Ignition coil VAZ 2106 is part of the car’s ignition system, so if your “Six” begins to have difficulty starting, or the spark to the spark plugs has disappeared, most likely the cause of the malfunction lies precisely in it.

In today’s article we will look at the principle of operation of the ignition system of a VAZ 2107 car, what the ignition coil is needed for and what it is responsible for, where it is located, typical signs of a malfunction and methods for repairing this element of the car.

The principle of operation of the ignition system of the VAZ 2106

Almost all classic models are traditionally equipped with a standard contact-type ignition system (KSZ). An exception is 21065, which uses a non-contact transistor circuit in which an interruption of the primary winding power circuit is realized using a breaker mounted in the distributor. Below we will consider in more detail how the contact ignition system of the VAZ-2106 is designed and works.

VAZ 2106 ignition system diagram

The ignition system is needed to create and supply a spark discharge to the spark plugs. A spark is supplied to the spark plugs at certain moments - the operating cycles of a gasoline engine.

The design of the ignition contact circuit includes the following components:

- lock (switch);

- coil (short circuit);

- breaker (MP);

- distributor (MR);

- regulators, centrifugal and vacuum (CR and VR);

- candles (SZ);

- high-voltage wires (VP).

Let's take a look at the ignition coil and take a closer look at what it is needed for and what it is responsible for.

Checking the ignition system on a VAZ 2106 car

| WARNING The VAZ 2106 is equipped with a contact ignition system. A voltage of approximately 24,000 V is supplied to the high-voltage wires (as an option, a contactless high-energy ignition system can be installed on a VAZ 2106 car - a voltage of approximately 40,000 V). At low current levels, this voltage is not life-threatening, but can lead to electrical injury. Therefore, if you handle a high-voltage wire with the ignition on, use a thick rubber glove or, as a last resort, pliers with insulated handles. |

To check the ignition system on a VAZ 2106 car, you will need: slotted and Phillips screwdrivers, pliers with insulated handles and a tester or 12 V test lamp with two wires connected to it. You can also use a car portable lamp.

RECOMMENDATIONS Before checking the ignition system, place the gear shift lever in neutral and leave the parking brake on.

1. With the ignition off on the car, check the integrity and fit of the high-voltage wires in the ignition distributor cover, as well as the fit of the high-voltage wire in the ignition coil. 2. Check the wires going to the ignition coil and their connections. Also check the wire connecting the distributor and the ignition coil.

3. Turn on the ignition on the VAZ 2106 car. Check if current is supplied to the ignition system. Connect one wire of the tester or warning lamp to the “+B” terminal of the ignition coil, and the other to ground. If no current is supplied to the ignition system, then the fault is in the ignition switch or in the wiring from the switch to the ignition coil. In order to get to the nearest car service center, you can apply emergency power to the ignition system. To do this, connect the “+B” terminal of the ignition coil and the “+” terminal of the battery with an additional wire. Fasten the wires securely. Keep in mind that now, in order to turn off the engine, you will need to disconnect the additional wire from the “+” terminal of the battery.

WARNING If strong sparking is noticed when connecting to the “+” terminal of the battery, this method will have to be abandoned - most likely, the wiring is shorted to ground.

5. If there is no spark between the spark plug electrodes, remove the distributor cover. Check if there is a gap between the breaker contacts. To do this, use a special wrench to turn the engine crankshaft so that the top of the ignition distributor shaft cam is strictly opposite the textolite pad of the moving contact lever. The gap between the moving and fixed contacts of the breaker should be 0.35-0.4 mm.

NOTE When using an autotester, the closed state angle of the contacts (UCS) is measured, which should be 55°. The measurement is carried out with the engine running! An approximate value can be obtained by cranking the engine crankshaft with the starter.

6. If the gap (UZSK) does not meet the standard, adjust it and be sure to check the ignition timing.

Location of the ignition coil VAZ 2106

The VAZ 2106 ignition coil is mounted in the upper front corner under the windshield frame

Location of the VAZ 2106 ignition coil under the hood

Externally, it is a cylinder enclosed in a metal shell, having three terminals at the outer end.

