Shock absorber: its role in suspension operation

An automobile shock absorber is a mechanism in the suspension of a car that serves to partially dampen the swaying (damping) that occurs during movement or completely absorb it.

Giving the car a smooth ride, shock absorbers act as protection for the car's chassis from overloads when driving on uneven roads and rough terrain. In the suspension, the shock absorber acts as an element to increase its elasticity along with the spring and torsion bar.

Shock absorbers are divided according to their types:

- gas single-pipe;

- gas two-pipe;

- oil two-pipe.

On the VAZ-2115 model, standard oil shock absorbers are installed at the factory. Later, when using the car, owners often replace them with gas ones, depending on their driving style.

There are 3 types of racks with different characteristics. You need to choose them based on the roads on which traffic occurs. Oil (hydraulic) – quite elastic. Designed for drivers who prefer a calm, measured ride or frequent trips on unpaved roads.

Gas shock absorbers are characterized by higher rigidity, and, as a rule, they are preferred by motorists who practice an aggressive, highway driving style. Such shock absorbers (gas) prevent swaying that occurs at high speeds and turns. Gas-oil shock absorbers combine the advantages and disadvantages of both types.

Front shock absorbers for VAZ 2113, 2114 and 2115

The front shock absorbers here are divided into right/left and have different part numbers. But their sizes are the same. As drivers note, these shock absorbers are moderately hard and hold the road well. If they are not used too intensively over uneven surfaces, the racks will last quite a long time.

Often, Samara 2 drivers install dozens of shock absorber struts on the front wheels (VAZ 2110). This car is heavier and the shock absorbers are a little stiffer. Therefore, when installing them, the front end rises slightly, and the suspension itself becomes a little stiffer. The table below shows the dimensions of the current original shock absorbers.

| Dimensions of original front shock absorbers for VAZ 2115, 2114, 2113 | ||||

| vendor code | Rod diameter, mm | Case diameter, mm | Body height (excluding stem), mm | Rod stroke, mm |

| 21700290500300 - left; 21700290500200 - right | 22 | 52 | 361 | 171 |

These shock absorber struts are also installed on Prioras of all modifications. Previously, slightly different part numbers were installed on the front wheels of VAZs 2115, 2114 and 2113: 21080290500200 - right, 21080290500300 - left. Now spare parts with these numbers are not sold.

Analogs of front shock absorbers for VAZ 2115, 2114, 2113

Numerous analogues are quite popular. Car owners are looking for substitutes to make the front suspension a little stiffer and increase ground clearance. In addition, the price of original spare parts is clearly overpriced. The following are the most popular analogs of shock absorbers VAZ 2115, 2114, 2113.

| Manufacturer | vendor code | price, rub. |

| Hola | S503 – left; S504 - right | 2000 |

| Trialli | AH 01159 – left; AH 01360 - right | 1900 |

| Pilenga | SH-P 2771–O – left; SH-P 2770-O - right | 1700 |

Determining the malfunction of the rear shock absorbers of the VAZ-2115

The role of shock absorbers in ensuring the safe operation of a car is often not taken into account by many, especially novice car enthusiasts. And this can lead to unpleasant and even tragic events. If the shock absorber fails, or even partially fails, the car wheel loses contact with the road.

And, as a result of this, the braking distance increases in case of emergency braking. When cornering, the stability of the car deteriorates, the chassis and tires are subject to greater load, which leads to their wear, and so on.

How to determine if a shock absorber is faulty

The first thing to do is conduct a visual inspection. Oil stains on the shock absorber itself, boot or rebound buffer warn that it needs to be replaced. Also, uneven tire wear may be an indication of problems with the rear suspension strut.

When driving at a speed of more than 80 kilometers, the car's handling noticeably deteriorates, the steering reacts late to road irregularities, and the car's swaying does not subside.

But the most reliable way is to inspect it at a specialized service station stand.

