If the wiper does not operate intermittently:

- disconnect the positive terminal from the battery;

- remove the decorative panel on the left side of the car, next to the hood release handle. There is a relay under the panel;

- unscrew the two screws securing the relay and disconnect the connector;

- install a new relay;

- putting everything back together;

In this guide, we did not touch on more complex troubleshooting diagrams for the windshield wiper system. Such as replacing the winding and armature of an electric drive or overhauling a windshield wiper gearbox, because this is a more complex task that requires certain special skills. With the modern availability of spare parts, it is easier to replace the entire unit than to repair it.

Features of removing the windshield wiper motor and trapezoid on a VAZ 2106

The first step is to disconnect the power plug from the wiper motor. To do this, disconnect it by pulling the ends to the sides with a little force:

Now you need to slightly lift the rubber of the hood seal from one edge, as is clearly shown in the photo below:

And after that we remove the wire with the plug from the slot in the body of the VAZ 2106:

Now you can unscrew the mount of the motor itself by slightly lifting the protective cover:

Then press on the slotted pins so that they fall inward. And we try to remove the windshield wiper motor, turning it from side to side to find the optimal position for removal:

Everything is ready; if necessary, we replace the entire mechanism along with the trapezoid. Again, I repeat, very few VAZ 2106 will have to undergo this procedure, since the entire structure is quite reliable.

Source

Windshield washer does not work

To remove dirt from the windshield, the washer is used together with the windshield wiper. The device sprays water or a special liquid. The main elements of this mechanism are:

- fluid reservoir;

- motor;

- nozzles;

- connecting tubes.

During the operation of a car with a washer, various problems may arise that lead to its inability to work:

- motor failure;

- fuse blown;

- kinking of tubes;

- breakdown of the steering column switch;

- poor contact on the power supply circuit.

Checking the motor

It is easy to check if the washer pump is not working properly. To do this, just open the hood and pull the lever of the steering column switch, which is responsible for the function of supplying fluid to the windshield. At this moment, the operation of the motor will be clearly audible. If this does not happen, then the malfunction may be caused either in the pump itself or in the fuse or other part of the electrical circuit. To make sure that the problem lies in the motor, we use a multimeter to measure the voltage when the washer is turned on. If there is voltage, but the pump does not work, then you need to take care of replacing it.

Video: checking the wiper motor on a “classic”

Injectors

If the motor is running, but liquid is not supplied through the nozzles, then the problem will not be difficult to identify, since there are only a few reasons for this phenomenon:

- clogged injector fittings;

- the supply tube has come off;

- kinking of the tube.

The malfunction can be determined by inspecting the tubes from the motor to the injectors. If there are no areas with kinks and the tube has not fallen off, then the reason lies in clogged nozzles, which can be cleaned with a sewing needle and blown out with a compressor.

Fuse and mounting block

The integrity of the fuse is checked in the same way as for windshield wipers. The same protective element as for the wipers is responsible for the operation of the washer. In addition to the fuse, sometimes the track in the mounting block through which power is supplied to the washer burns out. In this case, you need to disassemble the fuse box and restore the current-carrying element by soldering, having first cleared the varnish from the track.

You should start checking the steering column switch on a VAZ 2107 if the fuse, motor and the entire electrical circuit through which voltage is supplied to the pump are in good condition. In this case, the wiring should not have breaks, melted insulation or other visible damage. To check the steering column switch, only a multimeter will be enough. Having disconnected the connectors from the device in question, we connect the probes of the device in the dialing mode with a two-pin block. If the switch is working properly, then when the washer is turned on, the device will show zero resistance. Otherwise, the mechanism will have to be replaced.

Wiper malfunctions and their elimination

The VAZ 2106 windshield wiper fails infrequently and does not require special attention in maintenance. However, problems still arise with it, which requires repair work.

Electric motor malfunctions

Almost any problems that arise with the windshield wiper motor lead to disruption of the functioning of the mechanism as a whole. The main problems of the electric motor are:

- the gearmotor is not working. The reasons for this phenomenon may be different, but first of all you need to check the integrity of fuse F2. In addition, the commutator may burn out, a short circuit or break in its winding, or damage to the part of the wiring responsible for supplying power to the electric motor. Therefore, it will be necessary to check the circuit from the power source to the consumer;

- there is no intermittent mode. The problem may be in the breaker relay or steering column switch;

- The motor does not stop intermittently. A malfunction is possible both in the relay itself and in the limit switch. In this case, both elements need to be checked;

- The electric motor works, but the brushes do not move. There are two possible options for a malfunction: the fastening of the crank mechanism on the motor shaft is loose or the gear teeth of the gearbox are worn out. Therefore, you will need to check the fastening, as well as the condition of the electric motor.

