The engine is the heart of the car, and therefore its performance must be maintained at the proper level. Many drivers want to learn how to repair the engine of their own car, but when faced with difficulties during disassembly, they immediately abandon such an undertaking, citing an insufficient level of knowledge. In this article you will learn how to disassemble a VAZ 2107 engine with your own hands using an example. This manual is also relevant for all other engines of the classic VAZ family, as well as for the Niva 2121.

VAZ 2107 engine structure

The 2107 power plant can be called revolutionary for the line of car engines of the Togliatti Automobile Plant. This is the first of the so-called classic cars to receive an advanced injection system.

The “Seven” injection system operates in rather difficult conditions, with constant high loads, especially on our roads. For this reason, the engine requires good and timely maintenance. Even the slightest blockage will negatively affect the fuel supply, resulting in an increase in fuel consumption and a decrease in the efficiency of the internal combustion engine.

Lubrication system

One of the main areas of the VAZ 2107 engine is the lubrication system, which functions by supplying oil to the rubbing surfaces. Thanks to it, friction is reduced and the efficiency of the power plant is increased. Oil is filled through the oil filler neck, which is tightly closed with a lid. Old, no longer needed lubricant is drained from the system through another hole - it is closed with a rubber plug.

Important characteristics of the lubrication system:

- the system holds exactly 3.75 liters of oil, the level of which can be monitored using an indicator gauge;

- the pressure on a heated internal combustion engine at average crankshaft speed is 0.35–0.45 MPa;

- The lubrication system functions in a combined way - under pressure and by splashing.

The main problems of the lubrication system include:

- oil filter clogged;

- problems with crankcase ventilation;

- lubricant leakage through loose connections;

- destruction of crankshaft seals;

- problems with fluid pressure.

The reasons that cause problems to occur are quite varied. You must understand that long-term engine operation is directly related to the lubrication system - it determines the durability of the power plant. After all, even a short-term interruption in the supply of lubricant to the rubbing internal parts of the engine can lead to major repairs and even replacement of an expensive unit.

The lubrication system ensures the durability of the power plant

Find out which engine can be installed on the VAZ 2107: https://bumper.guru/klassicheskie-modeli-vaz/dvigatel/kakoy-dvigatel-mozhno-postavit-na-vaz-2107.html

Cooling system VAZ 2107

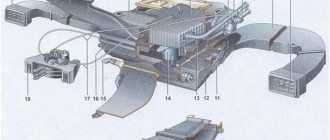

It is designed to maintain the desired thermal regime of the motor installation by correlating the heat removal from the hottest components and parts. The “seven” operates a sealed liquid system with forced circulation. Some of its important components are the pump, expansion tank, heater core with electric fan and thermostat.

- The centrifugal pump is driven by the crankshaft. It consists of a cover supported by four studs and a body connected to the cover through a sealing gasket. The pump also has a roller with an impeller, rotating on a bearing.

- The expansion tank is integrated into the cooling system for a reason. The element accepts excess antifreeze, which, when expanded, tends to create high pressure that can rupture all hoses, tubes and radiator honeycombs. The same force is possessed by the vacuum discharge formed when the liquid cools (reduces). The expansion tank is designed to eliminate both phenomena. It is a durable tank element with a filler neck and fittings. A special role is played by the tank lid, equipped with valves to release excess pressure.

- The heater core is a structural part with two reservoirs and an iron core. It is installed on rubber cushions and fixed to the body of the “seven” with two bolts. The element is connected to the expansion tank in a sealed manner. Equipped with an electric fan activated by a sensor. On the “sevens” of the early year of production, an electric fan was not installed; the blades were mechanically rotated by the motor. In injection systems, the electric fan receives a command from the computer through a relay and an antifreeze temperature sensor.

- The thermostat maintains the desired thermal regime of the power unit and helps it start quickly. Equipped with two valves: main and bypass. Thanks to the thermostat, the engine warms up quickly.

The operating principle of engine cooling can be represented as follows: antifreeze circulates through all zones of the system, heats up, then enters the radiator and the pump.

The cooling system of the VAZ 2107 is designed to maintain the desired thermal conditions of the engine installation

More information about the design of the cooling radiator: https://bumper.guru/klassicheskie-modeli-vaz/sistema-ohdazhdeniya/radiator-vaz-2107.html

Piston group

This includes 4 required elements.

- Pistons on the VAZ 2107 are sorted by pin diameter into 3 classes every 0.004 mm. During their manufacture, special attention is also paid to weight, so when overhauling a motor unit, it is not necessary to use pistons of the same group - it is enough that they are suitable for the “seven” engine. There is a direction arrow on the bottom of the piston.

- The piston pin is a structural element held in place by retaining rings.

- Connecting rods on the VAZ 2107 are used with a pressed-in bushing made of combined iron. They, too, like pistons, are classified into 3 classes, depending on the diameter of the sleeve. The connecting rods are made of forged steel.

- The rings in the “seven” piston group are cast iron. Two of them are barrel-shaped, semi-chrome plated and compression, one is oil scraper.