Sequence of work when replacing shock absorbers

Before dismantling the VAZ-2115 rear shock absorber, you need to remove the plastic plug from the rear strut cup and unscrew the nut securing the rod. To do this, use a special key that simultaneously fixes the rod and unscrews the nut.

After removing the nut and washer with a rubber cushion, jack up the car and remove the rear wheel to gain access to the bottom of the rear strut mount.

Using a 19-mm open-end wrench, we fix the nut, and with a 19-mm socket, we unscrew the bolt, lubricating it with pre-penetrating lubricant, unscrewing and removing the bolt from the hole, and remove the rear shock absorber from its seat. To do this, it is better to use a flat-head screwdriver, carefully prying up the lower part. The strut body is moved to the side, lowered down and the shock absorber is removed.

We take out the remaining rubber gasket inside the glass with the same screwdriver. We disassemble the old shock absorber, removing the spring, rubber bushing, cup, casing, bump stop, and then install these parts in the opposite (reverse) order on the new strut.

When installing the spring in place, the last coil should be in such a position in the lower cup of the rear shock absorber that the end of the spring does not extend beyond the cup. And after the installation of the stand is completed, it should be directed towards the wheel. Before installing the shock absorber, it is recommended to immediately put on the upper elastic band and, so that it does not change its location, use insulating tape to attach it to the coils of the spring.

Upon completion of complete assembly, the rear strut is installed in the reverse order, the upper nut and the lower bolt securing it are tightened.

Source

Replacement of front struts VAZ 2108, 2109, 21099

The front struts of VAZ 2108, 2109, 21099 cars and their modifications will have to be removed and replaced or their parts in case of the following malfunctions: leakage of shock-absorbing fluid, breakdown and knocking when driving, breakage and settling of springs, replacement of anthers and upper supports with support bearings , mechanical damage to parts, front suspension tuning. We replace shock absorbers and (or) or springs of the front struts on VAZ 2108, 2109, 21099 cars in pairs (on both sides). If the stand assembly is replaced, then we also change two at once.

Required tools and accessories

— Socket wrench or socket on “13”

— Spanners for “17” and “19”

— Device for unscrewing the front strut shock absorber rod nut

Tool for loosening the front strut shock absorber rod nut

— Soft metal drift

— Blowtorch or gas torch

Preparatory work

— Jack up and remove one of the front wheels of the car

— We clean the elements of the front suspension of the car from dirt

— We disengage the brake hose from the bracket on the rack

Replacing front struts on VAZ 2108, 2109, 21099 cars

Disconnect the tie rod end from the strut housing arm

Either we remove it with a special puller, or we disconnect the connection the “folk” way (using a pry bar and a hammer). Read more: “Replacing tie rod ends on VAZ 2108, 2109, 21099 vehicles.”

We disconnect the tie rod end using a pry bar and a hammer, creating tension in the connection and hitting the end of the boss

Loosen the shock absorber rod nut

In case you plan to disassemble the rack.

Loosen the shock absorber rod nut using a special tool

Unscrew the three nuts securing the upper strut support to the body

Use a socket wrench or socket set to “13”.

Unscrew the nuts securing the strut housing to the steering knuckle and remove the bolts

It is necessary to mark the position of the adjusting bolt (the upper bolt with the eccentric) with paint or a chisel, so that when installing the rack, it can be returned to its original position. In this case, the camber angle of the front wheels of the car practically does not change.

Unscrew the bolts securing the strut to the steering knuckle of the front suspension

There may be problems at the stage of removing the bolts, as they often become soured in the holes in the steering knuckle. If it was not possible to turn the bolts with a wrench, then first tap them with a hammer, then try to knock them out through a drift. In the most severe case, we heat the steering knuckle at the place where the bolts are attached using a gas torch or a blowtorch and try to unscrew them. Read more: “How to unscrew the bolts of the front struts of VAZ 2108, 2109, 21099 cars.”

Remove the front strut assembly from the car

Pull it out of the wheel arch to the right or left of the hub. Please note that the front pillar is quite heavy.