Video: troubleshooting the VAZ “classic” windshield wiper gearmotor

Which one can be installed

Sometimes owners of VAZ Sixes are not satisfied with the operation of the standard windshield wiper mechanism for one reason or another, for example, due to low speed. As a result, cars are equipped with a more powerful device. You can install a device from a VAZ 2110 on a classic Zhiguli. As a result, we get the following advantages:

- installation in a regular place;

- 3 operating speeds (requires installation of a steering column switch from a Chevrolet Niva);

- windshield wipers;

- high power and reliability;

- When washing the glass, the wipers make two strokes.

Despite all the positive aspects listed, some owners of the “classic”, who installed a more modern motor in their cars, came to the disappointing conclusion that the high power led to the failure of the trapezoid. Therefore, before installing a powerful mechanism, you should first perform an audit of the old device. If the performance of the structure after servicing is not satisfactory, then installing an electric motor from the “ten” will be justified.

How to remove

If a malfunction occurs with the windshield wiper motor, it is recommended to replace or repair the mechanism. To remove the assembly you will need the following list of tools:

- open-end or socket wrench 22;

- socket head 10;

- small extension cord;

- crank or ratchet handle.

The procedure is carried out in the following order:

- Unscrew the fastenings of the windshield wiper arms.

Disassembly

If the electric motor is planned to be repaired, it will need to be disassembled.

This is done as follows:

- Unscrew the gearbox cover and remove it.

Repair and assembly

After disassembling the motor, we immediately proceed to troubleshooting the mechanism:

- Remove the coals from the brush holders. If they have a lot of wear or signs of damage, we replace them with new ones. New elements in brush holders should move easily and without jamming. Elastic elements must be undamaged.

Video: how to adjust wipers

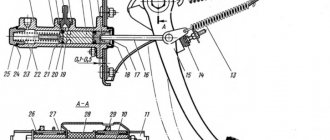

Trapezium malfunctions

The mechanical part has no less influence on the performance of the windshield wiper mechanism than the electrical part. If there is a lot of wear on the rod system or lack of lubrication on the hinges, the brushes can move slowly, which creates an increased load on the engine and shortens the service life of the trapezoid itself. Malfunctions of the rods are also indicated by squeaks and rattles that appear due to corrosion on the rubbing parts. Untimely maintenance and troubleshooting can lead to gearbox failure.

Trapezoid repair

To repair the trapezoid, the mechanism must be removed from the car. This is done in the same way as when dismantling the electric motor. If you only intend to lubricate the entire structure, then it is enough to fill a syringe with transmission oil and apply it to the rubbing elements. However, it is better to disassemble the mechanism for diagnostics. When the rod system is disconnected from the motor, we disassemble it in the following sequence:

- Using a screwdriver, remove the locking elements from the axles.

Video: how to replace the trapezoid on a classic Zhiguli car

Wiper relay not working

The main malfunction of the interrupter relay is the lack of intermittent mode. In most cases, the part must be replaced, for which it must be removed from the car.

Relay replacement

To remove the switching element, two screwdrivers will be enough - a Phillips and a flathead one. The process consists of the following steps:

- We tighten the door seal on the driver's side.

To attach the side panel you will need two new clips.

Faulty steering column switch

Problems with the steering column switch on the “six” occur quite rarely. The main malfunctions due to which the switch has to be removed are burnt contacts or mechanical wear. The replacement procedure is not complicated, but requires removing the steering wheel. The following tools will be required:

- knob;

- head 24;

- key to 8;

- crosshead screwdriver.

How to replace

Before starting repair work, remove the negative terminal from the battery, and then perform the following actions:

- Remove the plug on the steering wheel by prying it off with a screwdriver.

Video: checking the steering column switch

Fuse burned out

Each VAZ 2106 electrical wiring circuit is protected by a fuse, which prevents overheating and spontaneous combustion of the wires. One of the common reasons why the wipers do not work on the car in question is the blown fuse F2 installed in the fuse box. The latter is located on the driver's side near the hood release handle. On the “six”, this fuse protects the windshield washer and wiper circuits, as well as the heater motor. The fuse link is designed for a current of 8 A.

How to check and replace a fuse

To check the functionality of the fuse, you will need to perform the following steps:

- Use a flat-head screwdriver to pry up and remove the cover of the upper (main) fuse box.

- Visually assess the serviceability of the fuse link. To replace a faulty element, press out the upper and lower holders and remove the faulty part.

Sometimes it happens that voltage does not pass through the fuse, but the part is in good condition. In this case, you should remove the fuse-link from the seat, check and clean the contacts in the fuse block. The fact is that quite often the contacts simply oxidize, and this leads to the lack of functionality of one or another electrical circuit.

Why does the fuse burn?

There can be many reasons for an element to burn out:

- short circuit in the circuit during repair work;

- failure of the wiper motor;

- Trapezius problems.