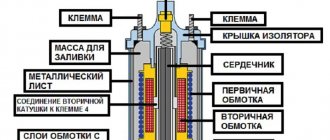

Device and connection diagrams for the VAZ 2106 ignition coil

The car coil is a high voltage pulse transformer. A thin wire of the secondary winding is wound around the core of the device. It contains 30 thousand turns. In accordance with the device diagram, a primary winding consisting of thick wire is located on top of the secondary winding. Both windings are connected to the car battery at one of their ends.

Photo: Used ignition coil or as car enthusiasts call it Babina VAZ 2106

The second end of the primary winding is connected to the distributor. The common connection point of the coil windings is connected to the voltage switch. The core plays the role of a magnetic field amplifier. At the moment the circuit breaks, a high voltage is generated in the secondary winding, which is supplied through a wire to the spark plug for breakdown and formation of a spark.

Device

The schematic design of the VAZ 2106 ignition coil is as follows:

Ignition coil device VAZ 2106

This assembly scheme has been practiced for quite a long time when completing the ignition systems of many types of cars. In its design, this ignition coil is similar to the device of a high-voltage transformer of a pulsed operating principle. A thin-section secondary type wire winding containing up to 30,000 turns is placed on the core, designed to increase the electrical potential. This design of the VAZ 2106 ignition coil involves placing a primary winding made of thick-section wire as a top coating layer.

Connection diagram

Some ends of both windings are connected to the battery, the other to a distributor that controls the power supply. During the winding process, the thin and thick wire will have points of contact. One of these points must be connected to a voltage switch. In this case, the function of the coil core is reduced to enhancing the magnetic field.

When connecting the coil, it is important to follow the order of connecting the individual wires in accordance with their functions

Determining why the ignition coil heats up

The main function of the coil is to convert low voltage voltage, which comes from a generator or battery, into high voltage. There is a generation of high-voltage electrical pulses on the candles. The ignition coil connection diagram provides a certain operating mechanism: when the starter is turned on, thanks to the contact disk, an additional resistance is turned on, this leads to an increase in the current passing through the primary winding, and, as a result, the voltage of the secondary winding increases, which contributes to the reliable ignition of the working mixture.

Malfunctions of the ignition coil can be noticed by the following symptoms. First of all, if it has a high temperature when the engine is off. The cause of this symptom may be turning the key to the active position for a fairly long period with the engine turned off. The next alarming sign is a short circuit, when the engine does not start at all, resulting in a smell of burnt insulation and strong heating of the lock, as well as the starter. In this case, repair and replacement of the ignition coil is necessary.

Unstable operation of the car also helps to understand that diagnostics are urgently needed. It begins to twitch when driving at speeds exceeding 60 km/h, and during a long stop, for example in a traffic jam, the spark may disappear altogether, then the ignition coil should be checked as soon as possible.

Features of choice

On the VAZ 2106 you can find the following types of ignition coils:

- B117: Transformation coefficient – 78.5, Design features – R, M

- 3705: Transformation ratio – 82, Design features – R, M

- 3705: Transformation coefficient – 80, Design features – Z, S.

P – open magnetic circuit; Z – closed magnetic circuit; M – oil-filled coil; C – dry coil; E – shielded coil; DR - the coil has additional resistance

The design of classic VAZ cars does not place excessive demands on the ignition coil. The coil must meet certain parameters and produce the required voltage.

Photo: New ignition coil for VAZ 2106 in packaging

On the VAZ 2106 you can install coils from the following manufacturers:

- ERA is a domestic manufacturer of components for various cars, offering ignition coils for the VAZ 2106 starting at RUB 1,350. Such coils have a very limited service life.

- MZATE-2 offers reliable ignition coils at prices starting from 600 rubles. In addition to the low price, the products are easy to install and are available in almost every car dealership.

- Bosch is a trusted manufacturer of auto parts. Despite the high price (from 2,700 rubles), German-made coils are extremely reliable and have the longest service life.

- SOATE is another domestic manufacturer that sells ignition coils for the VAZ 2106 at prices starting from 700 rubles.