If necessary, we disassemble the front strut and replace failed parts

We replace the second rack in the same way. The tightening torque of the rod nut is 66-81 N.m, the bolts securing the strut to the steering knuckle are 78-96 N.m.

After replacing the front struts of a VAZ 2108, 2109, 21099 car, it is necessary to check and adjust the angles of the front wheels.

Notes and additions

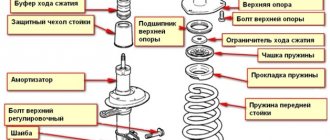

— The front strut of VAZ 2108, 2109, 21099 cars consists of a shock absorber body (“cup”), a shock absorber cartridge, a spring and an upper support with a bearing. Non-separable front struts are also available, without a cartridge, with a built-in shock absorber.

— Another option for replacing the front struts on VAZ 2108, 2109, 21099 vehicles, which does not disrupt the wheel camber angle, is to remove the strut along with the steering knuckle. To do this, you do not need to unscrew the bolts securing the strut to the steering knuckle, but rather unscrew the front wheel hub nut, disconnect the tie rod end from the steering knuckle, unscrew the two bolts securing the ball joint and remove the strut.

TWOKARBURATORS VK -More information on the topic in our VKontakte group

Do-it-yourself replacement of rear struts of VAZ 2113, 2114, 2115

If you hear dull sounds characteristic when driving on uneven sections of the road, and upon inspection you find deformation of the spring, damage to the rod and/or leakage of fluid, your car needs to replace the rear struts of the VAZ 2114, 2115 or 2113. Unlike the elements on the front of the car, they they break down less often, but if problems are detected, they need to be replaced as soon as possible, since strong vibrations do not have the best effect on all parts and assemblies of the machine. Restoration measures are simple; in this case, DIY repairs are possible even for a beginner. How to fix it will be discussed in this article, but first you need to familiarize yourself with the structure of the unit.

Replacing front struts, springs and supports on a VAZ 2114-2115

The front struts on VAZ 2114-2115 cars wear out much faster than the rear ones, and this is due to the fact that the front part of the car bears a large load, since the main units are located there. If the shock absorbers are leaking, or are starting to leak heavily in potholes, then it would be best to completely replace them. Many people are used to dealing with such problems at a service station, although if you try a little, you can do it all on your own. The main thing is to have all the necessary tools and equipment at hand. Below is a detailed list of everything:

- spring ties

- ball joint or steering wheel remover

- pliers

- hammer

- keys for 13 and 19 as well as similar heads

- crank and ratchet handle

- breakdown

I recommend that you first familiarize yourself with the video, which will be presented below, and then read my photo report on the work done.

Video on replacing front struts on Lada Samara cars - VAZ 2114, 2113 and 2115

If for some reason you were unable to watch the video, you can read the step-by-step instructions with photo materials. There, too, everything is clearly described and understandable, so that even a beginner can figure it out.

Guide to self-replacement of front suspension struts on VAZ 2114 - 2115

The first step is to put the car on the handbrake, remove the front wheel bolts and jack up the car. Then finally remove the wheel and you can begin this repair of the chassis on the VAZ 2114-2115.

First, you need to release the rack from the mount with the steering tip. Read about this in more detail in the article on Replacing tie rod ends. After we have completed this task, unscrew the two nuts securing the strut to the lever from below, as is clearly shown in the photo below:

And we try to pull out the bolts from the back side with our hands. If this cannot be done due to rusted connections, then you can use a punch or a wooden block to knock out the bolts with a hammer:

When the bolts pop out, the stand can be moved to the side, thereby disconnecting it from the lever:

Now open the hood and unscrew the three nuts securing the front support to the body glass of the VAZ 2114-2115. This is clearly shown in the picture below:

When you unscrew the last nut, hold the stand from below so that it does not fall. Then you can remove it without any problems:

So the entire front suspension module has been removed. To disassemble it, we will need spring ties and a special wrench to unscrew the central nut on top of the support. The first step is to loosen the top nut, holding the rod from turning:

Never let go completely, otherwise you might get a spring on your forehead or something else. Tighten the springs using special tools

And only then unscrew the nut completely and remove the upper support cup:

Then you can start removing the support itself:

And then the springs:

Now all that remains is to remove the rubber boot and compression buffers and you can begin replacing all the necessary parts of the front suspension: support bearings, supports, struts or springs. The entire assembly process is carried out in strictly reverse order and does not take much time. When installing the module on a car, it is possible that you will have to tinker a little so that the holes in the strut body itself and the lever line up at the bottom. But if you have a mount, you can do it yourself!