A burnt-out part indicates that the load on the circuit has increased for one reason or another. The current can increase sharply, even when the wipers are simply frozen to the windshield, and at that moment voltage was applied to the motor. To find the fault, you will need to check the power circuit starting from the battery and ending with the consumer, i.e., the gearmotor. If your “six” has a high mileage, then the reason may be a short circuit in the wiring to ground, for example, if the insulation is damaged. In this case, replacing the fuse will not help - it will continue to burn out. You will also have to pay attention to the mechanical part - the trapezoid: perhaps the rods are so rusty that the electric motor is not able to turn the structure.

Reasons for blown fuses

Even from the school curriculum, many remember Ohm's law, which states that the current must necessarily increase if the resistance in a certain part of the electrical circuit decreases. The result of such a violation is the combustion of a special fuse link, which is located in the fuse block of the VAZ 21053. The circuit can only be opened by interrupting the connection.

It may happen that the fuse is installed incorrectly. In this case, the shell can melt even with the slightest jump in current in the electrical wiring.

The last reason for fuses to malfunction is simple wear. In any case, this will happen over time, since even the best detail does not last forever. The part of the fuse made of plastic is most often susceptible to melting due to heat or overload. Over time, this will cause the formation of a smaller cross section. Many people know that when heated, metal threads increase their resistance. Its increase entails a decrease in current. As a result, the device will burn out due to a sudden voltage surge.

Modifications

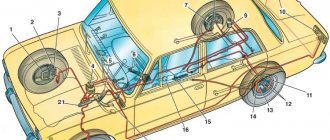

Switching diagram for electric windows of the front doors

1 - main fuse block; 2 — relay for turning on electric windows; 3 — left door power window switch; 4 — right door power window switch; 5 — gear motor for the right door electric window; 6 — gear motor for electric window lifter of the left door; 7 - additional fuse block; 8 — ignition switch; A - to terminal “30” of the generator; B - to the instrument lighting switch; B - conventional numbering of plugs in the gear motor block.

Carburetor solenoid valve control circuit

1 - ignition switch; 2 - generator; 3 - battery; 4 — ignition coil; 5 - switch; 6 — control unit; 7 — carburetor solenoid valve; 8 — carburetor limit switch.

Engine cooling fan motor

1 - generator; 2 - battery; 3 — ignition switch; 4 - main fuse block; 5 — electric fan activation relay, 6 — electric fan activation sensor; 7 — electric fan; 8 - additional fuse block

Windshield wiper malfunctions VAZ 2106

Home • VAZ • 2106 • Cleaning windows and headlights

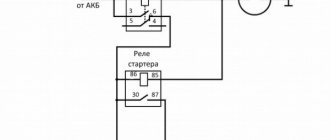

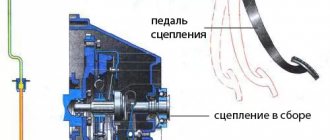

Electrical circuit for switching on the windshield cleaner and washer VAZ 2106

1 – washer motor; 2 – windshield wiper and washer switch; 3 – windshield wiper relay; 4 – purifier gear motor; 5 – fuse block; 6 – ignition switch; 7 – generator; 8 – battery.

Below is a table of the causes of malfunction of the VAZ 2106 wipers and methods for eliminating them:

Cause of malfunction Method of elimination The windshield wiper motor of the VAZ 2106 does not work. The wires are damaged, their tips are oxidized or loose, fuse F2 has blown. Crimp the terminals, replace the faulty wires, fuse

Eliminate the cause of its burnout The brushes are frozen to the glass Turn the ignition key to the “off” position, carefully separate the brushes from the glass, make sure that the rubber scraper is intact, restore the mobility of the brush connections A foreign object has gotten between the moving parts of the crank Check the correct installation of the levers, straighten the deformed levers or replace them windshield wiper The steering column wiper switch is faulty Replace the faulty switch The electric motor brushes are stuck, the commutator is very dirty or burnt Eliminate the stuck brushes, clean the commutator or replace the gear motor Break or short circuit in the armature winding of the electric motor Replace the gear motor The VAZ 2106 wiper motor does not work in intermittent mode The windshield wiper relay is faulty Replace the relay The steering column switch is faulty Replace the faulty switch The wiper motor of the VAZ 2106 does not stop intermittently The windshield wiper relay is faulty Clean the breaker contacts, replace the relay if necessary The contact plate of the gearmotor limit switch does not bend when the cam passes Disassemble the gearmotor and bend the contact plate or replace the gearmotor The limit switch contacts are oxidized Clean ite contacts or replace the windshield wiper motor The wiper blades of the VAZ 2106 stop in an arbitrary position The limit switch contacts are poorly pressed or oxidized Clean the contacts, if necessary, bend the switch plate or replace the gear motor The nut securing the crank on the shaft of the gear motor is loose Having installed the crank correctly, tighten the nut (pre-apply paint to the threads or anaerobic sealant) The electric motor of the VAZ 2106 windshield wiper is working, but the blades do not move. The nut securing the crank on the shaft of the gearmotor is loose. Having correctly installed the crank, tighten the nut (first apply paint or anaerobic sealant to the threads). The gear teeth of the gearmotor are chipped. Replace the gear or gearmotor.

