What is a backstage

The term appeared along with the first multi-speed gearboxes. It meant some kind of hidden mechanism connecting the driver and the transmission, with the help of which the driver gave a signal to the manual transmission about the need to change to the next or previous speed.

The term “scene” is not specified in any regulatory documents. This is the popular name for a mechanism or a specific part. Even drivers with many years of experience often use it differently. Some call this the gear selection mechanism located under the bottom of the car and connected to the gearbox by a lever (sometimes two levers) or cables. Others are the rod connecting the gearbox lever and the gearbox.

We propose to call the entire mechanism connecting the gear lever and transmission a “slide”. This makes it somewhat difficult to divide mechanical transmissions from AvtoVAZ into rocker and cable ones, but it allows us to perceive the gear shift mechanism as a single unit.

Installing a short-throw rocker on a VAZ 2114 and a classic

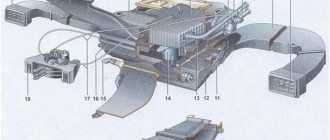

The car is packed very tightly, and it is extremely difficult to find free space in the engine compartment. Therefore, the control parts of any components are sometimes located at a considerable distance from the mechanism itself. All of the above fully applies to the gearbox, in which the box itself and the gear shift lever (GSL) are connected by a special part called the rocker. One of the disadvantages of VAZ, both on front-wheel drive 2110, 2112, 2115, 2114, and on classics, is the inconvenience of changing gears. This drawback is eliminated by a short-stroke rocker.

The photo shows what it looks like on a car.

How does the backstage work?

The principle of operation of any scene is the same: moving the manual transmission lever in two planes (forward - backward, left - right) through a system of levers and rigid or flexible rods leads to the movement of the corresponding forks inside the gearbox. In turn, the forks displace the clutches of one or another gear, due to which they engage with the secondary shaft, forming a full-fledged gearbox with a given transmission ratio.

Backstage on the Priora

In first gear, the ratio of the rotation speed of the secondary and primary shafts is minimal, due to which 3-4 revolutions of the primary shaft account for 1 revolution of the secondary. In direct (fourth) gear, the rotation speeds of both shafts are approximately the same. But at the highest gearbox it turns from a reduction gearbox into a step-up gearbox, because for 2 revolutions of the primary shaft there are approximately 3 revolutions of the secondary shaft.

What kind of scenes were installed on the Priora?

Three types of scenes were installed on the Lada Priora (one for each box):

- long-stroke with rigid rod and flat lever (for 2170 (aka 2110));

- short-stroke with rigid rod and round lever (for 2180);

- cable (2181).

The gearbox 2170, which Priora inherited from the tenth family (the entire VAZ 2110 line), was distinguished by a large lever stroke: it was difficult to quickly change gears. When developing the gear shift drive for the 2180 gearbox, engineers took into account the criticism of car owners and created a short-throw mechanism that made it possible to change gears much faster. In addition, both scenes inherited from the “ten” a not very reliable mechanism for transmitting force to the box, which is why it had to be adjusted from time to time. Another common problem was the vibration of the lever, which irritated many owners of this car.

Also, a common disadvantage of both transmissions was the lower location of the gear shift mechanism, because this led to:

- leaks of the gear selector rod seal;

- Difficulty switching gears in the cold.

When developing a new type of gearbox switch (2181) for the Lada Priora, engineers took into account previous mistakes. The gearshift mechanism was moved to the top, and Bowden cables were used as rods. This immediately solved many of the problems of the previous units. But the price for this improvement was the low reliability of the mechanism connecting the lever and the cables, because it is made of plastic. However, with careful operation, its service life exceeds 100 thousand km.

VAZ 2170 Adjusting the gearshift drive rod

Lada Priora Sedan Logbook Replacing valve seals

Adjusting the gear shift rod

Park the car, apply the handbrake and turn off the ignition.

Only for models up to 1994.