The VAZ 2107 piston group is selected according to one size

Cylinder block

The block is made of a special type of cast iron - high-strength. Liners for VAZ cylinders are not needed, since boring is meant on site. The cylinders are honed from the inside, which makes them highly accurate. They are divided into 5 classes, alternating by 0.01 mm.

Step-by-step instructions for disassembling the internal combustion engine of a car + Video

- Prepare all the necessary tools and drain the oil from the crankcase.

- Firstly, this will be necessary to lighten the weight of the motor, and secondly, it will help to avoid excess dirt on the workbench. Next, unscrew the oil filter. Also unscrew all the bolts that secure the oil pan. The old gasket can be thrown away as it is no longer suitable for further use.

- Now you need to remove the crankshaft pulley. This is not as easy to do as it seems at first glance, since in this case you will need good physical strength. However, no one has canceled the use of a pipe as a wrench extension. Secure the crankshaft from turning by blocking the flywheel. For this, a special device is used, which can be purchased in the store. Next, use a wrench to unscrew the ratchet and remove the pulley.

- Unscrew the nuts securing the valve covers and timing chain, remove it and pull out the gasket. Unscrew the bolts securing the camshaft gears, as well as the shaft that drives the engine oil pump. Next in line is the timing chain tensioner. First, loosen the special cap nut, and then unscrew the other two nuts that secure it to the cylinder head. Do not forget to unscrew the bolt securing the shoe, and then remove the tensioner itself, along with the shoe. Then the pin that restricts the chain is unscrewed, the camshaft and oil pump gears are removed, and the chain is removed.

- Now you need to remove the camshaft. To do this, unscrew two nuts located on its studs in the bearing housing. The housing must be removed and the camshaft carefully pulled out. Before pulling it out, do not forget to also remove the special thrust flange.

- Next, the bolts intended to secure the cylinder head to the block itself are unscrewed. The cylinder head is dismantled immediately along with the manifolds, which are not required to be removed (depending on the type of repair being carried out). After removing the head, it is also recommended to replace the gasket. This procedure will help you, in the future, get rid of repeated removal of this element.

- After this, you need to dismantle the oil pump. To pull it out you need to remove the special thrust flange. After this, remove the roller from the cylinder block, which is responsible for driving the oil pump.

- Using a special removable device, remove the gear that fits onto the engine crankshaft. Then remove the nuts located on the connecting rod bolts. Now remove the connecting rod caps and, using the cylindrical opening, pull out the connecting rods along with the pistons.

Attention! Before removing the connecting rods and pistons, as well as the main bearings and liners, you must first mark them all to prevent errors when assembling the element.

- We return to the flywheel retainer again and install it. Unscrew the bolts that are intended for fastening and remove the washer, then pull out the flywheel mounted on the crankshaft, and then remove the protective cover of the clutch housing.

- Using a puller, remove the gearbox input shaft bearing, which is located in a special socket at the rear of the power unit. Next you need to pull out the special crankshaft oil seal holder. Now unscrew the bolts that secure the caps covering the main bearings and pull them out along with the liners. After this, you need to remove the crankshaft and the uppermost shaft bearings. Also remove the special thrust half-rings that are located on the support.

That's all you need to do to disassemble the engine. The next step is to bore various elements to repair sizes and replace damaged and worn elements. It is recommended to pay special attention to the liners, which are most often subject to rotation, which is why the motor simply jams. After repair, the engine is assembled and installed on the car.

Source

Malfunctions of the standard VAZ 2107 engine

It is customary to distinguish between the main malfunctions of the standard 7 engine. All of them require prompt and mandatory permission to avoid major repairs.

Engine overheating

A frequent malfunction caused by various reasons and threatening a breakdown of the cylinder head gasket or complex engine repairs. Usually, when the engine overheats, an indicator appears on the dashboard. Unfortunately, many motorists do not respond in a timely manner to an arrow approaching the red zone.

At the first symptoms of overheating, you need to act while driving:

- open the air damper;

- turn on the heater fan at the highest speed;

- put the gearbox in neutral, try to use inertia to roll the car to the edge of the road (be sure to turn on the emergency lights);

- Leave the engine idling for 2-3 minutes.

This will work if there are no clouds of steam escaping from under the hood, i.e., the overheating level is low. Remember that it is not recommended to immediately turn off the engine with such overheating. This is done only if the hose has burst and there is a threat of depressurization of the cooling system.

After turning the key to the reverse position, the engine does not turn off completely, it works due to pseudo-heat ignition, so it must be turned off forcibly by placing the gearshift lever in any position except neutral, and press the brake - then release the clutch.

After stopping the engine, antifreeze continues to circulate, having the greatest impact on the connections of engine parts. If the outcome is unfavorable, this threatens the formation of vapor locks. The phenomenon is commonly called “heat stroke.”

If overheating of the engine unit is accompanied by steam escaping from under the hood of the car, the elimination instructions look different.

- Open the hood, check the presence of antifreeze in the expansion tank, the integrity of the hoses, radiator and thermostat.

- Grasp the reservoir cap with a rag and carefully unscrew it 1 turn to release the pressure. Work extremely carefully so as not to scald yourself with hot antifreeze!