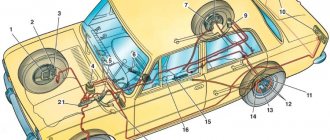

Wipers VAZ 2106

Various components are responsible for the safety of the VAZ “six”. However, an equally important device that ensures comfortable and safe movement is the windshield cleaner and washer. It is this part of automotive electrical equipment, its malfunctions and their elimination that is worth dwelling on in more detail.

Purpose

The vehicle is operated under different climatic and road conditions, which leads to a deterioration in the driver’s visibility of the road situation. One of the main factors that reduce visibility and visibility is dirt or moisture in the windshield and other windows. From a safety point of view, it is the contamination of the windshield that poses the greatest danger. To ensure that the windshield always remains clean, the design of the VAZ 2106 includes windshield wipers that remove dirt and precipitation from the surface of the glass.

Principle of operation

The principle of operation of the mechanism consists of the following steps:

- The driver selects the desired operating mode of the windshield wipers using the steering column switch lever.

- The gearmotor acts on the mechanism.

- The wipers begin to move left and right, cleaning the glass surface.

- To supply liquid to the surface, the driver pulls the steering column switch towards himself, turning on another electric motor installed in the washer reservoir.

- When the mechanism is not required, the switch lever is set to its original position.

Components

The main structural elements of the glass cleaning system are:

- electric motor with gearbox;

- drive levers;

- relay;

- Understeering's shifter;

- brushes

Trapezoid

The windshield wiper trapezoid is a lever system consisting of rods and an electric motor. The rods are connected by means of hinges and pins. On almost all cars, trapezoids have a similar design. The differences come down to different shapes and sizes of fastening elements, as well as the method of mounting the mechanism. The trapezoid works quite simply: rotation is transmitted from the electric motor to the rod system and then to the wipers, which move synchronously for better cleaning of the glass.

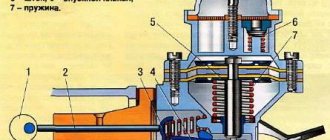

Motor

The electric motor of the wipers is necessary to influence the trapezoid. It is connected to the lever system using a shaft. Operating modes are controlled via a steering column switch, and power is supplied to it through a standard VAZ wiring connector. The motor is designed as a single device with a gearbox to reduce the number of revolutions. Both mechanisms are located in a housing protected from dust and moisture entering the electrical part. The design of the electric motor consists of a stator with permanent magnets, as well as a rotor having an elongated shaft with a screw end.

Wiper relay

The VAZ “classic” has two operating modes for windshield wipers - constant and intermittent. When the first mode is activated, the mechanism works constantly. This position is used in heavy rain or when necessary to quickly wash away dirt from the surface of the glass. When selecting intermittent mode, the device turns on at intervals of 4–6 seconds, for which the PC 514 relay is used.

Intermittent mode is relevant during light rain and fog, i.e. when there is no need for constant operation of the unit. The relay is connected to the car wiring via a standard four-pin connector. The device is located in the cabin near the driver’s feet on the left side under the trim.

Understeering's shifter

The main function of the switch is to switch voltage and supply it to the windshield wiper motor, washer, optics, turn signals and signal at the right time. The part consists of three control levers, each of which has its own function. The device is connected to the wiring using blocks.

Brushes

The brushes are a rubber element held by a special flexible mount with the body. It is this part that fits onto the windshield wiper arm and ensures that the glass is cleaned. The length of the standard brushes is 33.5 cm. Installing longer elements will cover a larger surface of the glass when cleaning, but there will be a high load on the gear motor, which will slow down its operation and may cause overheating and failure.

Replacing the VAZ 2107 crosspiece is divided into the following stages:

So, the first thing that is necessary before dismantling the driveshaft is to put marks on the parts, this is done with a hammer and chisel, this is necessary in order to then install them in the appropriate places during reassembly.

If you do not do this, the following malfunctions are possible: vibration and beating when moving, this, of course, does not always happen, but still occurs, and it will be quite difficult to eliminate the cause yourself later.

Now you can begin to remove the driveshaft; to do this, unscrew the two thirteen nuts that secure the driveshaft to the car body.

Then you need to unscrew the rear part of the cardan, which is attached to the gearbox shank with four bolts.

Next we proceed to removing the crosspieces, to do this we thoroughly clean everything with a metal brush. We take special pliers for removing retaining rings and remove them photo 1.

If there are none, use a screwdriver to pry up the ring and use pliers to pull it out; even if it bends, it’s no big deal, we’ll still install a new one.

After which, once all the rings have been removed, we begin to knock out the cups of the cross. To do this we need a hammer and a drift or some kind of mandrel of the appropriate diameter.