Only for models after 1994.

| Locate the locking hole on the top of the transmission housing adjacent to the nameplate. Remove the plug from the hole (indicated by the arrow). Place the gear lever in fourth gear, then take a screwdriver with a blade approximately 4mm in diameter and insert it into the hole; this will lock the gearbox in the fourth gear position - the screwdriver handle will not allow it to fall inside the gearbox. |

All models

| 1. Inside the vehicle, to gain access to the gearbox control lever housing, remove the control lever collar and mounting frame. Take a screwdriver with a blade approximately 4 mm in diameter and insert it into the locking hole in the side wall of the lever housing. |

| 2. If the screwdriver is inserted without difficulty, then the linkage is adjusted correctly and, therefore, is not the cause of poor gear shifting; Next, it would be best to remove the gear shift drive rod and inspect it for wear and damage (Section Removal, inspection and reinstallation of the gear shift drive). 3. If the screwdriver does not fit into the locking hole, the position of the rod is not adjusted correctly. |

| 4. At the point in the engine compartment where the selector rod passes through the bulkhead, loosen the selector rod pinch bolt (A) near the rubber coupling (B) to allow free play between the two halves of the selector rod. |

| 5. Move the gearbox control lever so that the tip of the screwdriver is inserted into the locking hole in the lever housing; Make sure that the lever is still in the fourth speed position. 6. In the engine compartment, tighten the pinch bolt on the gear selector rod to the required torque. 7. Remove the screwdriver from the locking hole and install the plastic plug. 8. Remove the screwdriver from the locking hole on the transmission control lever housing. 9. Reinstall the selector lever guard and mounting frame. 10. Before driving the vehicle, make sure that the gearbox control lever moves from the neutral gear position to all six gear positions. |

Main malfunctions of the scenes

All malfunctions of the Lada Priora gearbox and how to eliminate them:

| Symptom | Malfunction | Gearbox model | Way to solve the problem |

| Unclear gear shifting | Worn bushings | 2170–2181 | Replace all bushings |

| Damaged pillow | 2170–2180 | Replace pillow | |

| Cables stretched | 2181 | Replace cables | |

| The tension of the traction clamps is loose | 2170–2180 | Adjust then tighten | |

| The lever has failed | The pillow tore | 2170–2180 | Replace pillow |

| Lever travel too long | Worn bushings | 2170–2181 | Replace all bushings |

| Cables stretched | 2181 | Replace cables | |

| The tension of the traction clamps is loose | 2170–2180 | Adjust then tighten | |

| One or more speeds do not turn on the first time | Forks are deformed | 2170–2181 | Replace plugs |

| The tension of the traction clamps is loose | 2170–2180 | Adjust then tighten | |

| Cables stretched | 2181 | Replace cables |

The main malfunctions of the Priora gearbox are the same for any transmission and are determined by their design. The lever and rigid drive are made of steel, so they do not break. The remaining parts, all kinds of plastic bushings and cables, clamps that secure the rods, often fail (their nuts have a bad habit of becoming loose). In addition, on the so-called rocker boxes, that is, gearboxes 2170–2180, the rubber band (the rubber support of the lever) often fails, which also leads to problems with switching on the required speeds.

One of the rare defects is the rattling of the 2014 Priora gearbox, although it also occurs on cars of other years, but always with a rocker transmission. It is caused by contact between the torque rod and the gear shift rod. Due to the running engine, the contact becomes vibrating, and the collision of parts generates ringing. To eliminate it, just slightly move both rods away from each other.

Installation of the backstage from "Kalina"

Replacing the VAZ 2110 gearbox

On a VAZ 2110 you can successfully install a slide from Kalina:

- To do this, it needs to be modified a little.

- The cardan from the new model is 20 mm longer than the original “tenth”.

- Therefore, it needs to be cut, to do this, use a lathe.

Note: when cutting manually, you can ruin the part, since when the temperature of the metal increases, it loses its strength.

- The replacement of the slide must be carried out in the garage from the inspection hole.

- Remove the plastic tunnel from the car interior.

- Also remove the boot.

- Remove the old rocker, unscrew all the fasteners from under the bottom of the car.

- Install a new link and adjust it.