Usually, VAZ 2106 owners, when purchasing, look for powerful coils at a low price, since the power characteristics of the engine directly depend on the number of turns of the winding.

What causes ignition coil malfunctions?

It is a coil pulse transformer consisting of two windings: the primary winding, which has a small number of turns of thick wire, and the secondary, consisting of many turns of relatively thin wire. In addition, each bobbin has an additional ignition coil resistance. Therefore, many malfunctions can occur simply due to a break in one of the coil windings , and a short circuit in the bobbin windings is also quite possible.

If the key is turned to the active state, but while the engine is not running, this leads to excessive heating of the insulation of the bobbin windings, and, as a result, it dries out and crumbles. Thus, the wires remain exposed, which contributes to the occurrence of a short circuit. In addition, the silicone from which the ignition coil tips are made is also subject to aging, which contributes to the occurrence of leaks and the engine “troits”.

Reasons for failure

Like all electrical and electronic units, the reel has a certain trouble-free operation life. The average service life of ignition coils is approximately seven to ten years of operation or 150,000 - 200,000 thousand mileage.

There are many reasons for ignition coil failure. The most common is an internal short circuit. When the coil overheats, for example due to increased temperature conditions of the engine (lean mixture, faulty cooling system), the insulation is damaged. The use of worn-out spark plugs, in which an internal gap has arisen due to wear of the conductive glass sealant, also leads to overheating of the coil. In addition, reverse gases and breakdown of the insulator have a detrimental effect on the condition of the rubber tip of the ignition coil.

The photo shows a faulty ignition coil of a VAZ 2106

Let's look at the most common reasons for the failure of the VAZ 2106 ignition coil:

- Natural wear and tear. The device is operated in extreme conditions with large differences in temperature, humidity, and the possibility of ingress of moisture, dirt, and foreign liquids. In this case, large currents flow through the primary winding, and a high-voltage pulse is formed in the secondary winding.

- Electrical breakdown. Let's figure out why the ignition coil breaks. Over time, as a result of high temperature changes, the dielectric insulation cracks, and salty moisture, which is a conductor, can enter microcracks. For voltages of more than 15,000 volts generated in the secondary winding, even pure undistilled water acts as a conductor.

- Overheat. Some vehicles have ignition coils installed directly at or near the top of the engine. If there is no air access to their structure for natural ventilation (this is possible when installing additional equipment), the device may overheat and fail.

- Mechanical load. The coil mount must be standard. Some car enthusiasts neglect these requirements by “hanging” it on homemade structures.

- Wear of spark plugs and high-voltage conductors. Despite the fact that the circuit has a limiting resistance, wear of spark plugs and high-voltage conductors can cause electrical breakdown in them. Then the load current increases and the bobbin may overheat.

- Generator voltage regulator relay malfunction. Sometimes it leads to an increase in the voltage of the vehicle’s on-board network and failure of the electronic amplifier (switch).

- Malfunction of the contact group of the lock, electronic switch. If, during parking, +12 Volts are constantly supplied to the coil in the event of an abnormal closure of the lock contact group, the device may overheat and fail. The same situation is possible if the switch is faulty.

First signs of trouble

The main signs of ignition coil failure are lack of ignition. If it is a single device with a distributor, then in all cylinders; if it is a double or single device, then in those served by it. The absence of a spark is not necessarily a 100% sign of a faulty coil. Perhaps the limiting resistor has burned out, the spark plug is faulty, the high-voltage wire has broken, or there is a malfunction in the ignition system. A comprehensive fault diagnosis is required.

Visual signs that the ignition coil is not working:

- the presence of “breakdown tracks”, oxides on the coil;

- change in dielectric color;

- burning of contacts and connectors;

- traces of overheating on the body;

- increased pollution.

Let's talk in more detail about these and other points indicating that the ignition coil of the VAZ 2106 is in a faulty state.

Presence of interruption tracks in the ignition coil

Let's figure out why the ignition coil breaks. Firstly, over time, as a result of high temperature changes, the dielectric insulation cracks, and salty moisture, which is a conductor, can enter microcracks.