The prices of components are approximately the following (for example, I will name from the manufacturer SS20):

As for the remaining parts, such as compression buffers and anthers, in total you will spend about 1 thousand more rubles. Of course, the effect after installing a non-factory suspension is simply pleasing. In general, I’ll write about this in future articles.

Preparing for repairs

When replacing the rear struts of a VAZ-2115 with your own hands, you need to follow a certain sequence. Only in this case the repair will take place as quickly as possible. Rear struts are much easier to change than front struts - there are no steering ends, and there is no need to adjust the wheel camber and toe angles.

- Place the car on a viewing hole or overpass.

- Install wheel chocks under the front wheels.

- Loosen the bolts securing both rear wheels.

- Lift one side, completely unscrew the bolts, and place a reliable support under the body. Then do the same on the second side.

- As a result, the suspension should be completely unloaded. You cannot work on a loaded suspension - it is dangerous.

You cannot place supports under the beam - in this case the suspension will be loaded. If you only need to replace the silent block of the VAZ-2115 rear pillar, then you only need to unscrew the lower fastening. There is no need to completely remove the assembly.

How to change the rear struts on a VAZ 2110 yourself?

After 50 thousand km. mileage, it’s time to think about how to change the rear struts on a VAZ 2110-2112. Even if there are no obvious signs of wear, after such a long period of use, you should worry about this in advance and purchase new rear struts. This operation is not an overly complex or time-consuming job and does not require any special tools, so it is not necessary to go to a service station to carry it out. Replacement of rear shock absorbers can be easily done on your own in a garage.

TOP 10 best racks for VAZ and Lada cars

The suspension system of Lada cars is a successful solution for domestic roads. There is a lot of user debate on the Internet about which are the best racks for a VAZ in terms of cost and quality. Therefore, making the right choice is problematic. Properly selected parts stabilize the car in corners and give it stability when driving on bumpy areas. The price for VAZ racks starts from 4,000 rubles per set and ends at 15,000 rubles. a piece. However, in some cases, a high price tag is not an indicator. The compiled rating will help you determine which VAZ racks are good.

Do-it-yourself replacement of rear shock absorber struts on a VAZ-2112

The entire design of the rear shock absorber struts is completely identical to that of the younger model VAZ-2109, which is why the work to replace it is absolutely the same. Let’s say right away that replacing the rear struts is much easier to carry out than replacing the front struts. You can easily carry out such work with your own hands and in a short period of time. How to easily carry out this work is described below in our article.

The video shows the process of replacing rear shock absorber struts on VAZ cars of the 2110-2112 family.

Required tool for replacement

When the tool is ready, you can start working.

Before you begin work, you need to prepare the following tools:

- A driver or ratchet wrench.

- Head at “17” and “19”.

- Lubricant like WD-40.

- Spring ties.

- Jack.

- Special key for the rack rod.

Preparatory work

Carry out the following preparatory work:

- When the car is secured on a level surface, remove all the nuts on the rear wheels. Then we lift the car on a jack and finally remove the wheel.

- It is also necessary to loosen (but not completely unscrew - approx.) the nut securing the strut rod. This is done either from the trunk or the rear seat.

- Treat all unscrewing surfaces with lubricant for best unscrewing.

New elements are ready for installation.

Step-by-step work order

- First of all, we remove the plug and unscrew the nut on the rear pillar rod, and in order to prevent it from turning, you can use a regular “6” key or a special one - which is intended for this.

