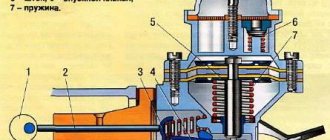

Design of the VAZ 2106, 2107 chain drive

To drive the VAZ 2106/2107 with a carburetor, a double-row roller chain is used. It transmits force from a sprocket mounted on the crankshaft to another sprocket mounted on the end of the camshaft. The chain is a structure that develops large inertia, so a chain drive requires vibration damping. Even if the chain is well tensioned, it retains the property of “playing” in those places where there are no sprockets or tensioners.

The chain has virtually zero ability to stretch and compress, and fairly limited flexibility. Therefore, in order to provide it with constant tension while working in its place at any speed, it has to be literally shackled, using a system of tensioners and dampers.

This problem on the VAZ 2106/2107 is solved by a damper - an additional spring-loaded clamping bar. It has a steel frame covered with a layer of durable rubber. Tensioners and dampers dampen vibration and noise quite effectively . The chain is prevented from falling off by a stop pin that is screwed into the block or cylinder head. During normal operation the chain does not touch it.

What are axle shafts, why are they needed and how are they designed?

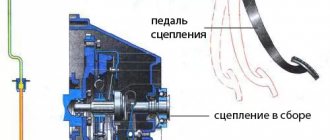

In rear-wheel drive cars, which the “seven” actually belongs to, the rear wheels are driving. It is they, rotating, that make the car move. The torque is transmitted to them from the gearbox through the drive (cardan) shaft, gearbox and axle shafts. There are only two axle shafts: one for each rear wheel. Their role is to transmit torque from the corresponding gear of the gearbox to the wheel rim.

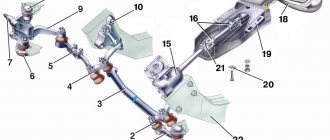

Axle shaft design

The axle shaft is an all-metal shaft made of steel. At one end there is a flange for attaching the wheel disk, and at the other there are splines for engagement with the gearbox gear. If we consider the axle shaft assembly, then in addition to the shaft, its design also includes:

- oil deflector;

- sealing gasket;

- oil seal (cuff);

- bearing.

In addition to the shaft, the design of the axle shaft also includes an oil deflector, a gasket, an oil seal and a bearing.

Each of the axle shafts is installed in the corresponding (left or right) rear axle housing. An oil deflector with a gasket and an oil seal are used to prevent lubricant from leaking out of the casing. The bearing is designed to ensure uniform rotation of the axle shaft and distribute shock loads coming from the wheel to the rear axle of the vehicle.

1 — oil deflector; 2 - gasket; 3 - seal; 4 - oil seal; 5 - axle shaft; 6 - casing; 7 — bearing mounting plate; 8 — brake shield; 9 — bearing; 10 — fixing sleeve

Reasons for replacing the timing chain drive on a VAZ 2106, 2107

The performance and durability of the timing chain drive depends on the material and quality of heat treatment of the chain and sprockets themselves. Manufacturing accuracy and cleanliness of working surfaces are of great importance. A broken circuit is a rare occurrence. The deterioration of its condition can be monitored by increased noise when the engine is running.

For engines 2101 and 21011, where the block is lower, the number of chain links is 114, and for 2103/2106 the number of links is 116.

A method on how to replace the timing chain on a VAZ 2106 may be required when its critical wear has occurred, its resource has been exhausted, and tightening it with all sorts of “cunning” methods no longer gives results. These methods include:

- increasing the length of the working part of the tensioner by pressing on a piece of tube of a suitable diameter;

- “addition” of an additional bracket to the shoe and other “bullying” of the engine.

An extended timing chain no longer ensures accurate valve timing, which negatively affects engine performance. In addition, she wears out the shoe and constantly “beats the head off” the pacifier. In addition, engine noise increases, fuel consumption increases and engine starting becomes worse. It is also worth saying that the chain sometimes breaks with all that it entails.

To remove the timing chain, you do not need to remove the crankshaft sprocket!

For work we will need: keys “10”, “13”, “17”, a special wrench for the crankshaft pulley nut (or a head “36”), a screwdriver, a mounting blade, a hammer, and a bit.

After removing the sprocket, do not turn the drive shaft, because this may disrupt the initial ignition setting!

When to change the timing chain

The chain drive on VAZ family engines has a longer service life. The life of the chain ranges from 100 to 200 thousand kilometers .

If high-quality materials were used in the manufacture of components, and proper tension and abundant lubrication of the drive were ensured during operation, then the chain will last no less than the engine itself.

The optimal frequency for changing is every 200 thousand km.

Main technical characteristics of VAZ 2107 axle shafts and their elements

Axle shafts for the “seven” in Russia are produced under catalog number 21030–2403069–00. The right and left parts, unlike some other rear-wheel drive cars, are absolutely identical in the VAZ 2107. They have a diameter of 30 mm (for the bearing) and 22 slots. On sale you can also find so-called reinforced axle shafts with 24 splines, but to install them you will need to change the design of the gearbox.