Note: adjustment must be carried out in order to later avoid troubles that arise during operation of the vehicle.

Why is it recommended to install a cardan from the new Kalina? On VAZ-2110 models, universal joints made of less resistant material are installed, so they quickly fail. This causes premature play in the rocker, which usually affects the quality of gear shifting while the vehicle is moving. After purchasing a new link, a visual comparison should be made of the old cardan and the purchased one. The comparison will be entirely in favor of the new acquisition. The Kalina cardan is made of better quality material, it is much more wear-resistant.

Gearbox slides for VAZ 2110

After installing a new link, the lever may rattle. Since this link completely eliminates play, that is, the vibration is transmitted completely to the lever.

Fixing lever rattling

- To do this, install a new ball joint for the lever and install a repair kit.

- The ball joint must be replaced from the inspection hole, since it is easier to change it from under the bottom of the car.

- Install the retaining spring to the gear lever.

It will dampen vibration by holding the lever in the desired position. This will not affect the application of additional forces when turning on the speeds. To get rid of the rattling of the lever, you can install additional plastic washers on the gearbox axle. To do this you will need:

- material - plastic (regular lid for jars);

- open-end wrench No. 10, No. 13;

- scissors;

- Phillips screwdriver;

- flat file, you can use a small flat file.

Stages of work:

- remove the plastic tunnel;

- unscrew the nut with an open-end wrench No. 13;

- Unscrew the screw using a Phillips screwdriver;

- unscrew the two nuts with a No. 10 wrench;

- remove the bolt;

- carefully pull out the bushing;

- remove the washers.

Using scissors, according to the size of the sleeve, cut two washers from the prepared plastic materials:

- Lubricate all parts with graphite lubricant.

- Place an additional washer on the bushing.

- Put it in place.

- Insert another washer on the right.

- Place oil-resistant rubber rings on both sides of the bushing.

- Reinsert the bolt.

- Treat the threads with graphite lubricant.

- Tighten the nuts.

Note: when tightening the nut to 13, you must take into account the following: if it is tightened too tightly, the lever will be difficult to move.

After such painstaking work, the car enthusiast will get rid of the rattling gear lever for a long time. The lever begins to work easier, and the gears are switched on more efficiently. You need to do the work yourself after watching the video and photos. Painstaking work must be carried out after a detailed study of each stage of work, since the gearbox gate ensures good operation of the gear lever. Therefore, how professionally the repair is carried out will completely affect the provision of comfort during operation of the VAZ-2110. It is also recommended to read the manufacturer's instructions. Price of spare parts for replacing the rocker:

- gearbox driveshaft from VAZ-2114/2115 from 300 rub.,

- boot from 65 rub.,

- drawstring from "Kalina" within 500 rubles.

Do-it-yourself installation and adjustment will give the car enthusiast the opportunity to fully feel the difference in the operation of the car.

https://carfrance.ru/regulirovka-kulisi-vaz-2110/https://vaz-remont.ru/samostoyatelnaya-regulirovka-kulisy-na-vaz-2110-regulirovka-kulisy-kpp-svoimi-rukami/https: //ladaprofi.ru/vaz-2110/kak-sdelat-regulirovku-kulisy-na-vaz-2110.htmlhttps://vaz-2110.ru/podveska/regulirovka-kulisy-na-vaz-2110.htmlhttps:// ladafakt.ru/kak-otregulirovat-kulisu-na-vaz-2110.htmlhttps://avto-zhelezo.ru/1742-kulisa-korobki-peredach-vaz-2110-menyaem-svoimi-rukami.html

Spare parts and repair kits

AvtoVAZ does not offer ready-made repair kits for repairing gear selection mechanisms: you can purchase a repair kit for the Priora gearbox rocker from third-party manufacturers or assemble them yourself.