If this whole process will take place on the floor, then we put something under the cardan eye so that when knocked out, the lower cup of the cross, and it is correctly called a needle bearing, does not rest on the floor.

Now we take a drift and place it on the upper bearing and hit it with a hammer, the lower one will fly down due to this, we also do the same from different sides (Photo 2).

After everything has been disassembled, we thoroughly clean the seats for the retaining rings, so that later there will be no problems with their installation.

Wipers on VAZ do not work

The serviceability of windshield wipers directly affects traffic safety. It happens that the wipers refuse to work in some mode or do not turn on at all. Why? Windshield wipers of all cars have at least two operating modes - intermittent and constant. For convenience, this list also includes additional options, for example, a slow speed of a constant mode, one stroke for quickly cleaning the glass, and so on, right down to adjusting the pause between strokes. Technically, this is all quite easy to implement: the intermittent mode creates an electronic or mechanical relay paired with a switch inside the electric motor, and with the constant movement of the brushes, voltage is constantly supplied to the same electric motor. Let's look at typical windshield wiper malfunctions and methods for finding them.

Wipers do not work intermittently

As mentioned above, the breaker relay is responsible for the intermittent operation of the wipers. It can be mechanical (on older cars) or electronic. Accordingly, if the wipers work in constant mode (which is created by bypassing this relay) and do not work in intermittent mode, there is a reason to check the relay.

However, before starting the test, you need to make sure that the relay is receiving voltage from the steering column switch set to the intermittent mode position. It may well be that the malfunction lies in it, and not in the relay. In the steering column switch, in particular, the corresponding contact may oxidize or the wire connecting it to the relay may break.

Based on this, you need to find a wiring diagram for the wipers on your car and check whether current flows from the switch to the relay. If not, look at the switch. If there is current, check the relay.

Wipers do not work constantly

When the windshield wipers work great in intermittent mode, but refuse to move constantly, you can immediately talk about a malfunction in the same steering column switch or problems in the area between it and the wiper motor. Simply put, the voltage from the switch is not supplied to the motor. You also need to check this electrical circuit with a multimeter or a test light to make sure that all terminals are clean and securely fastened.

The wipers don't turn on at all

If the windshield wipers do not react at all to the steering column switch, you should start with a classic check - make sure the fuse is intact. If it is intact, you need to check the steering column switch for voltage supply to it and correct closure of the contacts inside. Most likely, there will be no voltage on it.

A special case of complete failure of the wipers is when they are blocked by something. This could be a wrench left under the hood, a rag, or frozen wiper blades (read what to do if your wiper blades are frozen). For such situations, a special fuse is usually installed in windshield wiper systems. This device saves the wiper motor from overheating and failure by turning off the power. In the simplest case, such a fuse is a heat-sensitive plate that, when heated, changes shape and opens the contact. After turning off the voltage, it returns to its previous position and you can use the device (in this case, the wipers) again.

When the wipers are blocked, they usually still move at least a little from their “parking” position. Therefore, if there is still a slight reaction to switching on, check the freedom of movement of the brushes and trapezoid. Most importantly, do this with the wipers off.

! Accidental activation of the windshield wiper can cause serious injury!

The pause between strokes is not adjustable

If your car has the ability to adjust the pause between wiper sweeps and this function stops working, the adjusting resistor is most likely to blame. This part, depending on the rotation of the knob (or wheel), changes the resistance value in the wiper relay circuit, due to which it is possible to adjust the pause. This resistor should be replaced.

Where does which wire go, or just a diagram

Connecting wipers and washer

“Plus” power is supplied from the ignition switch through fuse No. 2 at 10 Amp of the mounting block. The permanent “plus” goes along the black and yellow wires to contacts “4” of the connectors of the gear motor and the steering column switch. It should not disappear even when the switch is in the “off” position. The blue wire supplies “+” 12 V power to the motor when the switch is in “continuous mode” position. On the blue-white wire, in the “off” position there should be a “minus”, and in the “continuous mode on” position the “minus” is turned off. This is done to slow down the motor when the power to the closer is turned off.

The red wire supplies the relay with “+” 12 V from the switch when the intermittent mode is turned on. At the moment of operation, contacts “2” and “4” close, and “1” and “3” open, the motor starts working and the brushes make one or two movements. Then “+” 12 V is turned off, and contacts “1” and “3” are closed to each other and to “minus”. The motor stops for a few seconds and then the cycle repeats.

The washer pump motor is connected to “+” 12 V constantly with a black and yellow wire through the same fuse No. 2. “Minus” is applied when you press the windshield wiper lever from bottom to top.

Video about how a windshield wiper works

Repair of windshield wiper VAZ 2106

Wiring diagram for windshield wiper and washer

| 1 – washer motor; 2 – windshield wiper and washer switch; 3 – windshield wiper relay; 4 – purifier gear motor; | 5 – fuse block; 6 – ignition switch; 7 – generator; 8 – battery. |

Execution order

Repairing a windshield wiper mainly comes down to straightening deformed parts of the lever drive or replacing them with new ones. We recommend replacing a faulty gearmotor with a new one. To check the condition of the gearmotor contacts, removing the windshield wiper is not required.