Axle bearing

The bearing is the element that bears most of the loads. And although its declared resource is about 150 thousand kilometers, it can become unusable much earlier. It all depends on the operating conditions of the car, the serviceability of other transmission parts, as well as the quality of its manufacture. The most reliable today are considered to be bearings from the Vologda Bearing Plant, produced under article numbers 2101–2403080 and 180306. Imported analogues have catalog number 6306 2RS.

Table: dimensions and technical characteristics of bearing 2101–2403080

| Position | Index |

| Type | Ball |

| Number of rows | 1 |

| Direction of loads | Two-way |

| Outer/inner diameter, mm | 72/30 |

| Width, mm | 19 |

| Load capacity dynamic/static, N | 28100/14600 |

| Weight, g | 350 |

Stuffing box

The axle shaft cuff has a much shorter lifespan than the bearing, since its main working material is rubber. It needs to be changed every 50 thousand kilometers. Axle shaft seals are available under catalog numbers 2101–2401034.

Table: dimensions and technical characteristics of the VAZ 2107 axle shaft seal

| Position | Index |

| Frame type | Rubberized |

| Type of rubber according to GOST | 8752–79 |

| Internal diameter, mm | 30 |

| Outer diameter, mm | 45 |

| Height, mm | 8 |

| Temperature range, 0С | -45 – +100 |

Which timing chain and tensioner should I install on the VAZ 2106, VAZ 2107?

timing chain number is 2103-1006040, the average price is 380 rubles.

Analogues:

- Fenox PC2103C3 — 519 rub.

- Kraft KT 017736 — 620 rub.

The original number of the timing chain tensioner is 2101-1006060, the average price is 364 rubles.

Analogues:

- TSN 671 — 254 rub.

- Riginal RG2101-1006060 — 230 rub.

- Trialli MT 151 — 407 rub.

Prices are current for 2022, although the cost has not changed much in three years.

Replacing the VAZ 2106 timing chain without disassembling

Replacing the timing chain without disassembling

There is a simple way to replace the timing chain of a VAZ 2106 without removing the front cover. To do this, you only need to remove the valve covers and prepare a new chain.

The principle of how to change the timing chain on a VAZ 2106 is as follows: you need to disconnect one link of the old chain, as well as one link of the new one. After this, the edges of the old and new chains must be connected by making a corresponding mark at the junction with chalk or a corrector. Then you need to take the second end of the old chain and pull it out of the mechanism, while the new chain will gradually be put on the sprockets.

When the old chain comes out completely, it must be disconnected from the new one, and carefully rivet the links of the replaced chain.

How to change the timing chain on a VAZ 2107 with an injector

Replacing the timing chain on a VAZ 2107 injector is carried out according to the same principle as on a Zhiguli 2106. Moreover, you can install a new element either in the standard way by removing the front cover, or in a simpler way.

Checking the timing chain quality

Before changing the timing chain on a VAZ-2107, you should decide on the manufacturer and quality of the chain.

The reliability of a new product can be roughly checked by taking the chain by one end and lifting it horizontally. Holding the chain edge up, its second end will bend down slightly - the smoother this bend is, the stronger and more reliable the product!

Prepare the necessary keys and be sure to put proofreader or chalk somewhere nearby.

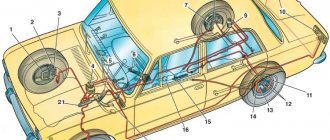

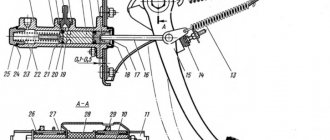

Steering gear reducer design

Before you begin repairing the steering column, you need to familiarize yourself with its structure, as well as its operating principle. The design consists of the following main elements:

- a unit designed to transmit force from turning the steering wheel to actuators;

- steering column, which turns the wheels to the desired angle.

The steering mechanism consists of:

- composite shaft with cardan transmission;

- steering wheel;

- worm type steering gear.

The design has the following components:

- pendulum;

- swing arms;

- steering rods.

Steering design: 1 - steering gear housing; 2 - shaft seal; 3 - intermediate shaft; 4 - upper shaft; 5 — fixing plate of the front part of the bracket; 6 — bracket for fastening the steering shaft; 7 - upper part of the facing casing; 8 — bearing sleeve; 9 — bearing; 10 — steering wheel; 11 — lower part of the facing casing; 12 — bracket fastening parts

Since the outer rods have two parts, this allows the toe angle to be adjusted. The steering functions as follows:

- The driver operates the steering wheel.

- Through universal joints, the worm shaft is driven, through which the number of revolutions is reduced.

- The worm rotates, which helps move the double-ridge roller.

- The secondary shaft of the gearbox turns.

- A bipod is mounted on the secondary shaft, which rotates and carries the steering rods with it.

- Through these parts, force is applied to the levers, thereby turning the front wheels to the angle desired by the driver.

The bipod is a rod that connects the steering gearbox to the steering linkage.