List of parts for each box that most often fail:

| checkpoint | Detail | vendor code | Quantity | Price, rubles per piece |

| 2110 and 2170 | Gearbox ball lever support cage | 2110-1703190/86/91 | 1 | 500 |

| Lever axis | 2110-1703219 | 1 | 80 | |

| Lever axis bushing | 21100-1703226-00 | 2 | 7 | |

| Remote gearshift lever axis bushing | 2110-1703227 | 1 | 40 | |

| Overlay | 2110-1703317 | 1 | 60 | |

| 2180 | Gearbox ball lever support cage | 2110-1703190/86/91 | 1 | 500 |

| Lever axis | 21700-1703219 | 1 | 80 | |

| Thrust washer | 21700-1703371-00 | 2 | 20 | |

| Bushing (spacer, gasket) of the hinge | 21700-1703226-00 | 2 | 20 | |

| Remote bushing | 11180-1703227-01 | 1 | 45 | |

| 2181 | Rocker assembly with lever | 21901-1703010-20 | 1 | 2000 |

| Transmission shift cables (set) | 21901-1703113-00 | 1 | 4000 |

Gearbox control drive Lada Priora Lada Priora

Adjustment may be required after removing and reinstalling the VAZ 2170 gearbox, as well as in case of unclear gear shifting during operation of the Lada Priora. You will need two “13” keys.

1. From below the car, loosen and unscrew the nut of the clamp bolt on the transmission control rod by 3–5 turns.

2. Use a screwdriver to slightly widen the groove of the clamp and the groove at the end of the rod to ensure free movement of the rod relative to the gear selection rod, and set the rod to the neutral position.

Scheme for adjusting the position of the Lada Priora gear shift lever: 1 – reverse lock bracket; 2 – axis stop; 3 – gear shift lever axis; 4 – axle bushings; 5 – gear shift lever; 6 – spacer sleeve; 7 – spherical washer of the ball joint; 8 – spherical pin of the gear shift lever; 9 – body floor; 10 – ball joint; 11 – buffer; 12 – spring; 13 – template 67.7834.9527; 14 – bracket cover

3. Inside the car, remove the gear shift lever cover from the handle, lower the cover down along the lever and install the lever so that its lower (non-bent) end is approximately vertical. If you have template 67.7834.9527, position the gear shift lever as follows: with the lever cover removed, install the template in the window of the lining 14 of the reverse locking bracket. Insert the stop 2 of the axis of the lever 5 into the groove of the template 13 and press it against the template in the transverse direction without causing elastic deformation of the bracket 1. Fix the lever 5 in this position.

4. From the bottom of the VAZ 2171 car, with light hand movements (so as not to move the levers of the VAZ 2172 gear selection mechanism), select the axial play of the rod in the rearward direction and its angular play in the counterclockwise direction.

5. Tighten the nut of the clamp bolt, placing the clamp at a distance of 1–3 mm from the end of the rod.

Gearbox and gearbox Lada Priora

Gearbox Lada Priora |

Lada Priora gearbox malfunctions, their causes and solutions |

| Removal and installation of the Lada Priora gearbox |

Disassembly and assembly of the Lada Priora gearbox |

| Disassembly and assembly of the secondary shaft Lada Priora (Lada Priora) |

Disassembly and assembly of the input shaft Lada Priora (Lada Priora) |

Dismantling and assembling the Lada Priora gearbox synchronizer (Lada Priora) |

Assembly and disassembly of differential Lada Priora (Lada Priora) |

Selection of differential bearing adjusting ring for Lada Priora |

Assembly and disassembly of the gear selection mechanism Lada Priora (Lada Priora) |

Removal and installation of gearbox seals Lada Priora (Lada Priora) |

Replacing gear shift lever axle bushings for Lada Priora |

Assembling and disassembling the gear shift lever Lada Priora (Lada Priora) |

| Gearbox control drive Lada Priora |

Backstage repair and adjustment

In this section we will describe the replacement of all consumables, as well as all the adjustments to the Priora gearbox that can be carried out on a particular transmission.

Backstage repair kit

To repair a Priora gearbox of any type, you will need:

- pit;

- overpass;

- lift;

- jack with safety stands.

In addition, you will need the following tools:

- a set of spanners and open-end wrenches;

- flat and Phillips screwdrivers;

- ratchet with extension and set of bits.