The photo shows a common malfunction - breakdown of the ignition coil of a VAZ 2106

For voltages of more than 15,000 volts generated in the secondary winding, even pure undistilled water acts as a conductor. Secondly, during operation, the physical properties of the dielectric and rubber insulation of the tips of high-voltage wires, especially those of dubious production, change.

High-voltage breakdown can be caused by the installation of non-standard high-voltage wires in which there is no distributed current-limiting resistance. A breakdown can occur as a result of severe contamination or waterlogging. Even in the event of a single breakdown, irreversible changes occur in the structure; further operation is not recommended.

Burning of contacts and connectors of the ignition coil of a VAZ 2106

The big disadvantage, the disadvantage of CG, is the sparking process, which cannot be eliminated in any way. However, significant minimization of sparking can be achieved by connecting a capacitor. Yes, and be sure to set the correct gap.

Experts say that if you increase the gap above standard values, you can get rid of sparking. In other words, if the distributor contacts are burning, increasing the gap will be the optimal measure to eliminate the problem. However, this also has its drawbacks. In particular, the angle decreases, which leads to a decrease in the additional current voltage.

Traces of overheating on the ignition coil body of a VAZ 2106

Another sign by which you can determine the malfunction of the ignition coil of the VAZ Six is the presence of traces of overheating on the short circuit housing. The photo shows what they look like:

This is what signs of overheating look like on the ignition coil housing

How to check the ignition coil?

Short circuit testing is performed in the following stages:

- visual inspection;

- checking for voltage;

- measuring resistance using an ohmmeter;

- checking for spark.

A visual inspection reveals mechanical damage to the surface, the presence of oil stains, mud deposits, and the reliability of connections and electrical contacts. To check the voltage supply to the unit, you need to turn on the ignition and measure the voltage between terminal “B” and ground with a voltmeter. It should be 12 V. If there is no voltage, then the problem is in the ignition switch.

Diagnostics and testing of the ignition coil of a VAZ 2106

How to check the ignition coil of a VAZ-2106 car at home? The best way is to use a multimeter or ohmmeter. Winding testing using this equipment is carried out as follows:

- to make sure that the primary winding is in good condition, connect an ohmmeter to its side terminals and look at the resistance readings. For a fully working ignition coil, it should be at least 3-4 ohms. Otherwise, the device will need to be repaired or replaced;

- to check the secondary winding, one of the ohmmeter outputs is connected to the same side one, and the second one is connected to the central terminal on the pulse transformer itself. The normal value is somewhere in the range of 7.5-9.2 ohms. To get accurate data, it is better to consult your vehicle's owner's manual. If there are any deviations, the ignition coil must be replaced.

Before performing the checks described above, you must disconnect the negative terminal from the battery. This will help eliminate the risk of short circuit

Diagnostics and testing of the ignition coil of a VAZ 2106

Checking for spark

Checking the spark is possible using several methods: to ground, using a multimeter, or a special tester on a piezoelectric element. The first method is the simplest. The body of the unscrewed spark plug is brought to the metal (usually the engine cylinder block), after which the engine is cranked by the starter and the presence of a spark is analyzed.

Please note that this verification method cannot be used when diagnosing fuel-injected vehicles. The fact is that a car with an injector has an ECU and other electrical equipment that is quite sensitive and can be damaged.

The photo shows checking the spark plug on a VAZ 2106

The second method allows you to better assess the condition of the spark plug, identify breakdown, etc. The use of a special tester is a method of checking the spark on injector cars, reminiscent in its principle of checking by analyzing the spark breakdown to ground (the first method). In this case, the risk of burning the control unit is minimized. Now let's talk about how to check the spark on a fuel-injected engine.

Checking the secondary winding

The secondary winding of the coil is checked in almost the same way, only one of the ohmmeter wires needs to be connected to the side terminal, and the second to the central one on the coil. Everything is demonstrated below:

Here the resistance data is completely different and during normal operation it should be in the region of 7.4-9.2 kOhm. Judging by the readings of the device, my case shows and confirms again that everything is fine with the coil.