Signs of a gearbox malfunction

As the vehicle is used, the steering column may develop problems that require repair. The most common of them are:

- oil leak from the gearbox;

- extraneous sounds in the mechanism;

- It takes a lot of effort to turn the steering wheel.

Table: VAZ 2107 steering faults and ways to solve them

| Malfunctions | Elimination method |

| Increased free play of the steering wheel | |

| Loosening the steering gear mounting bolts. | Tighten the nuts. |

| Loosening the tie rod ball pin nuts. | Check and tighten the nuts. |

| Increased clearance in the ball joints of the steering rods. | Replace tie rod ends or tie rods. |

| Increased clearance in the front wheel hub bearings. | Adjust the gap. |

| Increased clearance in the engagement of the roller with the worm. | Adjust the gap. |

| There is too much clearance between the swingarm shaft and the bushings. | Replace the bushings or bracket assembly. |

| Increased clearance in the worm bearings. | Adjust the gap. |

| Stiff steering wheel rotation | |

| Deformation of steering gear parts. | Replace deformed parts. |

| Incorrect alignment of the front wheel angles. | Check the wheel alignment angles and adjust. |

| The gap in the engagement of the roller with the worm is broken. | Adjust the gap. |

| The adjusting nut of the pendulum arm axis is overtightened. | Adjust the tightening of the nut. |

| Low pressure in the front tires. | Set the pressure to normal. |

| Damage to ball joint parts. | Check and replace damaged parts. |

| There is no oil in the steering gear housing | Check and top up. Replace the oil seal if necessary. |

| Damage to upper steering shaft bearings | Replace bearings. |

| Noise (knocking) in the steering | |

| Increased clearance in the front wheel hub bearings. | Adjust the gap. |

| Loosening the tie rod ball pin nuts. | Check and tighten the nuts. |

| Increased clearance between the pendulum arm axis and the bushings. | Replace the bushings or bracket assembly. |

| The adjusting nut of the pendulum arm axis is loose. | Adjust the tightening of the nut. |

| The clearance in the engagement of the roller with the worm or in the worm bearings is broken. | Adjust the gap. |

| Increased clearance in the ball joints of the steering rods. | Replace tie rod ends or tie rods. |

| Loosening of the steering gear mounting bolts or the swing arm bracket. | Check and tighten the bolt nuts. |

| Loosening the nuts securing the swing arms. | Tighten the nuts. |

| Loosening the steering intermediate shaft bolts. | Tighten the bolt nuts. |

| Self-excited angular oscillation of the front wheels | |

| Tire pressure is not correct. | Check and set normal pressure. |

| 2. The alignment angles of the front wheels are incorrect. | Check and adjust wheel alignment angles. |

| 3. Increased clearance in the front wheel hub bearings. | Adjust the gap. |

| 4. Wheel imbalance. | Balance the wheels. |

| 5. Loosening the tie rod ball pin nuts. | Check and tighten the nuts. |

| 6. Loosening the bolts securing the steering mechanism or the pendulum arm bracket. | Check and tighten the bolt nuts. |

| 7. The gap in the engagement of the roller with the worm is broken. | Adjust the gap. |

| Steering the vehicle away from straight-line motion in one direction | |

| Uneven tire pressure. | Check and set normal pressure. |

| The alignment angles of the front wheels are incorrect. | Check and adjust wheel alignment angles. |

| Different draft of front suspension springs. | Replace unsuitable springs. |

| Steering knuckles or suspension arms are deformed. | Check the fists and levers, replace unsuitable parts. |

| Incomplete release of the brakes on one or more wheels. | Check the condition of the brake system. |

| Vehicle instability | |

| The alignment angles of the front wheels are incorrect. | Check and adjust wheel alignment angles. |

| Increased clearance in front wheel bearings. | Adjust the gap. |

| Loosening the tie rod ball pin nuts. | Check and tighten the nuts. |

| There is too much play in the tie rod ball joints. | Replace tie rod ends or tie rods. |

| Loosening of the steering gear mounting bolts or the swing arm bracket. | Check and tighten the bolt nuts. |

| Increased clearance in the engagement of the roller and worm. | Adjust the gap. |

| Steering knuckles or suspension arms are deformed. | Check the knuckles and levers; replace deformed parts. |

| Oil leak from crankcase | |

| Wear of the bipod or worm shaft seal. | Replace the seal. |

| Loosening the bolts securing the steering gear housing covers. | Tighten the bolts. |

| Damage to sealing gaskets. | Replace gaskets. |

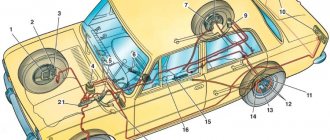

Where is the gearbox located?

The steering gearbox on the VAZ 2107 is located in the engine compartment on the left side under the vacuum brake booster. If you have insufficient experience, you may not find it at first glance, since it is usually covered with a layer of dirt.

The steering gearbox on the VAZ 2107 is located under the vacuum brake booster on the left side of the engine compartment