If you work from a jack, be sure to use safety stands. And after installing the car on them, shake it strongly in all directions. If it falls off the stands, it means you installed them incorrectly. But it’s better if the car falls while you’re not under it.

Principle of operation

Study the diagram below to understand how the short throw rocker works. The lever is installed in the neutral position, here it is indicated by the points “O” and “F”. To start the transmission, you need to move the rod - it will connect to the control gear at point “B” - at point “A”. After this, the handle will move to point “E”. Repairs and subsequent replacements are carried out in order to reduce the distance.

This can be done if the lever extends to point “H”. This move will increase the distance. On the diagram, "A" and "B" will become points "C" and "D". Replacing the standard rocker with a short-stroke one allows you to reduce the movement of the handle. We've sorted out the theory, now we can start the repairs.

Rigid traction mechanisms

For both “screw” mechanisms, the procedure is completely identical. So do this:

- Raise or hang the machine.

- Remove the cover and gearshift lever knob.

- Unscrew the nuts and bolts securing the reverse lock plate (bracket), then remove the bracket.

- Unscrew the lever axle nut. Be careful not to lose the nut and lock washer.

- Unscrew the bolt securing the lever axle, then pull out the axle.

- Go down under the car and unscrew the nuts of the rocker pad bracket (this is convenient to do with a ratchet and an extension).

- Unscrew the bolts securing the torque rod to the car body.

- Pull down the pillow with the lever.

- Remove the retaining ring from the cushion.

- Lubricate the ball joint of the new cushion with any grease.

- Insert the lever into the pillow and make sure that it rotates freely and does not fall out of it.

- Place the pillow with the lever in place and secure it.

- Lubricate the new bushings and insert them into the lever.

- Replace the lever shaft.

- Have an assistant sit behind the wheel and go under the car yourself.

- Ask an assistant to engage first gear. If the lever is where it should be, then the repair and adjustment is complete. If not, then loosen the nut and bolt that tighten the clamp on the rod next to the driveshaft. While holding the rod, have an assistant place the lever in place corresponding to first gear and tighten the clamp.

Ask an assistant to engage all gears in order. If they turn on clearly and there is no strong play in the lever (on the rocker boxes), then you have done everything correctly and the repair and adjustment are completed.

Attention!

If you first assemble the reverse gear locking mechanism, the long rod will not allow you to put the rod on the cardan shaft. The problem can be solved by shortening it. It is important not to forget to put the boot on the driveshaft.

Adjust the reverse gear locking mechanism, since the consequence of adjusting the scenes is that the mechanism does not match the plate to which it clings. The problem can be solved by removing the plate and adjusting the hook (it is a cutout on the mounting bracket). You can sharpen it with sandpaper or a file.

The photo shows the adjusted toe.

To complete the procedure, you need to put on a manual transmission cover with a knob.

Replacing the oil seal

On a Lada Priora car, replacing the gearbox seal does not cause serious difficulties. Since we have already talked about performing this operation in the article (Replacing the Kalina gearbox oil seal), we will repeat here only the general principles.

To replace the oil seal, do the following:

- Place the machine on a pit, lift, overpass or jack, observing all safety measures.

- Disconnect the jet rod from the box.

- Disconnect the gear shift rod from the driveshaft.

- Remove the boot.

- Disconnect the driveshaft from the gear selector rod.

- Pull out the bushing with the oil seal.

- Clean the seat in the transmission housing.

- Replace the seal in the bushing.

- Insert the bushing into the box, seating it on the sealant.

- Assemble the car.

Check the gearbox oil level and, if necessary, add the appropriate transmission fluid.