We remove the cover, opening access to the gearbox.

Unscrew the screws...

...and remove the cover.

We unscrew the screw of the bracket securing the wiring harness...

...and remove the panel with the gasket.

We inspect the contacts and conductive paths. We replace broken and worn elements in the assembly.

To remove the windshield wiper, disconnect the connecting block...

...and, having removed the left edge of the hood seal, remove the wiring harness from the panel slot.

Using a 10mm wrench, unscrew the nut securing the brush lever.

Using a 17mm wrench, pull the lever off the axle splines.

Use a 22mm wrench to unscrew the nut...

...and remove the bushing with the rubber gasket.

We also disassemble the drive of the second brush.

Using a 10mm wrench, unscrew the two nuts securing the windshield wiper to the body.

Carefully remove the cleaner, trying not to bend the drive rods.

Using a screwdriver, remove the short rod from the ball pin of the crank.

Using a 10mm wrench, unscrew the nut and remove the crank.

Use a 10mm wrench to unscrew the three bolts...

...and remove the purifier bracket.

To disassemble the gearmotor, remove the cover and panel with wires (as indicated above).

Using a screwdriver, remove the retaining ring...

...protective cap, steel and textolite washers.

After removing the seal and pressing on the axle, we push the gear out of the gearbox.

We remove the textolite and steel washers from its axis.

Using a screwdriver, unscrew the two screws securing the gearbox...

...remove the plates...

...and remove the motor housing, holding the armature by the worm with a screwdriver.

We remove the armature from the gearbox with the adjusting washer placed on its axis.

A spring and a thrust bearing installed at the end of the channel remain in the cover.

Remove the brushes from the brush holder. To remove dust from the electric motor, blow it with compressed air. We check the condition of the brushes, commutator and armature winding. The brushes must move freely in the brush holders without jamming, and the springs must remain elastic and not be damaged. We clean the collector with fine-grained sandpaper, then wipe it with solvent or gasoline

If the commutator is badly burned or worn out, it is better to replace the electric motor. We begin assembling the windshield wiper by installing the armature in the electric motor cover, for which...

...using a thin screwdriver we bend the end walls of the brush holders...

...and insert the brushes into them, recessing them completely, as far as the slots for the wires allow.

We install an anchor in the lid.

At the ends of the brush holder we insert the springs into place and bend the bent walls of the brush holders.

Having coated the gear and other rubbing joints with Litol-24 lubricant, we carry out further assembly in the reverse order of disassembly.

ATTENTION! To ensure proper operation of the wiper blades (so that the wiper blades stop in the correct position):

...before installing the gearmotor on the bracket, turn it on for a short time, connecting it to the vehicle’s on-board network via a connector.

Only after the electric motor has completely stopped do we disconnect the block and continue further assembly.

We install the crank parallel to the short drive rod.

Switching diagram for electric windows of the front doors

1 – main fuse block; 2 – relay for turning on electric windows; 3 – left door power window switch; 4 – right door power window switch; 5 – gear motor for the right door electric window; 6 – gear motor for electric window lifter of the left door; 7 – additional fuse block; 8 – ignition switch; A – to terminal “30” of the generator; B – to the instrument lighting switch; B – conventional numbering of plugs in the gear motor block.

Transmission oil change

To carry out the work you will need the following tools:

Changing the oil in a VAZ 2105 gearbox is carried out as follows.

The process of changing the oil in the rear axle gearbox of this vehicle is carried out in a similar way. First, the drain plug is removed, then a similar part of the gearbox is unscrewed. Transmission oil is filled to the lower level.

If the fluid in the gearbox or gearbox is dirty, it is necessary to flush the gearbox or gearbox housing. For these purposes, the oil is mixed with a diesel analogue, and the diesel content must be at least 30%. Lubricant is poured into the gearbox or gearbox. Next, the rear wheel of the VAZ 2105 is lifted onto a jack. The engine starts and first gear is engaged. In this position the car runs for 3-4 minutes. Then the oil is drained and fresh transmission fluid is added. The process of flushing the crankcase is carried out both independently and with the help of professionals. In any case, you must adhere to the above recommendations.

https://youtube.com/watch?v=CYtzF4p9KBU

Sources

- https://remont-vaz2106.ru/vaz-2105-kak-snyat-korobku-peredach

- https://avtovazlada.ru/index.php?page=2989

- https://expertvaz.ru/2105/remont-korobki-peredach.html

Signs and possible causes

Here are the most common signs that indicate a malfunctioning element, as well as their main causes.

Streaks appeared on the glass.