The photo shows a check of the secondary winding of the ignition coil of a VAZ 2106

To avoid any misunderstandings, I want to warn you that the figures given in this article apply to a greater extent to VAZ 2106 type B117-A ignition coils, although on many models the parameters are identical. But still, for your modification, it is better to look at the data in specialized sources.

If, as a result of the check, it turns out that the element is faulty, then it is necessary to replace it with a new one.

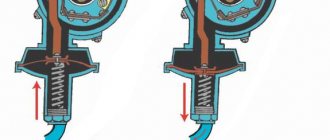

Checking the distributor

If the coil is working properly, but the engine does not start, the problem must be looked for in the distributor; to do this, you need to remove its top cover by unfastening 2 latches. The inside of the cover must be carefully inspected; all contacts and the ember must be intact. You need to remove the slider from the distributor and also inspect it from the inside; it happens that it cracks and a spark hits ground.

Photo: Checking the VAZ 2106 distributor

Next, you need to carefully inspect the breaker contacts and, if necessary, clean them with fine sandpaper. You also need to inspect the capacitor, which is usually screwed to the distributor; without it, there will be no spark either. To test the capacitor, you need to apply power to it from the battery, and then connect a light bulb or short-circuit the contacts with a metal object. If the light does not blink and there is no spark when it closes, the capacitor is faulty. It can be replaced by any other, but not polar.

In conclusion, I would like to note the fact that you should never check the spark for the gap from the wire to the engine; in this case, the ignition coil quickly fails and the VAZ 2106 will no longer be able to start without replacing it. All this happens because the coil is punctured from the inside, and all because of the very large gap for breakdown.

Coil arrangement diagram

Its catalog number

When switch 5 is on and the engine is not running, transistor VT1 K. In coils with a closed magnetic circuit, the magnetic flux passes most of the way through the steel magnetic core and only a small part of the way through air gaps of the order of a few tenths of a millimeter each.

Some coils continue to operate even if the secondary winding is broken, and during throttling, misfires are observed. Additional resistor The arc voltage remains almost constant until the energy reserve is less than a certain minimum value. Particular attention should be paid to the choice of product, since this will determine how well the engine and ignition system will work. The TB is closed because its base and emitter have the same potential.

Transistor switch The transistor switch is designed to switch the opening and closing of the primary circuit of the ignition system in accordance with the signals received from the distributor sensor. Figure To install the ignition, marks 20 are applied to the stator and rotor, which are aligned when the piston of the first cylinder of the engine is positioned at TDC of the end of the compression stroke.

How sparking is implemented in practice: After turning on the ignition, a voltage of 12 V is supplied to the primary winding from the battery. The principle of operation is the same as that of a two-terminal one, only similar ones are used on 6-cylinder engines. If you don’t know which wires to connect to which connector later, it’s better to immediately remember or mark them somehow, so that later during installation you can connect them correctly. The single terminal design is not the only one possible; there are other options. We put the tester in resistance measurement mode and measure it at the high-voltage terminals of the module cover.

The general design of the ignition coil has three output terminals. Therefore, many ignition coils are made with an external primary winding. To check the module in the second way, we only need a multimeter, then follow the step-by-step instructions: Check the power supply and the presence of pulses supplied from the ECU. As a rule, the problem lies in the ignition system, or more precisely, in the failure of some element of this system.

How to check the ignition coil of a VAZ If the ignition coil is faulty, the engine will not start. Therefore, there was no need for an ignition module. Correct connection of the ignition coil and more.

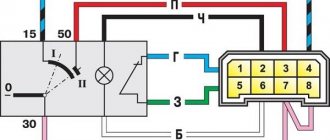

A few words about the BZS (Contactless ignition system) VAZ 2106

The coil operating as part of a contactless circuit differs in the number of turns of the primary and secondary windings. Simply put, it is more powerful than the old version, since it is designed to create pulses of 22-24 thousand volts. The predecessor supplied a maximum of 18 kV to the spark plug electrodes.

The cable with connectors is used for reliable connection of the terminals of the ignition distributor and the switch. The structure of these two elements should be considered separately.

In terms of reliability, the BSZ is significantly superior to the outdated contact ignition of the “six”; problems arise much less frequently and are easier to diagnose.