The plug will come off easily by prying it off with a screwdriver.

With some force, the nut will unscrew

The lower mount for the rear pillar sometimes sticks.

It is necessary to tighten the springs until they release the upper cup. The photo shows an example with a front shock absorber on a VAZ-2112.

Removing the rack components

- With the rack removed, we inspect the condition of the boot and bumper, and when installing new racks, we replace them, or if they are in good condition, we leave them.

As you can see, the bumpers are in worn condition.

Rear shock absorber assembly

We assemble all elements of the rear pillar strictly in the reverse order, paying special attention to all connections and places where the pillars come into contact with the body.

The stand is installed and ready to use.

Which racks to choose (poll)?

Prices for racks for VAZ-2112

In all stores that offer spare parts for cars of the VAZ family, you will find rear struts for the VAZ-2112 to suit your wallet and all the most necessary characteristics.

HOLA rear struts have proven themselves well

- for racks of good characteristics will vary within 5000 rubles per pair,

- for springs 3000 rubles,

- for buffers 500 rubles,

- and for anthers 300 rubles.

conclusions

Thus, a complete replacement of the rear shock absorber struts will cost less than 10,000 rubles, since thanks to this instruction, you will significantly save on the work of replacing them.

It’s not an incredibly easy task, as my friend and I thought. But after everything is ready, it seems that it is not so difficult. You just have to try to do it yourself.

Choosing racks for a VAZ: top best

1st place: KONI

The rating of racks that are suitable for VAZ is headed by the Koni company. This is a popular brand represented on all continents. The Dutch brand provides a lifetime quality guarantee on all equipment supplied to Germany. However, the quality of the batches imported to the CIS is not inferior to the standard.

FSD shock absorbers are popular among domestic car enthusiasts. The implemented technology allows the dampers to automatically adjust to driving conditions and speed limits. Buying racks for a VAZ 2114 or 2115 will be very expensive, but the expense is worth the effect of use. Thanks to the high throttle response of the suspension, the control and directional stability of the car are noticeably improved.

However, experts criticize the need to install a full set of shock absorbers. When mounting racks on only one axis, the desired effect is completely lost.

Advantages:

- excellent quality;

- high stability;

- long service life.

Flaws:

- price.

2nd place: SACHS

The German brand, which supplies components to 17 countries, falls slightly short of first place. The main advantage of the product is the presence of a factory warranty for 2 years. For domestic VAZ cars, two types of shock absorbers are relevant.

Everyday racks are marked with blue stripes, which indicates moderate rigidity and sufficient comfort of movement. Rigid, racing versions have increased stability and cornering performance.

Among the negative factors, buyers highlight a large number of fakes - the popularity of the brand has a negative impact on original spare parts.

Advantages:

- availability of factory warranty;

- stable behavior in difficult climatic conditions;

- excellent efficiency.

Flaws:

- a large number of fakes.

3rd place: BILSTEIN

The top three is opened by a manufacturer popular all over the world. The manufacturer supplies products to leading automobile factories in Europe and the USA. If you have a question about what struts to install on Vesta to improve driving characteristics, you can safely contact the company.

The brand has two types of shock absorbers.

- Gas-oil - designed for hard use in sports mode and aggressive driving. Holds turns and high-speed maneuvers perfectly. Among the disadvantages, users include a complete lack of comfort - the rigid suspension “shakes” the entire breakfast out of the driver.

- Oil racks are good quality racks for everyday use, they have sufficient comfort and stability.

Advantages:

- excellent build quality;

- good driving characteristics.

Flaws:

- there are fakes;

- high price tag.

4th place: Kayaba

A Japanese brand introduced in Russia more than 20 years ago. The organization supplies parts to Toyota and Nissan factories, which guarantees excellent quality of all products - strict quality control eliminates differences in assembly for different countries.

The manufacturer's range includes shock absorbers designed for urban and sports use. In Russia, 4 lines are especially popular.