VAZ 2110 replacement of the ball joint cage of the gearshift knob

Replacing the gearshift pad on VAZ-2110, VAZ-2111, VAZ-2112 cars

On VAZ-2110, VAZ-2111, VAZ-2112 cars, when unpleasant rattling, vibration and increased play in the gearshift knob appear, the happy owners of these vehicles should pay attention to the condition of the ball joint race of the gear shift link or as it is also called in common parlance gear shift pad. There is another option - butterfly wings But, I personally like the second option)))

Due to the fault of this very pillow (ball joint cage) being completely broken, the clarity of gear shifting may also disappear. Yes, I know that all the listed symptoms also include a broken cardan (joint) of the gear selection rod. What kind of cardan is this and how to replace it you can find out from this article. But we’re not talking about him now and let’s assume that everything is ok with him. Or, as another option, the cardan was replaced, but the rattling and play of the rocker did not disappear. This also happens; not everyone immediately pays attention to the backstage cushion. But, it exists and it periodically fails (breakage of rubber “ears”, flying out of metal bushings, breaking of a plastic bushing or spring). The destruction of the rubber part of the cushion (ball joint race) of the rocker is not difficult to replace (see photos 1 and 15). And if you find them, then it’s time for you to get ready for work. Let me reassure you right away, it’s not complicated. But for everything to go smoothly, you need to be thoroughly prepared. That is, buy the necessary spare parts, decide on the location of the work, assemble the necessary tools and, of course, familiarize yourself with and remember in what sequence you should replace the cushion (ball joint race) of the gear shift lever on VAZ-2110, VAZ-2111, VAZ- 2112. And I will try to help you with this, and I invite you to further read this material.

Spare parts. Here the choice is obvious. I recommend choosing the ball joint bracket for the gearshift mechanism of VAZ 2110-2112 cars - BRT (Balakovo). As they say, time-tested quality. Photo 2.

List of tools that you will need to replace the cushion (ball joint race) of the gearshift gates of VAZ-2110, VAZ-2111, VAZ-2112 cars: a 13-socket and socket wrench, a 10-size combination wrench, pliers, a flat-head screwdriver and a small ratchet with with a cross attachment (photos 3 and 4). The need for a ratchet with an attachment will be shown a little later. And you should immediately decide on the location of the work. It is advisable to replace the cushion in an inspection pit, overpass or lift. Why is it desirable? Because this work can be done “from the ground”, but believe me, it will take more time and effort. And it will still be a pleasure.

And so, into battle! Let's proceed to independently replacing the cushion (ball joint cage) of the gearshift slides of VAZ-2110, VAZ-2111, VAZ-2112 cars:

Let's start working inside the car. Use a screwdriver to pry up the frame of the decorative cover of the gearshift slide (photo 5). Pull the lever handle up and remove it along with the cover.

Using a 10 mm spanner, unscrew the two fastening nuts and the bolt of the reverse locking bracket lining and remove it (photos 6 and 7).

Using a 13mm wrench, unscrew the lever axle nut (photo 8). After this, use a wrench with an attachment (in my case it’s a ratchet) to unscrew the axle locking screw (photo 9). Without such a key, this screw will be difficult to unscrew. We take out the axle (photo 10). We remove the set of bushings from the lever, otherwise we risk losing them (photo 11). All. Now the work inside the car is finished, let's climb under the car.

Using a 13 mm socket wrench, unscrew the two nuts of the rocker pad bracket (photo 12). And remove the bracket.

Next, you should disconnect the reaction rod from the cushion (ball joint cage) of the rocker. We use a spanner wrench (hold the nut on top with it) and a 13mm socket wrench (photo 13).

We manufacture and replace short-stroke gearbox shifter for VAZ 2112

We pull down the pillow along with the lever (photos 14 and 15). Remove the retaining ring (photo 16) and remove the lever along with the plastic bushing (photos 17 and 18).

All. We clean the lever hinge from dirt, lubricate it, and put on a plastic bushing. We place this whole thing in the pillow body and secure it with a locking ring (photos 19 and 20). We return this entire structure to its place (photo 21). Don't forget to put a cover on the pillow (photo 22).

Ready. We carry out the rest of the assembly in reverse order. The work on replacing the butterfly cushion (ball joint cage) of the gearshift gates of VAZ-2110, VAZ-2111, VAZ-2112 cars has been completed. I hope it's successful)))

If you find an error, please select a piece of text and press Ctrl+Enter.