products at a relatively low cost.

- "CEDAR" - low cost and very poor quality.

This is a list of the most popular manufacturers that can be found on the market.

Motorists praise TRACK very much - these are very high-quality VAZ-2107 steering linkages. Its price is approximately 1700-2000 rubles. Its resource is very high, it cannot be compared with KEDR products. Most of them are of very poor quality - it gets to the point that they last 2000-5000 kilometers, after which terrible knocking noises appear. Therefore, it is better to purchase quality products.

Steering rods are responsible for turning the front wheels, so for safety reasons they should always be kept in working order. The VAZ 2107 is equipped with an outdated rod system with hinges, which is called a trapezoid. It has a small resource, so it has to be changed often. Knowing the device and following the instructions for dismantling and reassembling, you can replace the steering rods with your own hands.

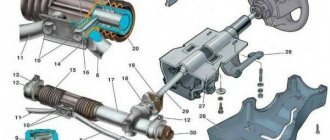

Design and principle of operation of a trapezoid

Steering rods turn the wheels in the direction in which the driver turned the steering wheel. It is located at the level of the bottom of the car under the power unit, attached from below to the side members. Consists of three rods: right, middle and left. The middle link has two hinges, the other two are prefabricated parts from a long and short part.

Problems when paying with bank cards

Sometimes difficulties may arise when paying with Visa/MasterCard bank cards. The most common of them:

- There is a restriction on the card for paying for online purchases

- A plastic card is not intended for making payments online.

- The plastic card is not activated for making payments online.

- There are not enough funds on the plastic card.

In order to solve these problems, you need to call or write to the technical support of the bank where you are served. Bank specialists will help you resolve them and make payments.

That's basically it. The entire process of paying for a book in PDF format on car repair on our website takes 1-2 minutes.

Where is the trapezoid located?

The steering tips and rods are located in the lower part of the engine compartment, in close proximity to the interior partition. You can see them on a lift or overpass, or when turning the steering wheel to its extreme position. The design of the trapezoid consists of the following elements:

- Two lateral rods (left and right short).

- One medium pull.

- Tips – total quantity 6 pieces.

The design also contains a pendulum lever - it is installed on the right side in the engine compartment.