- Gas-a-Just - reinforced single-pipe design is perfectly compatible with the harsh operating conditions of domestic roads. For Zhiguli car enthusiasts, this is a decisive factor during the purchase.

- MonoMax - the best front struts for VAZ. According to customer comments, they are distinguished by increased sensitivity on small bumps and irregularities. Thanks to the characteristics, the steering is radically improved.

- Kayaba Ultra SR is a lightweight version designed for sporty riding. Provides good handling when cornering on a flat road. The downside is excessive rigidity.

- Exel-G – the price of a set of racks for a VAZ 2115 starts from 15,000 rubles. However, the cost is completely justified. These are high-quality shock absorbers with good running performance.

Advantages:

- excellent quality;

- wide range of standard sizes;

- confident compatibility with winter frosts.

Flaws:

- the price tag is a little high;

- a large number of fakes.

5th place: BELMAG

A popular domestic manufacturer that supplies parts to the assembly lines of Lada and GAZ companies. In 60% of cases, such racks on VAZ 2112/2115 or Kalina are stock.

The series series of shock absorbers is distinguished by good reliability and good performance. The racks are moderately soft and reliably hold the road. They also perform well on primers. Hydraulic shock absorbers adequately withstand critical frosts and the “impeccable” condition of domestic roads.

A wide network of branded stores and partners ensures the necessary distribution throughout the CIS countries.

Among the negative aspects, users highlight excessive softness - on the highway at a speed of more than 90 km/h, the car may sway.

Advantages:

- good assembly;

- holds the road well;

- moderate cost;

- wide use;

- durable design.

Flaws:

- excessive softness when speed increases;

- there is a marriage.

6th place: BOGE

The next representative is quite a bit inferior to the competitor who took fifth place in the ranking. Positive reviews of racks for VAZ and other domestic manufacturers indicate good quality assembly and good driving characteristics of the products. This kit can replace the standard stabilizer struts on a Lada X Rey or Largus.

The brand is a supplier of parts to the assembly lines of the Volvo and VAG automakers, which indicates high quality products and modern solutions.

Among the general model range, the company has two lines of shock absorbers, produced in Lada sizes.

- Turbo-Gas are rigid and reliable struts designed for racing loads. They are not afraid of primers and can withstand prolonged heating or dynamic loads.

- Automatic – moderately tight and comfortable shock absorbers, designed for normal “every day” use. They stand out among competitors due to their good comfort and good handling.

According to sources, for the maximum effect of the parts, you will need to install a full set of 4 pieces. When steaming, third-party units can reduce the efficiency of the units.

Advantages:

- noticeable improvement in control;

- stable operation under temperature changes;

- sufficient choice of modifications;

- great build.

Flaws:

- there are fakes.

7th place: DELPHI

Stiff, racing shock absorbers presented on the domestic market by a British company. The brand is the main supplier of suspension components for GM conveyors.

If the user is going to improve the suspension of the VAZ 2110, which struts to install, the choice is obvious. The company has created a line of shock absorbers of suitable sizes specifically for the Lada. The models use a modern damper system and synthetic oil of optimal viscosity. The combination guarantees excellent directional stability and stable behavior in high-speed corners, which will protect a fast motorist from running into a ditch. It also uses advanced alloys, which minimizes the coefficient of thermal expansion and creates the necessary stability during overheating.

The other side of the coin is its inability to cope with bumpy roads and sections of dirt roads. Due to the reduced cross-sections of the bypass valves, the struts wear out quickly. The second negative factor is the complete lack of comfort - the hard suspension makes your teeth “chatter” in some situations.

Advantages:

- excellent stability of the car on the road;

- withstands long turns at high speed with minimal roll.

Flaws:

- price;

- lack of comfort while driving;

- wear out quickly on bad roads.

8th place: Fenox

In eighth place is the company whose parts are most common on classic Lada car models. If the buyer is interested in the dilemma of which racks to install on the VAZ 21099 and similar ones, it is recommended to contact this company. Also here you can find optimal solutions for modifications 2101-07, 2109.