A similar effect usually occurs when cracks form in the edge of the tape. Cracks can occur due to brushes running on dry, dirty glass, ice crust or insects stuck to the glass. To prevent this problem, you should remove any dirt or ice from the windshield before turning on your windshield wipers. This can be done with a napkin, and during frosts you need to use a special scraper that will remove ice from the surface. Cracks can also form due to the natural aging of the part. Under the influence of ultraviolet rays, rubber loses elasticity and other performance properties.

In this case, repair is impossible, and the correct solution would be to replace the brushes.

Cloudy glass.

The wipers are working, but the glass remains cloudy:

- there is resin or some viscous chemical compound on the surface;

- there was a longitudinal rupture of the rubber band.

In the first case, the glass must be thoroughly washed; for this you can use special chemical compounds. The second situation occurs when the cleaning element of the brushes does not maintain the specified operating angle; the wipers should be replaced.

Uncleared areas.

Such areas appear on the windshield due to deformation of the rubber tape. As a rule, one of the factors leads to this:

- contamination of frame brushes;

- change in shape under the influence of temperature.

Fixing the first type of problem is quite simple - you just need to remove the wipers and wash them with warm water. In the second case, when high temperature is applied to the element for a long time, the rubber band becomes deformed. Therefore, you should not leave your car in direct sunlight for more than one day. Or at least raise the brushes so they don't touch the glass.

Such deformation is usually irreversible, so replacement is necessary.

Wipers "jumping" on the glass.

This problem appears in such a way that the brush begins to jump on the glass, leaving streaks. The VAZ 2103 car is equipped with classic windshield wipers, in which the mechanism of the rocker arms, mounting unit or system leads can become loose. In this case, the play of the drivers and rocker arms is usually checked, as well as the correct attachment of the brush to the driver. Most likely it will need replacement.

There is another reason, which lies in the curved wiper leash, and the usual situation is when one side is cleaned well, while the other remains dirty. Most likely the leash is a little twisted and needs to be fixed or replaced.

This is what the main malfunctions of windshield wiper blades look like and their possible causes. To repair the windshield wipers of your VAZ 2103, you can contact Expo Car Service, a specialized auto service center that provides any restoration services for domestic and foreign cars.

We guarantee that our clients will not face large markups on work and will be able to benefit from high-quality and affordable service.

Main components of VAZ

I’ll say right away that in all the years of ownership of the “classic” by both me and my father, I don’t remember a time when I had to remove the windshield wiper trapezoid together with the motor. It turns out that in my case this mechanism was always quite reliable and never needed repair or replacement. If you are a little less fortunate, then using my VAZ 2106 as an example, I will try to describe the procedure for performing the procedure. And before that, as usual, I will give a list of necessary tools for repairs:

- Open-end or combination wrench 22

- 10mm socket

- Ratchet handle with extension

Wipers do not work on VAZ 2106

VAZ-2106 windshield wipers are driven by an electric motor that transmits torque through a gearbox to a mechanism that drives the blades. The easiest malfunction of this device to troubleshoot is the weakening of the crank fastening, which occurs due to the loosening of the fastening nut under the influence of vibration. Once you tighten it, everything returns to normal.

Another malfunction that leads to the fact that the blades, after turning off the wipers, do not return to the lower edge of the windshield, occurs due to an increase in the gap between the contacts of the limit switch, or due to their burning. In this case, you will have to either bend or clean these contacts.

If the wipers refuse to work in a mode called intermittent, then the culprit for this malfunction will be the windshield wiper relay. It most likely has stuck contacts or a burnt out winding. The contacts can be cleaned and then the relay will work, but if the winding is at fault, the relay will have to be replaced.

In the cold season, at subzero temperatures, the wiper blades may freeze to the windshield and will not be able to move when the windshield wiper is turned on. In this case, warm water will help to warm them up.

The remaining malfunctions can be divided into two groups: the wiper motor works, but the brushes do not move and when the electric motor does not work. In the first case, the culprit may be a gearbox whose plastic gear teeth have been cut off. In the second case, when the noise of the windshield wiper motor is not heard, there may be many more reasons. This could be a blown fuse or a malfunction in the wiper switch located on the steering column, as well as wear on the commutator brushes.

Troubleshooting equipment

A failed washer that does not blow the windshield with a special liquid is restored. Most often, the injection pump needs to be replaced, which occurs in the following sequence:

- The contact group is removed from the device.

- Using a short screwdriver, remove the compressor from the hole.

- In its place we insert a new unit into the tank.

- We put connectors on the contact group, after which you can perform the test.

The engine operates with a characteristic sound when functioning correctly. The glass is blown with a water jet from the nozzles. If the tubes are replaced, you will have to wait a little time for them to fill with liquid. Using this system as intended will allow you to drive in any weather.

Technical side of the issue

How to modify the wiper relay?