All elements of the system are connected to each other and to the engine as follows:

- The distributor shaft rotates from the motor drive gear;

- The Hall sensor installed inside the distributor is connected to the switch;

- the coil is connected by a low voltage line to the controller, a high voltage line to the central electrode of the distributor cover;

- high-voltage wires from the spark plugs are connected to the side contacts of the main distributor cap.

The threaded clamp “K” on the coil is connected to the positive contact of the ignition switch relay and terminal “4” of the switch. The second clamp marked “K” is connected to contact “1” of the controller, and the tachometer wire also comes here. Terminals “3”, “5” and “6” of the switch are used to connect a Hall sensor.

One of the effective options is to replace the standard ignition system with a non-contact ignition system (abbreviated as BSZ), where electronics are in charge of sparking

Vehicle ignition system components

Previously, a distributor of the R-125B brand was installed on the car. This unit was mounted on the machine together with a carburetor marked 2103. The distributor had a special mechanical corrector in its design, and there was no vacuum regulator. The VAZ 2106 is equipped with spark plugs of type A17DV or plugs that have similar technical characteristics. The design of the automotive system uses a VK347 type lock, equipped with an anti-theft device.

The car uses a B117-A type ignition coil, which has an open magnetic circuit and is an oil-filled and sealed system. The VAZ 2106 has a contact ignition, but it is worth noting that sometimes a contactless version is also available. The contact system is considered simpler in its design.

VAZ contact ignition requires regular maintenance and monitoring of the condition of the contacts. This type of ignition is considered to be a classic version of the system. The design of the VAZ 2106 spark plugs is non-separable and has a ceramic insulator. The distributor is designed to interrupt low-voltage currents in the primary winding and distribute high-voltage pulses across the spark plugs.

The distributor breaker consists of a cam with four protrusions and a stand on which contacts are located that open during rotation. At the upper end of the cam bushing, a support strip of the advance regulator with weights is soldered. A vacuum regulator is attached to the side of the distributor. The design of the distributor provides for the installation of an interference suppression resistor.

The operation of the contactless system is based on the use of an electrical impulse distribution sensor. It operates using the Hall effect. The sensor consists of a semiconductor wafer, a special chip and a magnet.

How to replace the ignition coil on a VAZ 2106 with your own hands (photo report)

The ignition coil on a VAZ 2106 car cannot be repaired and, if it fails, must be replaced. Before making a replacement, it is worth checking its functionality. To do this you will need a tester, also prepare a standard set of tools

To replace the ignition coil on a VAZ 2106 car, you will need keys “8” and “10”.

- Unscrew the ignition coil output nut “1” (“OE”), remove the spring washer and wire ends.

- Unscrew the ignition coil output nut “1” (“OE”), remove the spring washer and wire ends.

- Unscrew the terminal nut “16” (“+B”) of the ignition coil, remove the spring washer and the wire tip.

- The B117-A ignition coil is installed in the left front corner of the engine compartment and secured to the mudguard with two nuts.

- Unscrew the two nuts securing the coil, remove the wire ends and remove the ignition coil.

- Check winding and insulation resistance. The resistance of the primary winding at 20 °C should be 3.07-3.5 Ohms, the secondary winding - 5400-9200 Ohms. The insulation resistance to ground must be at least 50 MOhm. If the readings do not correspond to those shown, replace the ignition coil.

- Install a new ignition coil on a VAZ 2106 car in the reverse order of removal.

How to connect a coil

The ignition coil, in principle, cannot be disassembled, for this reason it cannot be repaired. Thus, if it is possible to find out that it is the short circuit that has failed, it is simply replaced with a working unit.

To complete this task, prepare:

• pliers; • or 8 and 10 mm spanners.

The procedure is as follows:

• first of all, disconnect the battery - the coil is a fairly powerful transformer, so the likelihood of getting an electric shock is quite high; • then remove the high-voltage wire from the corresponding connector; • unscrew the nuts from both terminals of the winding terminals - “K” (or OE) and “B”; • screw together the fasteners holding the unit on the machine body; • dismantle the short circuit and put a working one in its place; • We carry out the assembly in the reverse order.