The brand produces front and rear struts of good quality. Oil-type shock absorbers provide sufficient directional stability and handle small things well in the form of small holes and paving stones. Also, the parts withstand frost tests perfectly and function properly at temperatures down to -25 degrees Celsius.

However, the models are not intended for driving on primers - under conditions of critical overload and heating, the seals quickly wear out. So, it will be better for rural residents to pay attention to the next applicant.

Advantages:

- moderate cost;

- wide range of classics;

- good quality;

- few fakes;

- perform well in the cold.

Flaws:

- short service life;

- Can't stand dirt roads.

9th place: Monroe

The next representative of the list comes from the USA, however, it is produced in Belgium. The company's products are famous for their high-quality cases and high-quality fillings, which, at a moderate cost, ensure good demand among car enthusiasts.

The model range consists of 25 varieties of shock absorbers and struts installed on foreign and domestic cars. Thanks to strict quality control, the company eliminates the possibility of defects or hidden defects by 99%.

When asking which pillars are softer to install on a modern-generation VAZ, it is recommended to pay attention to the Reflex modification. This is a gas-oil version intended for use on asphalt. The average mileage to failure is 30,000 km, which is quite tolerable.

If a user is willing to sacrifice comfort for durability, the Van-Magnum generation is a smart choice. The racks are designed for off-road use and are distinguished by their increased range and durability, which guarantees up to 50,000 kilometers of driving range.

The only caveat is the need to carefully select and search for trusted stores - there are a large number of copies of dubious origin on the market.

Advantages:

- The optimum ratio of price and quality;

- wide range of models;

- good strength;

- long service life.

Flaws:

- a large number of fakes.

Assembly of the unit

After purchasing all the new components, you only have to do a few simple steps:

- Compress the spring using a puller. It must be installed in such a way as to engage at least three turns.

- Install rubber pads on the spring; they can be secured with tape or tape.

- Place the bump stop on the rod and the boot on top.

- Install the rod into the hole in the body and tighten the nut.

- Secure the lower part of the shock absorber to the rear beam by aligning the holes and inserting the bolt. Tighten the nut.

Do-it-yourself replacement of rear shock absorbers on a VAZ 2110 (video)

It is not difficult to replace the rear pillars of a VAZ 2110 even in your own garage without the help of specialists. Self-repair will not take much time, but will save an impressive amount of money that you would have to pay at a service station.

Tasks of the rear pillars

Beam design diagram As a result, the racks affect comfort and safety. There are several main tasks of these elements.

- They are responsible for wear on the chassis and help shock absorbers when the body “bounces.” After all, if the car jumps, at that moment the wheels do not contact the surface, the brakes do not work, and lateral forces act on the body. It is not safe.

- Increases driving comfort. The lack of effective cushioning negatively affects comfort. Especially when it comes to uneven road sections.

- Properly installed shock absorbers minimize braking distances and prevent the body from oscillating when bouncing.

If the struts are poorly installed, the braking distance will increase noticeably, the body will sway to the sides when bouncing, which will lead to wear on the chassis, tires and other elements of the car.

Knocks

You should approach this issue wisely, study the replacement procedure in a video, consult with specialists, and be sure to review the operating manual for your car.

Knocks occur for various reasons from the rear, so this should be looked into in more detail.

- If knocking noises are observed when driving on uneven ground, the shock absorbers have apparently failed. The only solution is to replace with new ones.

- If you see that the rubber bushings of the levers are worn out, change the suspension.

- When the spring settles, it must be replaced.

- A knocking sound is likely a sign of a loose shock absorber or worn rubber eye bushings.

- When the rear suspension is overloaded or damaged, knocking noise also occurs.

- If the bushings of the suspension arms are destroyed, the rear axle moves and a knock appears.

- When knocking is observed from the suspension arms, it is recommended to replace them with new ones.

- Knocks can also be determined by how busy the rear part is. Empty the trunk and do not seat anyone in the second row. This makes it easier to figure out what the reason is - shock absorbers or springs.