Let's start with why this is needed at all. In heavy rain, the classic wipers cope very well, and the speed is quite decent. But when the rain is lightly drizzling, thousands of “classic” drivers scold the plant for the fact that it is impossible to select the required frequency of operation of the windshield wipers. And so, it turns out that they work on dry glass for a long time, which is not good. To avoid this unpleasant phenomenon, you have to turn the wipers on and off manually.

Many will say that there is nothing complicated there - turn it on/off, yes, I agree, but if you drive at least 100 kilometers, your opinion will change.

Description of frameless brushes

If you install frameless wiper blades on a VAZ 2106, you will feel the difference. They are more expensive. They are also in great demand among car enthusiasts. They last a long time, operate quietly and clean glass well. Such windshield wiper blades on the VAZ 2106 are less susceptible to temperature effects, do not freeze due to frost and work well during snowfall. It is necessary to change the device when the rubber tip has weakened (stopped cleaning). This means that the wiper housing is worn out and does not provide sufficient contact between the cleaning surface and the glass.

Lighting repair

Possible causes of malfunction

So, if the low beam on a VAZ 2106 in one of the headlights has disappeared, then, as mentioned above, most likely the light bulb has burned out.

If replacing the lamp does not produce results, then the following malfunctions may occur:

- The contacts in the block are oxidized or burnt;

- The fuse has blown;

- The relay has failed;

- The switch is faulty;

- There is a break in the circuit.

Below we will take a closer look at how to diagnose and fix the problem.

H4 standard double filament bulb

Replacing a light bulb

First of all, it should be said that the low beam lamp on the VAZ 2106 complies with the H4 standard, i.e. it has two threads, which allows the headlight to operate in two modes. Currently, such light bulbs are produced by different companies, both well-known brands and little-known companies.

It should be noted that domestic light bulbs are very popular among car owners. Their price is significantly lower than their imported counterparts, but at the same time they are not inferior in quality.

Advice!

It is advisable to change the bulbs in two headlights at the same time, since their service life is approximately the same. In addition, different lamp models may differ in glow.

Instructions for doing this work look like this:

First of all, you need to use a flat-head screwdriver to dismantle the plastic panel that frames the headlights.

The photo shows the dismantling of the plastic panel

- Then use a Phillips screwdriver to loosen the clamps that hold the headlight.

- Next, you need to slightly turn the metal hoop and dismantle it.

Headlight fixing screws

Now you can pull out the headlight with your own hands and disconnect it from the block

At this stage, you need to pay attention to the connector contacts. If necessary, they need to be cleaned. Then you need to unfasten the lock and remove the light bulb. Next, the work is performed in the reverse order - a new lamp is installed, which is pressed with a clamp, and the block is connected to the contacts

The headlight assembly must be installed in place and secured with a hoop. To complete the work, a plastic panel is inserted, on which you need to press lightly until you hear a characteristic click.

Note!

When replacing a lamp, do not touch its glass bulb with your fingers, otherwise it may quickly burn out. If you do touch glass, you should wipe the surface with a cotton swab soaked in alcohol.

This completes the process of replacing the light bulb.

Replacing fuses

If after replacing the light bulb the low beam headlight on 2106 still does not light, you should check the fuses. They are located under the instrument panel.

Fuse box location

In this case, you need to pay attention to two fuses:

- No. 5 – protects the left headlight from short circuit;

- No. 6 – protects the right headlight.

It must be said that the low beam on the VAZ 2106 often does not work due to the fuse contacts being bent or oxidized. In this case, they need to be bent and cleaned. If the protective element has melted, it must be replaced.

Fuse diagram

Note!

The contacts in the fuse box cannot be closed directly, since the protective element could burn out due to the failure of the electrical equipment; accordingly, this could lead to more serious damage or even a fire in the VAZ wiring.

https://youtube.com/watch?v=Sp-9eKkz-IQ

https://youtube.com/watch?v=6VxE8x8KVaQ

Main causes of failures of additional equipment

If the washer on the car does not work, it is necessary to diagnose it using simple techniques. This system may fail for a number of reasons, which are listed below:

- breakdown of the injection pump;

- fuse blown;

- kinking or squeezing of the supply hose;

- breakdown of the steering column switch;

- freezing of water in pipelines or other devices;

- loss of contact in the electrical network.

It is possible to determine the cause of the malfunction and the amount of costs to restore the system's functionality based on the results of a careful inspection. If you need to replace individual parts or elements, you can do it yourself. The device that blows the windshield to clean it from fresh or dried dirt does not work.

Most likely, you will need to replace failed equipment.

Problems when paying with bank cards

Sometimes difficulties may arise when paying with Visa/MasterCard bank cards. The most common of them:

- There is a restriction on the card for paying for online purchases

- A plastic card is not intended for making payments online.

- The plastic card is not activated for making payments online.

- There are not enough funds on the plastic card.

In order to solve these problems, you need to call or write to the technical support of the bank where you are served. Bank specialists will help you resolve them and make payments.

That's basically it. The entire process of paying for a book in PDF format on car repair on our website takes 1-2 minutes.