- Restore the causes of overheating and depressurization of the cooling system: wrap the burst hose with electrical tape or replace it, close the crack in the radiator due to corrosion, fill in the required dose of refrigerant, etc.

In some cases, the culprit for overheating is the sensor that turns on the fan motor. It is easy to check: you need to remove both wires from the sensor terminals and connect them to each other - if the fan starts working when the ignition is on, you need to change the sensor, it does not work.

The thermostat that regulates the flow of antifreeze through and around the radiator may also be malfunctioning. The cooling system unit is checked as follows: with the engine warm, you should feel with your hand the upper and lower pipes connecting the engine to the radiator. A thermostat malfunction can be judged by a cold lower hose.

Engine knock

It can be different.

- First of all, when it comes to knocking, we mean the connecting rod. If the element begins to knock, the oil pressure immediately drops. As a rule, experienced motorists easily recognize the sound of a damaged connecting rod by a dull knock that increases as the car accelerates.

- A knock also occurs in the crankshaft journals when the pressure in the system drops and a dull metallic noise is heard. It is recognized at all engine speeds, and the fault can be diagnosed without disassembling the internal combustion engine.

- Knocking when cold occurs on worn-out engines. There's nothing wrong with it. It’s just that the gaps between the mating parts have exceeded the permissible standards; when the power plant heats up, everything returns to normal.

- The knock is possible due to valve beating, which occurs due to poor camshaft bed adjustment or rocker wear.

- Finally, it can be caused by a loose chain drive. In this case, a metallic ringing sound can be clearly distinguished at idle speed. As the speed increases, the sound disappears partially or completely.

Smoke from breather

If we talk about this, there is no smoke coming into the muffler, no steam, but the car begins to consume liters of oil. At the same time, the first and fourth cylinders of the engine become clogged.

This malfunction has several causes: changes in engine compression, wear of oil seals, or bursting of rings.

Engine tripping

The family of VAZ cars equipped with old-generation injection systems often suffer from such an effect as tripping. The causes of the malfunction, as a rule, should be sought in the injection, fuel supply systems, etc.

The only way to eliminate friction caused by a clogged fuel pump or filters is by replacing the elements or cleaning them. In some cases, the pump may not work correctly, then it will have to be disassembled and the cause found.

If the injectors become clogged, this happens more often due to low-quality fuel. The elements themselves are also subject to wear. The injectors are checked using a special stand, which not only allows you to diagnose the condition of the injectors, but also carries out cleaning.

Tribbing may occur due to loss of spark. In this case, suspicion immediately falls on the spark plugs. It is recommended to carefully check them, visually inspect them for cracks or accumulated dirt. Replace any questionable items immediately. The “seven” engine may stall due to burnt-out valves.

Smoke from the muffler

Many people unknowingly ignore smoke, because it is almost invisible on a hot engine. However, if it does not stop, this is a sign of more or less serious problems in the motor system.

According to experienced motorists, the smoke worsens when starting the engine unit. You should pay special attention to it, identifying the malfunction in time.

Smoke from the VAZ 2107 muffler is a sign of more or less serious problems

Basically, excessively dense smoke hints at errors in the cooling and fuel supply systems. There may be problems with the distribution mechanism or piston group.

About the design of the VAZ 2107 exhaust system: https://bumper.guru/klassicheskie-modeli-vaz/dvigatel/glushitel-vaz-2107.html

Throws oil at the candles

This is also one of the common malfunctions of the VAZ 2107 engine. Oil covers the spark plug threads or the housing, and in special cases, even the entire base. At the same time, the engine signals deterioration in dynamic properties, increased smoke and high oil consumption.

Experts cite damage or wear to valve guides, valve stem seals, piston group elements or cylinder head gaskets as the reason for oil splashing onto the spark plugs.

The motor doesn't pull

Has the car lost its former traction? Almost every owner of a “Seven” who has been using the car for more than 5 years encounters this phenomenon. It takes a long time to accelerate and cannot climb hills in high gears.

As you know, the VAZ 2107 comes with injection and carburetor engines. Depending on this, the causes of the malfunction are distinguished.

- On a carburetor internal combustion engine, the lack of traction is caused by the power system - there is not enough fuel or its supply is too large. Carburetors need proper adjustment, otherwise engine operation will be unstable. The engine power indicator is also affected by the gas distribution mechanism, which is characterized by a decrease in pressure.

- If an engine with an injection system pulls poorly, the reason may be related to the timing belt, filters, ignition systems and problems in the piston group.

Why is it worth disassembling the engine?

Engine disassembly is carried out if the engine is planned to undergo a major overhaul. At the same time, it must be completely disassembled and all worn elements replaced. In addition, boring the cylinder block, which must be freed from all parts of the engine, will be relevant. In addition, you can disassemble the engine in order to simply clean it, in case of serious contamination, when it is not possible to get by with simple flushing oil.

We will try to omit the details regarding its removal, since this is quite simple to do: you just need to unscrew the nuts 19 from the cushions, remove the attached parts (all parts of electrical equipment, hoses and pipes, as well as drives of various elements) and unscrew it from the gearbox. After this, the motor is thoroughly washed and installed on a special stand (the use of a regular workbench is also welcome).